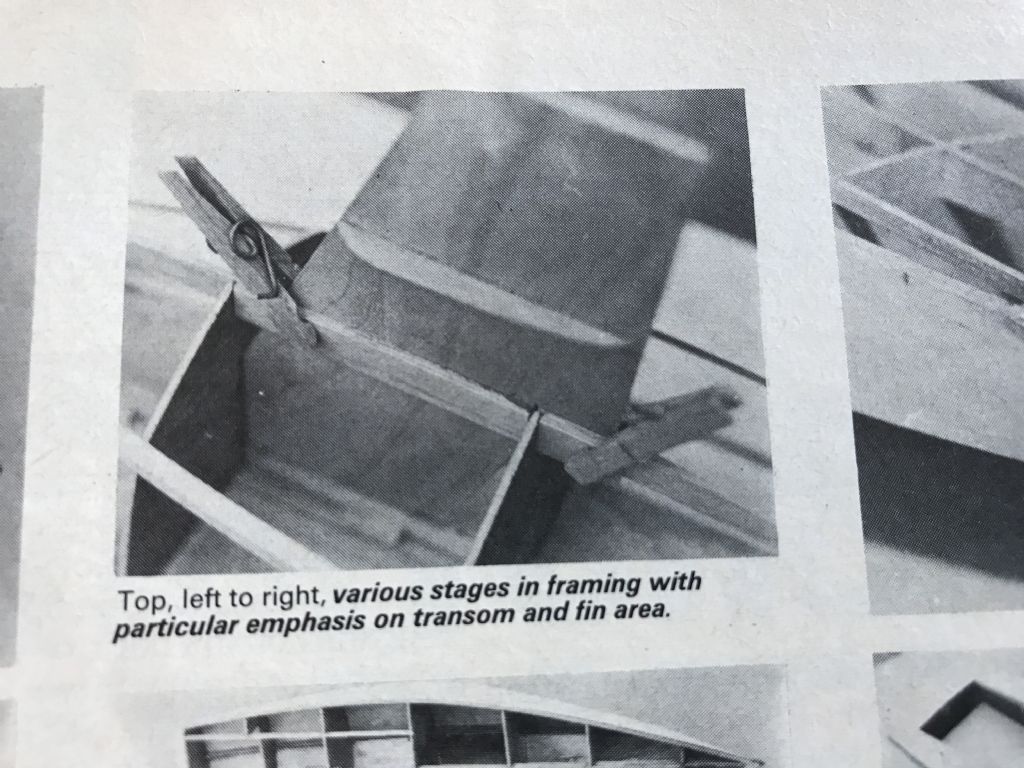

This evening I managed a little more on the frames. I managed to remove most of the glued template paper at the weekend and the rest tonight.

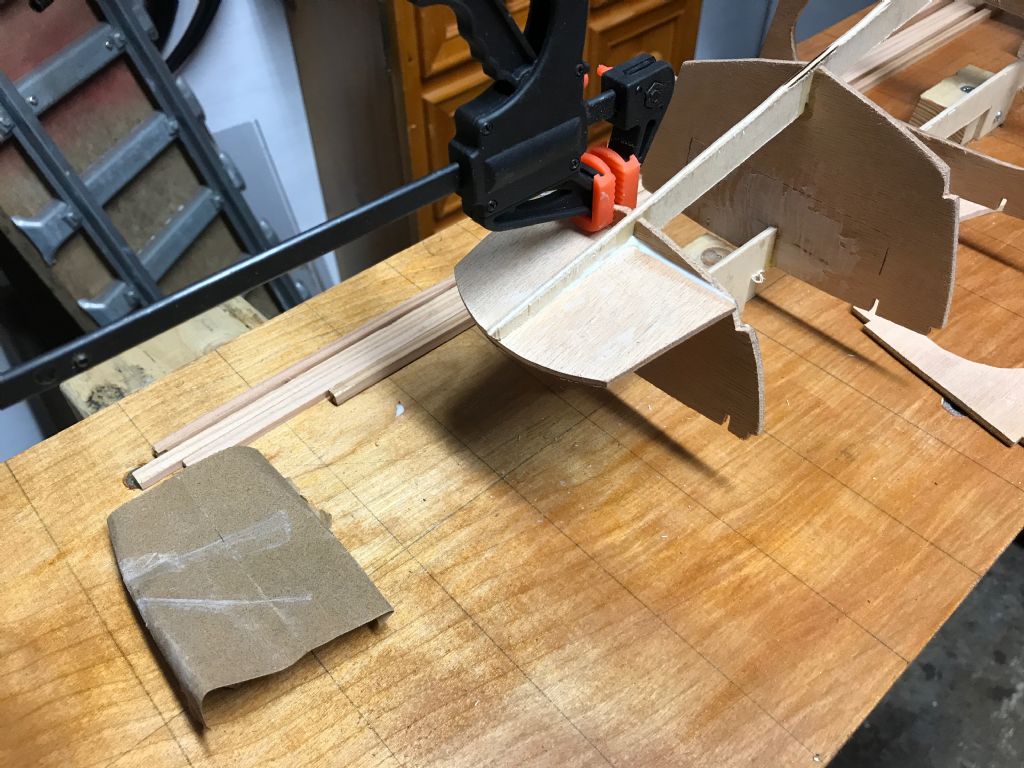

I had to sand a few of the location slots to get the frames to fit, and I am now quite happy with the results. So that's a big thank you to all the chaps who have offered advice so far. I am going to have a go at glueing them all in place soon and I intend using some Gorrila glue. Will this be strong enough?

I have asked at work for any round bar off cuts to be saved so I can make some weights to place against the frames to hold them square whilst they set. Unless anyone can advise on a easier method. Turning the bar ends square will not be a problem for me.

The cut outs in the middle of the formers was done on my milling machine as described earlier, however this left a rough cut. To clean it up I used this:-

It removes wood very easily so I was very careful.

I am very happy with the fit, I was very careful when I cut then out sticking to the outside of the printed lines. Normally I tend to rush and make a b-/::;r of things. So for me this is quite good.

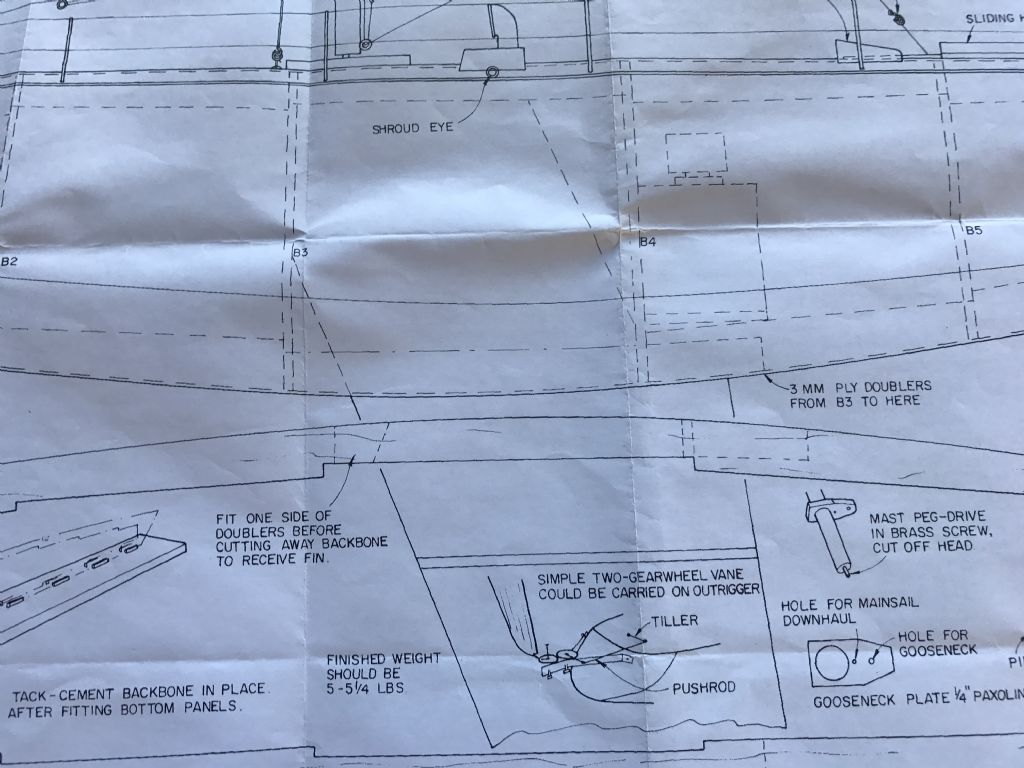

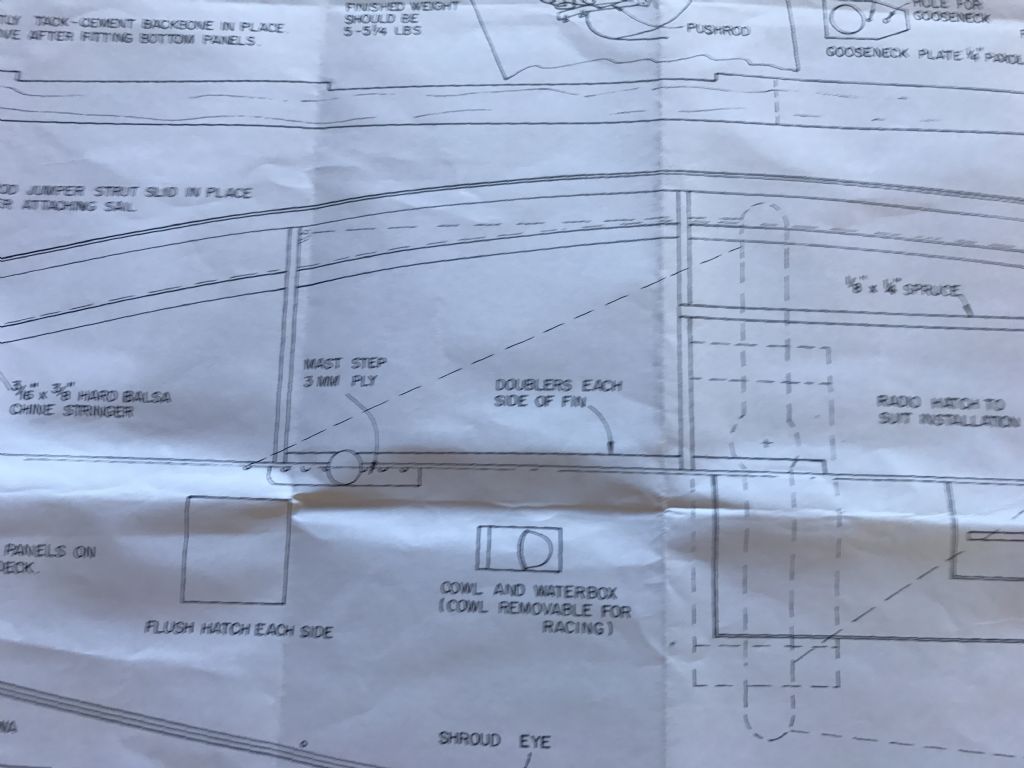

Now that I am at this stage I need to re read the MB mags and check what material is used for the long frame sides, I have plenty of balsa wood but I think it should be spruce. I will read the mags and check.

Happy modelling, Brian

Edited By Brian Dickinson 1 on 31/08/2017 20:13:59

spruce or obeche are the usual culprits. Getting longish lengths of this of a reasonable quality is not always easy at local model shops . A good source of this is SLEC. They are really good for ply as well

spruce or obeche are the usual culprits. Getting longish lengths of this of a reasonable quality is not always easy at local model shops . A good source of this is SLEC. They are really good for ply as well Gorilla white glue is great & cheap at Wilkinsons, both Aerolite & Cascamite are still available at Axminster Tools

Gorilla white glue is great & cheap at Wilkinsons, both Aerolite & Cascamite are still available at Axminster Tools