Thanks Gareth

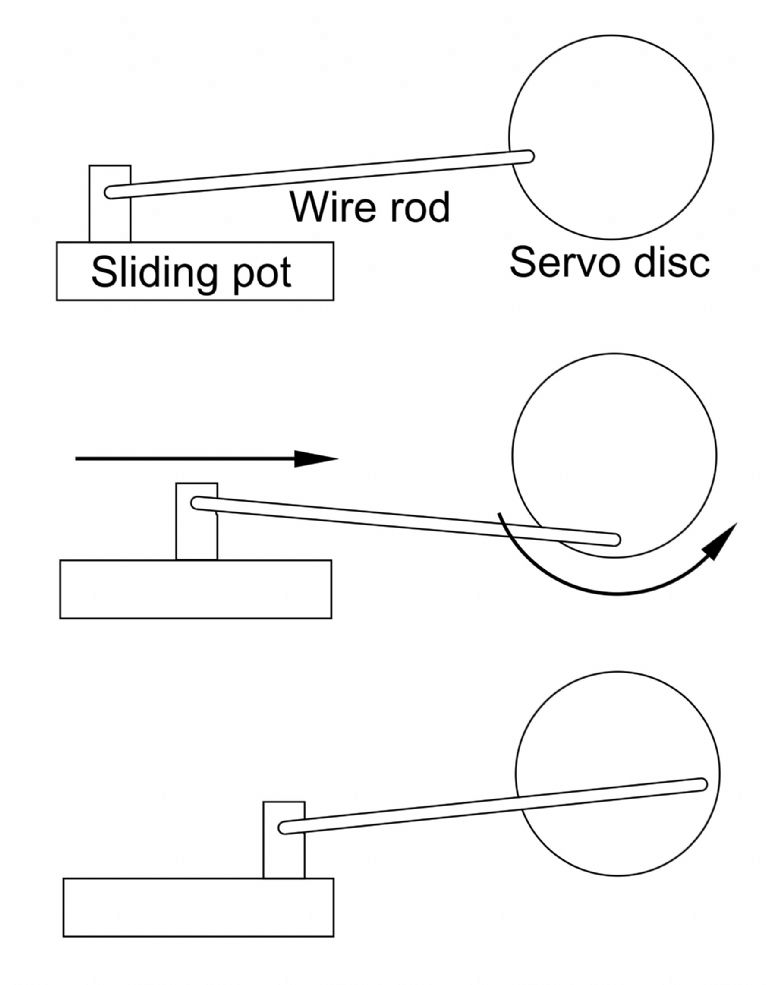

The Servos, well I needed a high power one for the rudders because First of all they are are twin rudders, 35 degrees each way, and With the amount of possible resistance from the props which are 104mm in diameter remember I was unsure how much stress they would be facing, I just got the biggest we can get over her and the price was really good, I pain $79.00 each for them.

6 servos needed for

Rudders x 1

Bow Rudder x1

Motor Throttles x 2

Bow Thruster x 1

Stern Thruster x 1

I will get the remote switches for lights etc so I can have Navigation,Outdoor and internal lights on 3 channels.

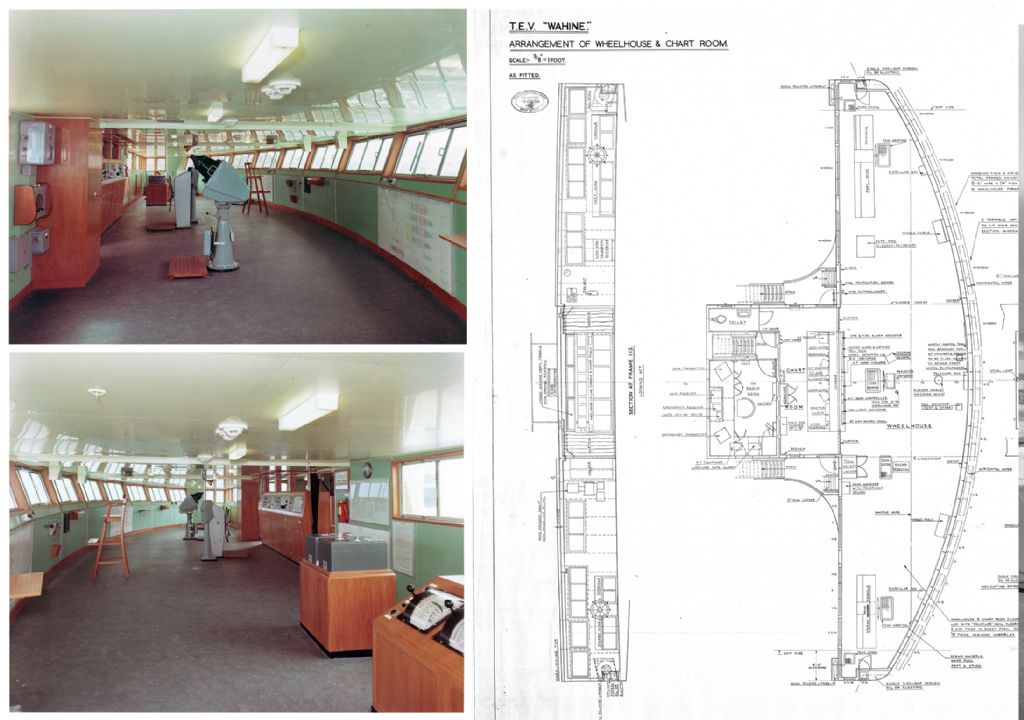

The other stuff like radar will all be just a switch on board ship and run via a tiny motor 5mm in diameter inside rudder pedestal.

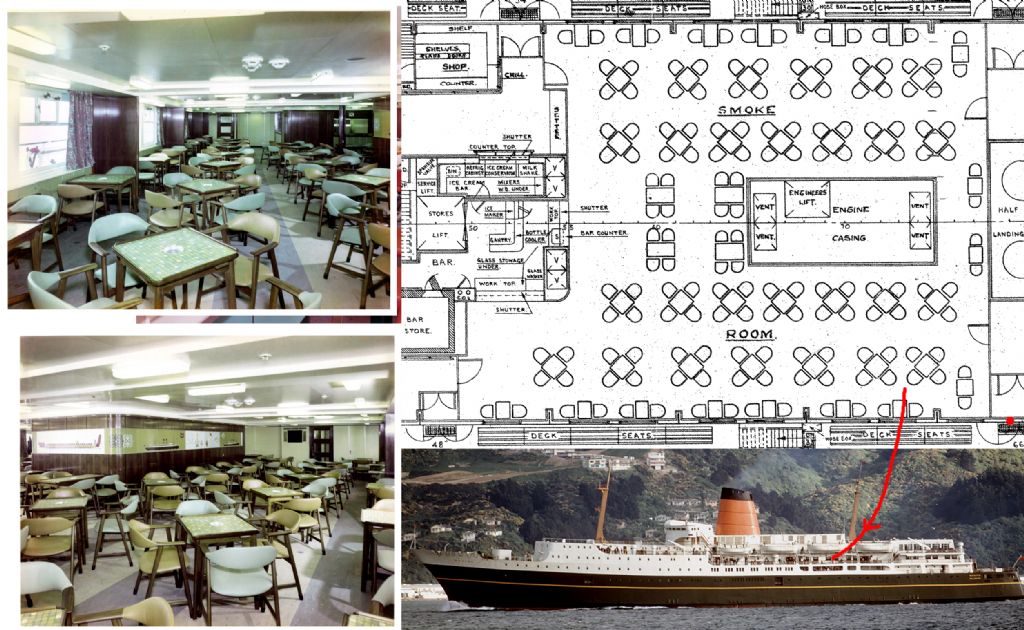

Here is a night shot showing how many darn lights their are in this ship, and why I need so many LEDs, and Flouro tubes.Gareth I think you will feel sorry for me………… 50 approx of those to make for deck heads.

I might from China as i can get 100 for a good price, I normally wouldn't but with needing so many……….

Back on page 10 about 2/3 of the way down some can be seen.

Has anyone used the yellow water clear ones and do they have a subtle yellow light? like below.

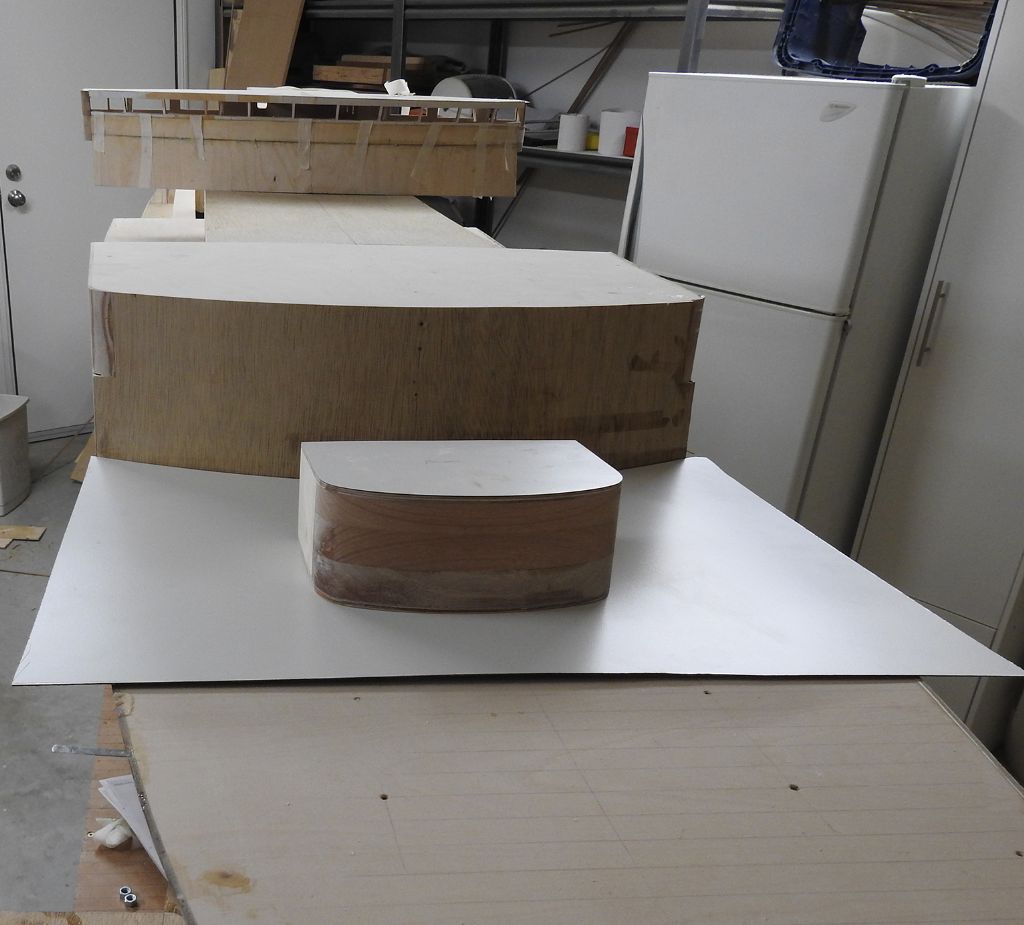

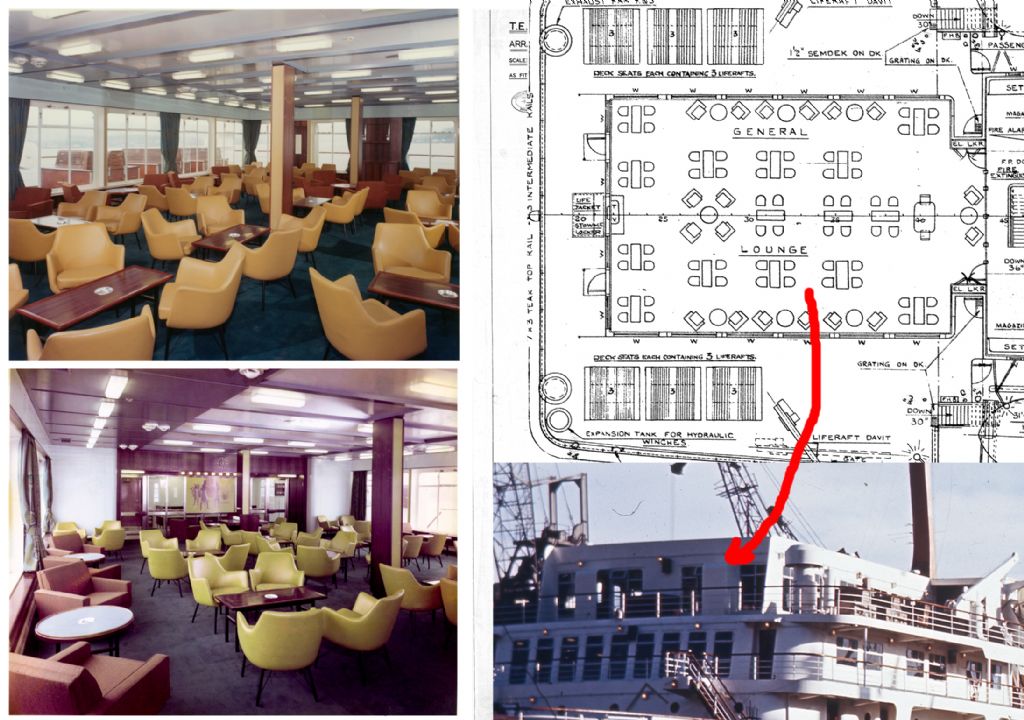

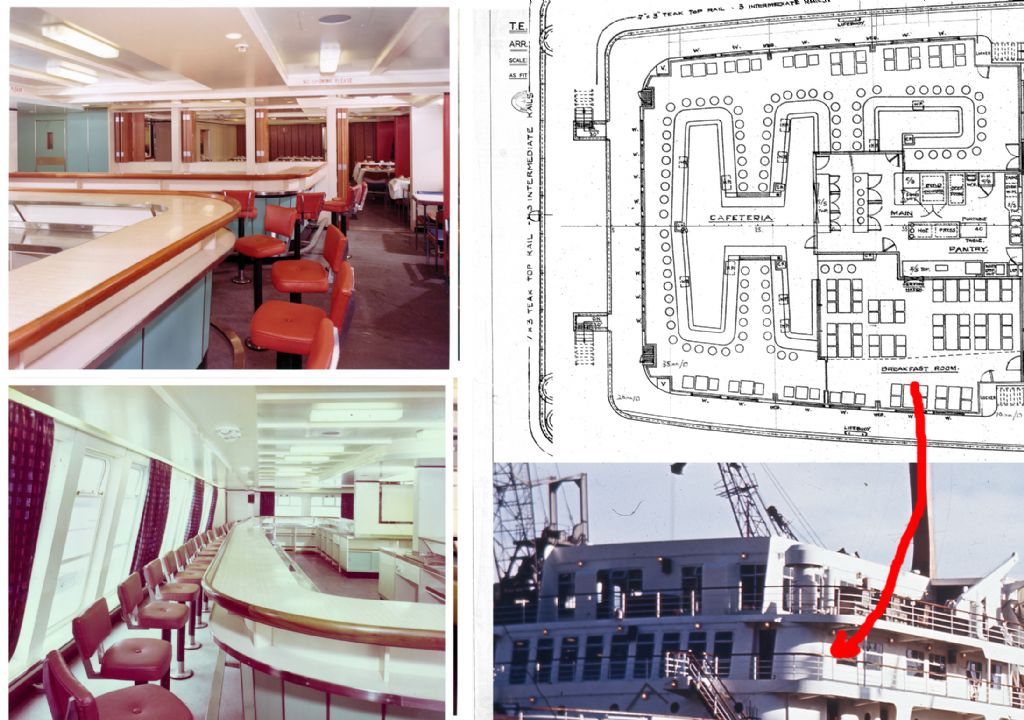

Here is a shot of the the typical Superstructure layout and components, the deck lights can be clearly seen and the conduit that links them as well.

I have hundreds of shots like this of the ship and the wreck.

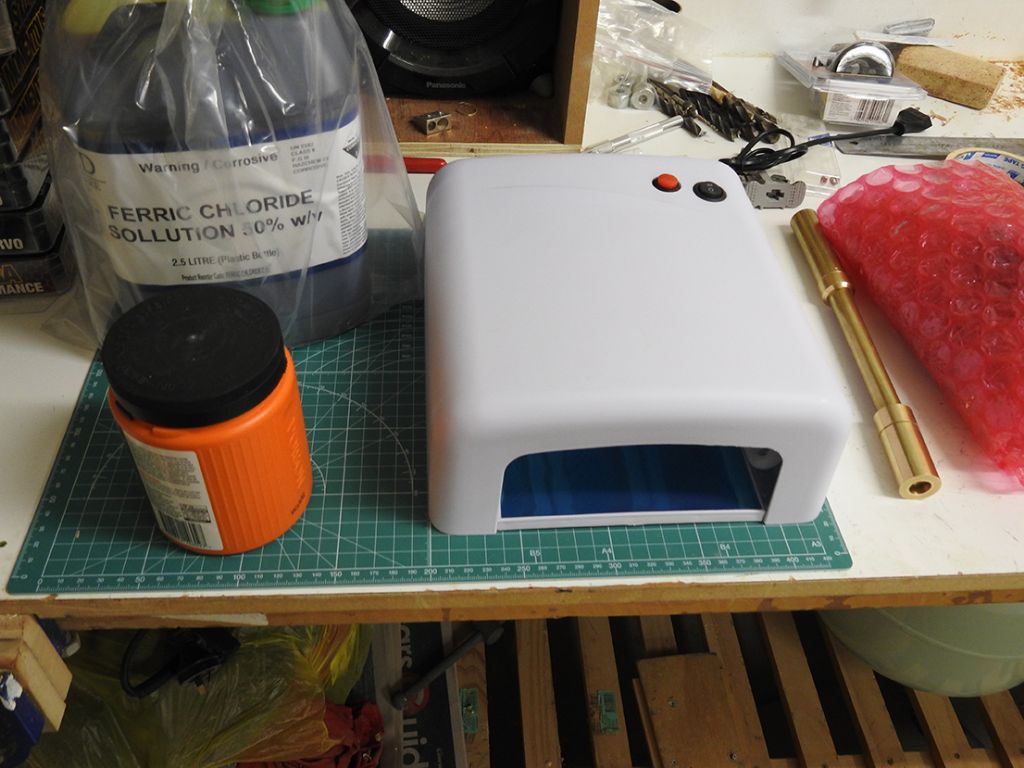

My first thought is to etch the bases and fold them up and solder them, the lens I might have to vacuum form from clear plastic, the lights are 11 x 7 mm.

Ray Wood 3.

Ray Wood 3.