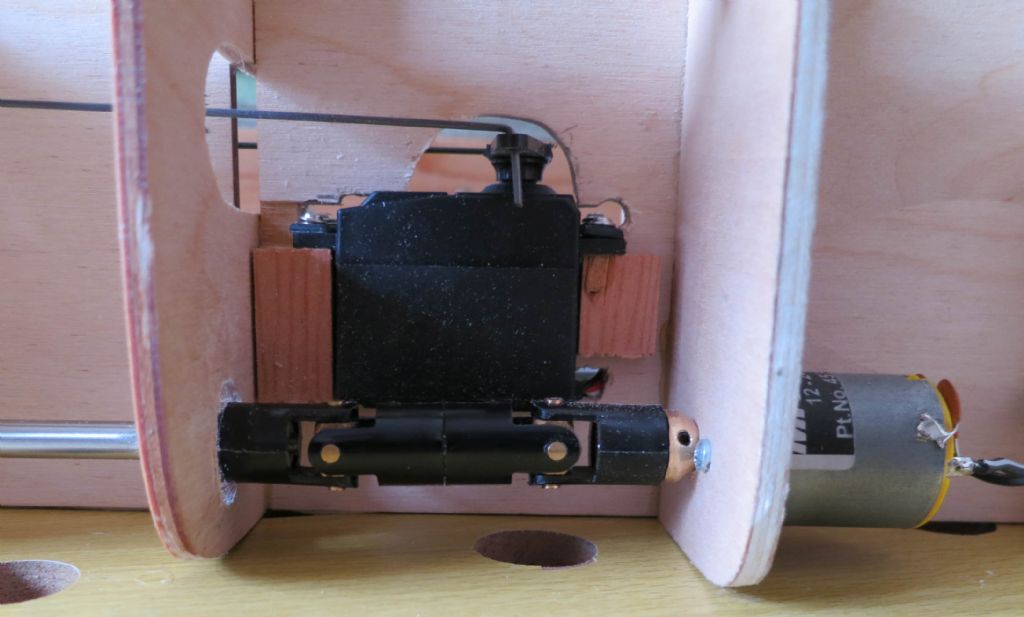

Prop shafts came out easily without damage, thanks to a tip I found on another web site – a hot soldering iron degrades the epoxy allowing, in this case, the shafts to slide out. Keith – thanks for the in-phase suggestion. I will make sure I do this although, if I get it right, the drive should be virtually straight.

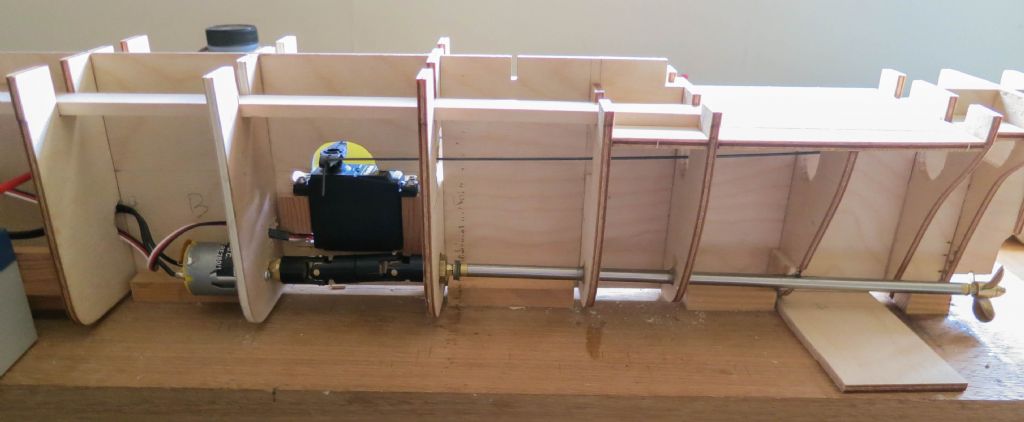

I think that the conversion required a double coupling for dimensional reasons.. The prop shaft tube is 9" long and the second coupling adds 1.5". if a 10.5" shaft had been available, I could have done without the second coupling. However, 10" or 11" were the only options. It is a pity, however, because the junction between the coupling and the prop shaft will be inaccessible. The lift-off section of the superstructure does not go back quite far enough, at least according to the plans.

Jeremy