Hi Folks,

Since making enquiries about the ‘chilling effect’ on LPG cans I have made a new LPG tank hydraulically tested to 320 PSI. It has three valves based on the designs by a combination of Martin Ranson and Peter Arnott both of whom have written for Model Boats.

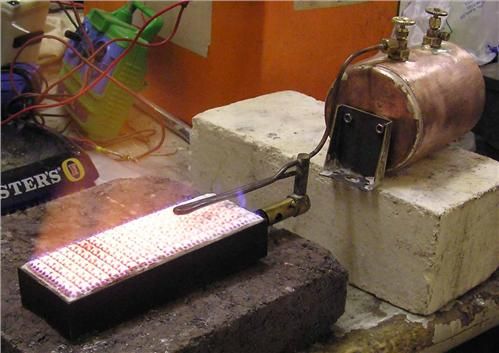

One valve is for venting when filling, as advised by Mr Ranson. The two other valves are, one for gas and one with a pipe which has an inner pipe which reaches the bottom of the tank. This pipe also has a gauze filter as I am led to believe that LPG can be dirty. The two valves have outlet pipes which join to a common connection and thence to the burner connector. The Tank is fitted with a pressure gauge which has a range of 0 -100 PSI. All conncetions are 1/4" x 40 tpi coned fittings, silver soldered as is the tank shell and the bosses for the valves. The tank and all pipework is thick walled copper.

The burner is started by turning on the gas outlet (the liquid valve is closed at this stage) and lit in the nornal manner. The pipe which is attached to the jet block makes two turns around the outside of the entry end of the centre flue where it is reasonably warm but not in the flame and then passes to the jet block.

After the burner has been burning for about ten minuted the valve which allows liquid fuel to pass to the jet is opened and the fuel is warmed as it passes round the coil of pipe round the centre flue entry pipe.

The liquid fuel which is thus vaporised burns without any ‘flaring’ and the gas pressure inside the tank is what pushes the fluid up the supply pipe. Pressure shown on the gauge is about 40 psi when the gas valve is opened and this remains at the same pressure when the liquid fuel valve is opened. When the burner is stable the gas valve is closed and the burner runs exclusively on liquid fuel. This arrangement was described by Peter Arnott in his article about building a V-Four oscillating engine.

Since the gas is not being vaporised by the ambient air outside the tank the can remains at the ambient temperature and the burner continues to burn until all the liquid has been used. If the valve is turned off before the can is empty the pressure can be seen to fall as the residual gas in the supply pipe is used up.

I have seen this arrangement on a boat at Harrogate although I did not get the opportunity to talk to the constructor, so I make no claims whatever for originality.

I also acknowledge the articles by messrs Arnott and Ranson who have given me the leads to develop my arrangement and thus far it is proving very satisfactory.

Hapy steaming, all the best, Fred Graham