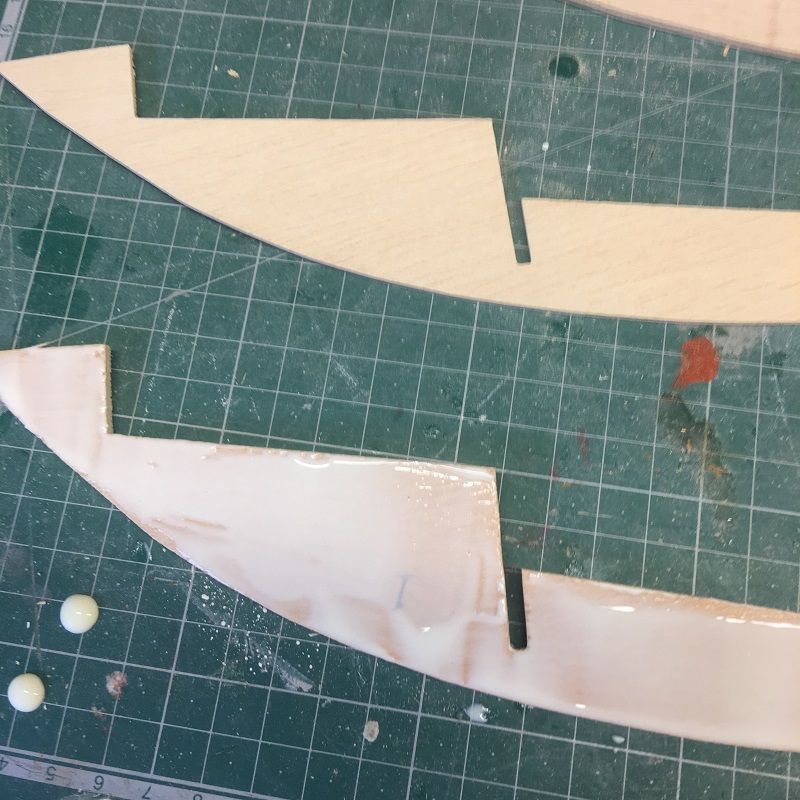

Hi. Tim,yes, all he main parts are CNC router cut, using a 1.5 mm. cutter, making a very clean cut, only needing a light sanding with 600 grit paper, after removing the holding tabs flush with edge.

The deck is laser cut and engraved with the planking lines, there is no room for error what so ever in the size of the sub deck and the side planking before fitting the deck to the hull.

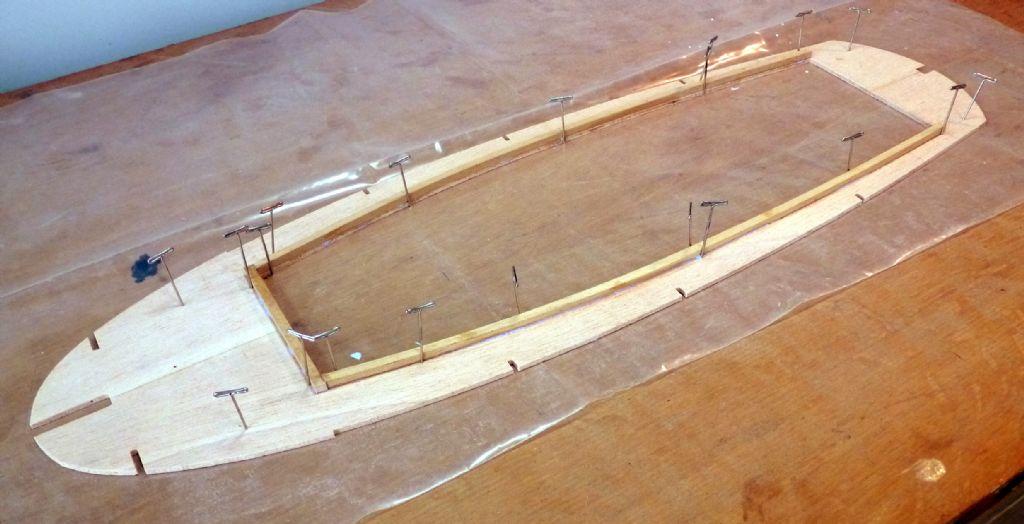

I found out the hard way that the liteply will warp when the glue dries.

When I fitted the 3/16" sq.pices under the sub deck I clamped them instead of pinningthem to a flat board, so as the glue dried it puuled the sub deck, only around 1/8"over the 23 1/2" lengh, but still anoying when it should be flat,I over came the problem by holding the frame onto a flat board with four servo screws, becourse they havea washer as part of the head, I then fitted the bottom skins and they then held the frame flat and true.

Regards.

Eddie.