Thanks all – appreciate the advice – it will be a 'slow burn' to get all the right equipment I think, depending on how many of these I start working on over time.

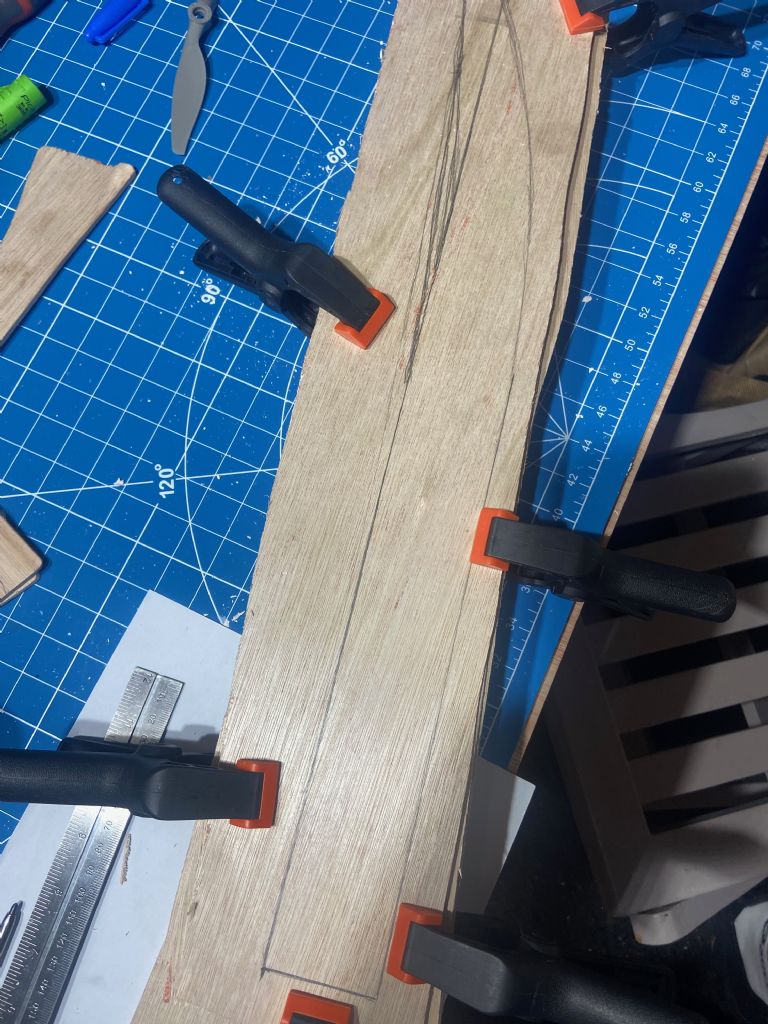

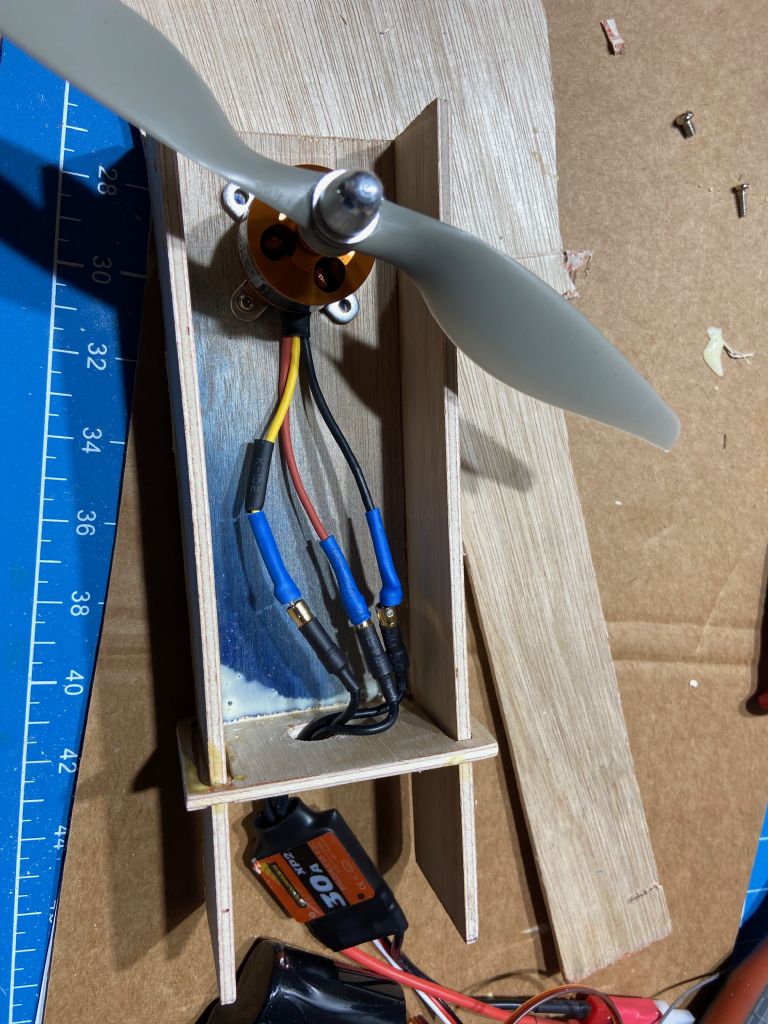

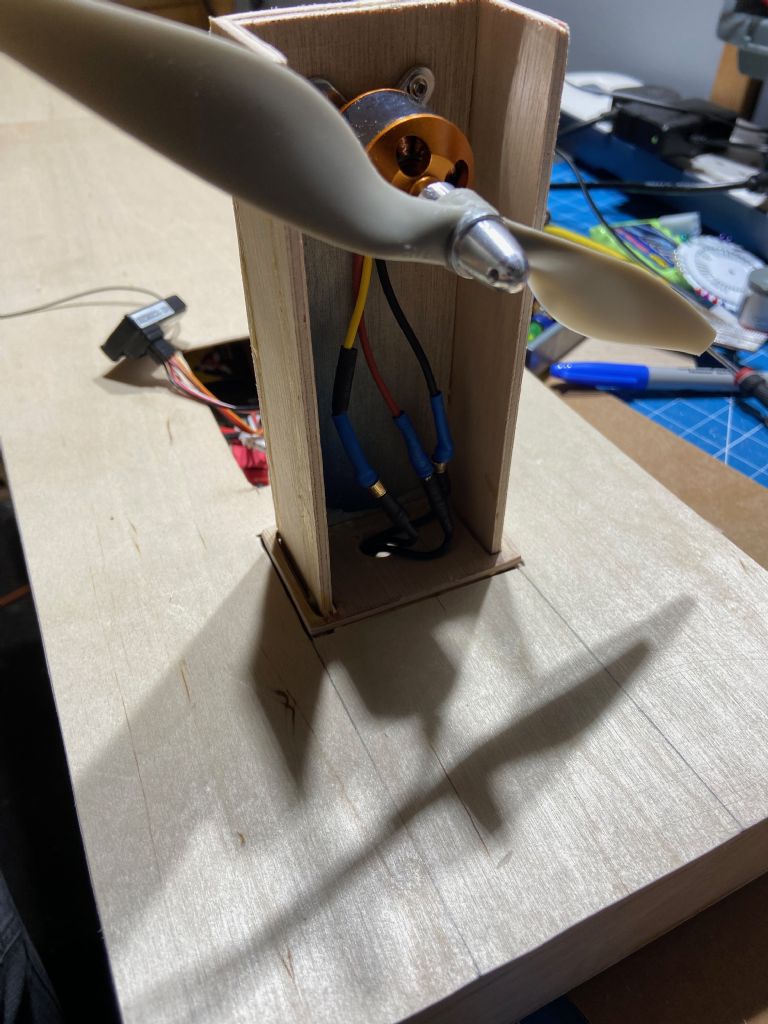

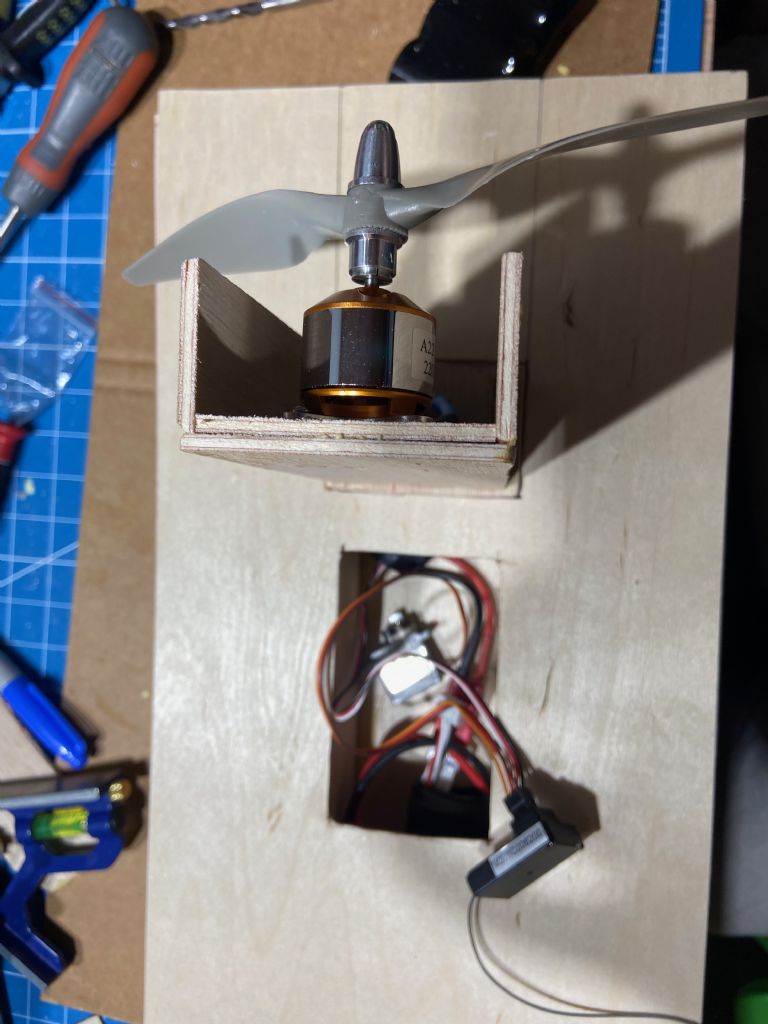

Good news for now is that the basic shape is coming together – glueing the thinner 1.5mm ply base with a couple of heavy toolboxes seemed to do the trick and I held it down right at the end of the curve as well. I used titebond glue.

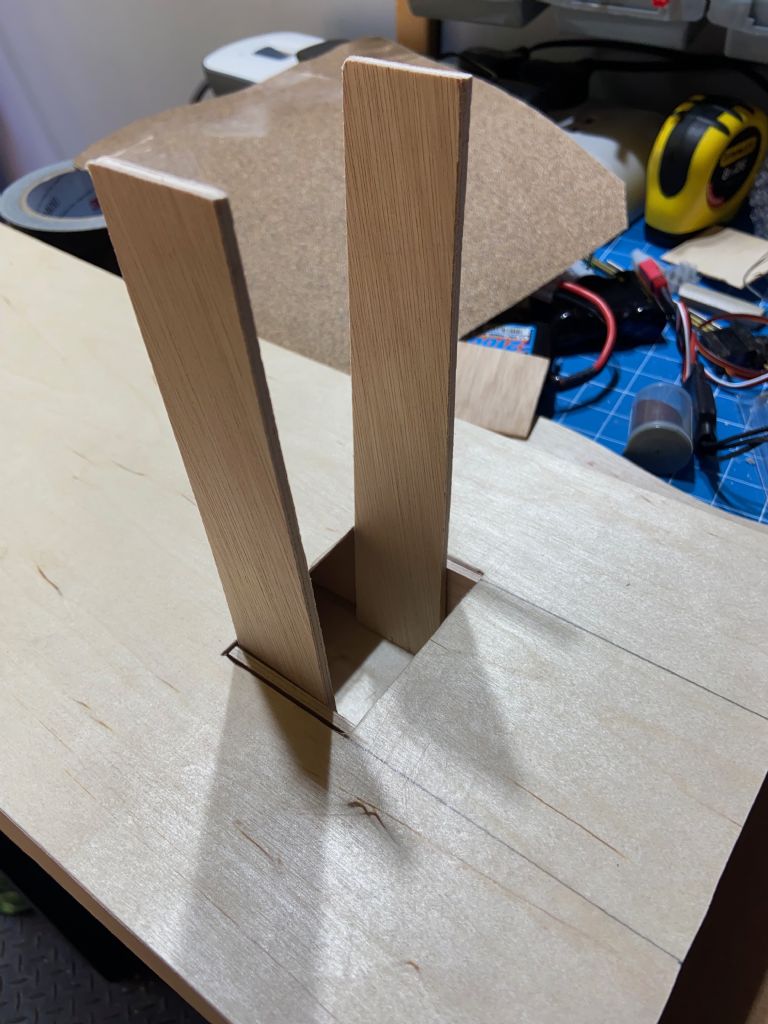

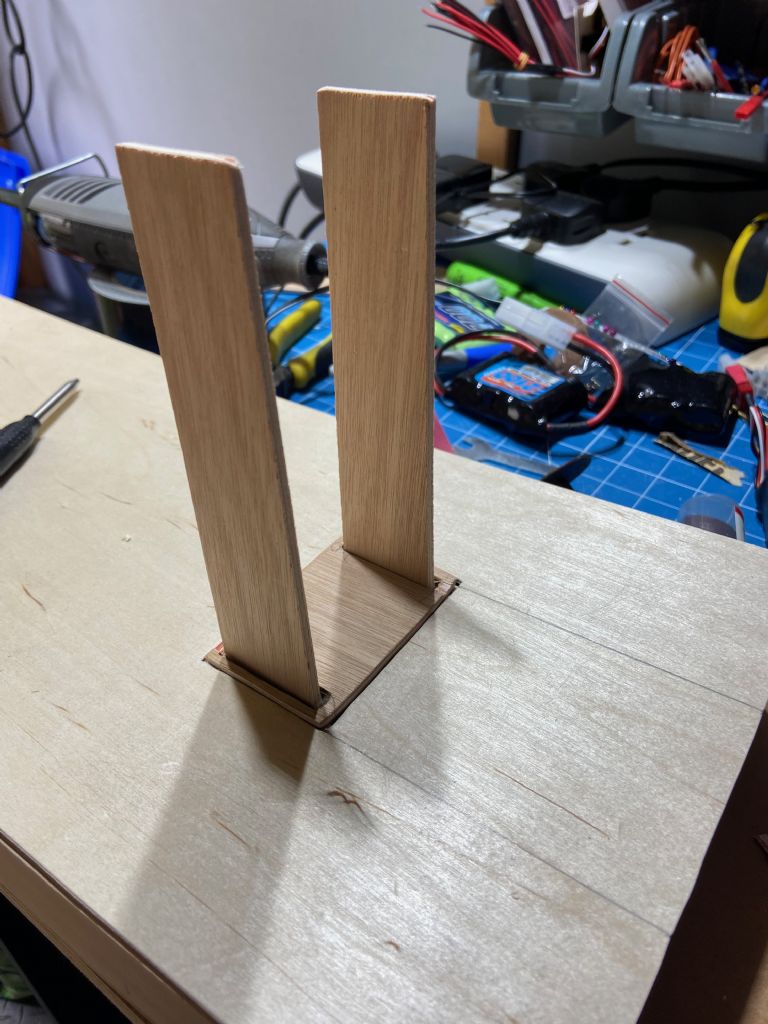

The body shape I widened slightly as the first one looked a bit long and thin proportionally. I also added 4 spines to this one.

I also found I could cut the 1.5mm ply with a ruler and a Stanley knife which saved time for the length and width of the base.

My next challenge is how best to design the air rudders (or whatever they are called!). I guessed 2 because most of the boats I've seen have 2 in place.

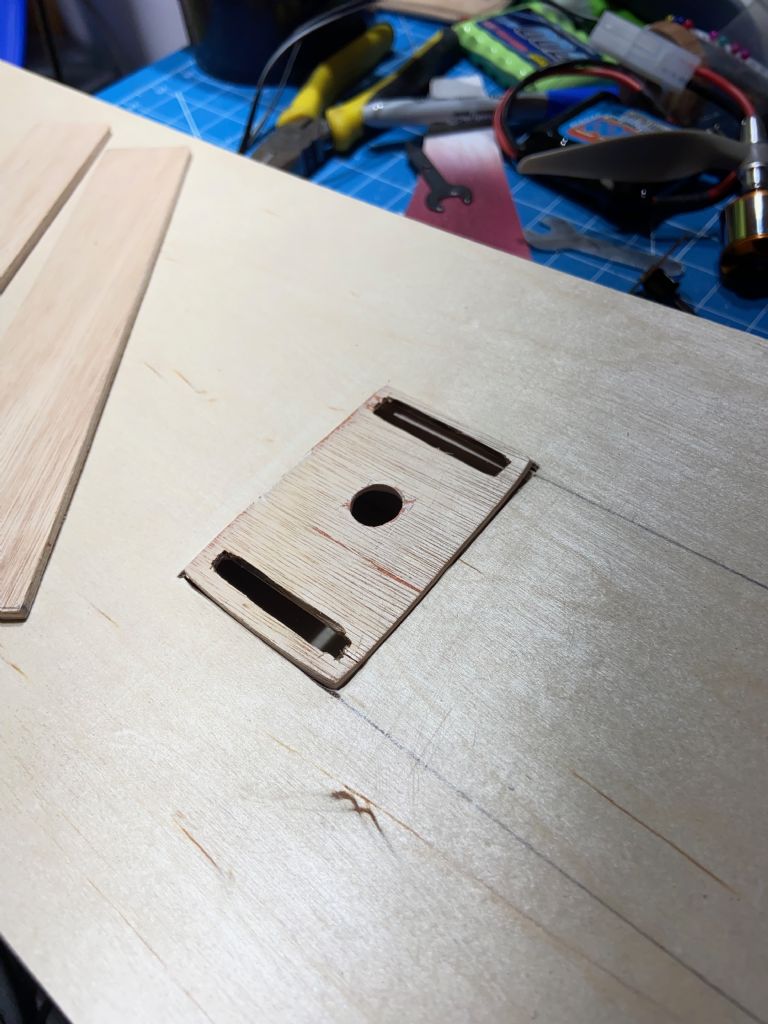

I cut some out of 3.6mm ply and 1.5mm ply – the 1.5 is much lighter but seems like it might be too flimsy … I tried glueing 2 halves of a brass tube to the the thicker one but then they seem a bit on the heavy side ..

Any suggestions / advice about how best to design and attach the rudders to the boat? I was thinking originally a metal rod could go up the brass tube as something for it to rotate around but not sure if there are known ways of doing this as this seems quite heavy. Another idea I had is to put some very small hinges and attach to the wooden rudders directly (from a wooden post that I will attach to the back of the main hull).

Edited By Simon Anderson 1 on 20/06/2022 19:00:52