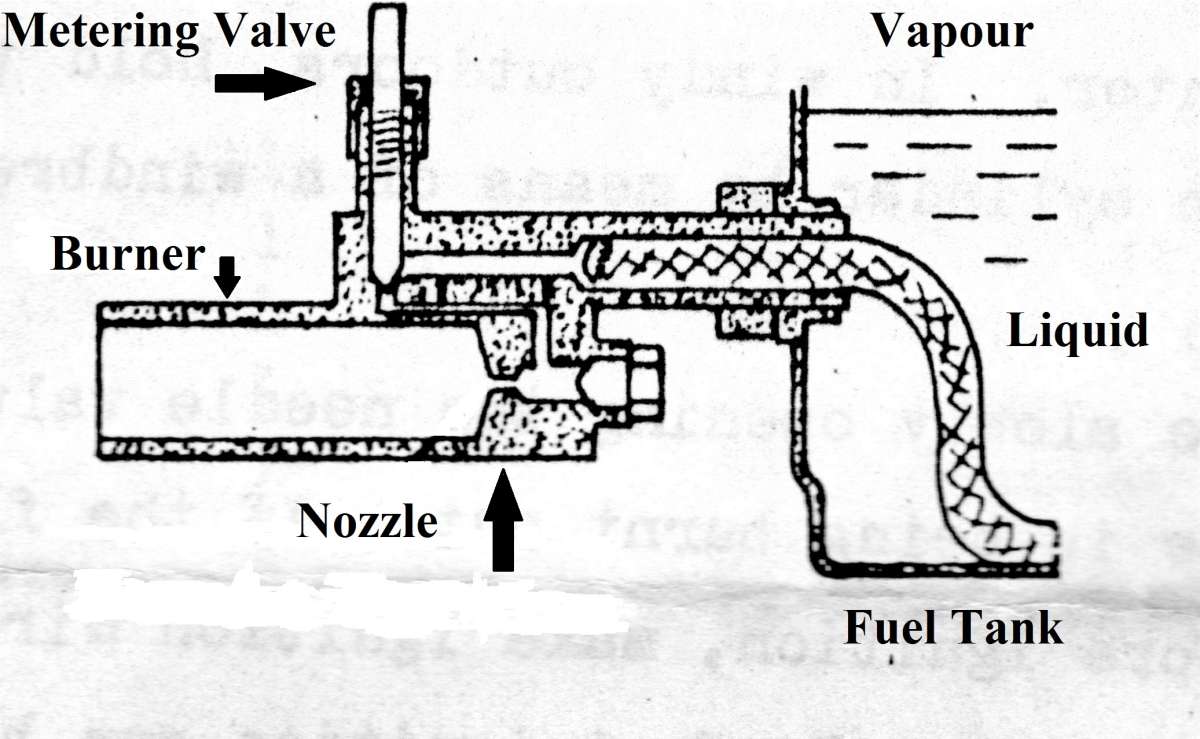

Just a couple of thoughts Ray. While a pressurised liquid burner has some significant advantages over a gas fired one the handling of liquid fuel is one disadvantage. With such a burner inside an enclosed hull we have to consider a number of scenarios. First up is initial lighting, which is a big difference to gas, which is simply put a light to the top of the funnel and turn on the gas. With liquid fuel you have to go through the process of warming the burner and hence tank to create some pressure, when you can open the needle valve to ignite the burner. You may have to use an alternative flame if the tray of meths has gone out. If you want to do this outside the model you then have to consider whether you want to make the burner and fuel tank unit individually removeable or whether you want to remove the entire plant on its base. Removing the entire plant is a bit of a faff as you are going to have to drop the entire unit back in the boat, with the burner lit and a hot boiler. Then you will have to reconnect the shaft and the engine control servo, and, in your case the water pipework as well. Probably too difficult to consider.

It would obviously be significantly easier to remove only the burner to light it. If you do that you will then have to manhandle a lit burner and fuel tank unit back into the model with a naked flame emitting from one end. The chances of burning something, such as deck details, rigging, coaming, internals such as wiring, electronics etc. in the process could be significant.

I have only ever come across gas burners in enclosed models because they are so much easier to operate, despite the gas cooling challenges. I have no doubt that there will be some who have tried to operate a pressurised liquid burner in an enclosed model, possibly with some success, but I have no doubt that the risks involved are considerably higher.

Lets now consider that we have used the liquid fuel and it’s time for a top up. The burner and fuel tank unit is now hot so removing it is going to be even more of a challenge. Then you will fill it and ignite it before going through the process of trying to put it back in the model. Alternatively you might consider filling the tank in place, but a spill would be too high a risk when doing that and then you would have liquid fuel inside the model that would have to be dealt with before trying to re-ignite the burner. Filling outside the model if definitely preferable.

I’m not trying to put anyone off here, but I am trying to highlight the challenges with such an installation that have to be considered before embarking on a build that could produce a model that is difficult to operate and manage. This will only lead to disappointment and frustration and, inevitably the model will not get taken out much. One of the biggest aspects that is so frequently overlooked by steam boat builders is the ease of operation. This is much more of an issue in an enclosed model and it is much more of an issue with a pressurised liquid burner.

I would encourage anyone contemplating building a steam powered model to think through their operating philosophy, see Boiler Room 156, Sept ’24, and how the design of the model is going to support this. i.e. if the burner and fuel tank assembly is to be removeable how is it going to be held in the model? Is the deck access big enough to allow easy removal of the burner/tank unit and replacement without the risk of burning something. I have always agreed that you have to start with a model that interests you, otherwise there is always the danger of loosing enthusiasm during the build, but when considering steam the model has to be easy, convenient and safe to operate as well. There is no point in building a beautiful model that you are proud of but are reluctant to put it on the water because you are worried about setting fire to it when you put the lit burner in place.

As always just food for thought!

Ray Wood 3.

Ray Wood 3.