Going back a bit you can see that the luff of the main was not reinforced over its entire length. We just had local reinforcement at the lashing points. With new sail cloth or with film you don’t need that many either.

The luff of the main doesn’t have to support a big load. Some tension is required to keep the luff straight and to stop it from flapping and because the luff is on the bias as supposed to the selvedge putting tension on the luff induces a little bit of shape and the more tension there is, the more this shape moves forward which is useful in strong winds. These sails are too small for this to be that relevant, but in larger sails where performance is important it is a very useful feature.

The jib on the other hand is different and it is quite usual and good practice to use the jib luff as the forestay. Now the sail is supporting rig loads and not just those required to set nicely. This is where we use the luff tape.

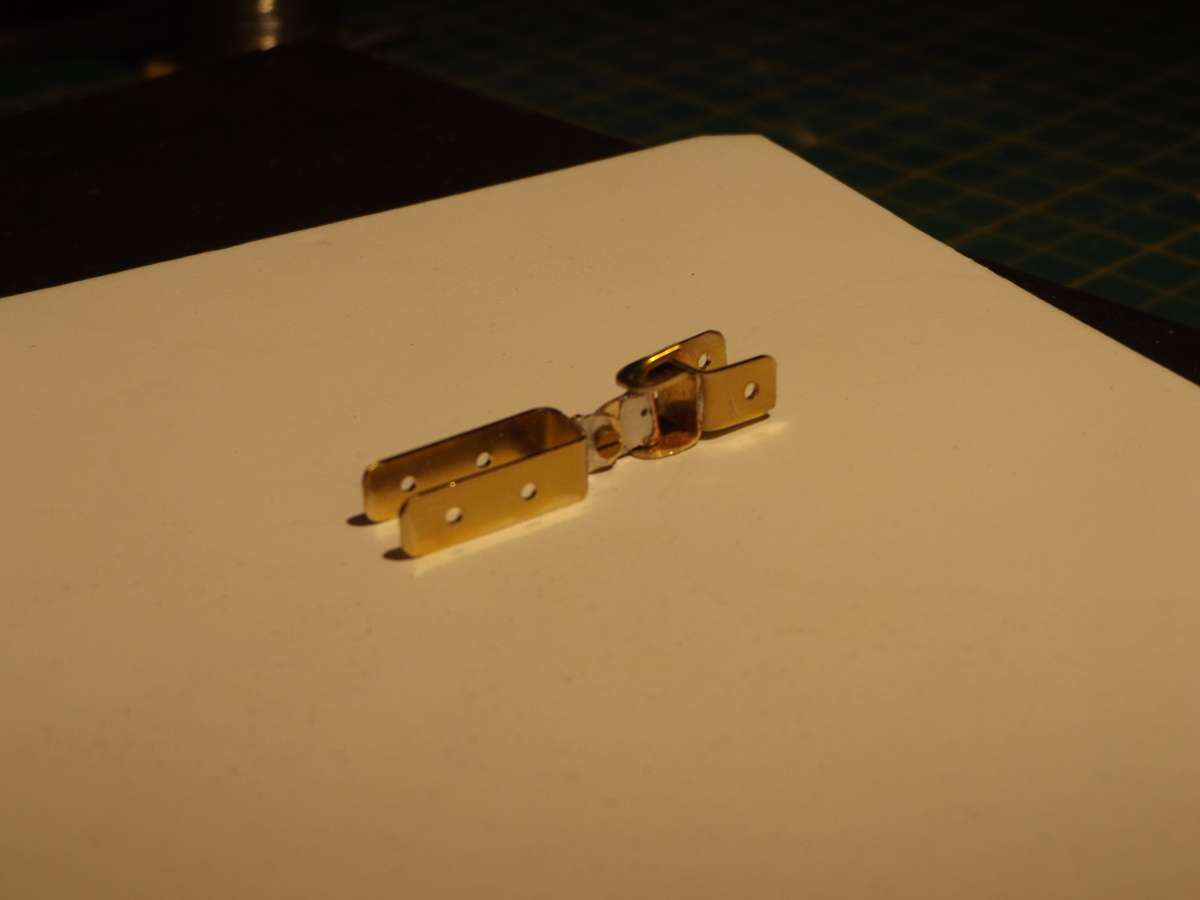

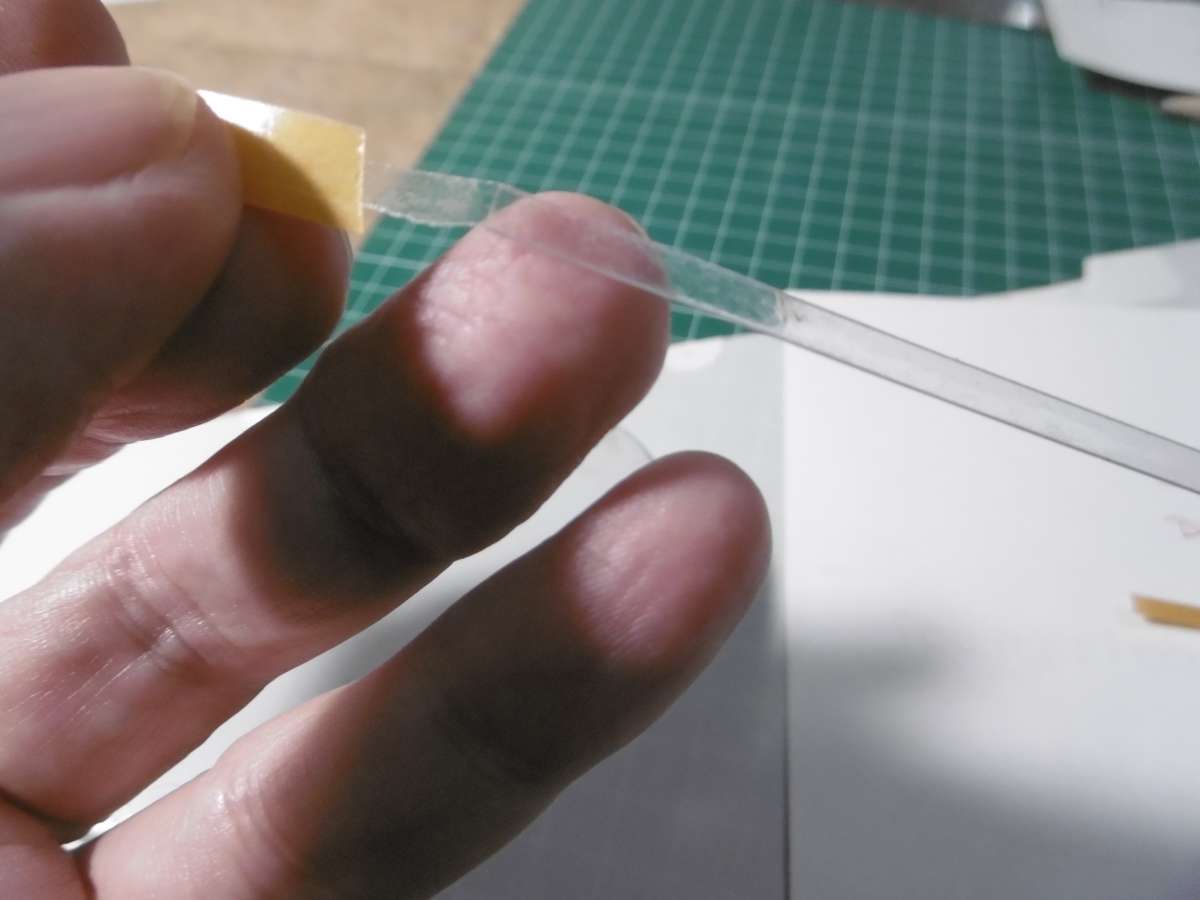

This stuff.

The idea is to make a pocket on the luff of the jib and run a wire through it so the wire itself is the forestay.

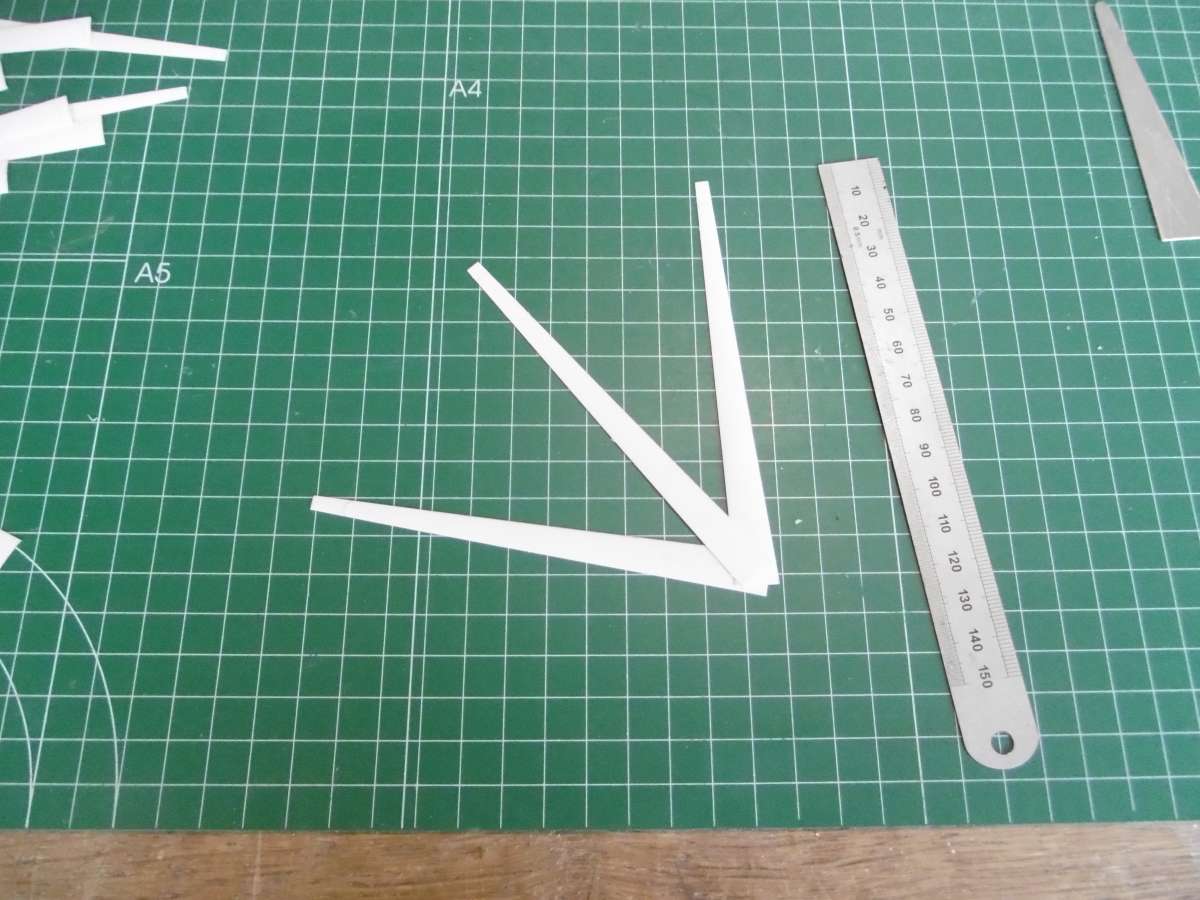

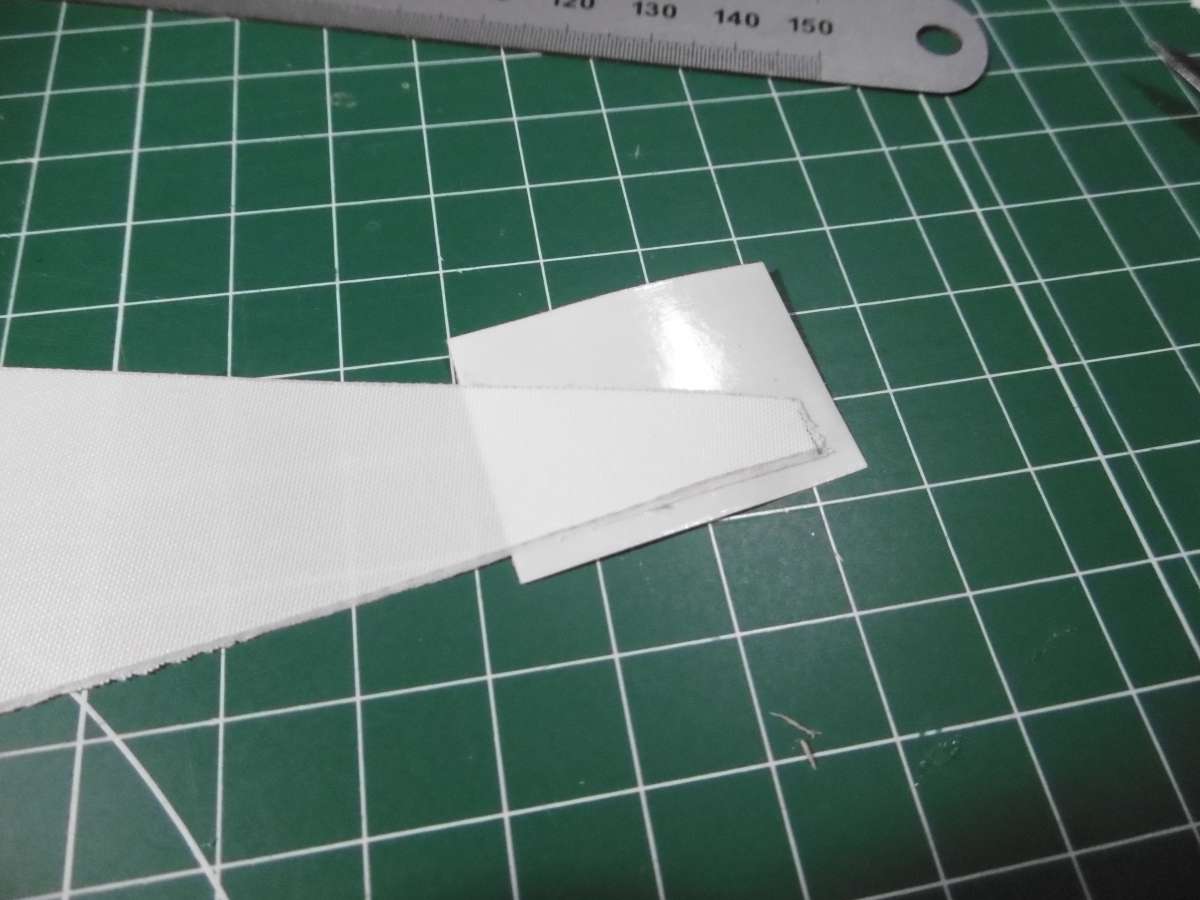

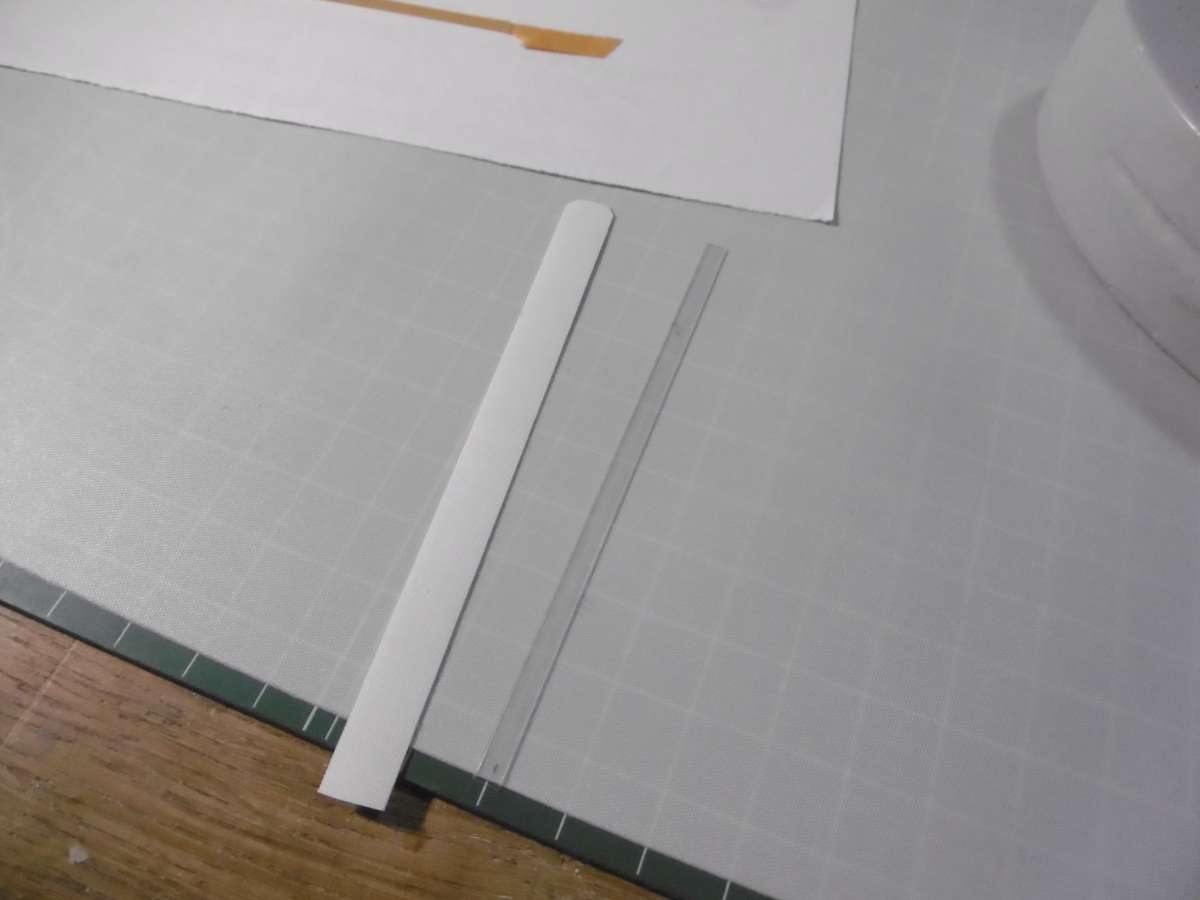

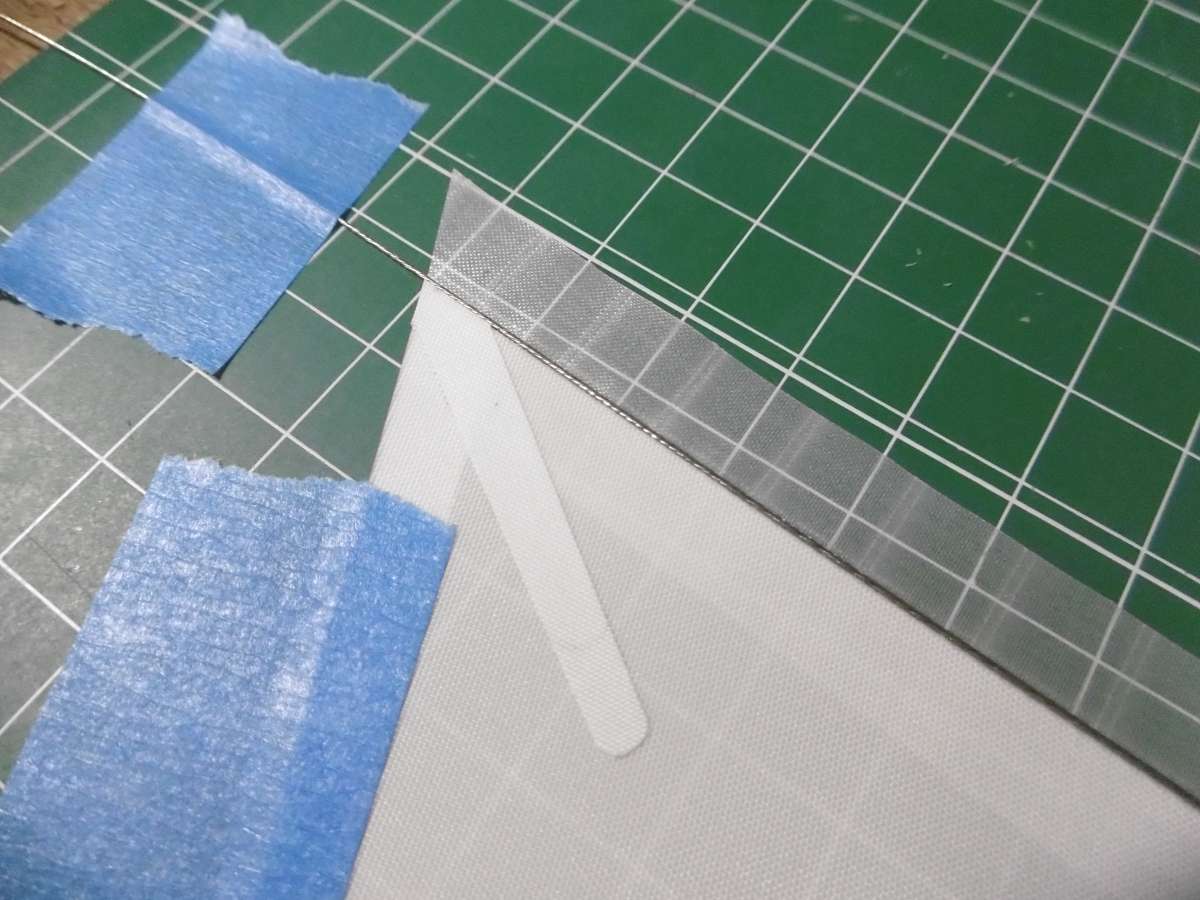

Here are the three components for making the luff pocket. The sail itself, the double sided tape and the luff tape.

The double sided tape is applied to one side of the sail. The width of the tape and its position on the luff is quite critical. If the tape is too close to the luff aft edge of the luff tap may not be stuck and this make the join

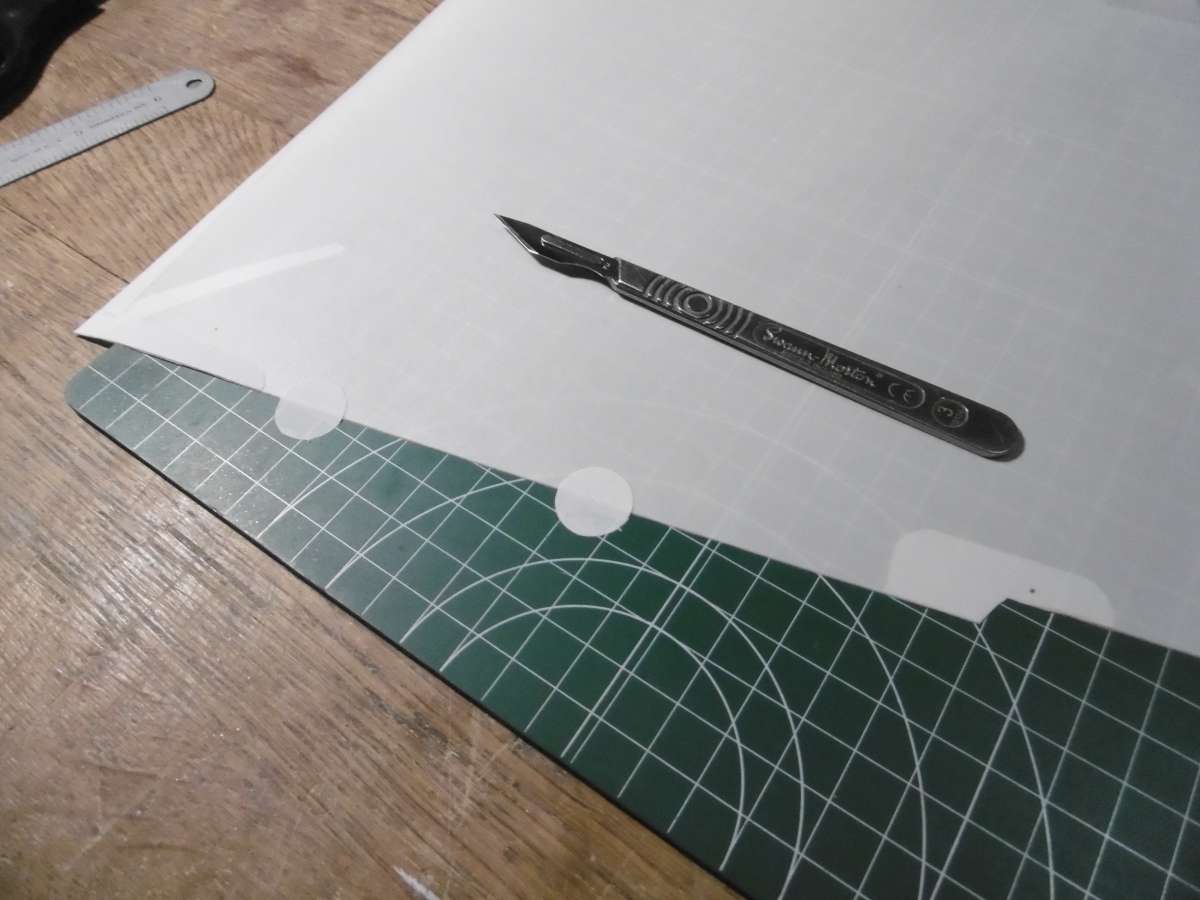

at risk of peel. The tape may not lie flat on the sail which doesn’t look so good. If the double sided tape is too far aft it may not be covered by the luff tape leaving a sticky line exposed. This will attract dust and dirt and in no time will look horrible. Here I have done one side and then turned the jib over so that the luff tape is towards to cutting mat.

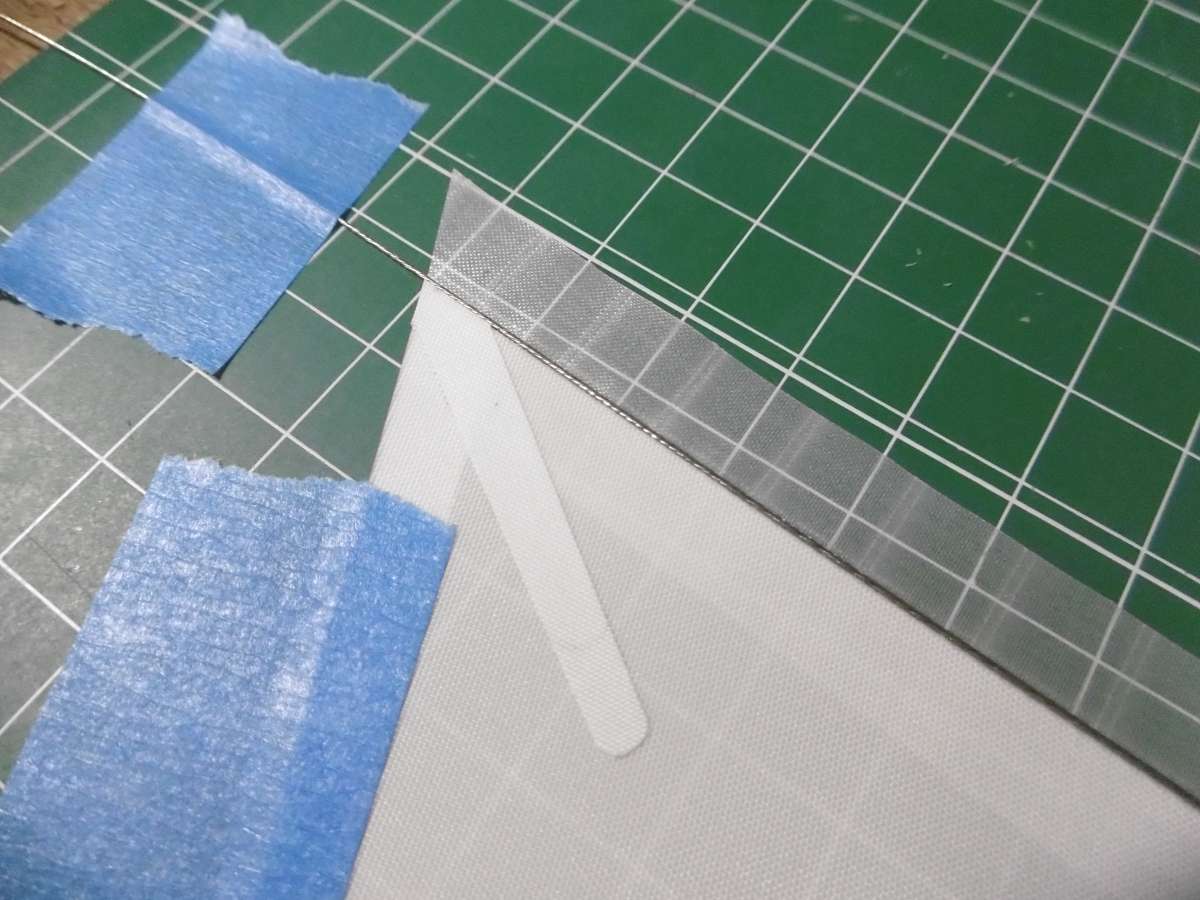

Now we lay in the wire and this is the tack of the sail.

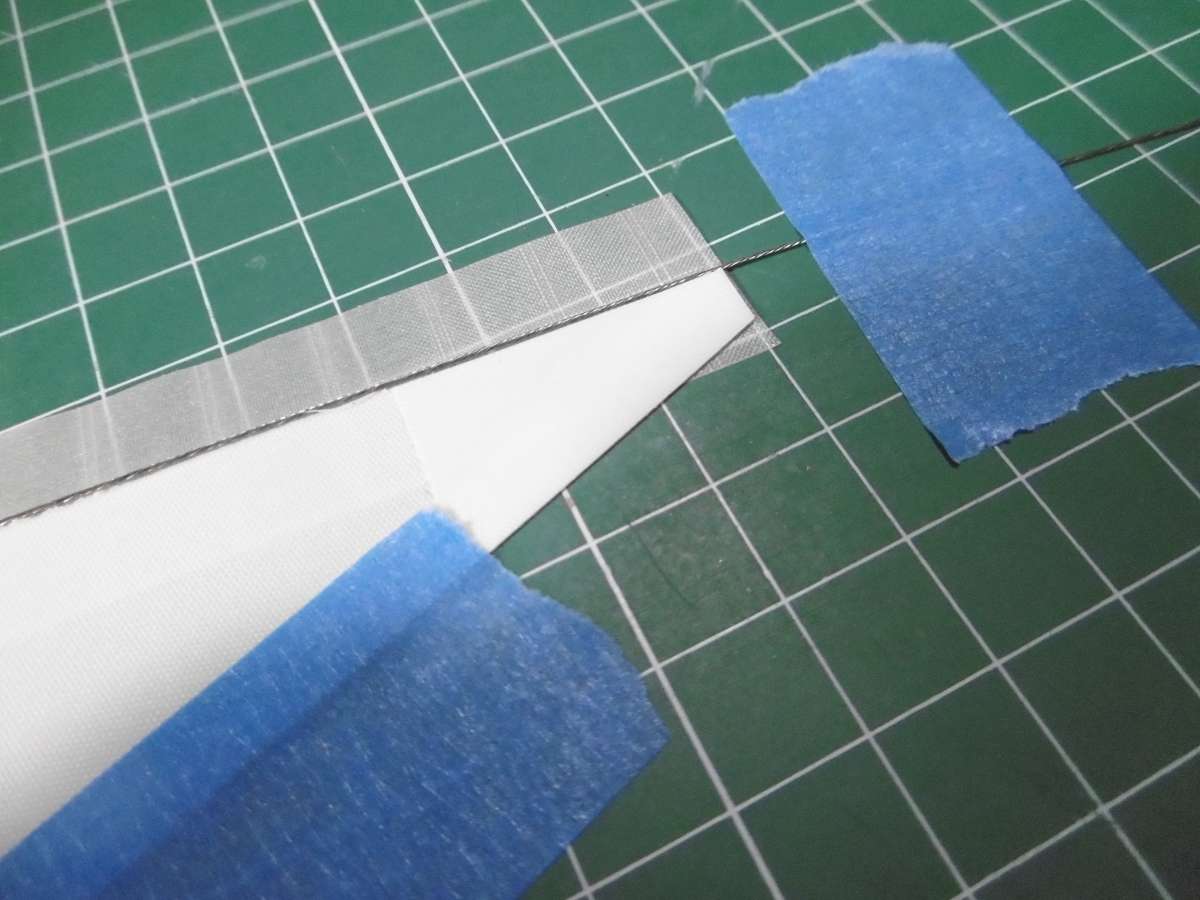

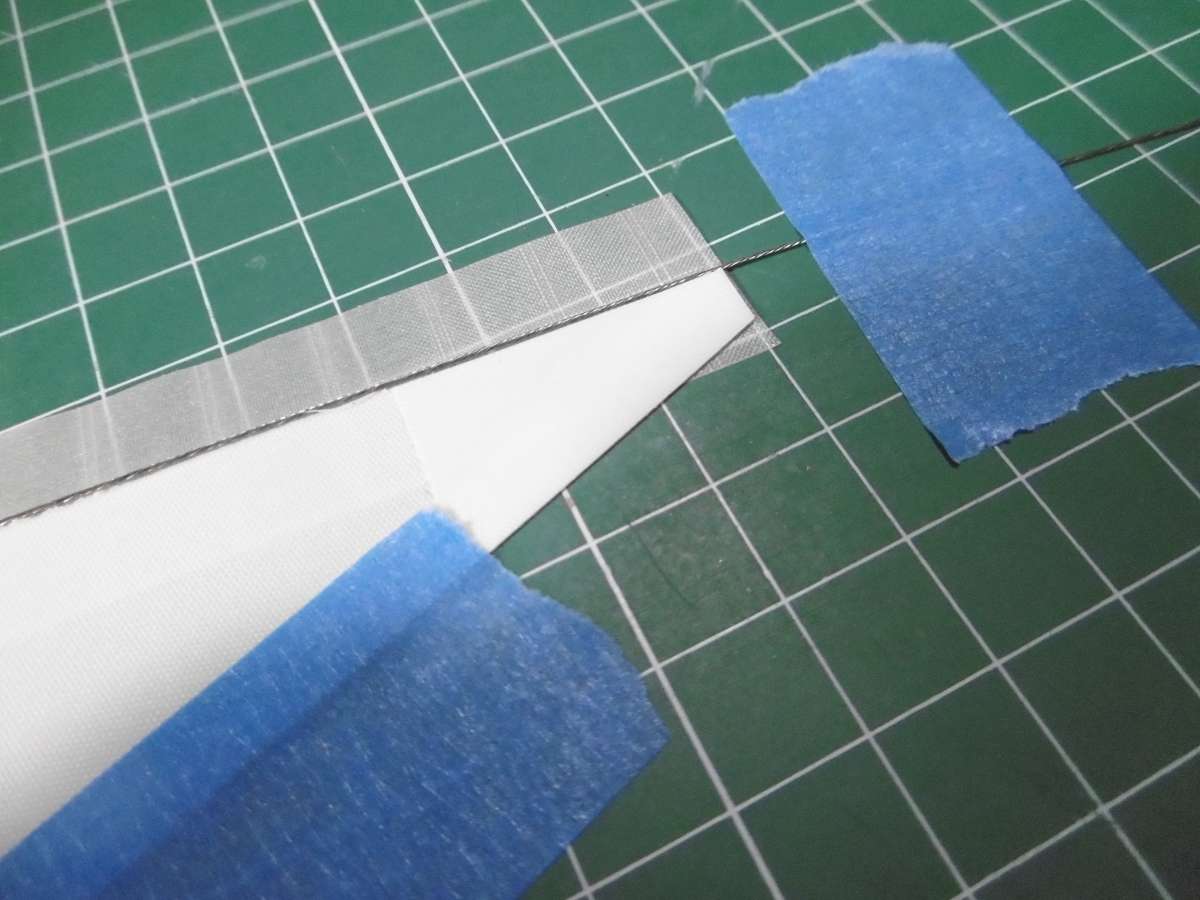

And here is the head. The wire is taped down at each end with as much tension as possible. This is to keel it accurately aligned with the luff. This is important.

Next, double sided tape is applied to the top surface of the sail taking care to position it correctly. The luff tape is then folded over the wire and stuck to the sticky tape. The wire is now running in a pocket down the luff of the sail.

We don’t want the wire to be stuck in the pocket. It should have just enough clearance to slide. This means that the tension on the wire (now the forestay) can be adjusted separately from the tension on the jib luff. Typically the forestay forestay has much more tension than the jib luff.

I supplied Ray with a wire with (I hope) plenty of spare because I don’t have details of his attachment points. Also a couple of crimp ferrules so he can make the forestay to the length he needs.

Actually Ray has a choice. He can have a separate forestay if he wants and not feed the wire into the luff pocket. Because the luff is reinforced along its length it will be plenty strong enough for this boat. We will see when he posts.

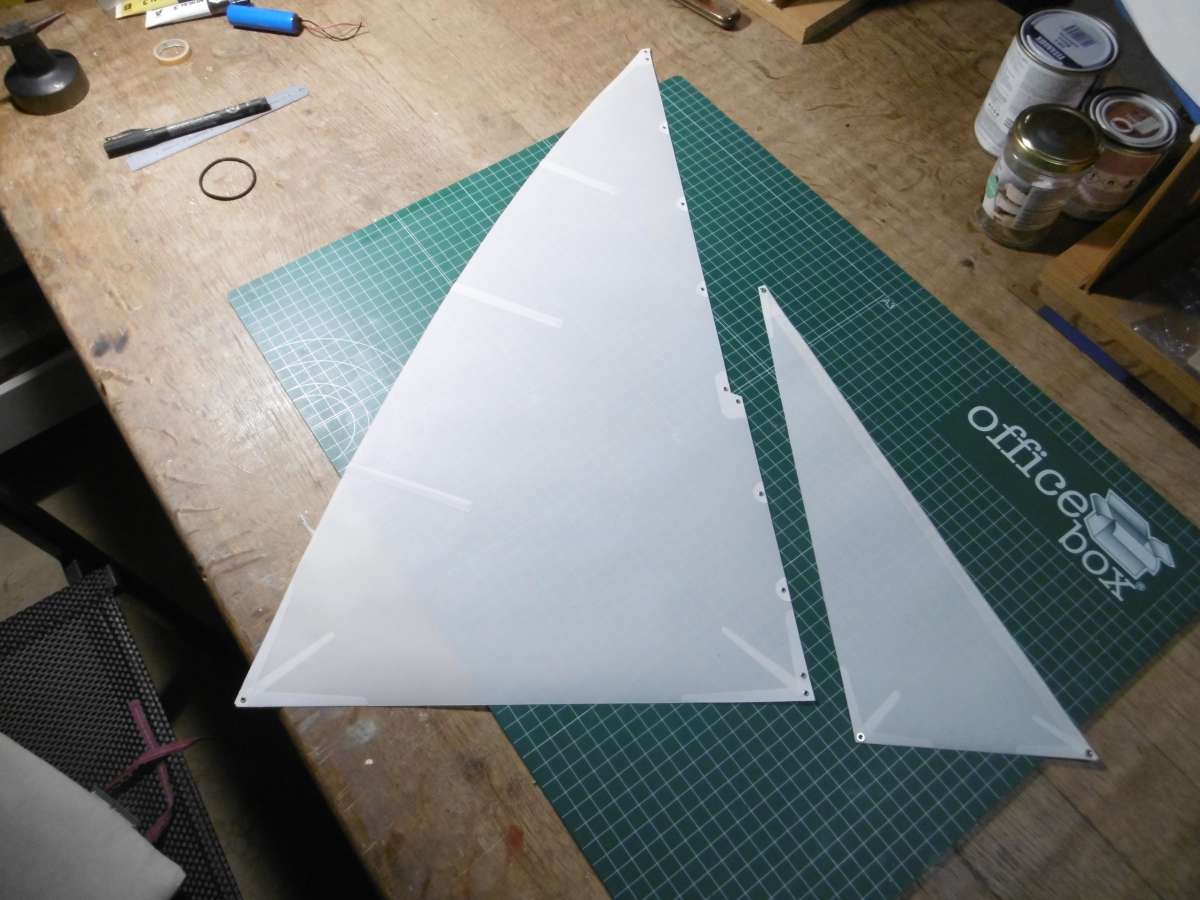

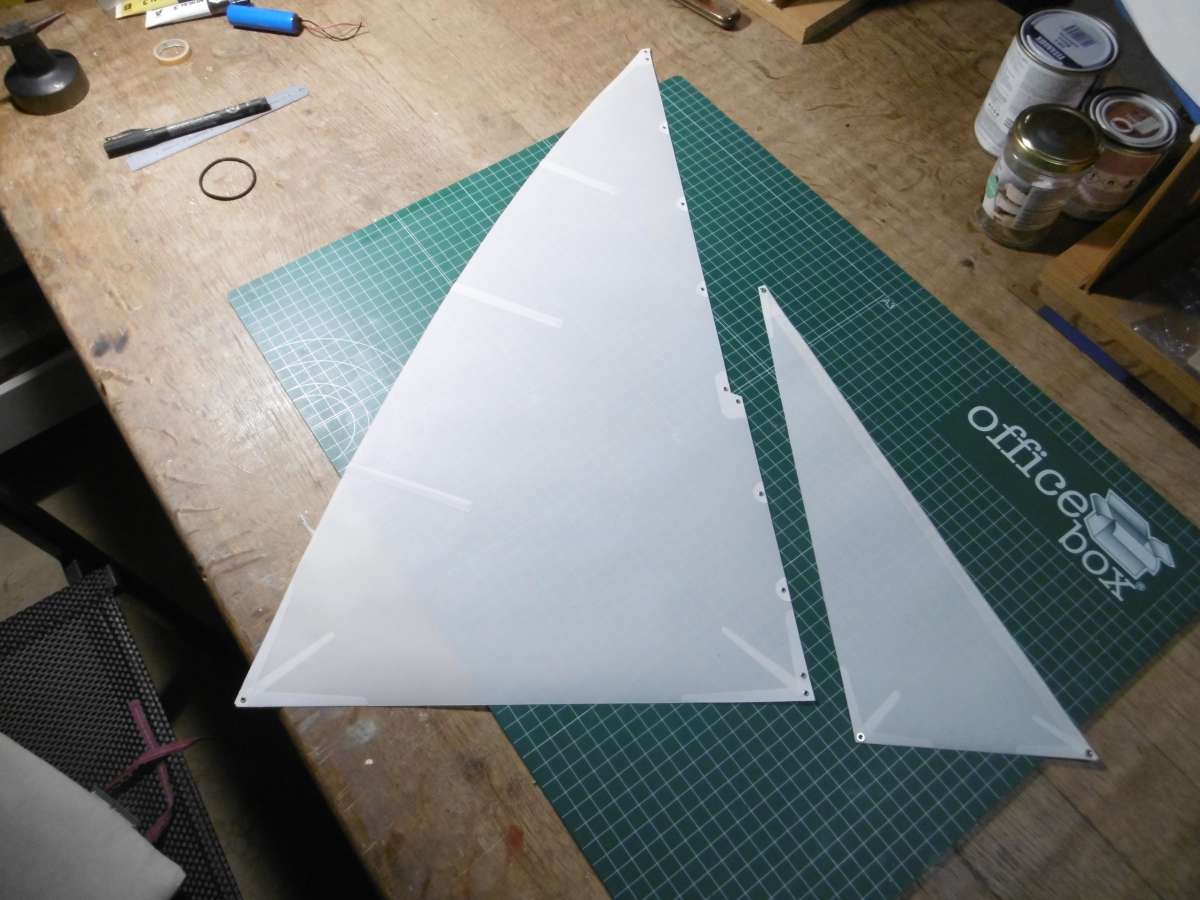

Here are the finished sails ready to be rolled up for shipment. There is quite a bit to show on setting up the sails on the mast and boom but I will describe that in the Wild Duck / Eventide thread to save hijacking Ray’s any further.

I look forward very much to seeing Lysander on the water.

Tim

Ray Wood 3.

Ray Wood 3.