Hello All

I am overwhelmed by the many responses I have now had to my call for help. Thank you all.

I accept that the oil I have used may have caused the problem but, if that is so, I am surprised. Many years ago, I was a projector mechanic by trade and we sucessfully used this oil for numerous different types of projector where it came into contact with all sorts of plastics and other synthetic materials. I cannot now remember the exact name of the oil but it was made by Shell and I think it had a name like “rotax”. It occurs to me that if it was the oil, the same problem would have occurred in both cylinders yet only one is affected.

It would help to know what sort of material Cheddar used for the seals in these engines. If anyone knows what it was and, even better, whether that material may be affected by methanol or synthetic oils, I would be very pleased to know.

Someone suggested that the stiffness may be due to mecahnical misalignment. That does not seem to be the case as, when I remove the cylinder assembly, it is clear that the stiffness is in pushing the piston back and forth.

Someone else asked about the origins of the engine. The complete plant was purchased new from Cheddar by a collector some years ago (not sure how long). He died last year and I purchased it from his widow.

One possible explanation which has just occured to me is that the original owner may have tried to lap the vavle face on the cylinder in question. The assemply instructions specifically warn against this for the very obvious reason that it will inevitably result in abrasive getting into the cylinder. If this is what happened, it would explain why the problem is occurring in only one cylinder. Would this be consistent, however, with the problem only coming to light when the engine got hot?

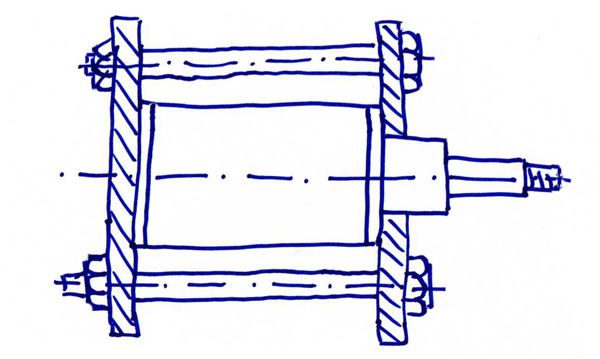

The conclusion I am coming to is that I will have to dismantle the offending cylinder. If this reveals that the seals are damaged, does anyone know where I can obtain replacements, either original or suitable substitutes?

I appreciate the warnings about the need for care in reassembling the cylinder if I do dismantle it. A technique we used to use in similar situations on projectors was to lightly pop with a centre punch one of the surfaces which have to be pressed back together. This effectively creates a mild interference fit which, in conjunction with a little loctite, makes a sound joint.

If anyone has any further suggestions, they would be greatly appreciated. In particular, if there is anyone who has had actual experience in dismantling or servicing this particular engine, I would be very interested to hear their views.

Regards.

Tony