TEV Wahine 1/35 Build

TEV Wahine 1/35 Build

- This topic has 410 replies, 3 voices, and was last updated 10 months, 1 week ago by

Ray Wood 3.

Ray Wood 3.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Code of conduct | Forum Help/FAQs

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

-

- Fairey Huntsman 31 1 2 … 5 6

- 14

- 1 week, 1 day ago

- Todays Boating 1 2 … 210 211

- 84

- 2 weeks, 1 day ago

Viewing 25 topics - 1 through 25 (of 25 total)

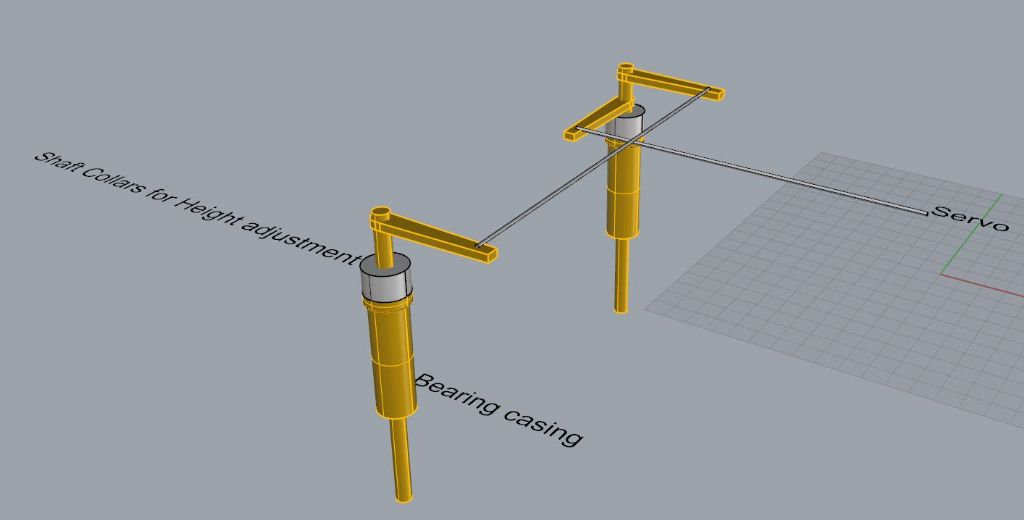

![dscn1159[1].jpg dscn1159[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/690000.jpg)

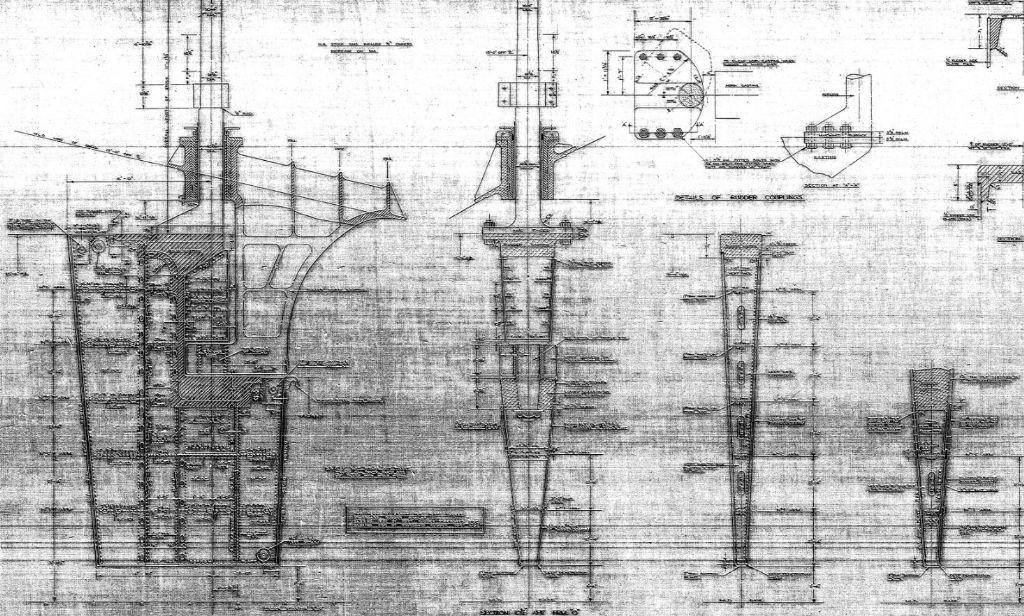

![dscn1160[1].jpg dscn1160[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/690001.jpg)

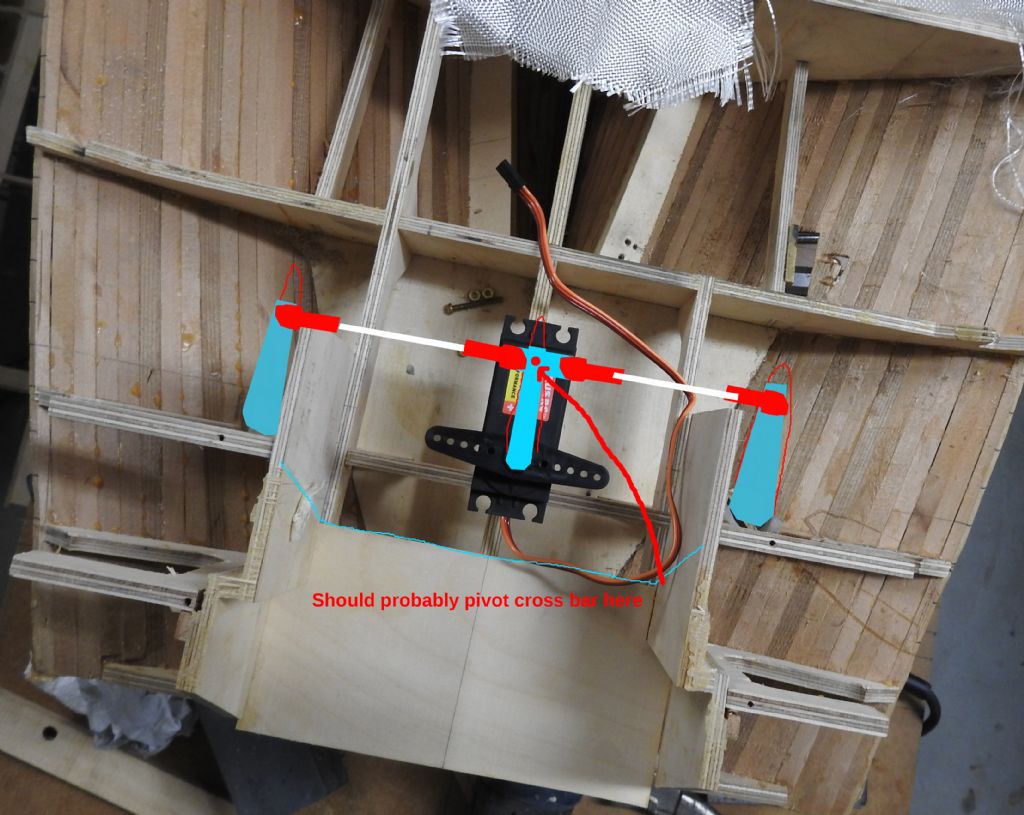

![dscn1162[1].jpg dscn1162[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/690002.jpg)

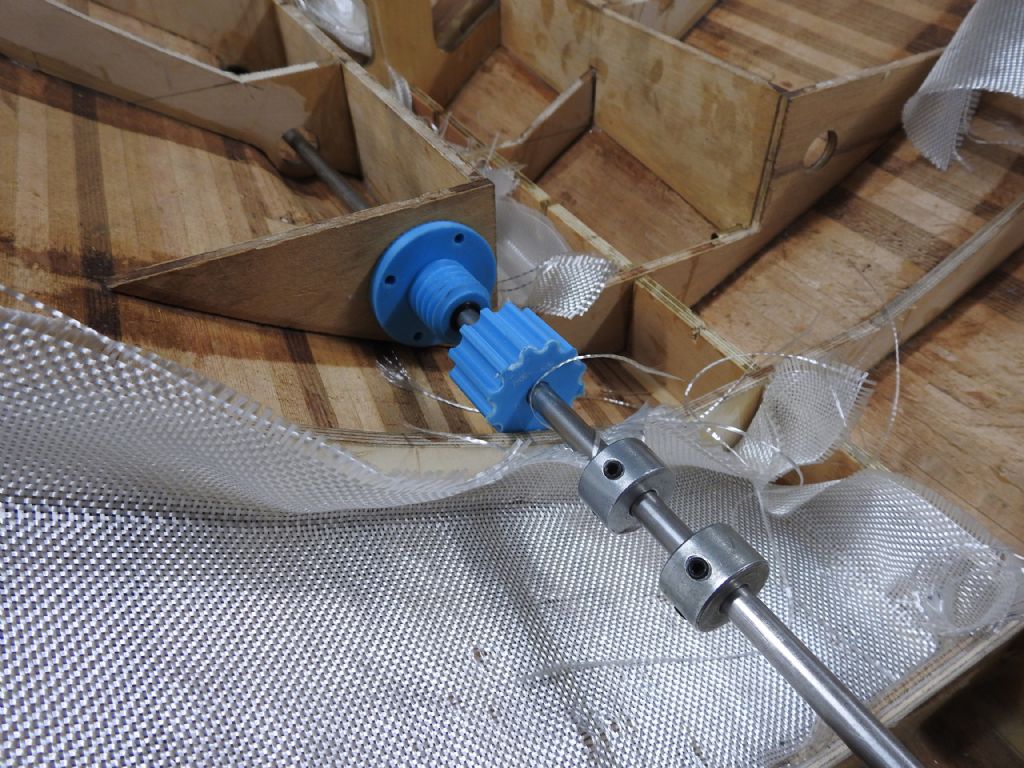

![dscn1163[1].jpg dscn1163[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/690003.jpg)