For a boat this size, white bin liner bags are a good source for sail material. "Magic Tape" from the stationery shop is excellent strengthening for the parts that need it, just the leading edges that are subject to stretching and bracing patches at the corners and possibly battens on the main if required. A pointy soldering iron makes excellent rigging holes in plastic, forming a plastic eylet as it melts the hole. The only downside to the plastic/tape method is that you learn a lot about static electricity that you never wanted to know, but the items are cheap and plentiful.

The common arrangement for running rigging lines is to go from the servo arm, backwards to emerge over the deck and turn round something near the stern. This line then splits to work the two sails. As the end of the arm moves forward, the line and the attached sails pull in, as it moves toward the back of the boat, it allows the wind on the sails to pull the line out.

On its way to the main that line passes through a bridle ring sited where you think best, then up to a point on the boom.

The fore sail line goes through a deck eye at a preferred spot in front of the mast and onward the the jib boom. An elastic line from the splitting point helps avoid tangles in light airs, but with an arm servo isn't really vital. It is extra work for the servo to pull against when you really want all of the effort to be on pulling in the sails.

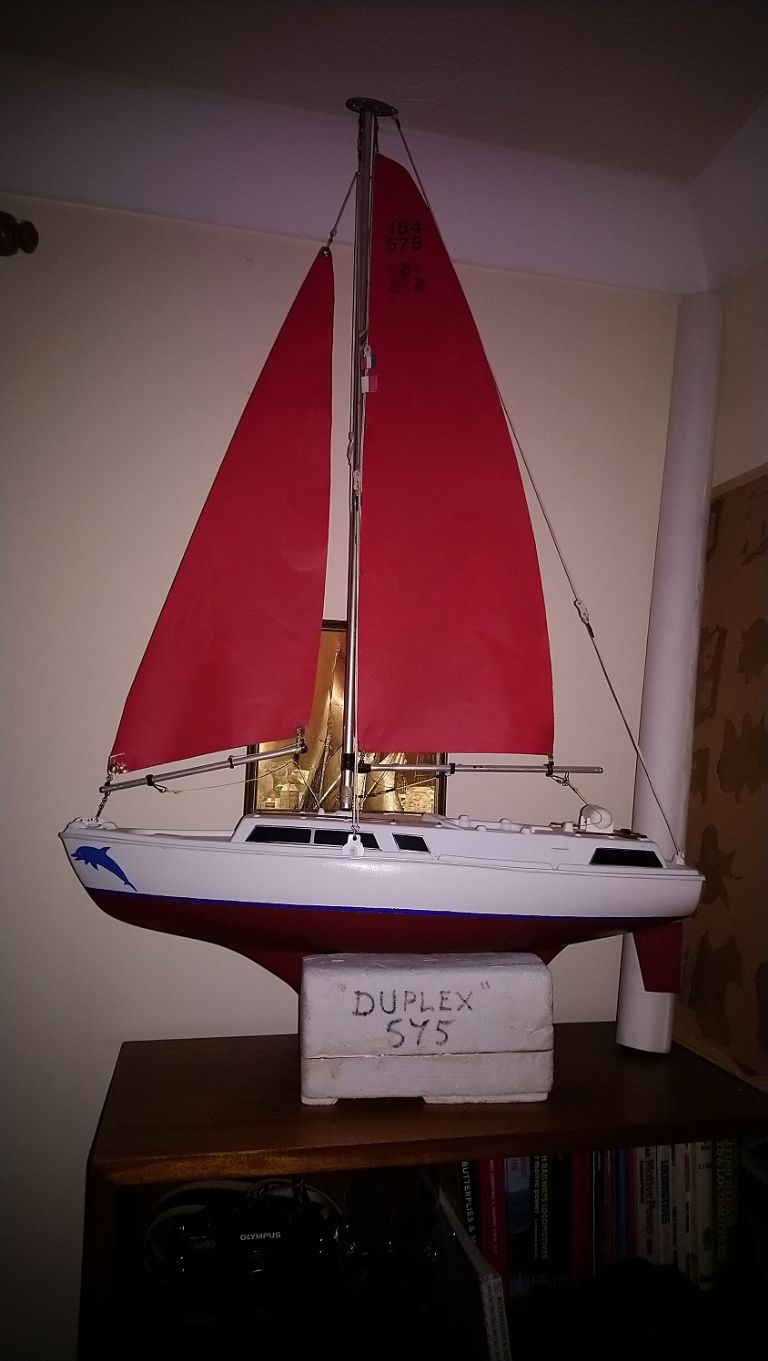

Some kit models (and this might be one) run the lines all below deck until they pop out of deck holes, or in some cases, out of the cabin roof.

Obviously neither the pukka sahib way … but cheap.

Obviously neither the pukka sahib way … but cheap.