Hi Bob

Am I enjoying it…absolutely..its therapy as I have a very stressful job.

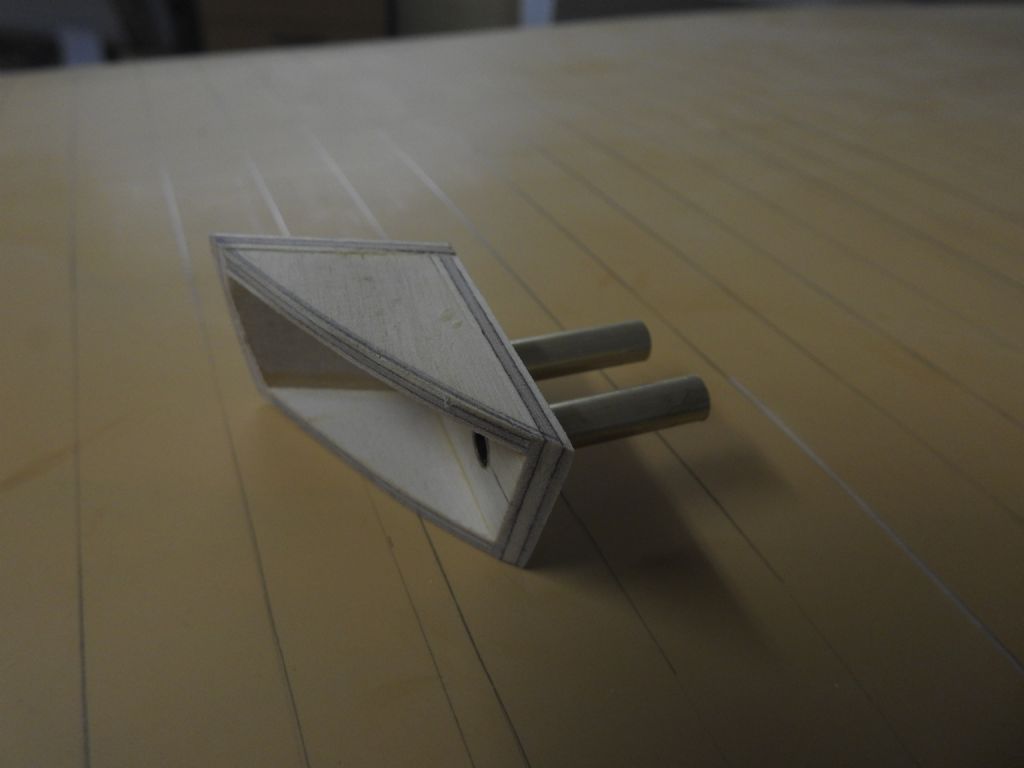

Thanks for the kind words, but I am in need of some guidance on the best material to use, the hull is now about 50 kgs and getting heavy.

That means the hull will be about 60-75 % of its displaced weight of 200 kgs while dry.

I have been building hulls for 10 years, sometimes for other people so I am comfortable with this part but starting to get more into the realms of the unknown.

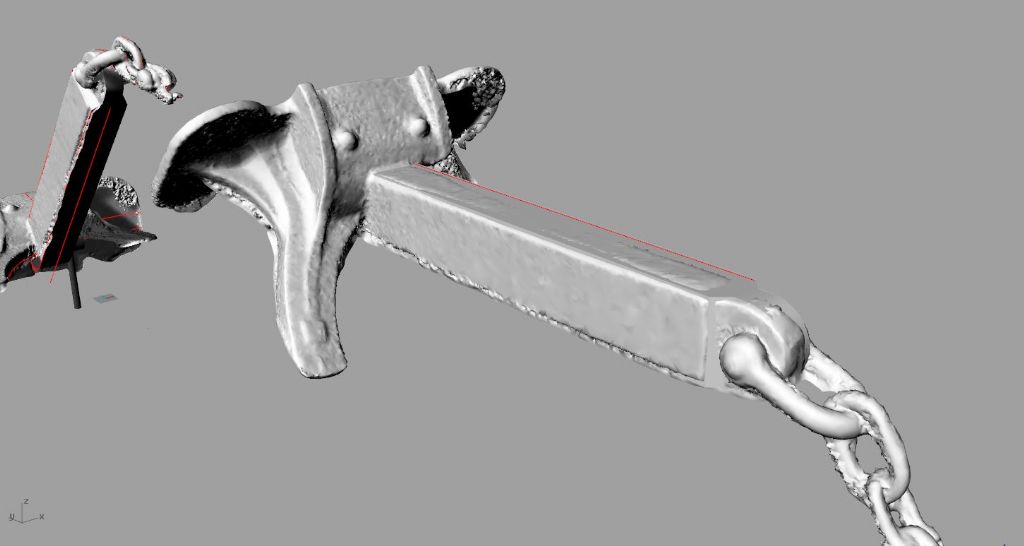

The fine detail I am really looking forward to as I have can slow down the pace and chip away instead of having deadlines to get the hull glassed and primed, I wanted to get it done so The wood does not move too much in our 30 degree temps.

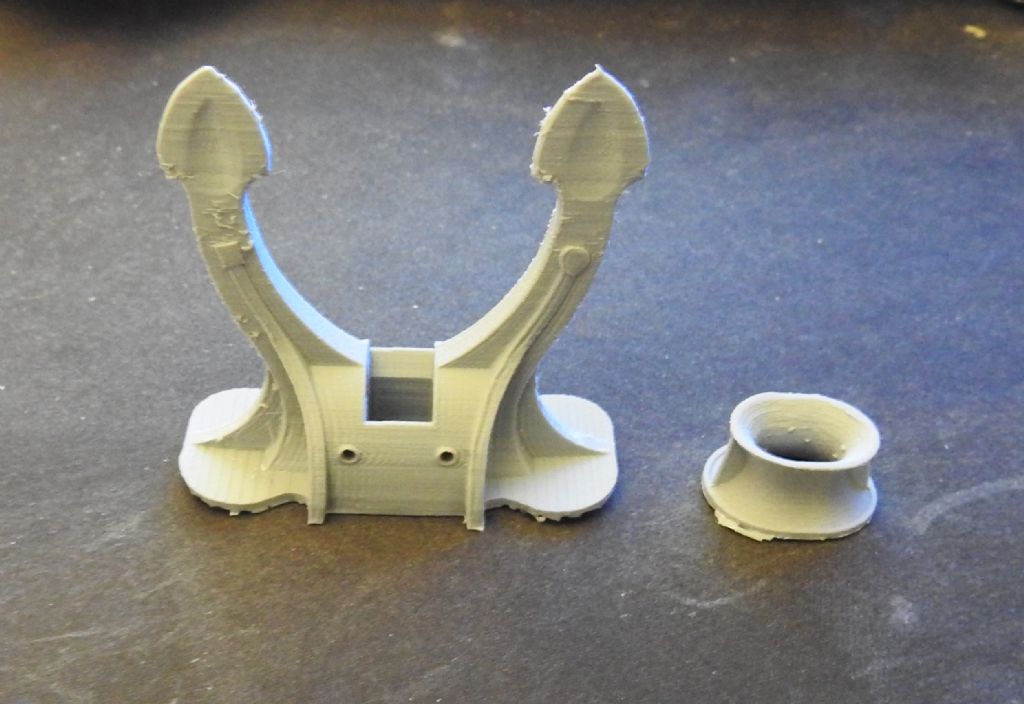

I plan on using etching for a lot of parts that better suite that method but the styrene is appealing for its ease of use, just worried about the fact it's not as robust and could get damaged.

I have set myself up for etching but not done any yet.

Paint…airbrush I think and regular spray paint for the hull,I have the actual paint formulas for the ship paint and had some made, now I need to get some matched and made..not sure what sort yet.

Most of the paint is from the BS 381c chart

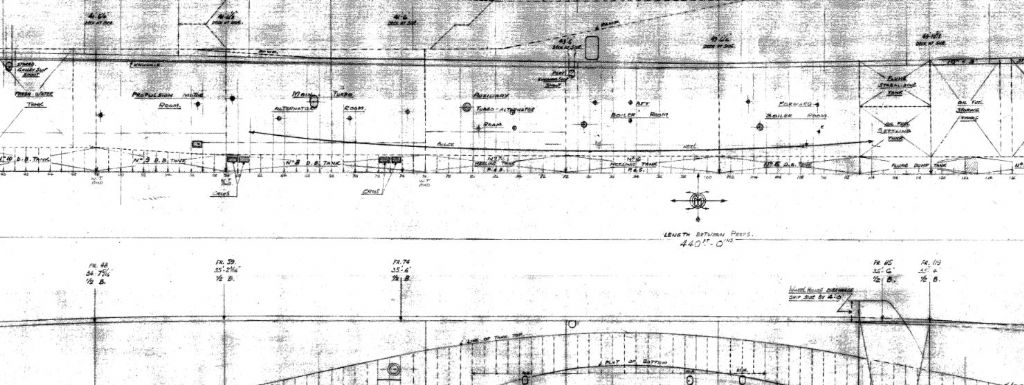

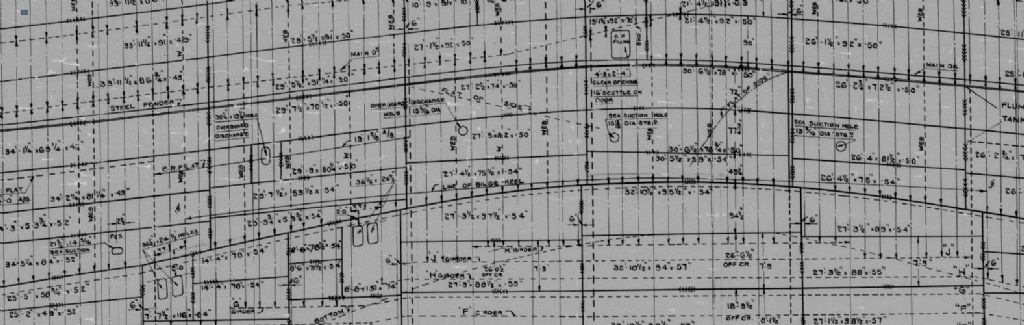

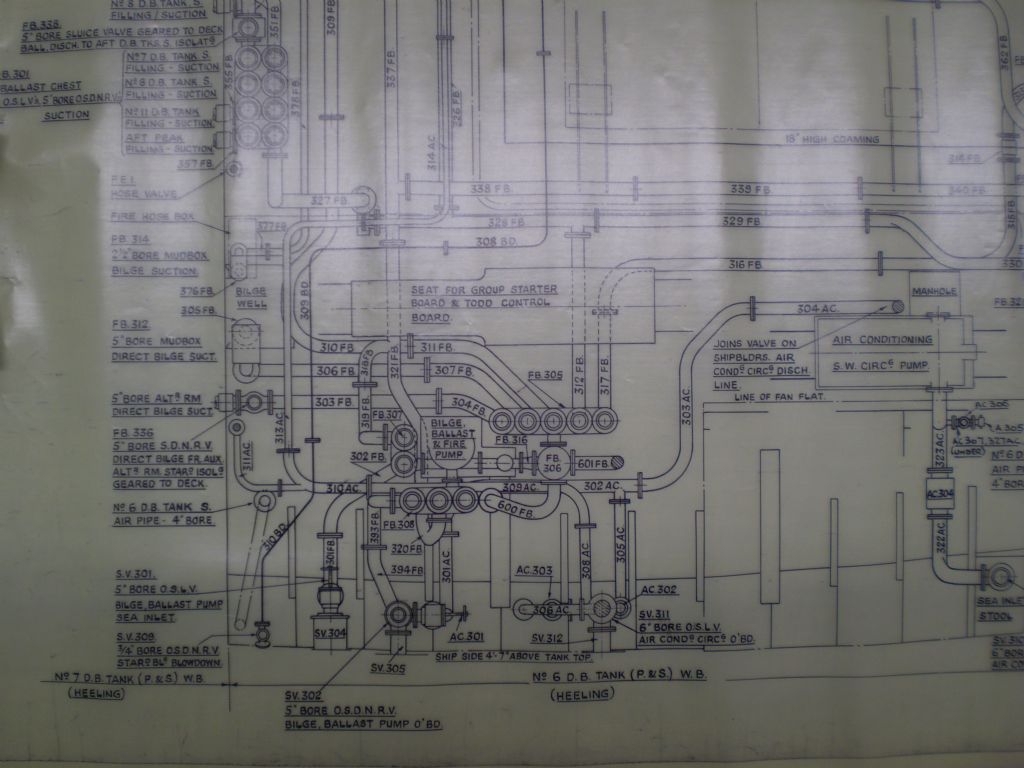

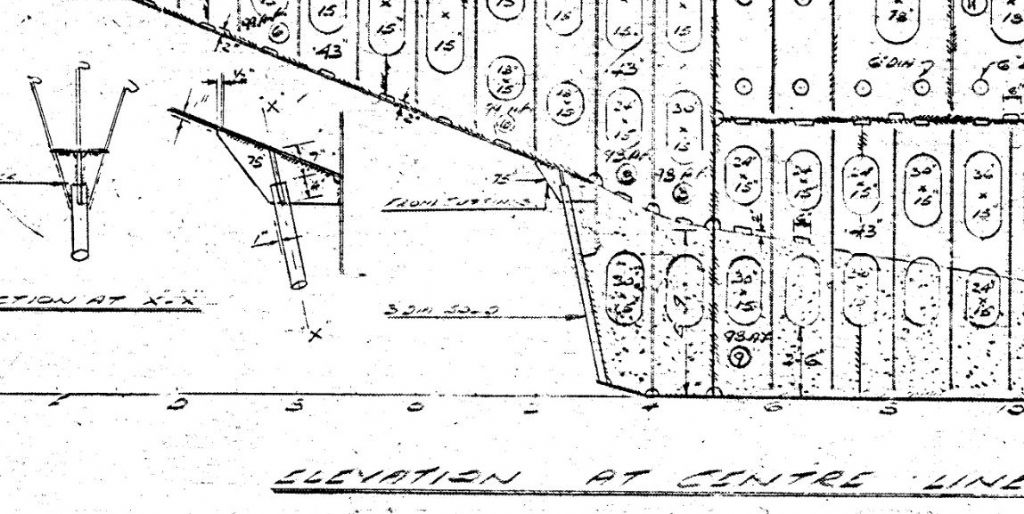

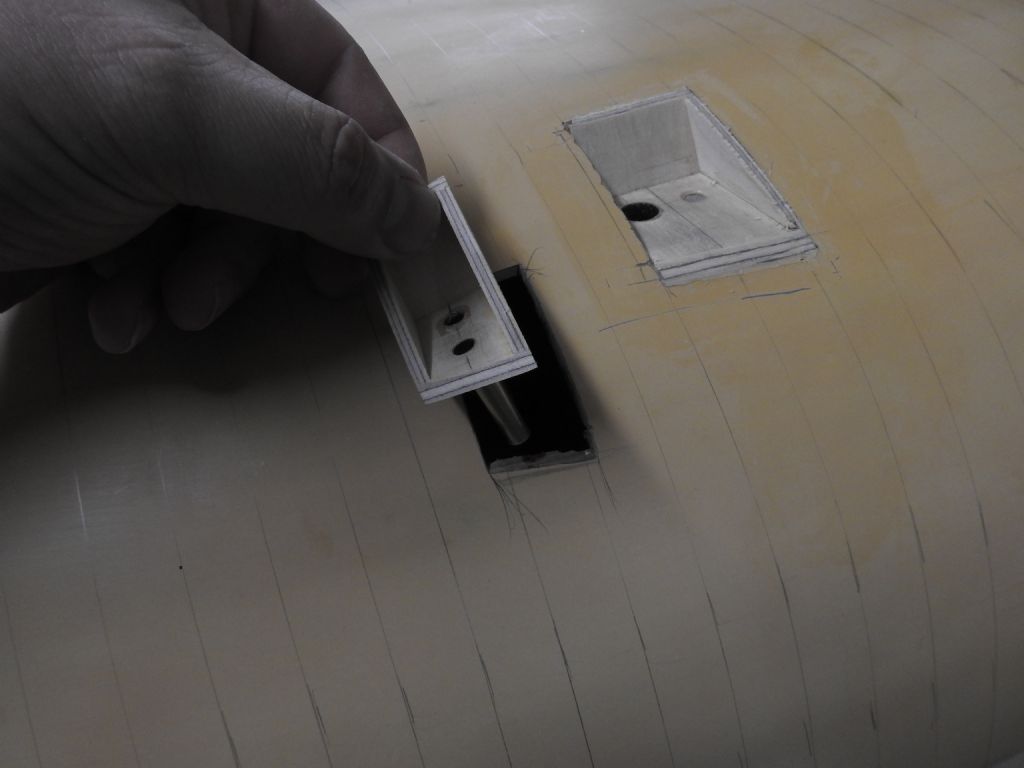

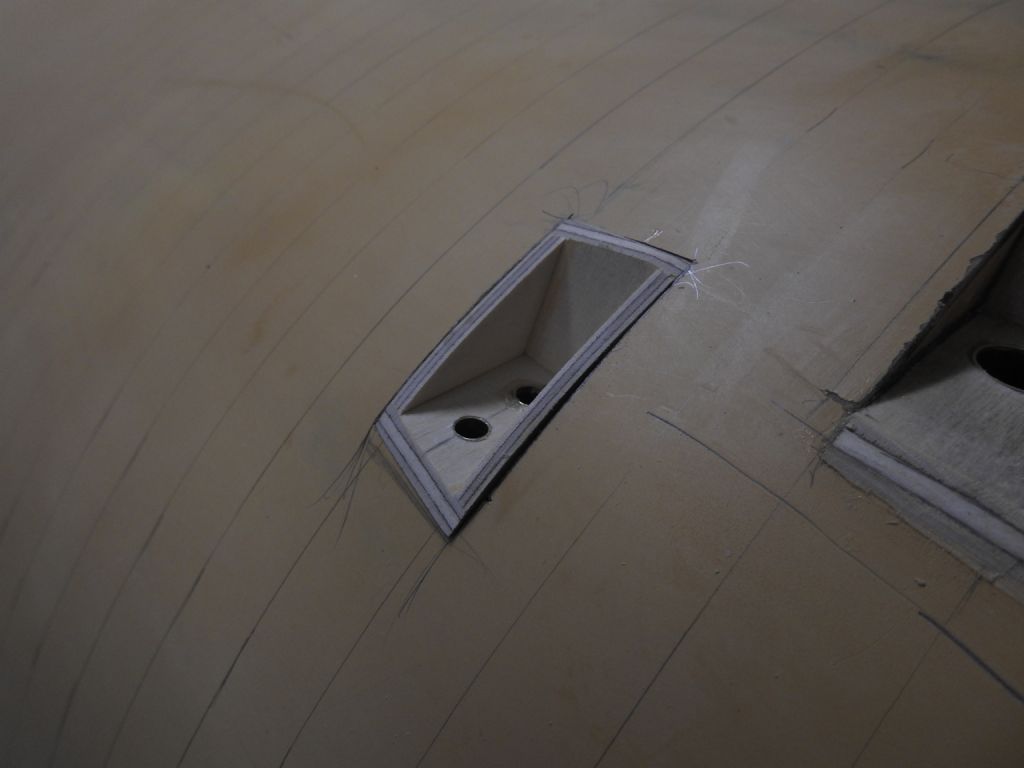

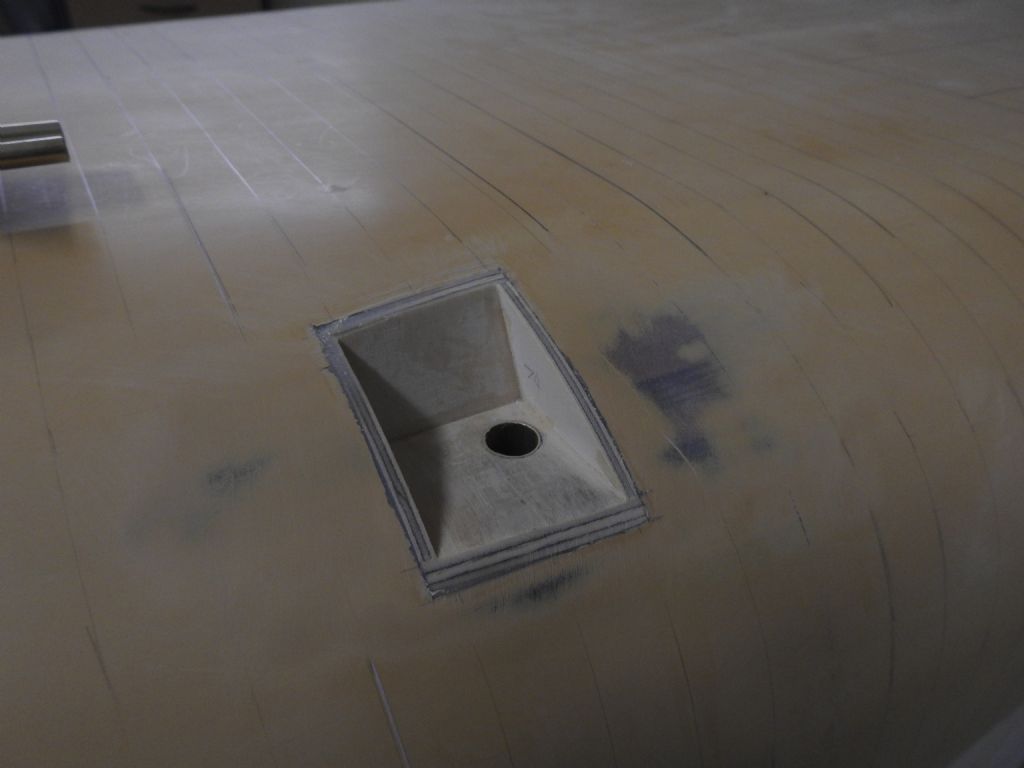

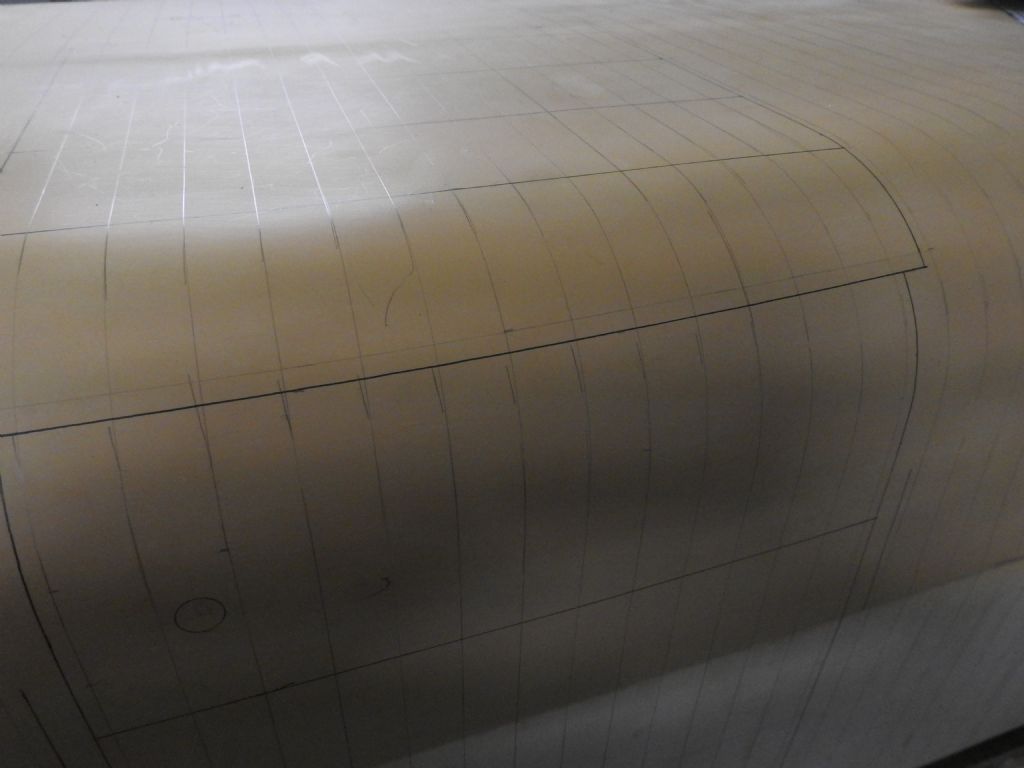

The next step I plan to do is once the hull is glassed, faired and primed is to level her up on the building board which needs to have every frame marked and draw all the frames on the hull so I can then markout the hull for openings..of which their are about 300 all up, ports,discharges.intakes, sea suctions,scuppers as well as adding in the weld seams with a technique I have not yet devised.

Funny thing, now its closed in it looks a lot smaller

Edited By Richard Dunn 3 on 15/12/2015 08:19:28

Edited By Richard Dunn 3 on 15/12/2015 08:20:33

Ray Wood 3.

Ray Wood 3.

![dscn0733[1].jpg dscn0733[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/650560.jpg)

![dscn0734[1].jpg dscn0734[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/650561.jpg)

![dscn0736[1].jpg dscn0736[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/650562.jpg)

![dscn0821[1].jpg dscn0821[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/655996.jpg)

![dscn0819[1].jpg dscn0819[1].jpg](/wp-content/uploads/sites/5/images/member_albums/148754/656354.jpg)