Hi Dave,

I found it's best to do a trial assembly of the whole thrust line : Motor-Coupling-Shaft-Prop'. This should show up where you have 'free play' in the system.

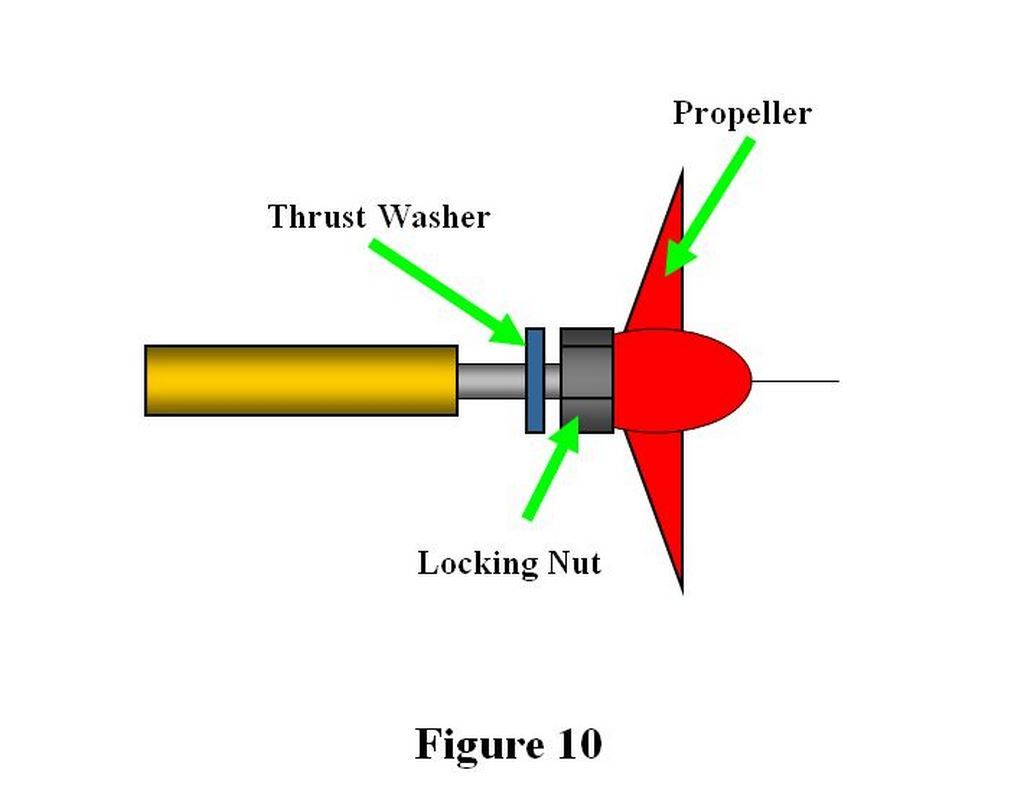

On the pilot cutter, my shaft was about 2-3mm too long to make the prop a snug fit to the bushing. I trimmed the threaded end with a junior hacksaw and filed off the rough edges (Tip: leave the nut on while you saw the end off ,this will help 'de-burr' the cut end).

For your motor end, I would file a small 'flat' on the shaft so that the little grub screw in the coupling has a good 'seat' to bear on. This should help to prevent any slippage between the coupling and the shaft.

All this can be done before the shafts are installed in the boat. When fitting the prop, you can always use a drop of thread lock for added security. I use Locktite (but other brands are available !).

I also found it useful to have a little adjustability in the motor mount, fore-and-aft and side-to-side. One other thing to think of is whether (or not) the motor end of the shaft will be above the waterline. If it's below, I usually pack the two ends of the shaft with a little Vaseline (or, similar). Otherwise, be prepared to regularly mop out…

Please shout if there's too much jargon here…

Regards,

Dave