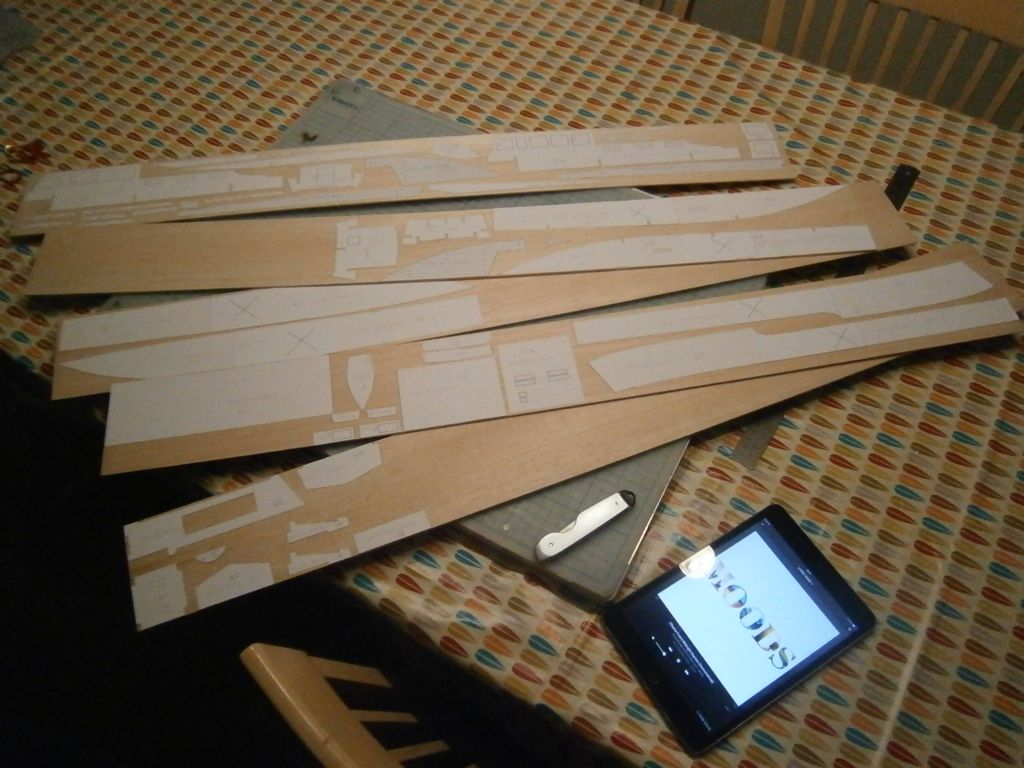

Right Progress report time

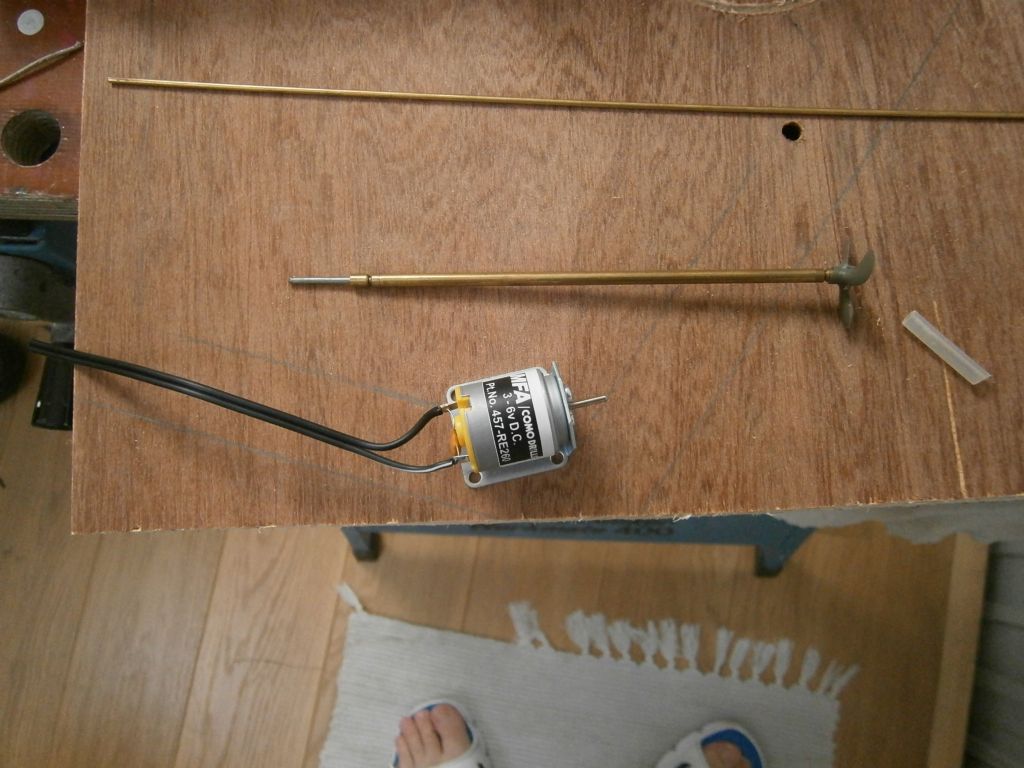

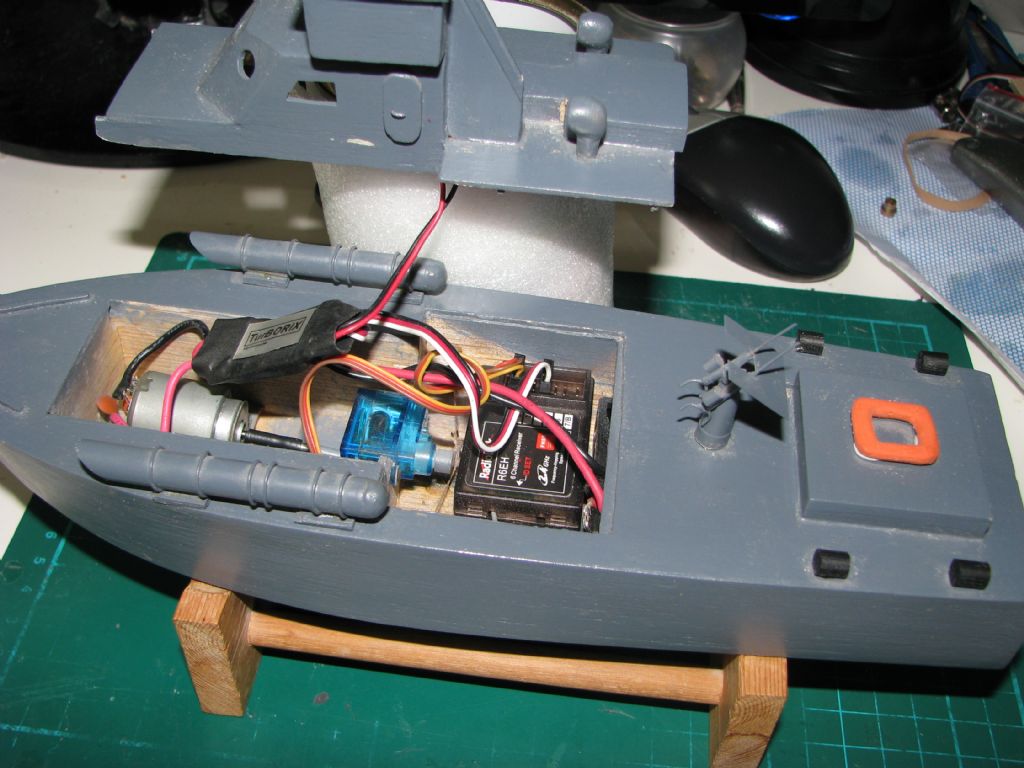

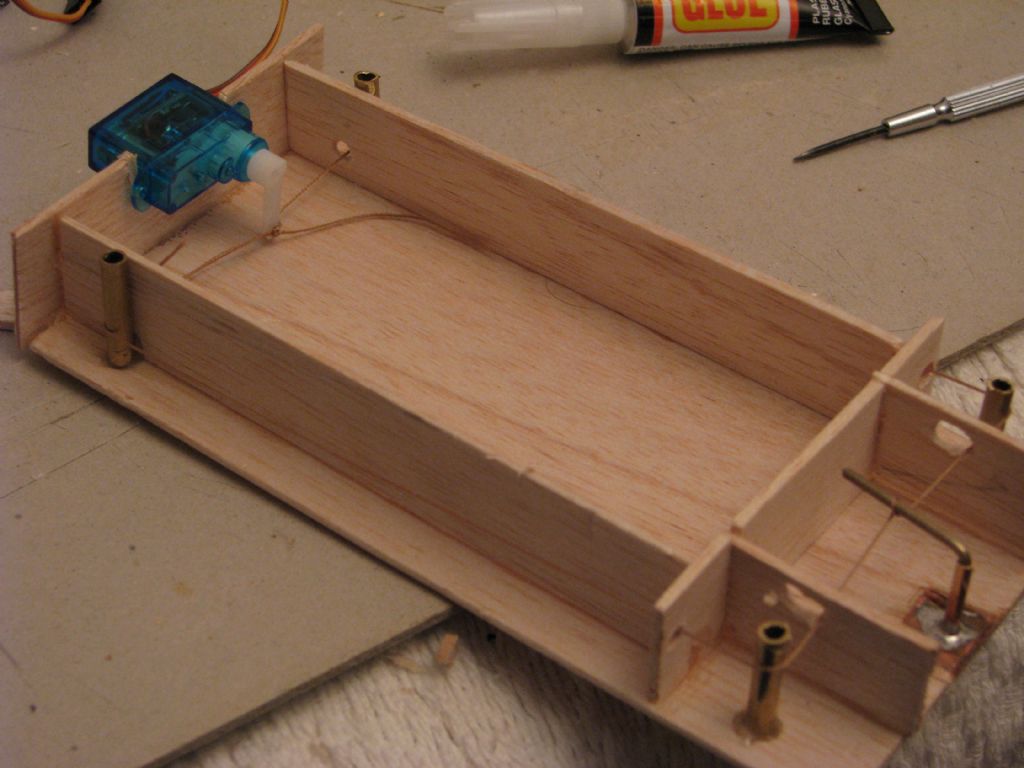

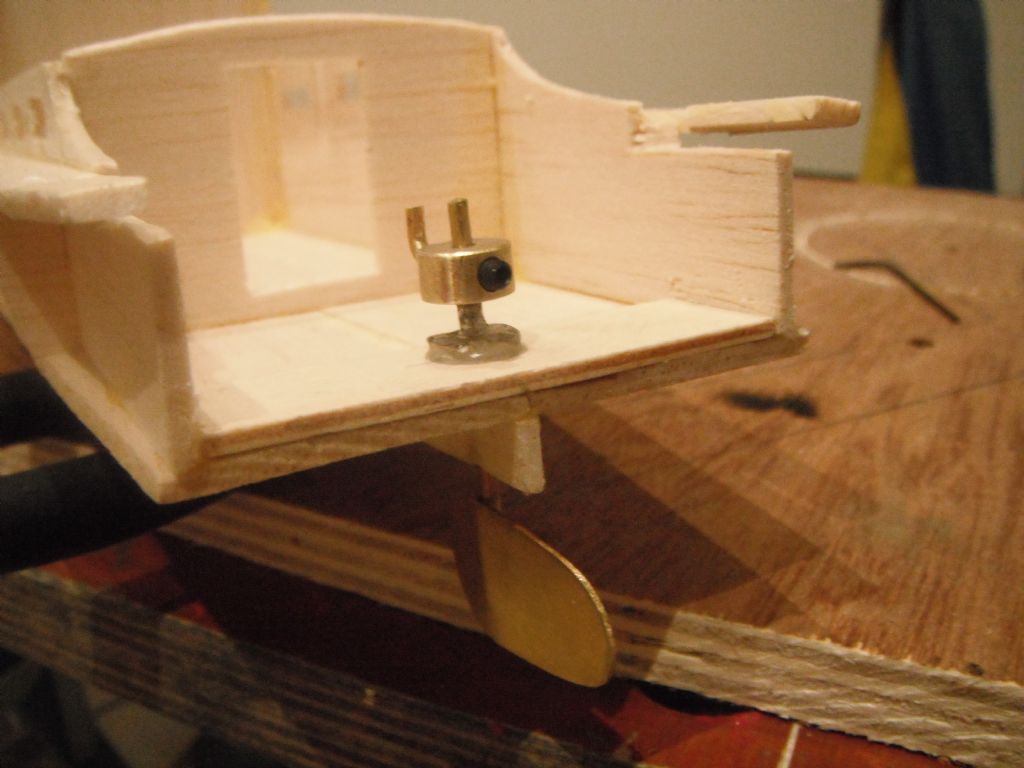

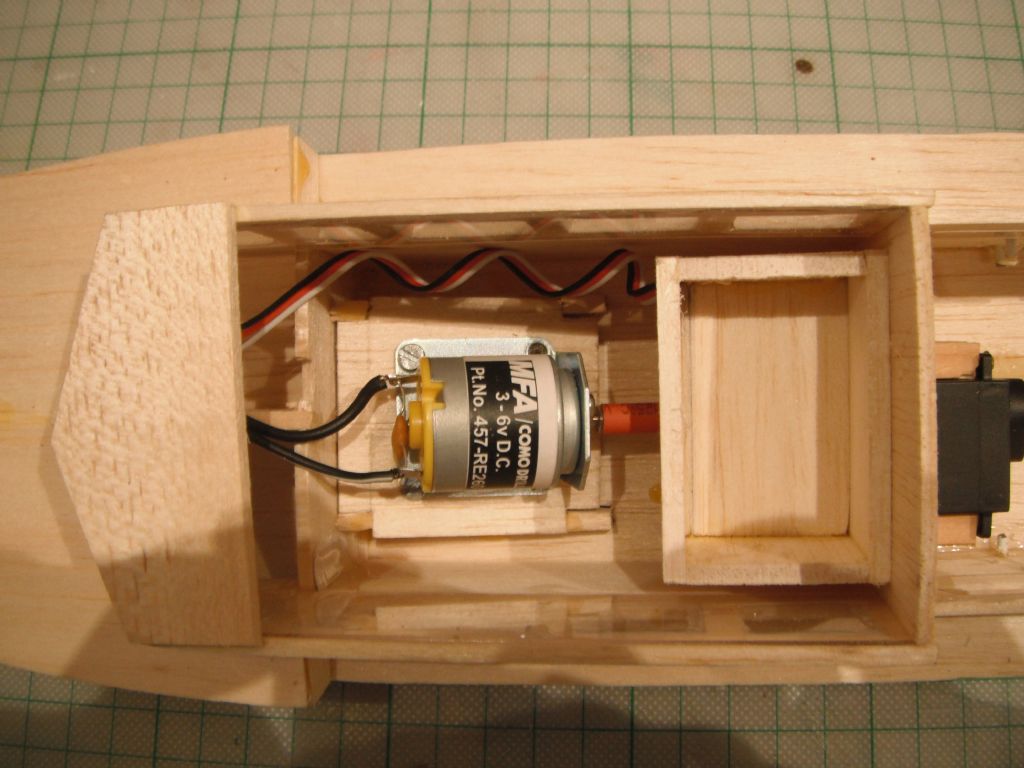

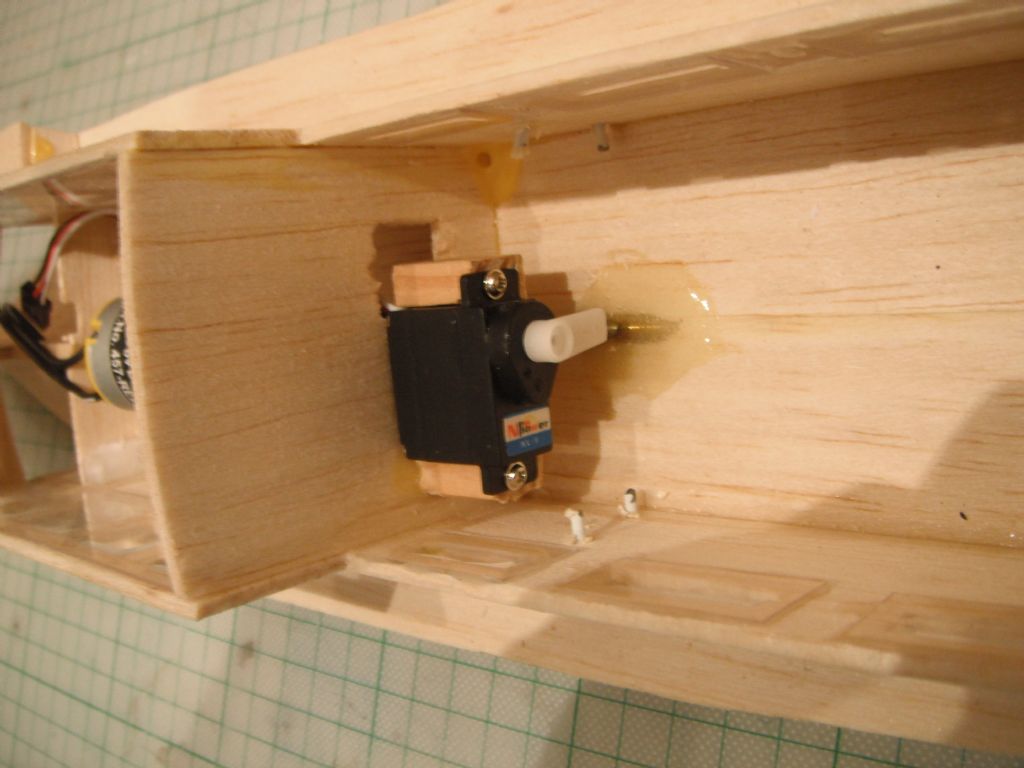

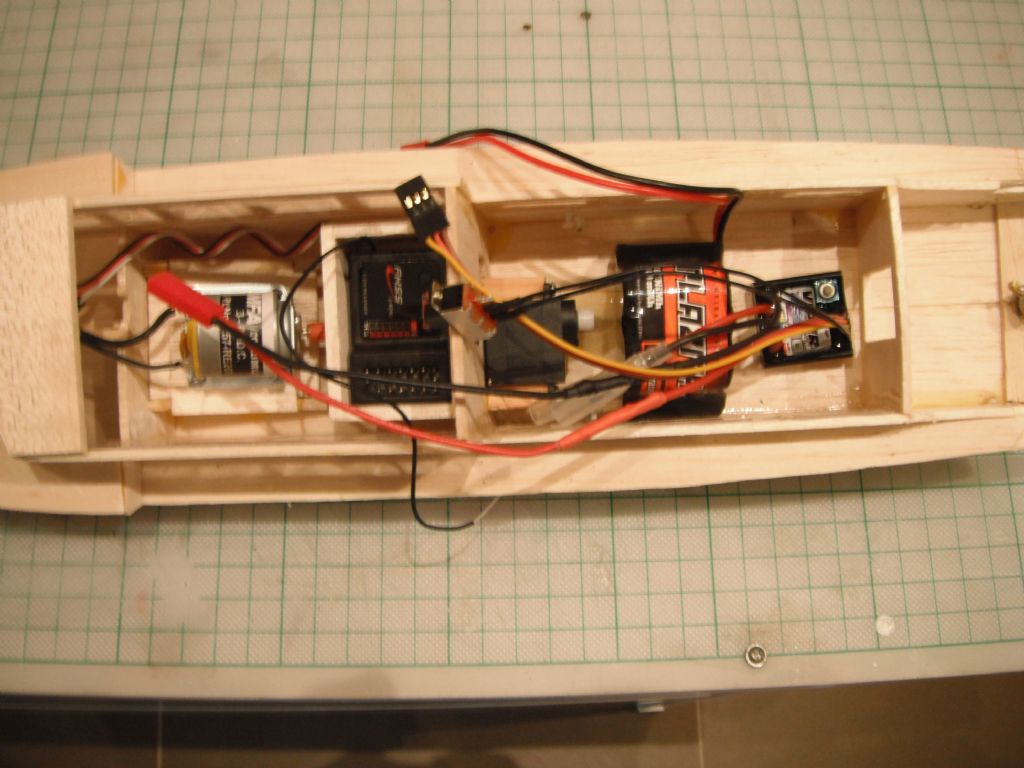

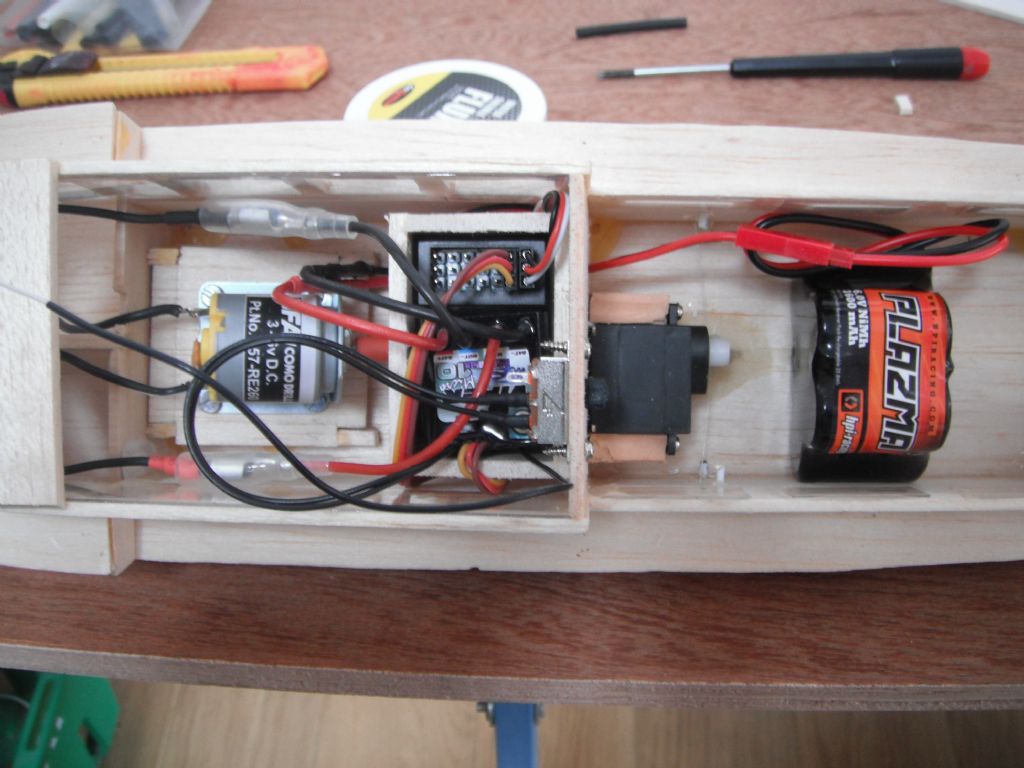

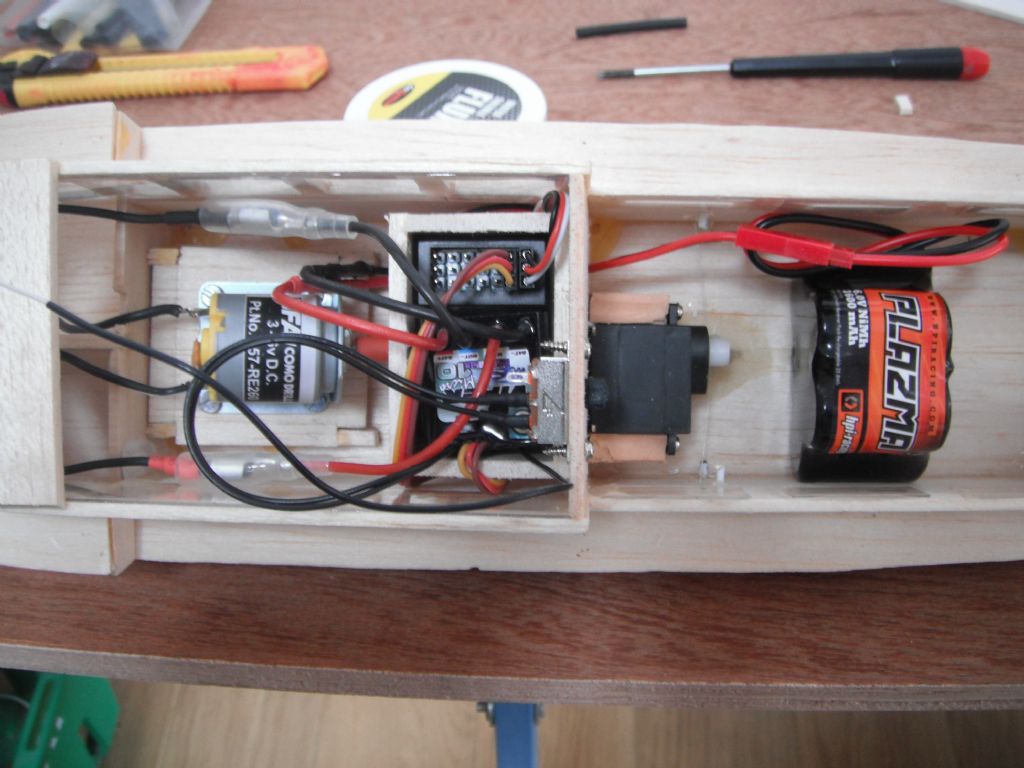

Ok, had a rethink on layout. Micro Viper sits quite nicely on top of the receiver, is this a good idea? Will it get too hot?? Not sure???

Next up skinning the thing. Sides first, bit of a gap at the bow. Sort that out later.

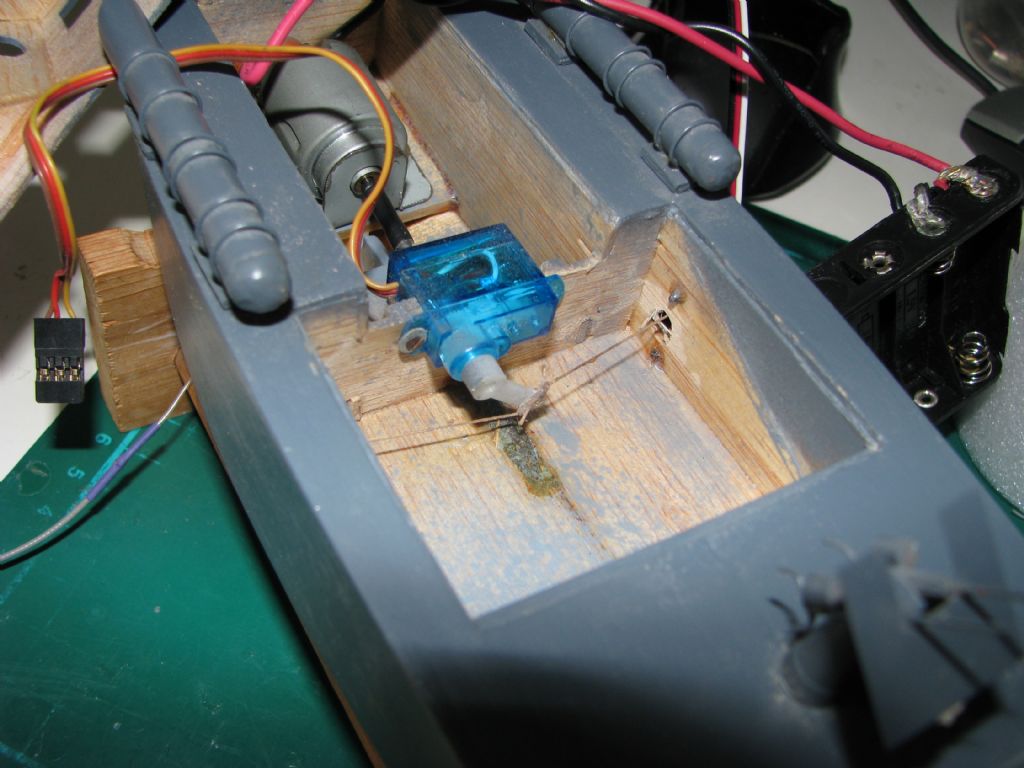

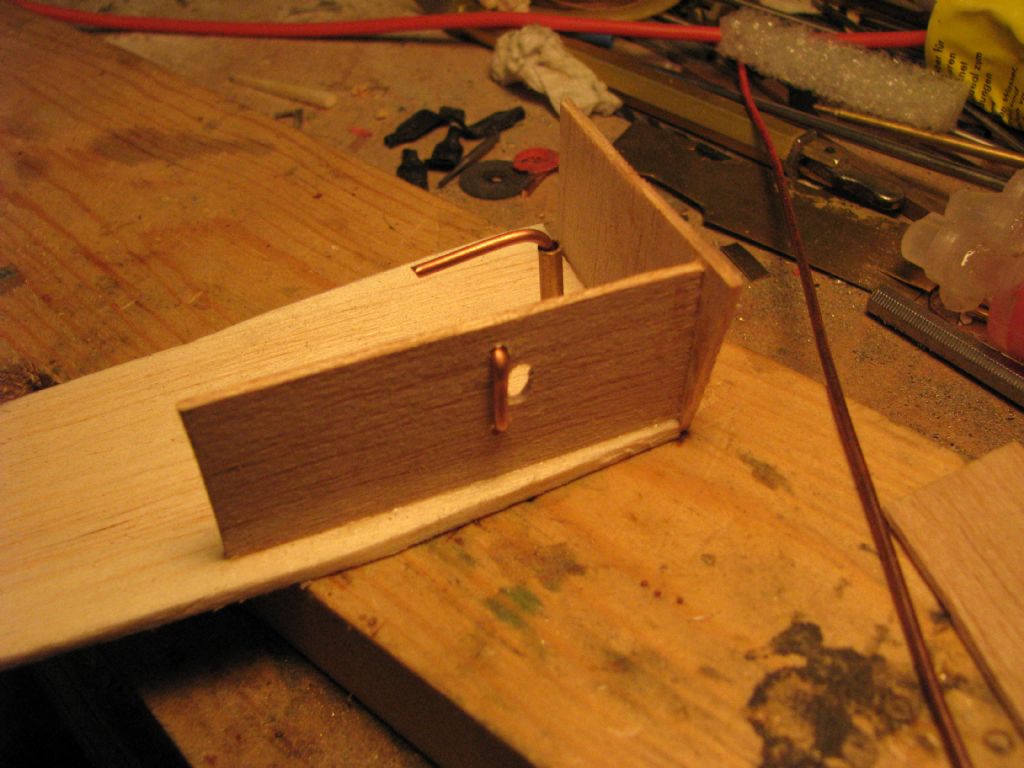

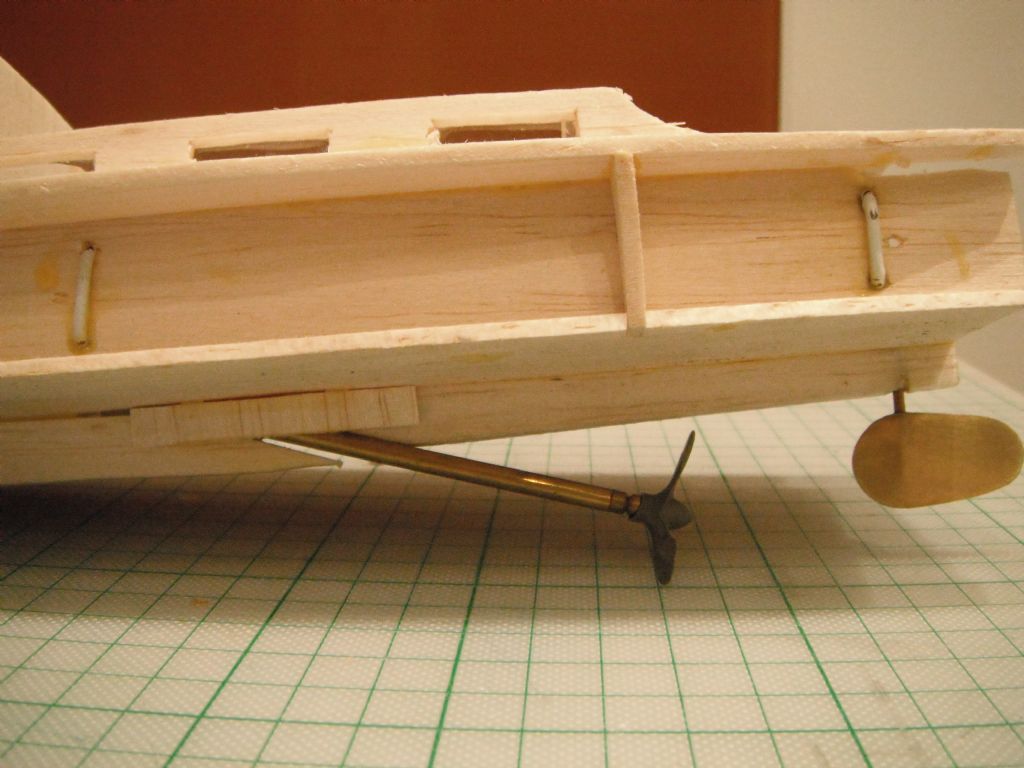

You remember I had that trouble with access to the rudder assembly, well, sorted now. Cut a hatch in the back didn't I. Now just need a hatch.

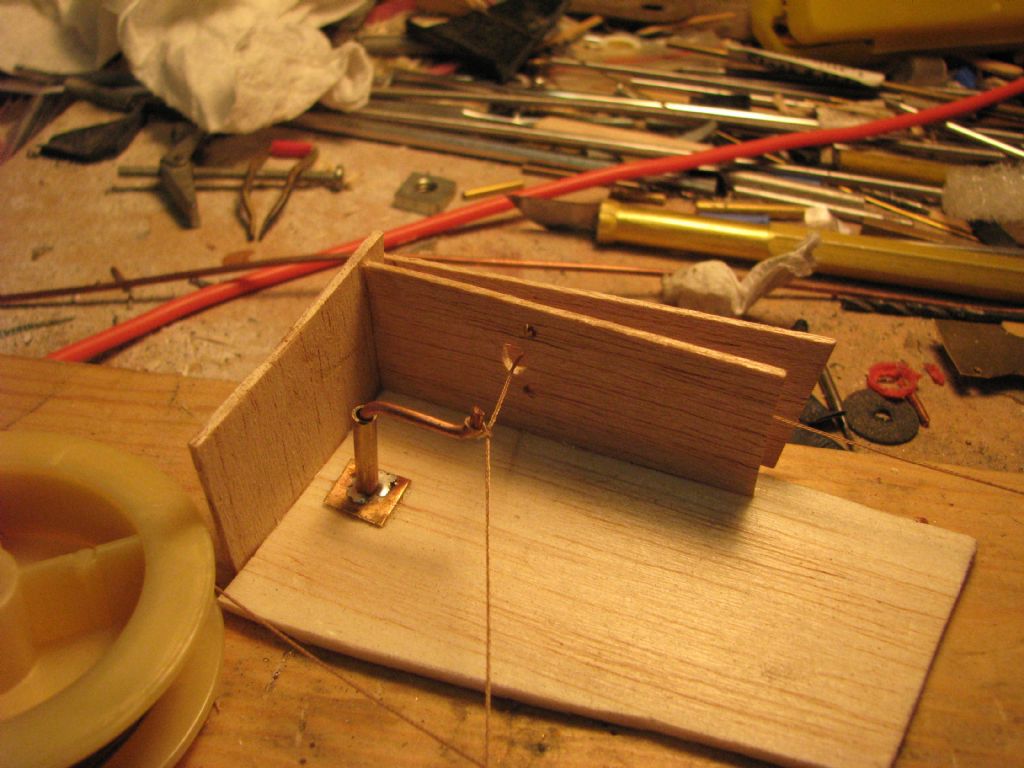

Oh look. A hatch, glued a piece of balsa slightly oversize onto the piece that came out of the hole. I know what you're think, is it blurry or is it my eyes. It's your eyes, just kidding, waterproof camera with a really hard shutter button. Does it get adorned with stuff, painted a different colour? Who knows.

Hatch in place, fits quite tight actually, if a little wonky. Precision, not on this one, still learning. Have to watch painting it, as it might not fit after.

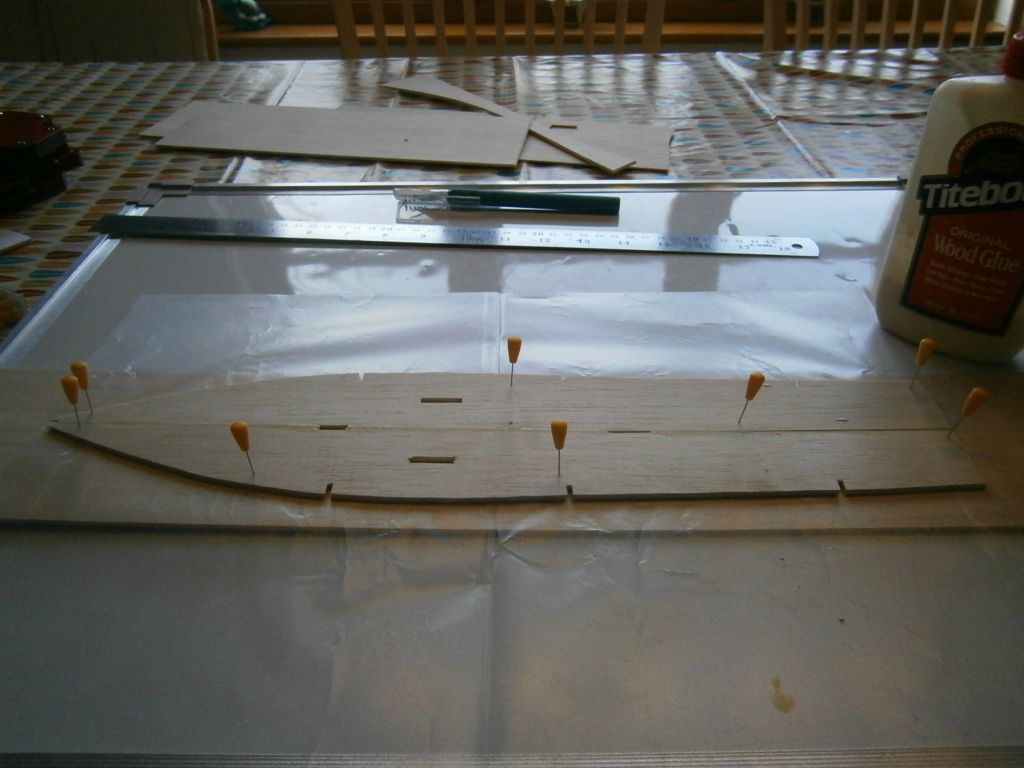

Now for hull bottom skins. Tricky to fit these as they needed a bit of cutting out at the propshaft and rudder tube. Looking a bit like a hedgehog with all the pins in it, but holds them in place while the glue cures. Now to the problem with the glue. I use Titebond II, which is yellow. Dries really hard and is not very forgiving. What do other people use, I have seen some using normal wood PVA, blue or green, but is there a real preference?

Glue dry, pins removed. she looks like a boat now. You can just see Goblin in the back ground, awaiting new sails and a paint touch up. Isobel has chosen a new colour for the top half, but more on that in the Goblin thread.

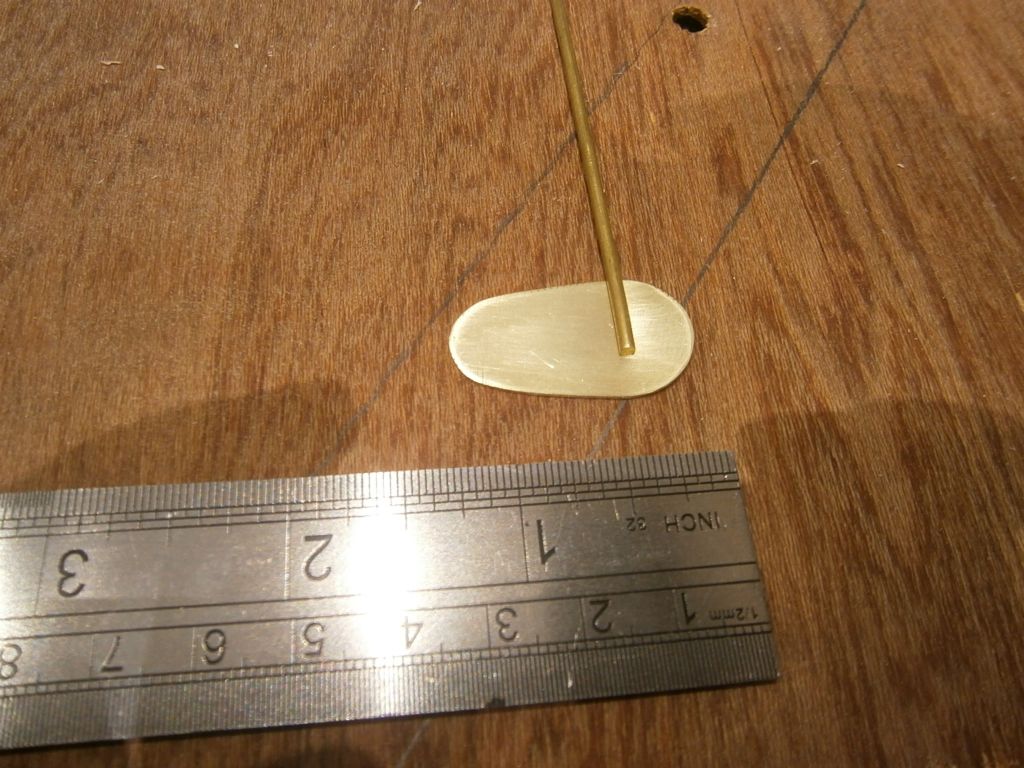

Back to Triton. Need to fit the outer keels, front and rear. Now we will see if it is all square and in line. Well not far off, Keel is slightly off, but a bit of fiddling about straightens it up, a bit.

Now for the filling and rubbing down before the next stage, sealing and painting. The gap at the bow is bigger than I originally thought. I have some Deluxe Materials White Model Lite filler. Thought it would be better than the twin tailed lightning from across the pond. Oh, don't start that again, wot me.

You may not know this "but I HATE Balsa", have I mentioned that. Well as you can see, I dropped it whilst filling the pin holes etc. Not to worry a bit of P38, no that is not right, Lite filler will sort it out. I hope.

so what is next I hear you ask. You did ask didn't you. Now that reminds me, Tom listens to a Story book going to bed, The Boxcar Children, know it? Nor did I until we bought some. Well it is American and there is a young lad that keeps saying won't in all the wrong places and it sparked a debate about the use of the apostrophe and where you can use it. Don't worry I am getting there. Anyway Didn't came up, and as you know it is short for did not, so can you use it in the sentence above? "You did ask did not you".

Anyway back to the build. Triton is now in the shop after a quick shopping trip to buy some cellulose thinners for the sanding sealer, now thinned 50/50 and painted on. Need to rub it down and may put another coat on before tissue and dope stage.

Well that is enough rambling from me, left the kettle on didn't I. (Really that again)

Andy

Edited By Andy C on 16/06/2015 17:46:01

Edited By Andy C on 16/06/2015 17:48:17

Edited By Andy C on 16/06/2015 17:48:55

Edited By Andy C on 16/06/2015 17:50:48