Richard,

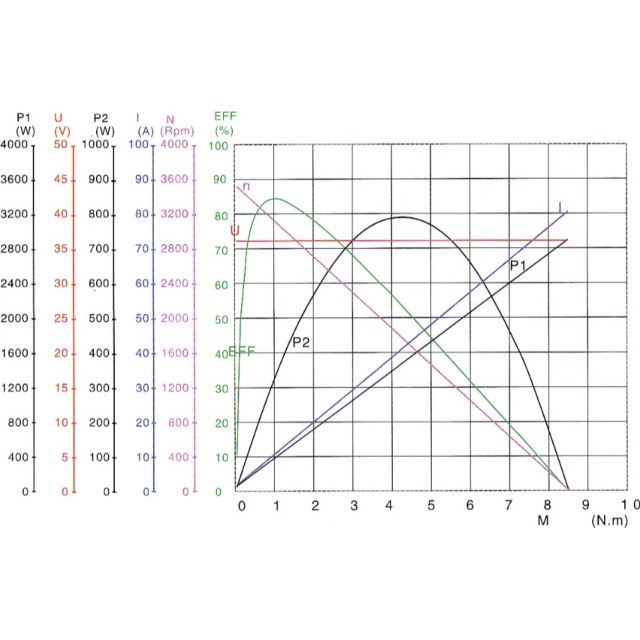

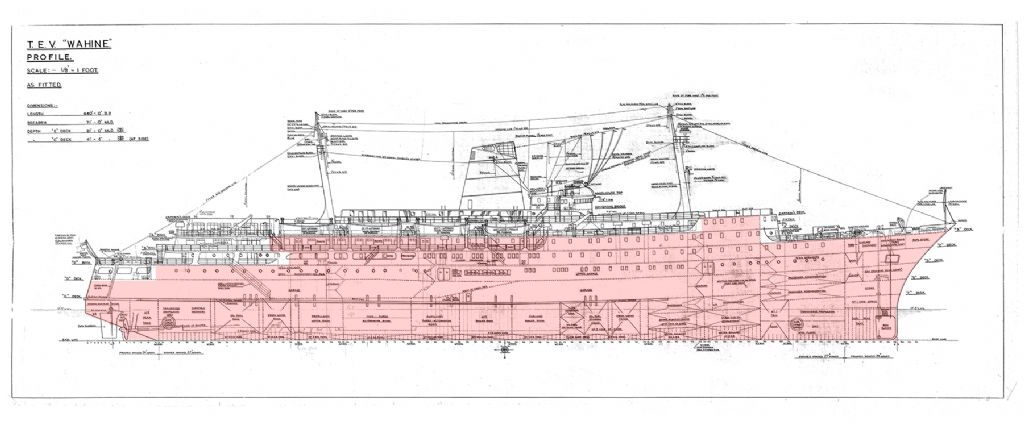

The graph supplied with your motors seems a bit confusing as it seems to have been plotted for 36 volts, rather than the 24 volts that the motor is rated at, and what I believe you plan to run them at. I would guess that for the majority of time when you are cruising around you are unlikely to be drawing more than 10 amps per motor if you are reasonably close to the max efficiency rating. However you will need to go up to maybe 30 amps for occasional short periods. There is a group who have built a large grey model, possibly a type 42 destroyer if I remember rightly. I will try and find a link to their website as I think they sailed it down the length of the Thames a couple of years ago. It would be of comparable weight and size to your model so might give you a clue.

Sealed, gel type lead acid batteries tend to be poor at delivering high currents so I would not really recommend them for your model.

Low maintenance lead acid car batteries (wet/flooded type) would be OK and relatively low risk of spillage. You would probably need to use a couple of 12 volt units wired in series and they might be more manageable to fit in that form. A typical car rating at around 40 amp hours would give you a reasonable sailing time.

NiMh batteries would give you the current capability and are readily available in 12 volt packs. However you can't get much bigger than 5 amp hours so your duration would be limited.

LiPo batteries would give you the current delivery but the high power/capacity units used in model aircraft and the like tend to have a limited number of charge/discharge cycles, maybe only in the range 100 or so, perhaps 200 if you are careful, so they might be expensive in both the short and long term.

Overall I think a couple of 12 volt car batteries wired in series looks the best bet, or two pairs if you want to have a separate power supply for each motor.

PS

I have not found all the info on the 'grey model' but here is a link to their website, there should be some other data available about it on the web if you follow it up, or even get in touch with them.

http://www.ateamboatyard.co.uk/

Gareth

Edited By Gareth Jones on 06/06/2016 08:34:24

Edited By Gareth Jones on 06/06/2016 08:35:28

Ray Wood 3.

Ray Wood 3.

![dscn0846[1].jpg dscn0846[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/656912.jpg)

![dscn0847[1].jpg dscn0847[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/656913.jpg)

![dscn0848[1].jpg dscn0848[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/656914.jpg)

![dscn0849[1].jpg dscn0849[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/656915.jpg)

![dscn0850[1].jpg dscn0850[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/656916.jpg)

![dscn1014[1].jpg dscn1014[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/676288.jpg)