I've been thinking again, sorry.

In the 'hints & tips' section, Glynn Guest writes about prop-shaft lubrication. The article is not dated so I was wondering if perhaps oil -as opposed to grease- in the sterntube is no longer 'politically correct' ?

Oil will surely gradually leak out of the sterntube and cause a rainbow-coloured wake astern?

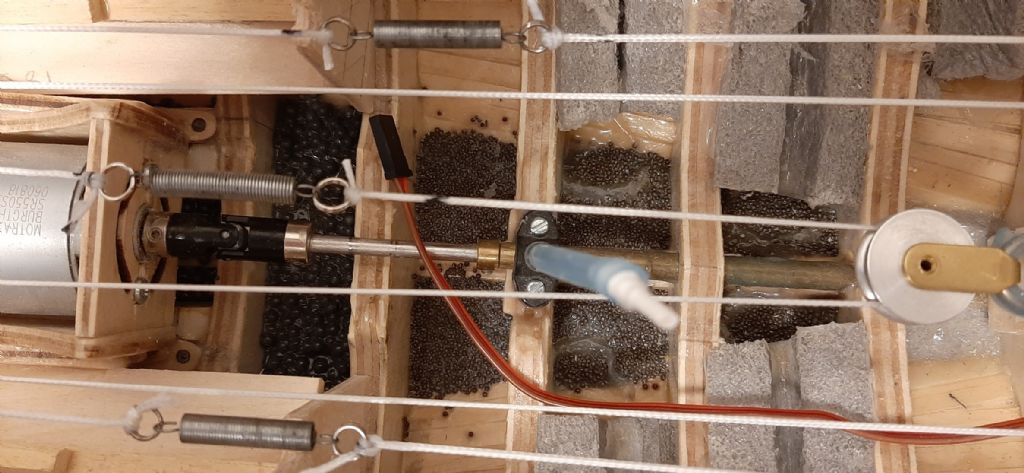

Last winter I bought (together with the Comtesse kit) a tube of dedicated sterntube grease from Krick Ro-Marin. The only boat I've had in the water in recent years is the Comtesse yacht launched this summer so -as usual- I have little experience with this.

When applying the grease to the feed tube with a syringe it does not seem to accept much grease. Perhaps it should be applied while the shaft is turning at low speed?

The drive line has been so little used that it's probably not even been slightly warm so I consider it impossible for any lubricant to have 'left the building'. The grease used is what was recommended in the kit instructions but obviously KRICK grease would be recommended in a KRICK kit. There no info about operating temperature.

In view of the low temperatures involved -low water temp and low speed/short periods of motor use, is it perhaps better to use a thick motoroil?

Or can just I forget about the lubrication issue -due to low temp and short periods of motoring etc and just use the grease as sterntube water-proofing?

Any (inuendo-free ) tips/ideas appreciated. Replies need only be simple : Use the grease. Use the oil or even 'Get a life'! Thanks in advance,

) tips/ideas appreciated. Replies need only be simple : Use the grease. Use the oil or even 'Get a life'! Thanks in advance,

George