Why not, eh?

The issue of control. when the boat starts off, there is laods of torque, and the boat steers on this torque like a good un, until the motor wears down a bit, and then the rudder takes more control. This is a bit unavoidable unless a) you have govenor, like a Hornby clockwork locomotive, or b) twin props.

The govenor I thought could be of the simple pivoted weights on sprung restrained arms running inside a drum variety…the faster the shaft spins, the more the weighted arm drags on the drum and slows it down. NOTE; you are not wasting energy as would be the case for an electric boat, as the energy you have in the `band is a set quantity and is excpended, all of it, despite anything like a govenor. Twin props if made contra rotating, would solve this issue. Nylon gears would probably be adequate pushed on to shafts and fairly efficient.

The rubber needs to be lubricated with Glycerene to stop in sticking together when wound into knots. This makes a MASSIVE difference to the use of latent energy as stored etc.

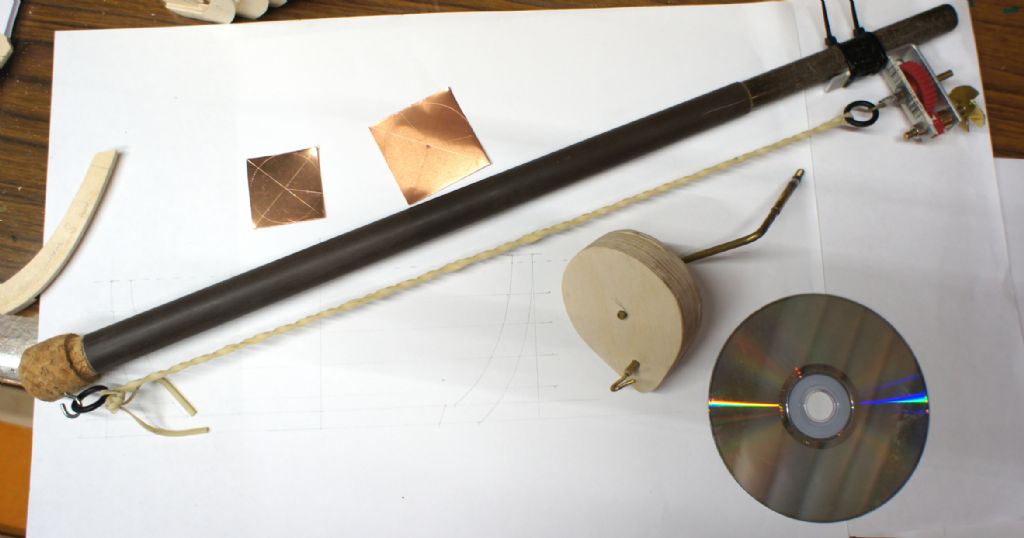

The motor needs gearing UP to drive the prop to get the distance. The bigger the prop diameter, the worse the torque effect. My big stripy boat (4 foot long) was TURNED OVER by the twisting of a 70mm prop on its first test, not that the prop is in the middle(ish) of the boat for better leverage…. I had made a nice well pitched sheetr brass prop in good vintage style, but after this fitted a commercial 50mm 5-bladed prop I happened to have. Some commercial toy kits use a big flight rubber band type prop with no gearing…not sure how efficient this is. It would need to be placed deep in the water, and is too easy.

I have a feeling that of the types of propulsion suggested, a water screw is the most efficient and so would be the method of choice.

A long thin band or skein twists up more than a short one, I would go for max length of boat. On mine the (meccano) gear is as far back as poss so I could get the most rubber in. Two `motors` of 10m rubber each in this case. It would take a lot more, I never dared to try.

The PULL of the rubber is considerable to thought should be given to ensuring the rear drive/cog hook arrangement is adequately free…a little bearing or lots of grease….nylon washers..that sort of thing, and also push fit gears bay be a bit wanting especially the larger one that is connected to the motor although I suppose a grub-screwed collar would be ok to take this force .

I found a small keel useful in keeping the craft upright (to counter initiial torque), but mine was immensley powerful and yours is not likely to need this. My first one was a sort of Bowman Aeroboat copy and didnt have a keel, and was only 2 foot or so long. and 3m or so of rubber.

Obviously you want as light a boat as poss, but it needs to resist the rubber contraction.

A sub of course would be best as is it more efficient at getting through the water.

Notice below how much hull length is wasted by having a conventional shaft drive arrangement as opposed to the second one. One could I suppose use a cat hull for stability and have the motor as a stick in the mddle? Hull-on-water would be much less, whilst keeping with the 50mm limit.

I`ll stop now.

Ashley

Edited By ashley needham on 01/03/2015 14:29:22