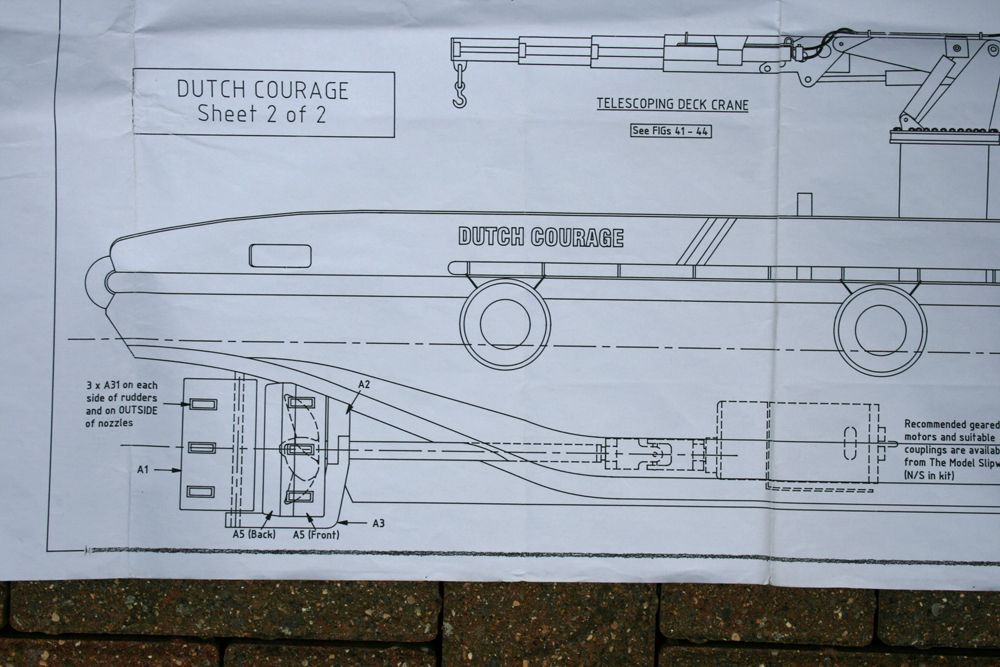

Ashley, unfortunately there’s no bare shaft at the inner end. Mistake number 143 (ish!) was to mount the motors too near the propshafts, something I couldn’t rectify later on as I had built, and mounted with copious P38 filler, a battery box to hold the two 6v batteries, virtually touching the motors to get it as central in the boat as possible.

Paul, the shaft/hull seal is solid & leak-free, plenty of epoxy followed when dry by plenty of P38 to give a good seal.

It is more than possible that the motor is slightly offset. When running the motors individually, however, they both sound the same, ie the port side is no noisier.

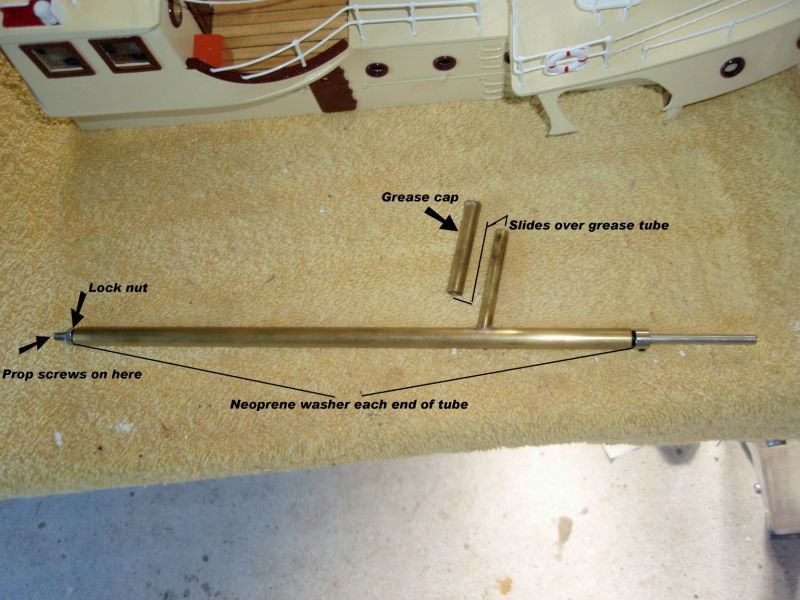

The props are contra rotating, and the port rotates clockwise. Therefore, when going forward, the thread would pump water away from the tube. Of course, when reversing, the opposite would happen, and here’s the thing – after trying to minimise the end-play earlier, a test in the bath initially seemed successful, but after going into reverse, water started to come in. However, water continued to come in even when going forward (and in fact when the props weren’t moving, but only an occassional drip).

I have now managed to remove the shaft from its tube, but before doing so, I was able to wiggle it about very slightly! Defect? Wear already?! I had lubricated the shafts with hypoid oil (car gearboxes & differentials), as thicker than machine oil, but thinner than grease. maybe this was mistake 144!!

The tube was, of course, full of water, so maybe the silicon grease is the way to go – I’m not worried about a bit more drag as I’m only using about half the available power, and the boat’s fitted with two 6v 12ah lead batteries.

Paul