Richard,

Thank you very much for your comments. They are greatly appreciated, even if you haven’t got me convinced.

Even if I could modify the model along the lines that you’re suggesting by simply waving a magic wand, I’m not sure that I’d want to do so, and in practice making the changes would obviously involve considerably more effort (to put things mildly).

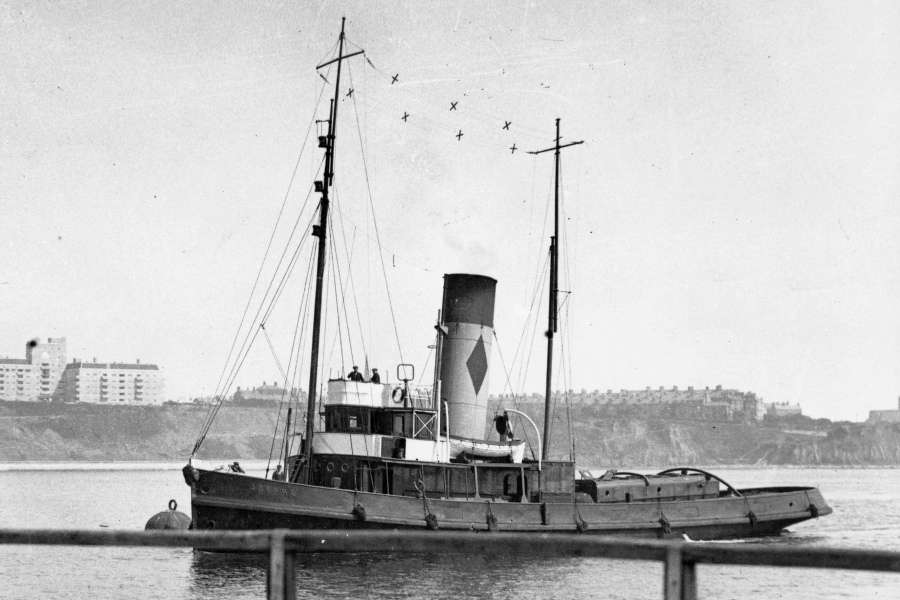

One issue is that I don’t fancy lugging the tug around with all required ballast in place. Rather I envision dropping much of the the ballast in after launching. And obviously getting ballast into the appropriate places would be a lot more difficult (if not impossible) if it all had to go in through superstructure and engine casing openings, particularly given that, assuming a steam plant, one opening would be largely filled by the boiler and the other would be largely filled by the engine. Keep in mind that at best the superstructure opening would be only 1″ wider than the boiler (i.e. 1/2″ on either side), and that with steam and exhaust pipes in place, the engine is a pretty snug fit for the engine casing.

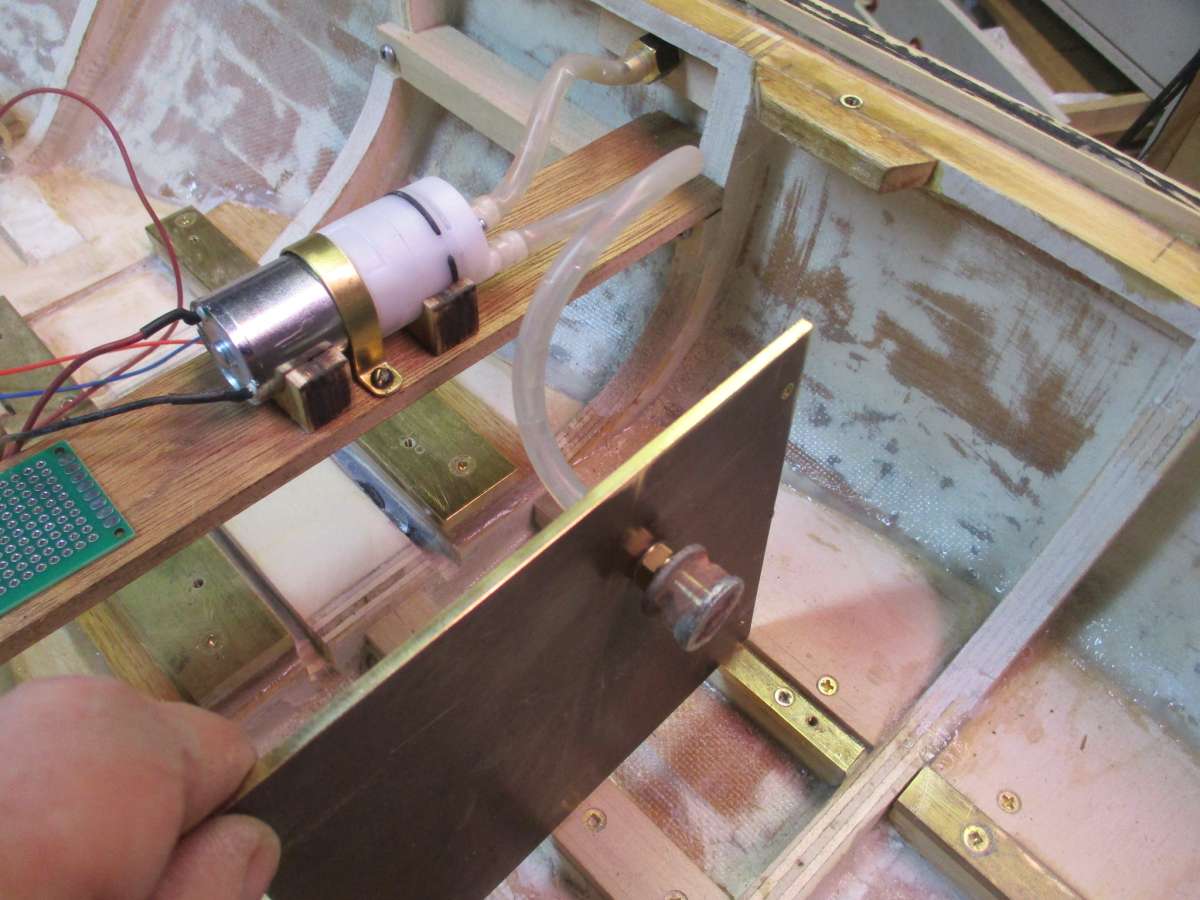

And, yes, there is a definitely an elegant solution to this particular problem. Ideally all of the ballast would take the form of water tanks. These would get filled with pond water (either by natural flooding or pumping) after launching, and would be emptied (using either a pump or compressed air) prior to haul out. But something like this would need to be planned from the outset, and isn’t really a possibility given where things stand now.

And how about the rudder servo and indeed the entire rudder linkage arrangements? As things stand now (hull/superstructure joint) everything is completely accessible should I ever have to change the servo or make other changes. But were I to permanently attach the superstructure to the hull and go with just two openings, everything would become complete inaccessible. I do realize that normal practice is probably to extend the linkage (assumed to be good for ever) so that the servo can be accessed through an opening, but I don’t see this as a viable option for me. Quite apart from the fact that with the steam engine in place it would be difficult to find space for the servo, I want to be able to replace the rudder with a larger one should it prove inadequate, and in order to replace the rudder it is necessary to be able to get to the top of the rudder post. A removable section of some form at the stern isn’t a viable option and even if it were, just how many separate joints can one have before one comes to the conclusion that perhaps just one big joint isn’t such a bad thing after all?

In general I think that a “two opening” solution and a steam plant are almost certainly mutually incompatible. Save for the rudder issue, an electric installation would be feasible, but if steam is going to be ruled out, surely simply largely filling the hull with foam is a much easier way of dealing with probable water ingress than engaging in a massive rebuilding project? And should by some miracle it proves possible to make the hull/superstructure reasonably watertight, I’ll retain the option of giving the steam plant a shot.

I might add in closing that making the superstructure removable would be a major job. Just thinking about it makes me shudder. Just to mention one little issue, two of the stay wires for the funnel terminate on deck. They’d have to be made detachable, and so on and so on. And of course one would have to make the joint reasonably watertight and devise some way of holding the superstructure in place. It would be a nightmare, and in comparison improving the hull/superstructure joint (and installing a bilge pump) strikes me as a relatively trivial exercise.

– John

jcbryant.