Hi boaters,

Inspired to post after reading Harry’s Sea Rover post.

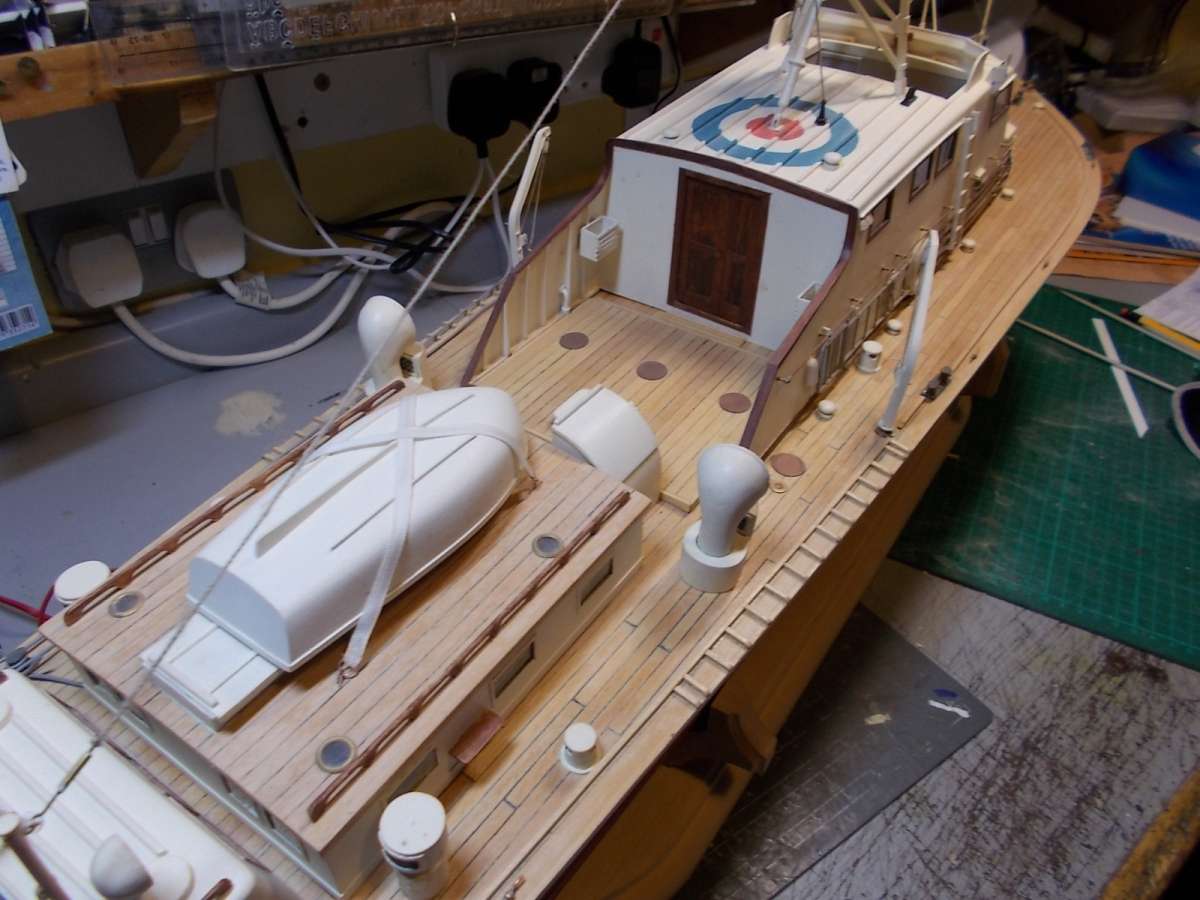

I’ve recently acquired an old Fireboat 1:16 scale that appears to have been built from a kit. Out of interest I wondered if anyone can identify which kit it is. Here’s a few photos.

This on back of cabin, can anyone identify it?

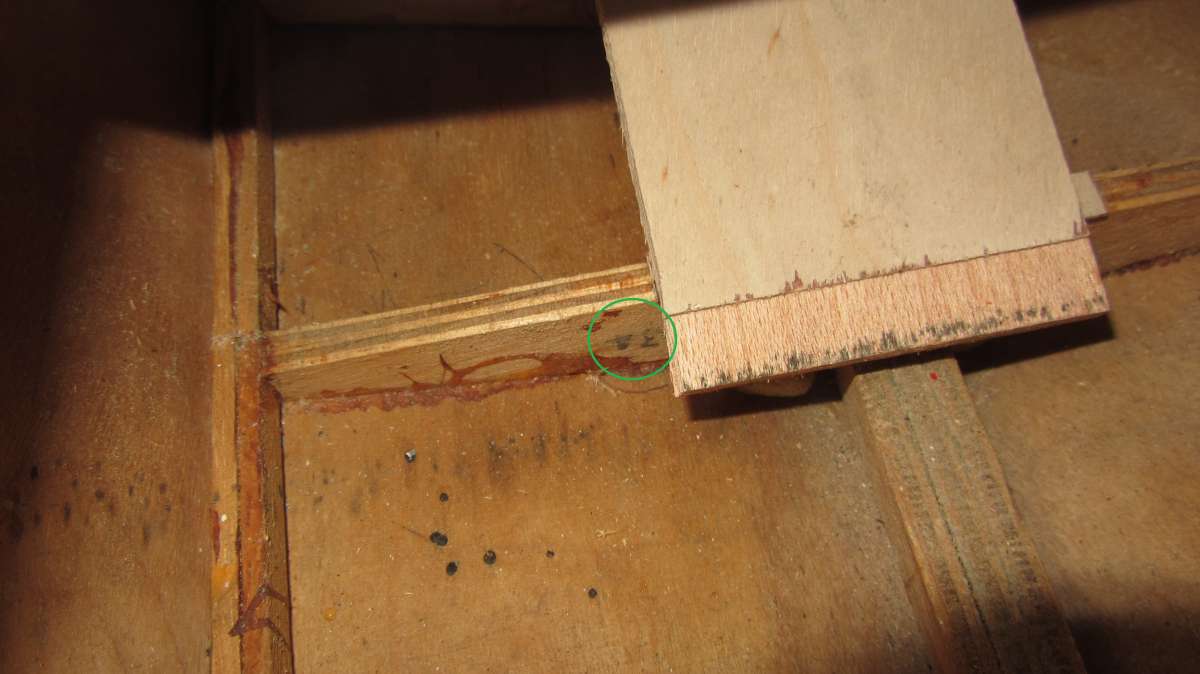

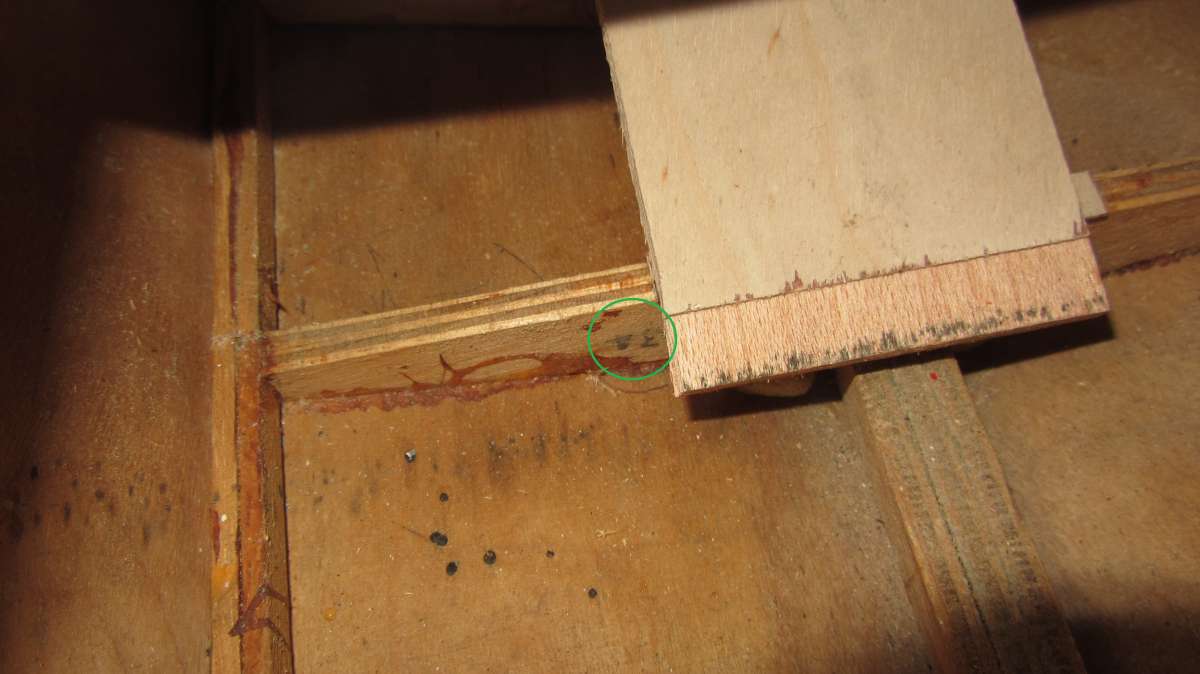

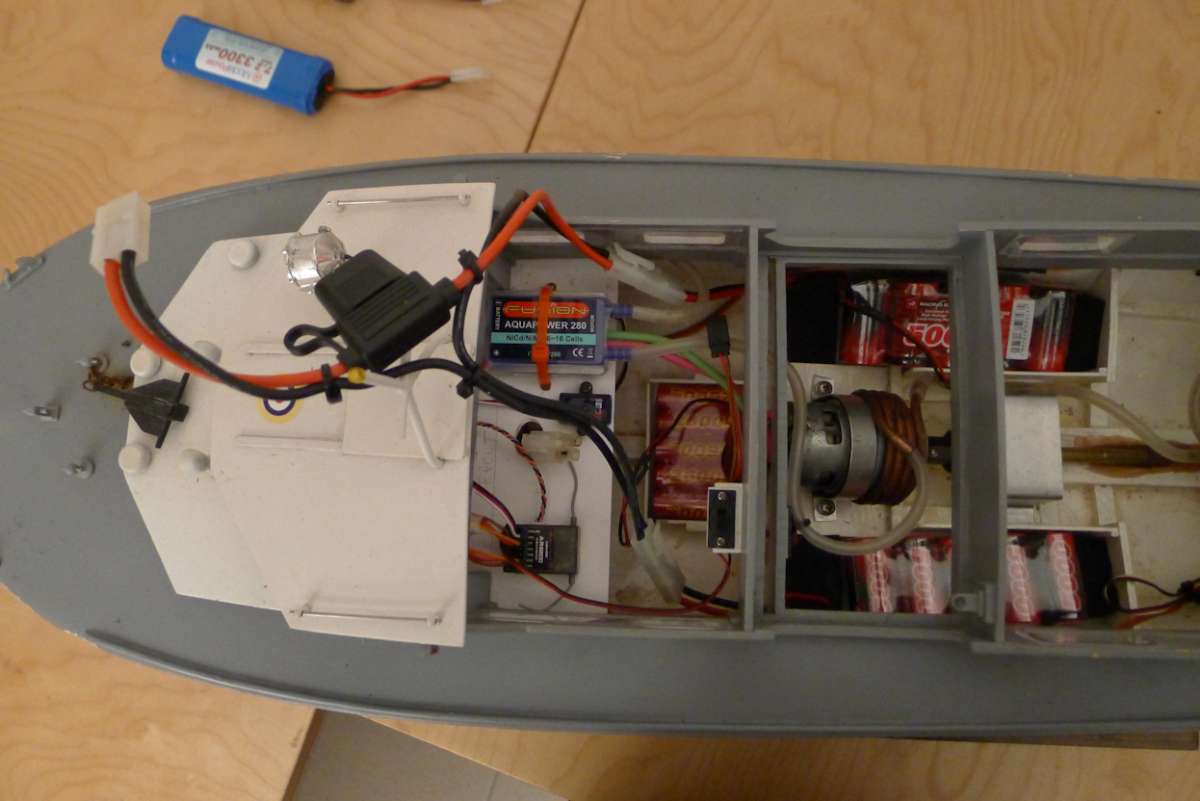

B5 stamped on bulkhead near stern (location shown on interior photo)

3A stamped on part near motor mount

Propshaft with aluminium tube and rudder that were fitted when I received it. Tube bearings badly worn. The stringy thing and pins were around the edge of the deck, presumably an addition by a previous owner.

Side view

Interior view

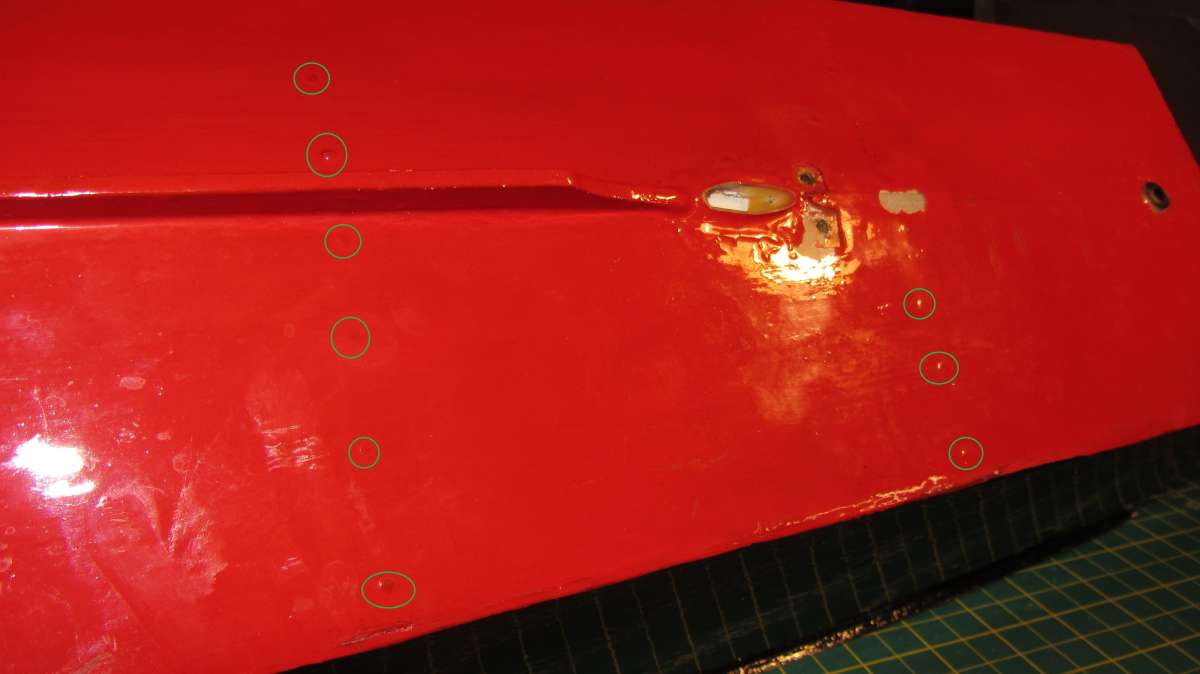

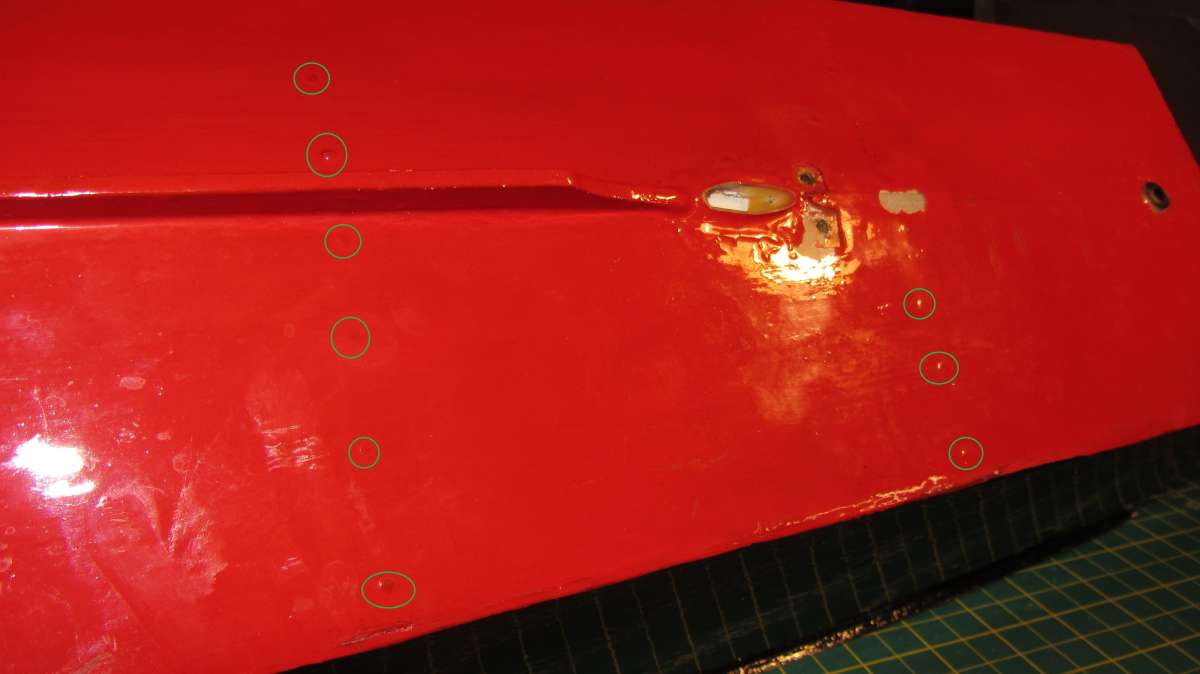

Entire boat is nailed and glued together. They don’t show up well in my photo so have marked some of the more obvious ones.

The rear deck was much too high as rudder servo mount was up above the keel – I’ve already changed it’s location in the photo so the rear deck can be lowered to a more realistic level.

I did install a motor and give it a brief test run with a light(ish) LiPo velcroed to the existing battery just behind the cabin but it was very unstable on the water. Maybe needs weight further back or additional ballast?

Any info gratefully received.

Dave.

John W E.

John W E.

hi there,

hi there,![001 [800x600]](https://www.modelboats.co.uk/wp-content/uploads/sites/5/hm_bbpui/125980/rq96n1st4iy7a5dqy05forp1h7ytdd01.jpg)