Everyone knows Ray builds at the speed of Warp Factor 10 so it was time to get my skates on and make the sails.

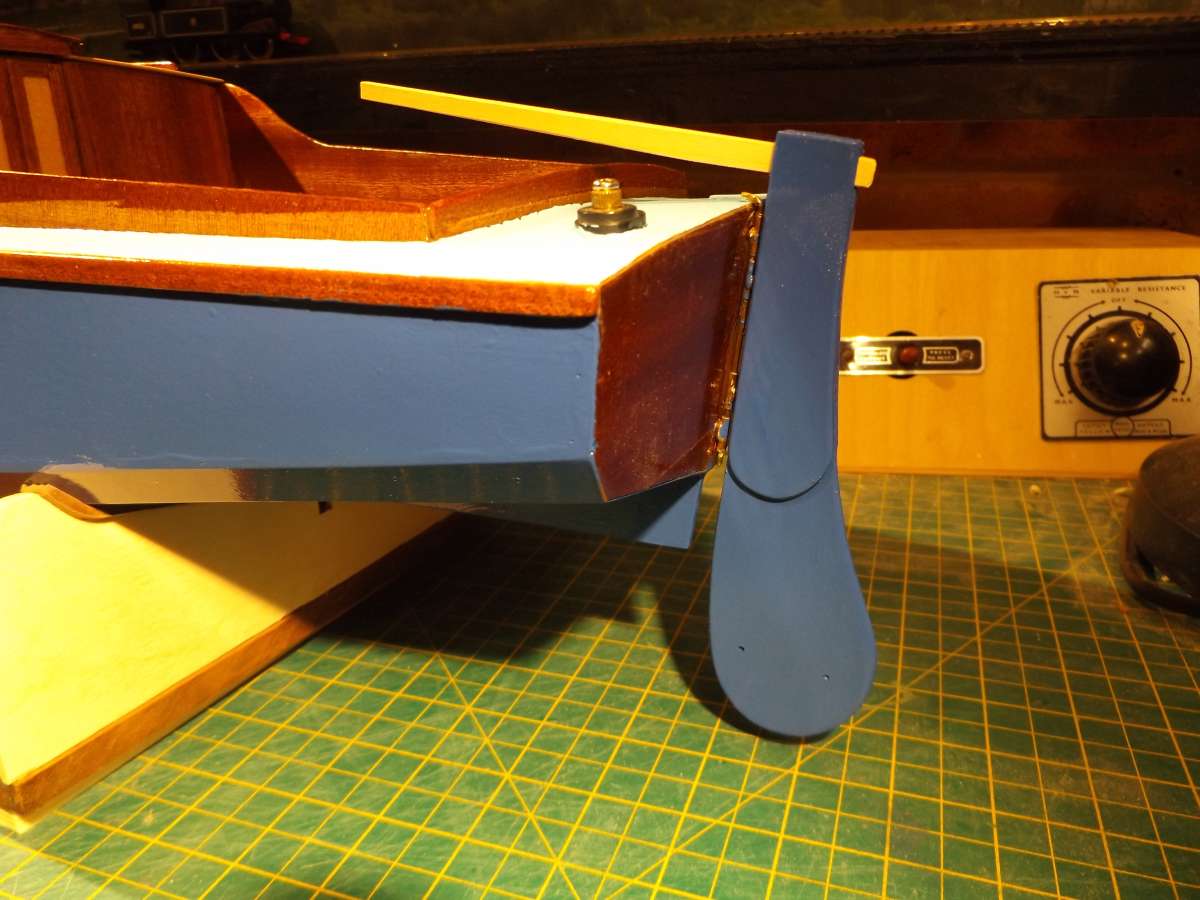

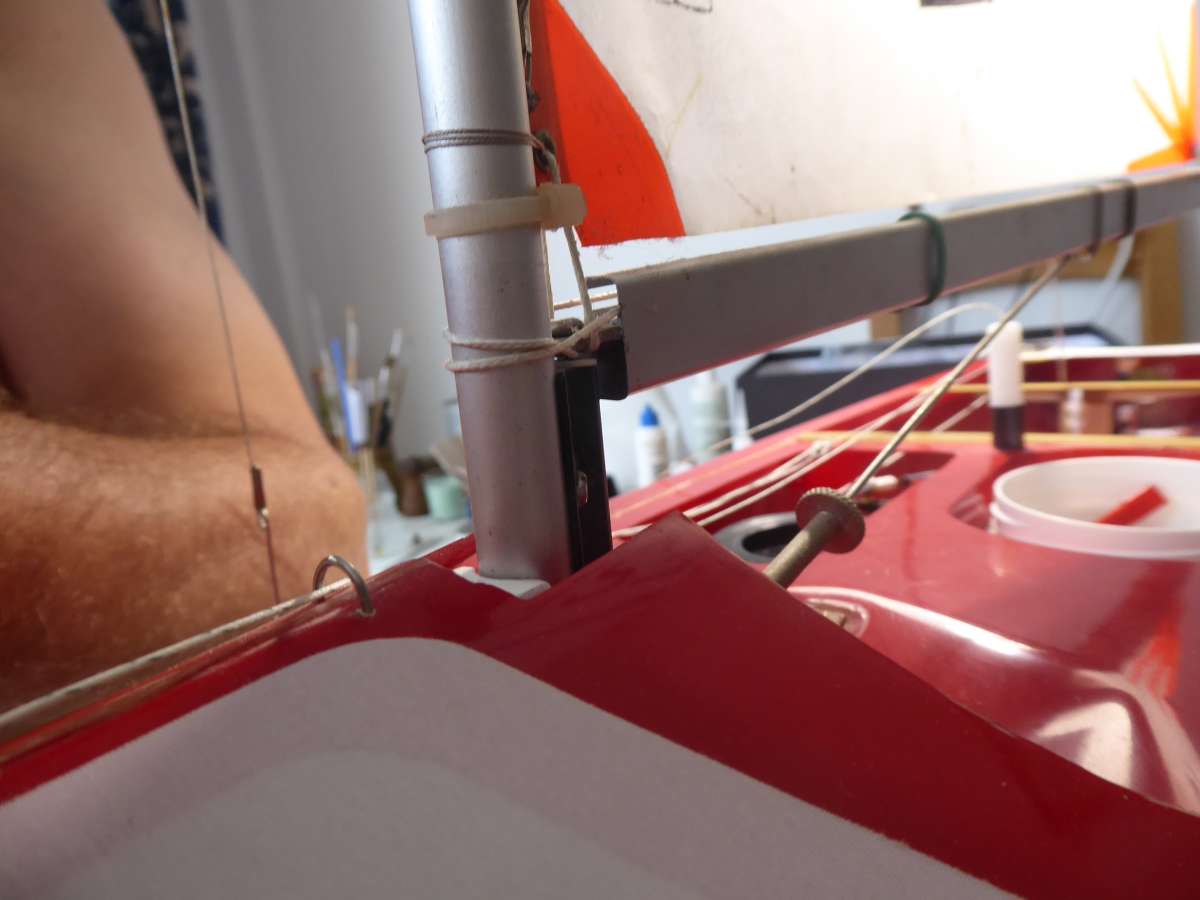

This is what the real thing looks like and the rig is quite distinctive for a number of reasons. The mast is stepped well forward and is large in comparison to the jib. The boom is significantly raised at the aft end presumably to give a bit more headroom for occupants of the cockpit. It is a Gunter rig which is basically a Gaff that is raised right up to snuggle against the mast so it has the appearance, at first glance, of being Bermudan rigged. The advantage of the Gunter is that all the spars fit within the length of the boat which is useful for trailering and camping. This is the same rig on the famous Mirror dinghy and I know Ray has a very pretty sailing model of the Mirror. Perhaps he will post a picture.

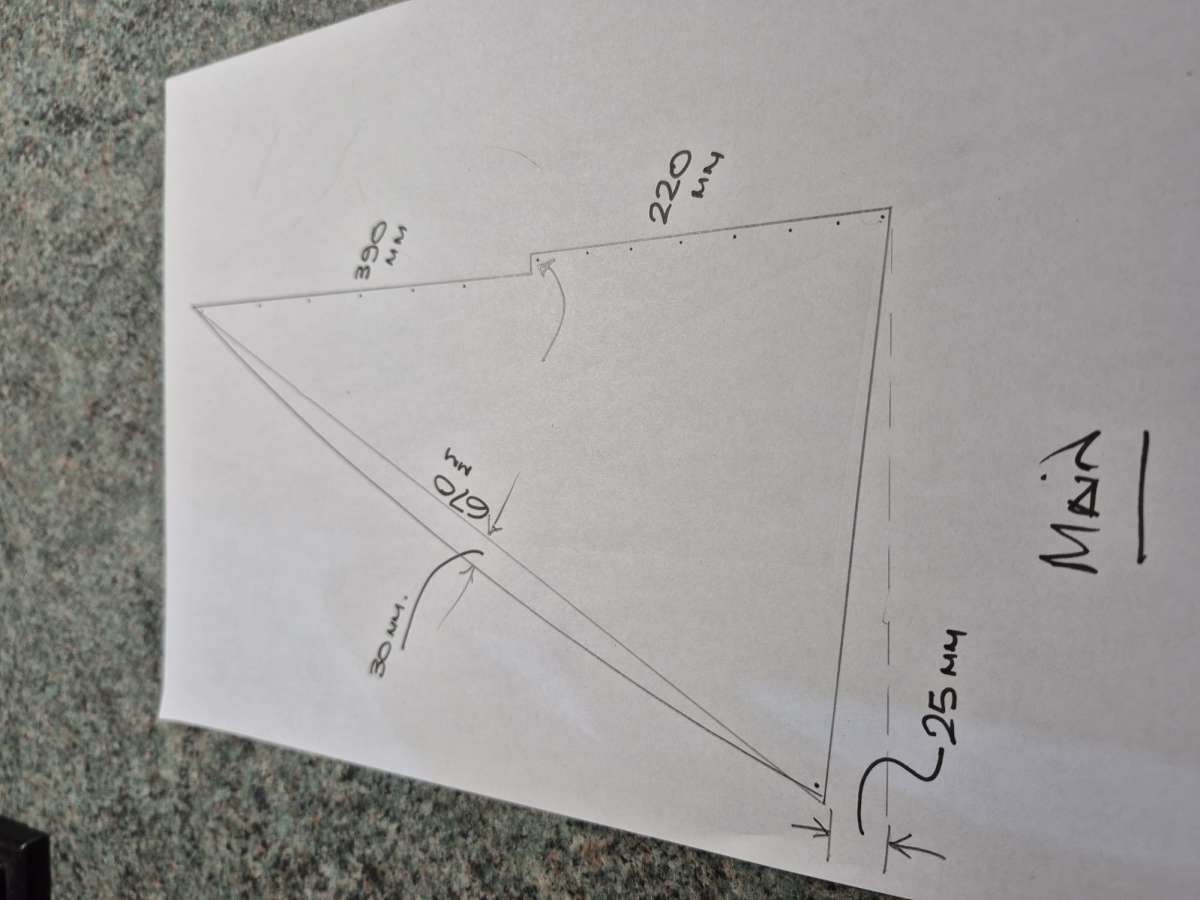

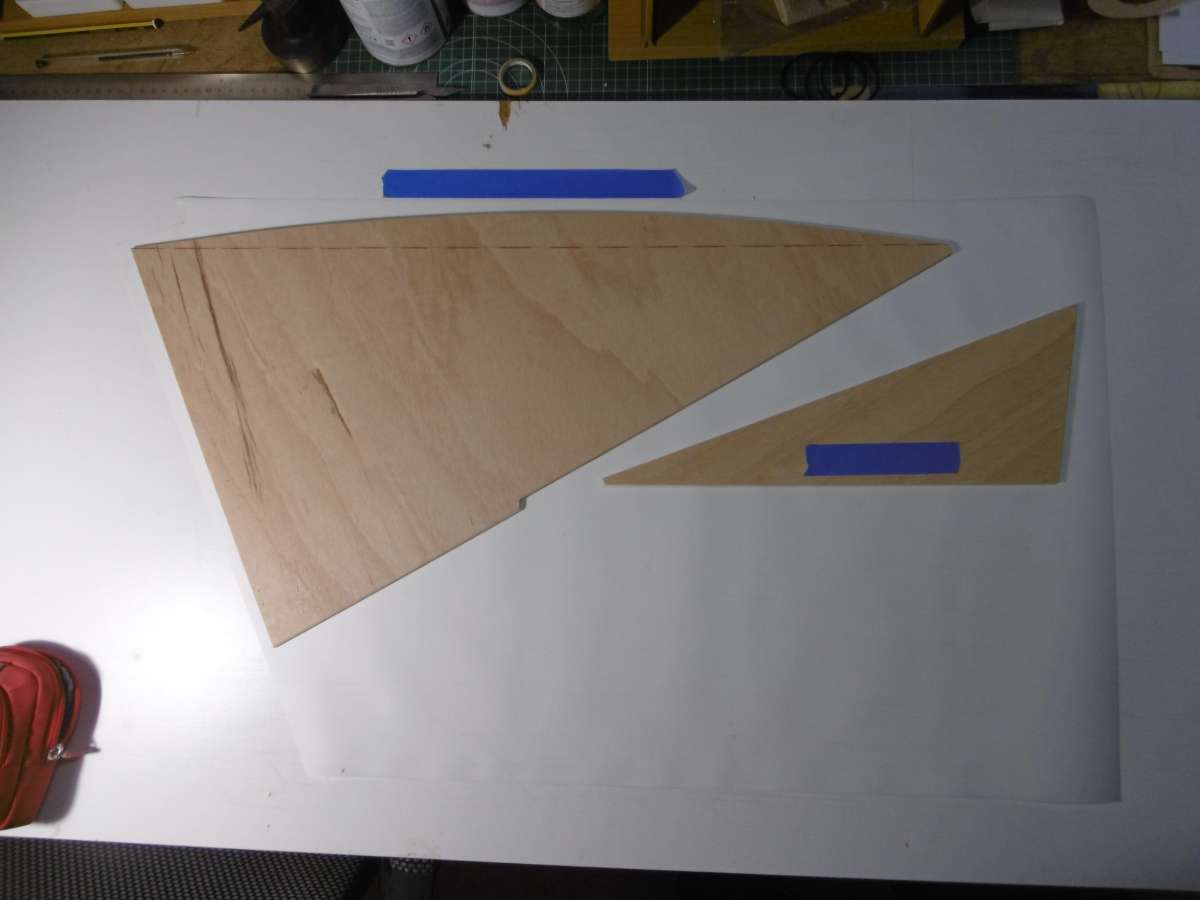

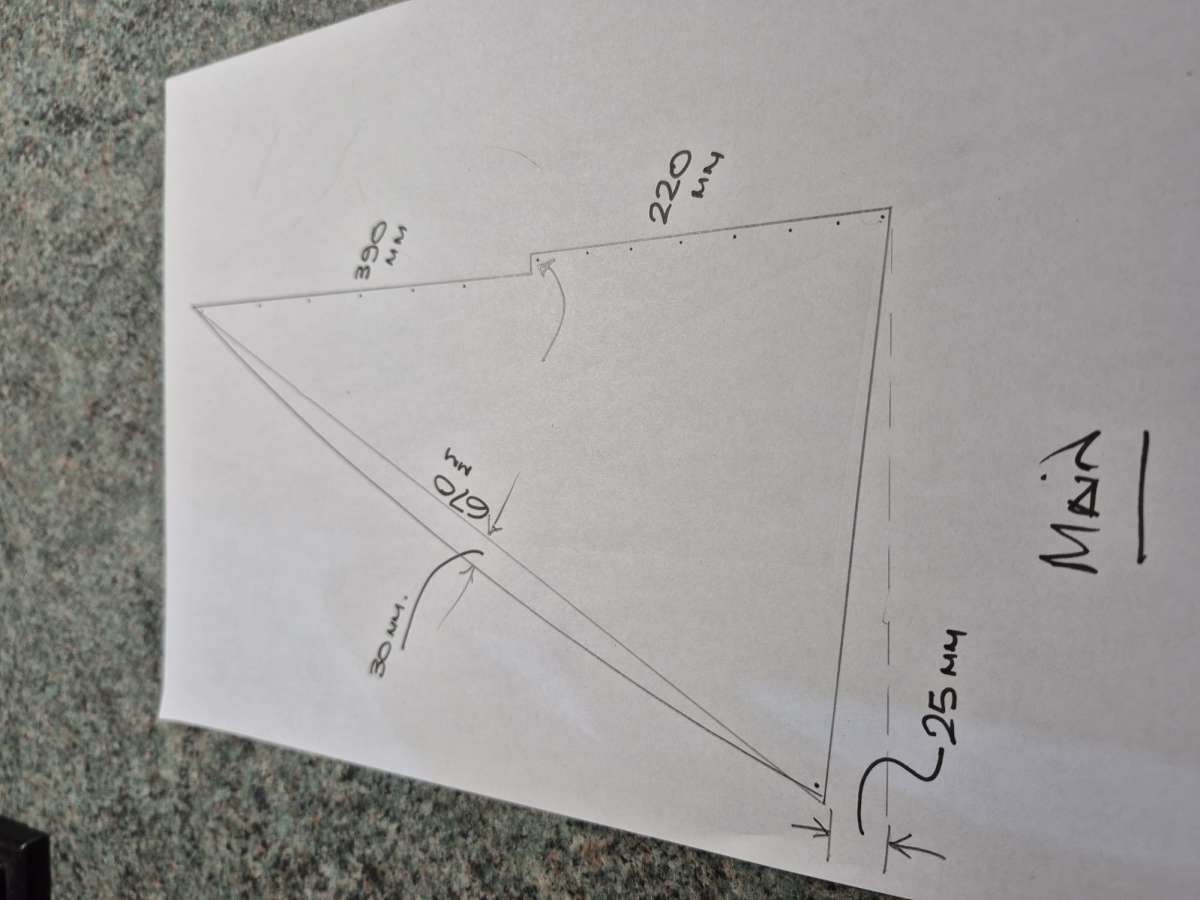

Ray is totally forgiven for the slip-up on the drawings because we sorted it out before anything was cut. Here is the corrected mainsail and the step on the forward side of the sail (luff) is to allow for the gaff when it sits against the mast.

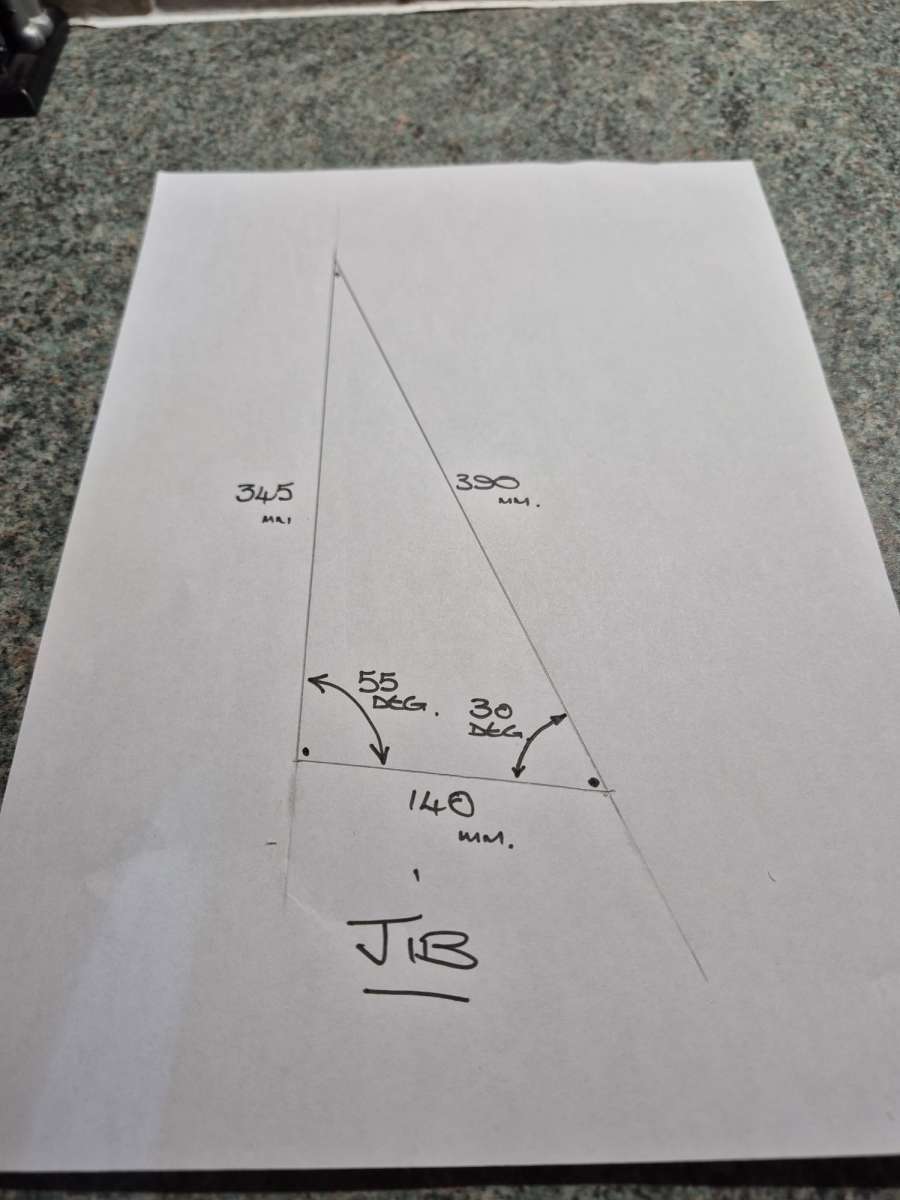

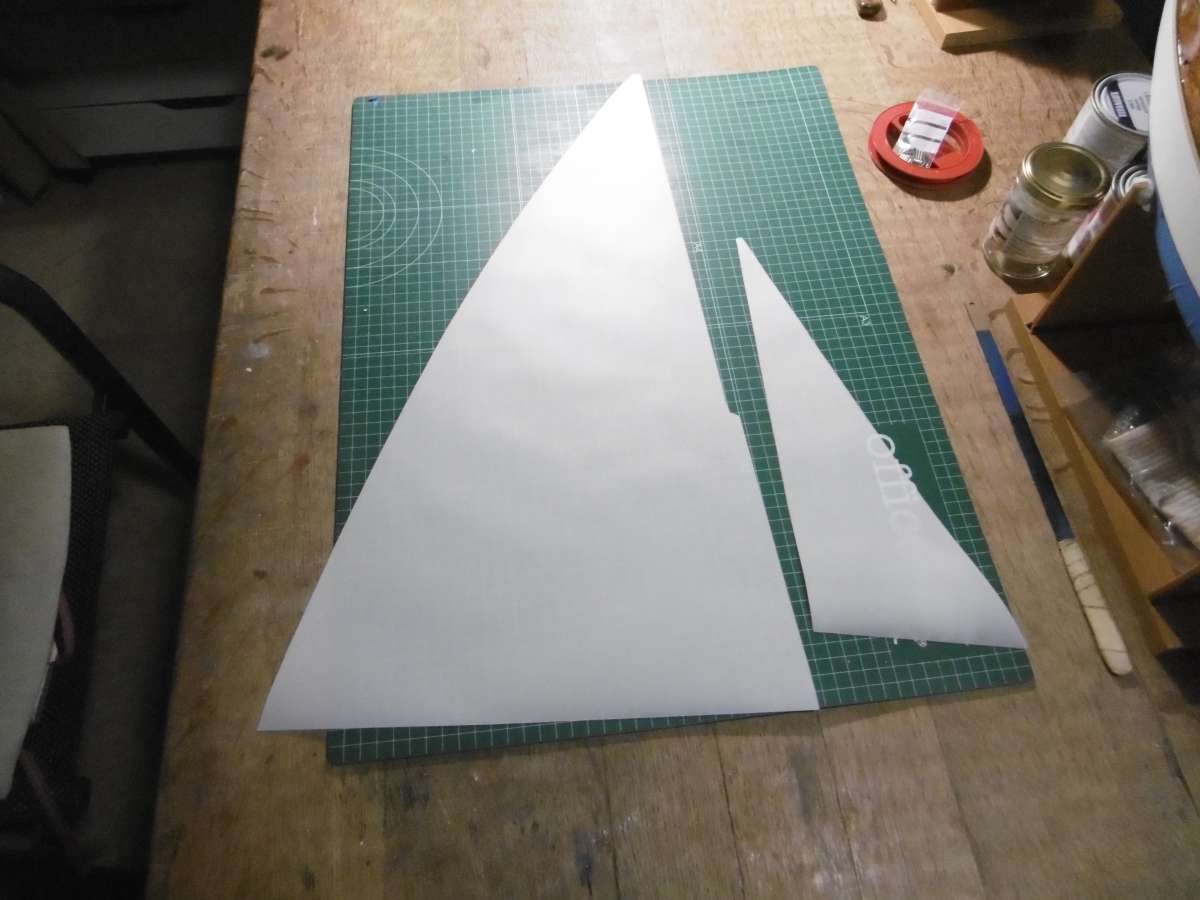

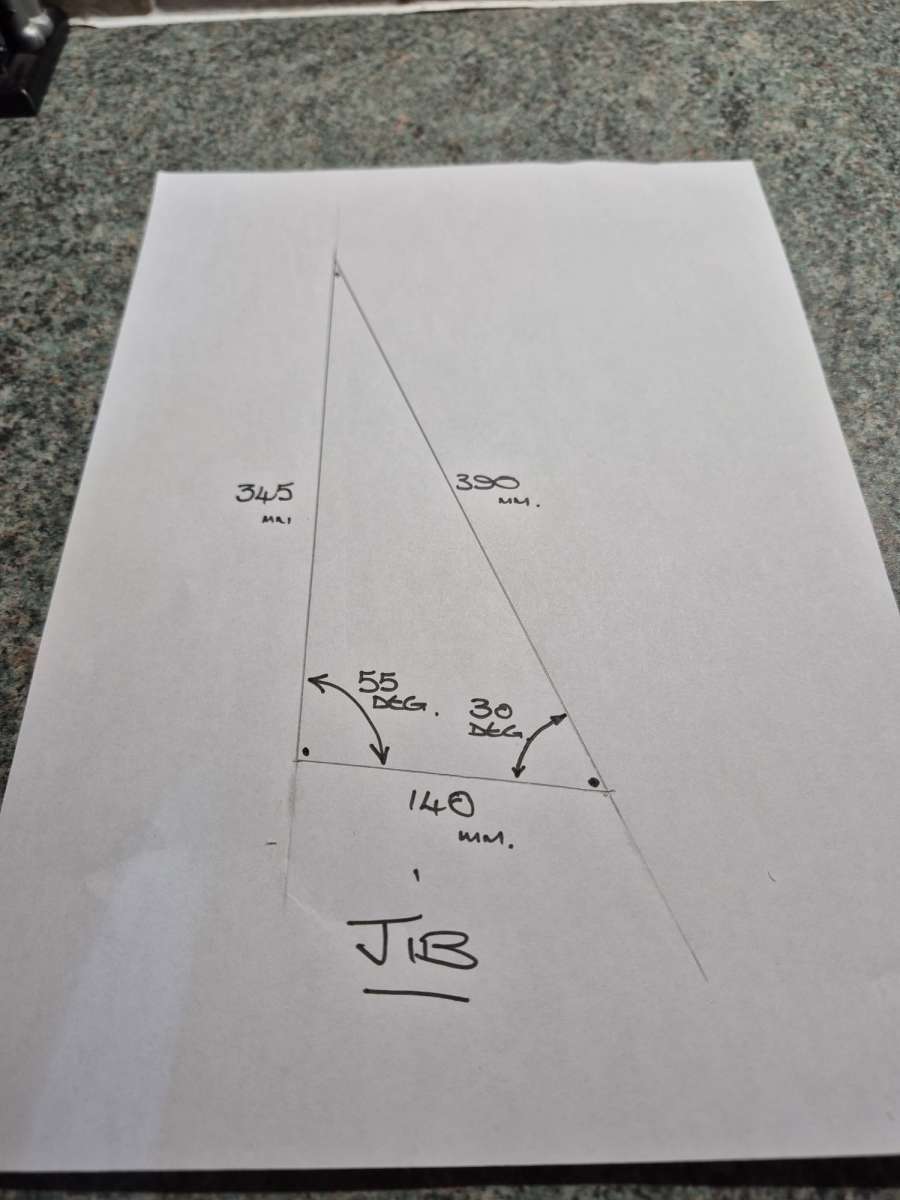

As it says on the drawing, this is the jib with the corrected dimensions but this time we have a little slip-up with the angles. The 30 degrees should be at the top of the sail (Head), the 55 degrees should be where the 30 degrees is at the lower fore end of the sail (Tack) and the missing angle at the Clew should make them all add up to 180 degrees.

Ray will be forgiven when he buys me a beer on his next visit to Mallorca!

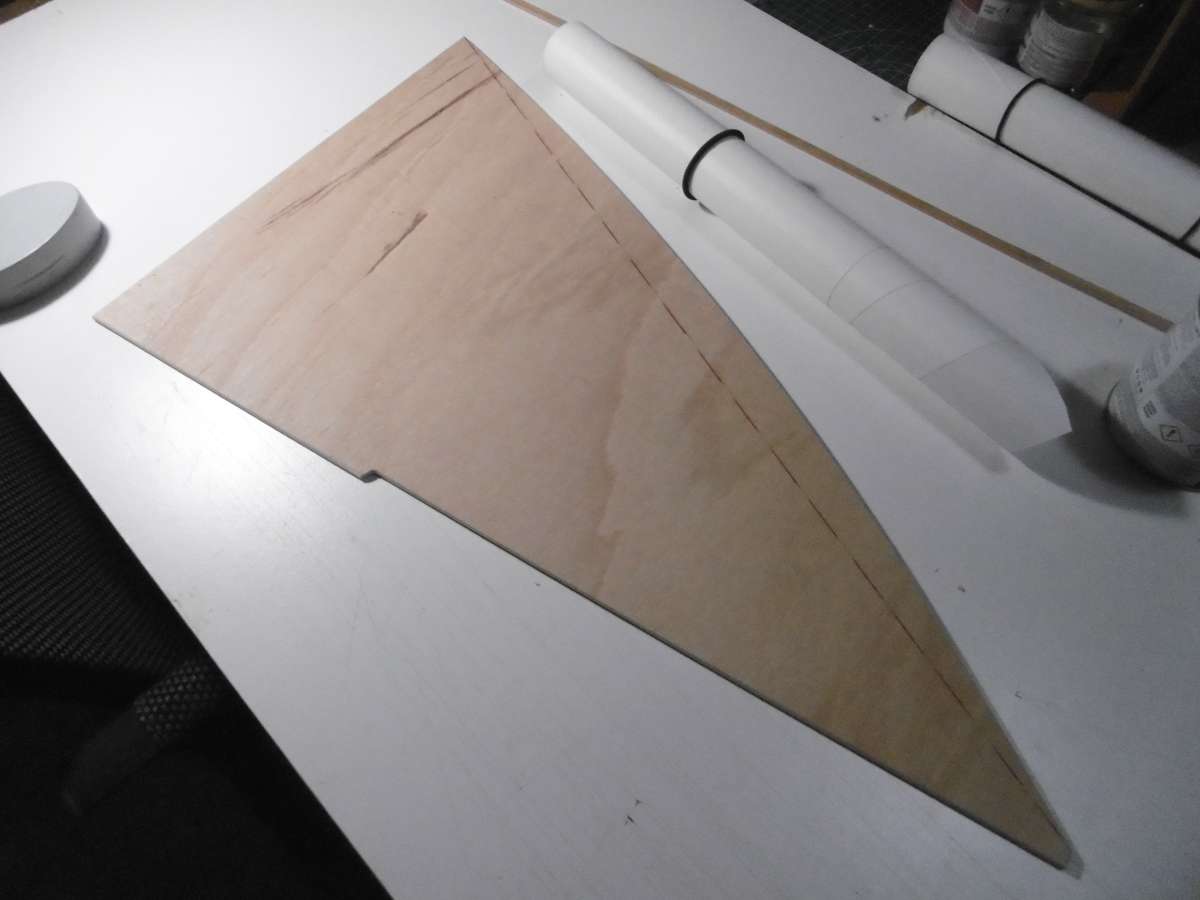

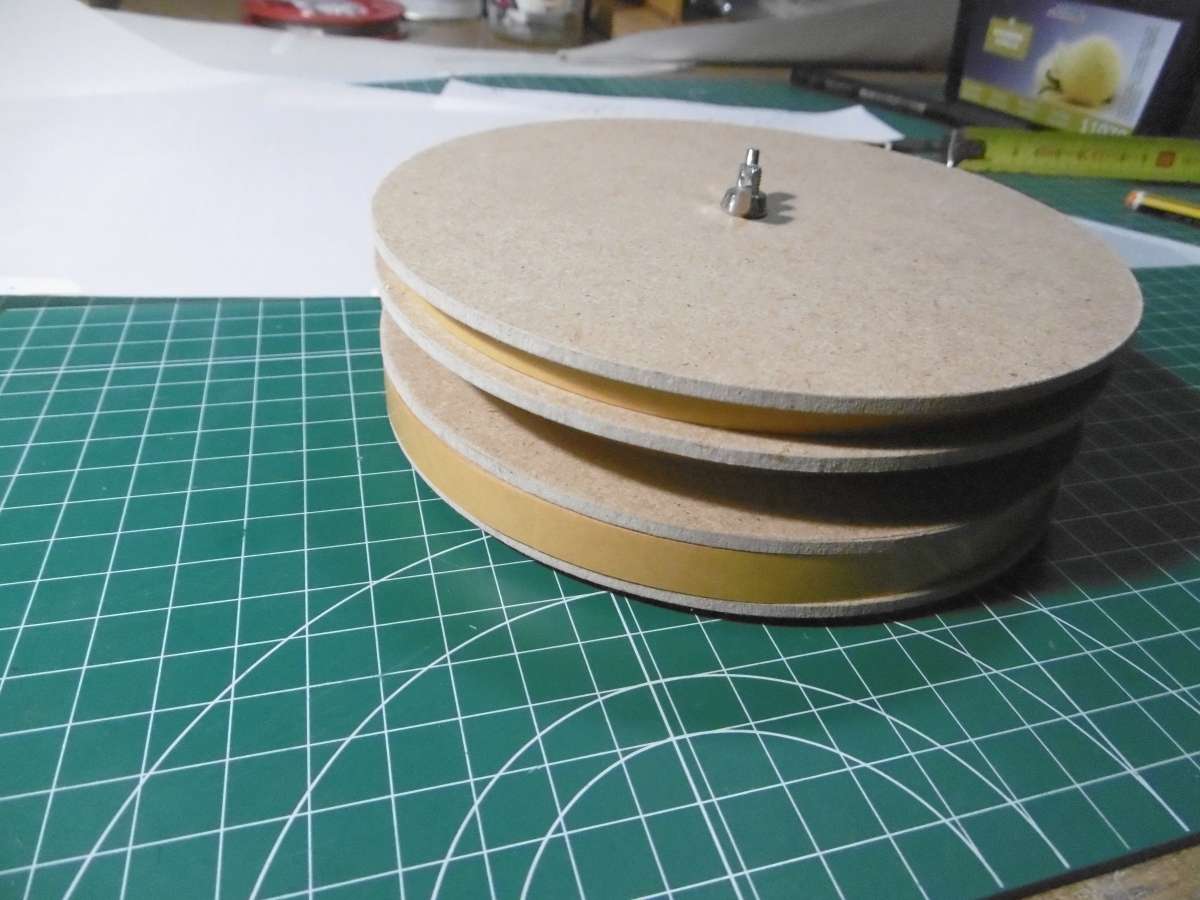

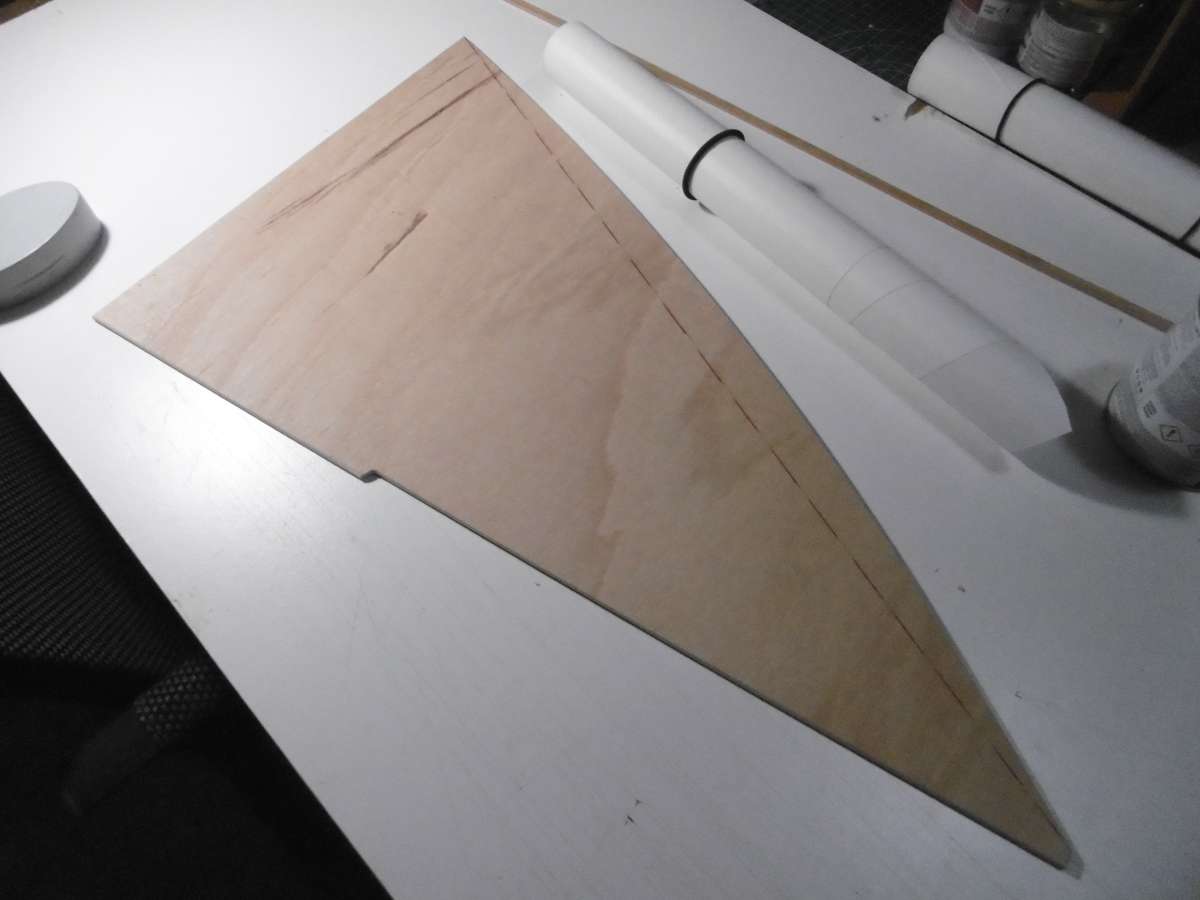

I have made quite a few sails using cloth and Mylar film and I always make a template out of 3mm ply so I am building up a library. Currently I templates for the following:

IOM (A and B rigs)

Eventide

Wild Duck

Thames Barge Veronica

Swallow (A and B rigs)

Gallileo (A and B rigs)

Lysander

The dotted red line is a straight line the head and the clew. The curved area outside the dotted line is called the Roach and provides some extra sail area for free. it also looks much nicer than s straight line. The reason for marking the red line comes a bit later.

At the top of the picture is a roll of the cloth. The cloth is actually quite stiff and even at only 3.5 oz / square yard it is on the heavy side for this size of model. It is important to cut the amount you need for the project and counter-roll it for a couple of days so that following on, it stays reasonably flat.

To be continued.

Tim

Ray Wood 3.

Ray Wood 3.