Just a quick 'look-in' with a short story and a quiz……

Just a quick 'look-in' with a short story and a quiz……

Oh dear, I've made a king size blunder. My apologies to Ray, and all other lovers of barges, pintles and gudgeons.

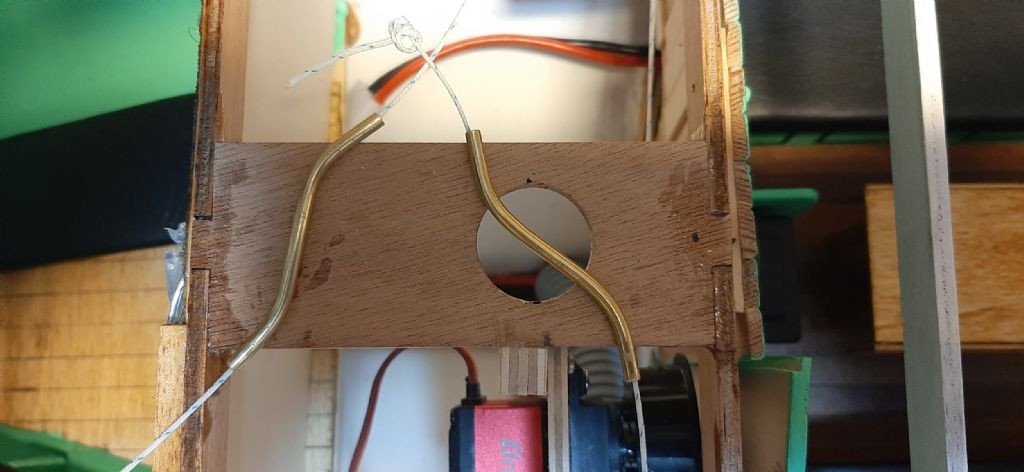

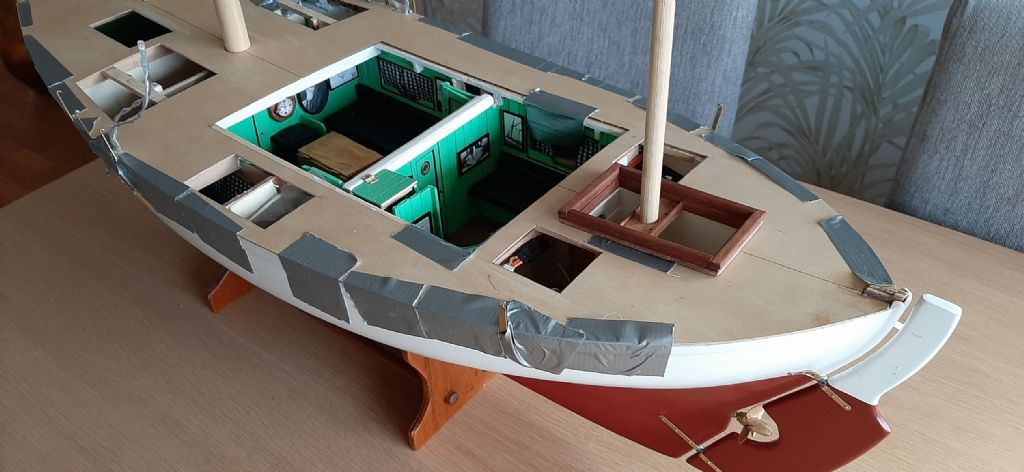

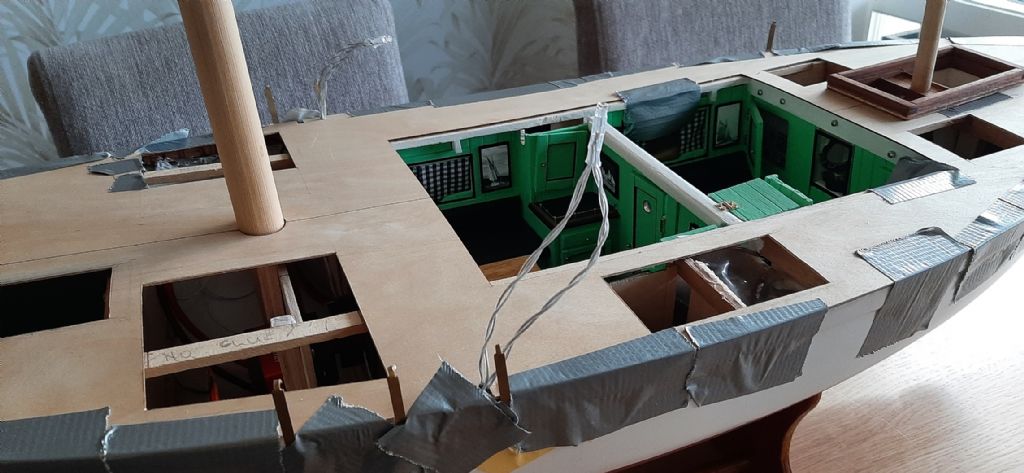

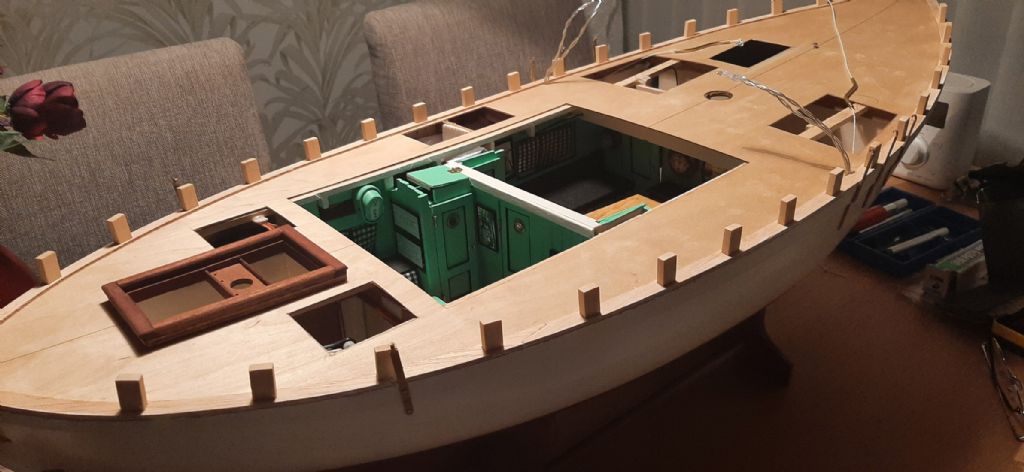

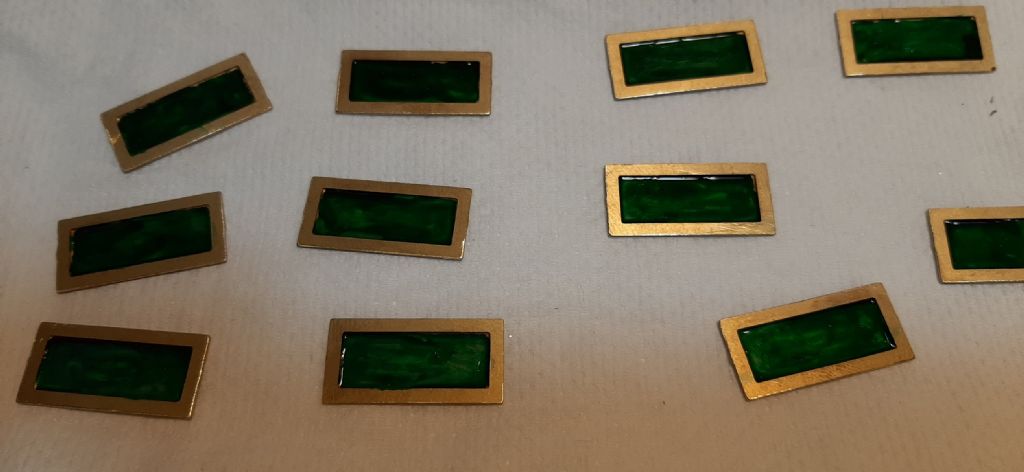

My home-produce pintles were simply not good enough, and I could not see how starting all over again would give a better result. I cut away the gudgeon pin sections and installed the Robart 'hinge-point' units. Then the grey cell kicked in and I decided to use the brass 'arms' of the pintles to simulate….yes, pintles.

When the crew heard about the plan, they arrived in no-time-flat with a surveyor from Lloyds to have a look at the plan. The next day they came back to see the result and all were dismayed at what they saw. Chopper had to comfort his son, Lambchop, The surveyor had a migraine attack.

I did not see the blunder before I looked at my own photos of the end product. I can hardly bare looking at them. All the parts are pinned and epoxied in place  so it's too late to change anything.

so it's too late to change anything.

There is one thing I could do to which might help to hide the blunder, but I'll wait a while before taking any action.

I suspect that the experts will see the blunder immediately. Any suggestions how to disguise it? Paint? Maybe I'll just look the other way. It will hardly be visible when the yacht is afloat.

Maybe I'll just look the other way. It will hardly be visible when the yacht is afloat.

George

Edited By gecon on 01/02/2022 18:06:32

Johannes Jones.