Quick update. Done the keel bulb halves and my face hasn't fallen off and my lungs, liver and kidneys are still functioning I think, thanks to the windy weather we've been having, (and the PPE)

Had to order a small amount of scrap lead from fleabay. The Lorry battery didn't give me as much lead as I was expecting. I got 4lb 5oz, basically the terminals and the bits connecting the plates.

I first emptied out the acid then neutralised the plates with a bicarbonate of soda solution, left it overnight and emptied it out. Then with the help of an angle grinder I opened the battery, I had overalls, glasses, facemask and gloves on obviously. The terminals and bits connecting the plates were easy to liberate and melt down with a blow lamp the plates however needed more processing than I was able to give them, they yealded very little lead. The amount of energy used to get the lead from the plates outweighed the amount of lead I got so I gave up.

Anyway, I'm glad I did it, it was a dirty job but I won't be doing it again! I'll buy it from eBay!

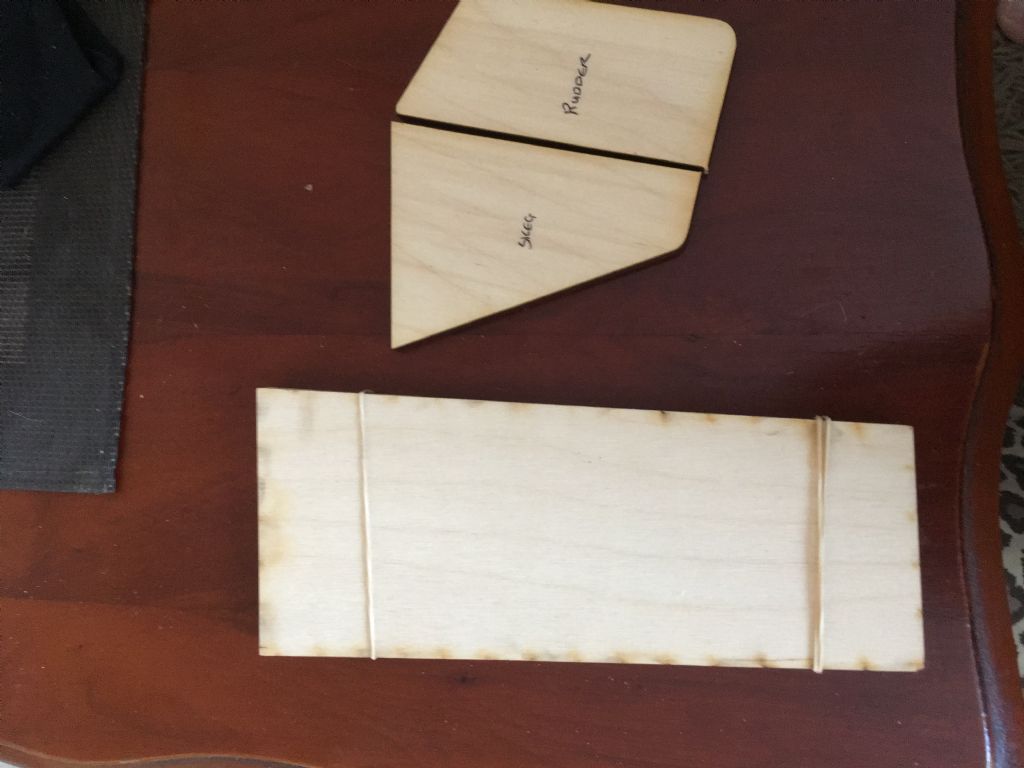

Sail winch and rudder servo fitted and working, just got to work out how to get the sheets through the deck and the cabin roof, made both booms as per the plans from 3/8 inch spruce. Next step is the mast, deck on and cabin built, obviously after I've sorted the sheeting conundrum.