My chest has been bad for a couple of weeks and the moist atmosphere in the workshop does not help, but today with it being a lovely day i decided to move out of the workshop and into the garden to play.

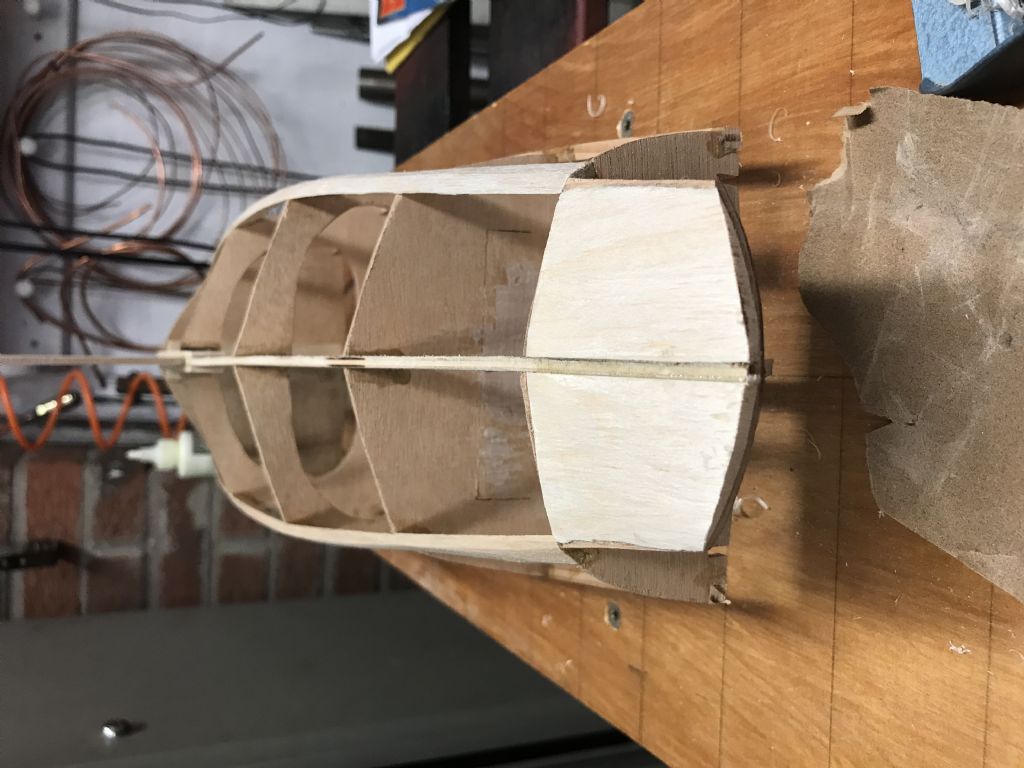

The ply i ordered had been with me for a couple of weeks so it was nice to have things to hand rather than having to go for it. I bought four sheets so that i have stock.

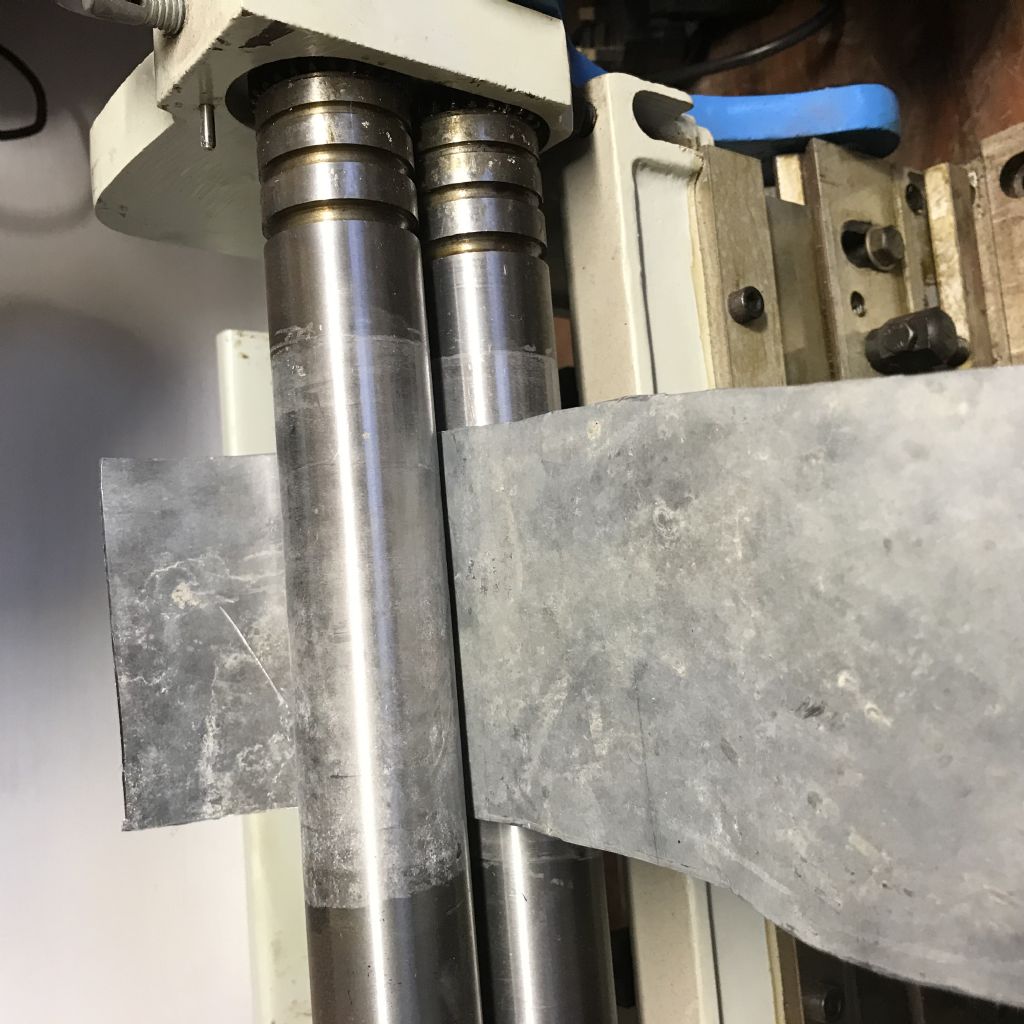

I firstly cut the sheet to fit around the keel, then clamped the sheet in place so that i could draw around it and then cut it out. I was very patient and used a craft knife and rule. I seem to remember cutting some before with the kitchen scissors. Age and practice, hem hem !

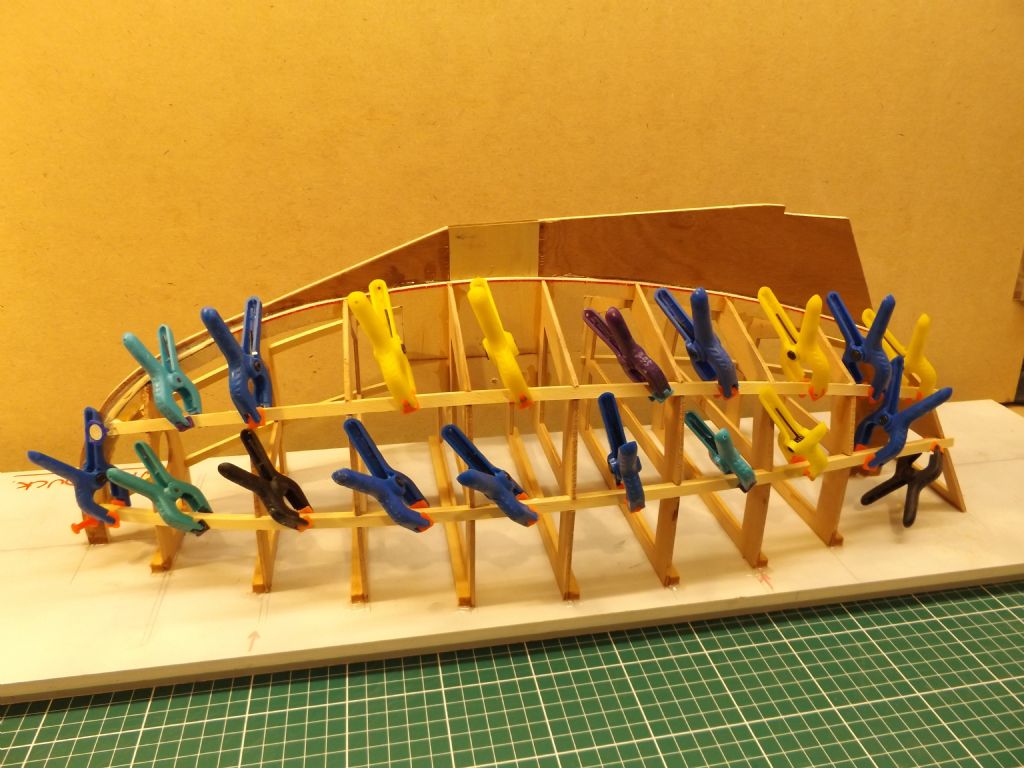

The .8mm ply bends to shape quite easily, so after a trial fitting i glued it in place with the Aliphatic glue. In the heat the glue soon started to go off and i was tempted after an hour to fit the other side, but my thoughts of the skin popping off because i was impatient got the better of me.

I had already bought some more clamps (12) but even they were not enough and i had to use some clothes pegs. I will get a few more clamps from flea bay, i don't suppose you can have too many.

I am on a train ride tomorrow on the Churnet valley line, so i may not get the other side on. I will have to see, and the fitted side may need a little sanding to accept the other side's fit.

The sheet popped up a little around the keel base, so i tacked it in place with a pin.

I didn't use the scissors. Honest!

Brian