Hi George,

Ah yes, the “instructions”. Utterly useless. They might as well read,”Using the materials provided in the box, build the ship.”

Had the plastic hulled version still been available, I’d probably have bought it, but I think I’ll derive greater satisfaction from building the wooden hull. Assuming I manage to finish it, of course. Talking about inadequate instructions, I’ve just finished sorting out the sheets for the jib and foresail (not certain if those are the correct names: the sails ahead of the mainmast.) Wasn’t as difficult as I’d expected. I used the plastic tubing that normally used for elevator and rudder control in RC planes. If you imsert the inner (to keep the outer from collapsing), then heat the outer with boiling water, you can bend it to quite small radii (radiuses?), although there’s less friction if you keep the bends fairly open. The inner’s not much use for anything after you’ve used it a few times, though. I do like having plenty of space in which to work.

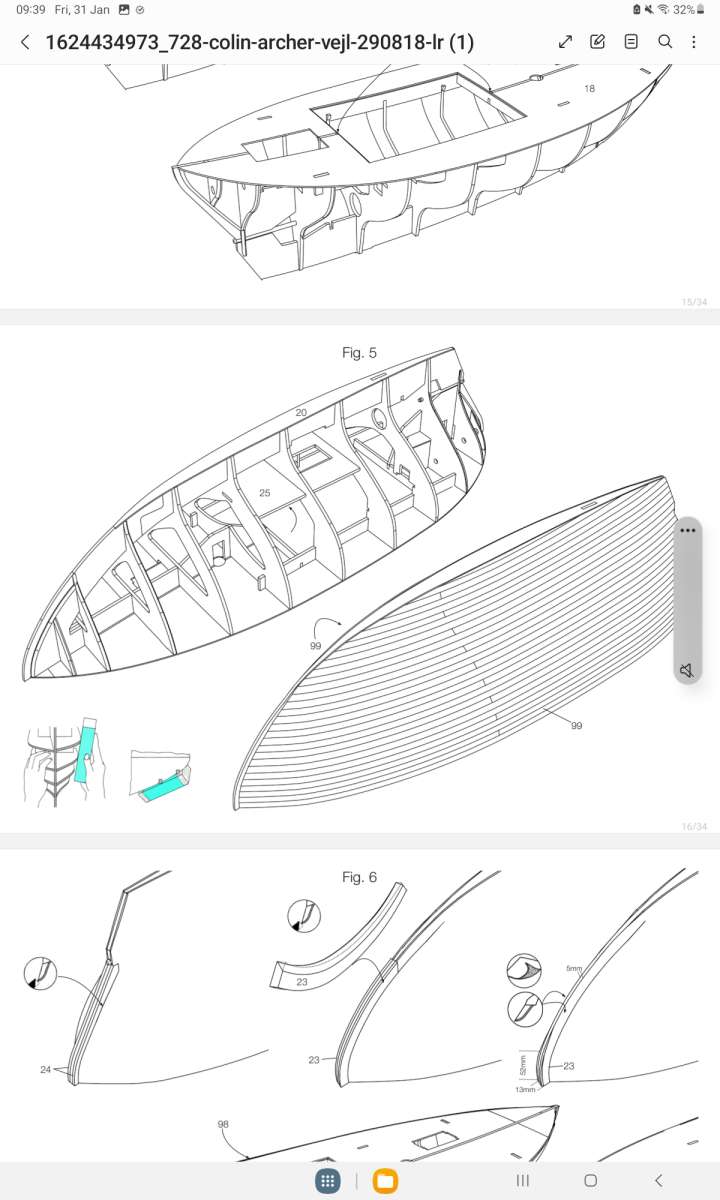

The (jocular) comment I made regarding the cockpit (again, don’t know if that’s the right name; just seemed appropriate) is true: in the upper illustration of Fig. 5, it is clearly visible; in the lower left illustration, it’s equally clearly not there. This may give you some idea of how closely I’ve examined the illustrations in the absence of useful instructions.

I’ve made up my mind about how I’m going to plank the hull. Not 100% confident whether or not it’ll work, but I’ll be using water-resistant glue, so worst case scenario, I’ll be able to remove the planks if necessary.

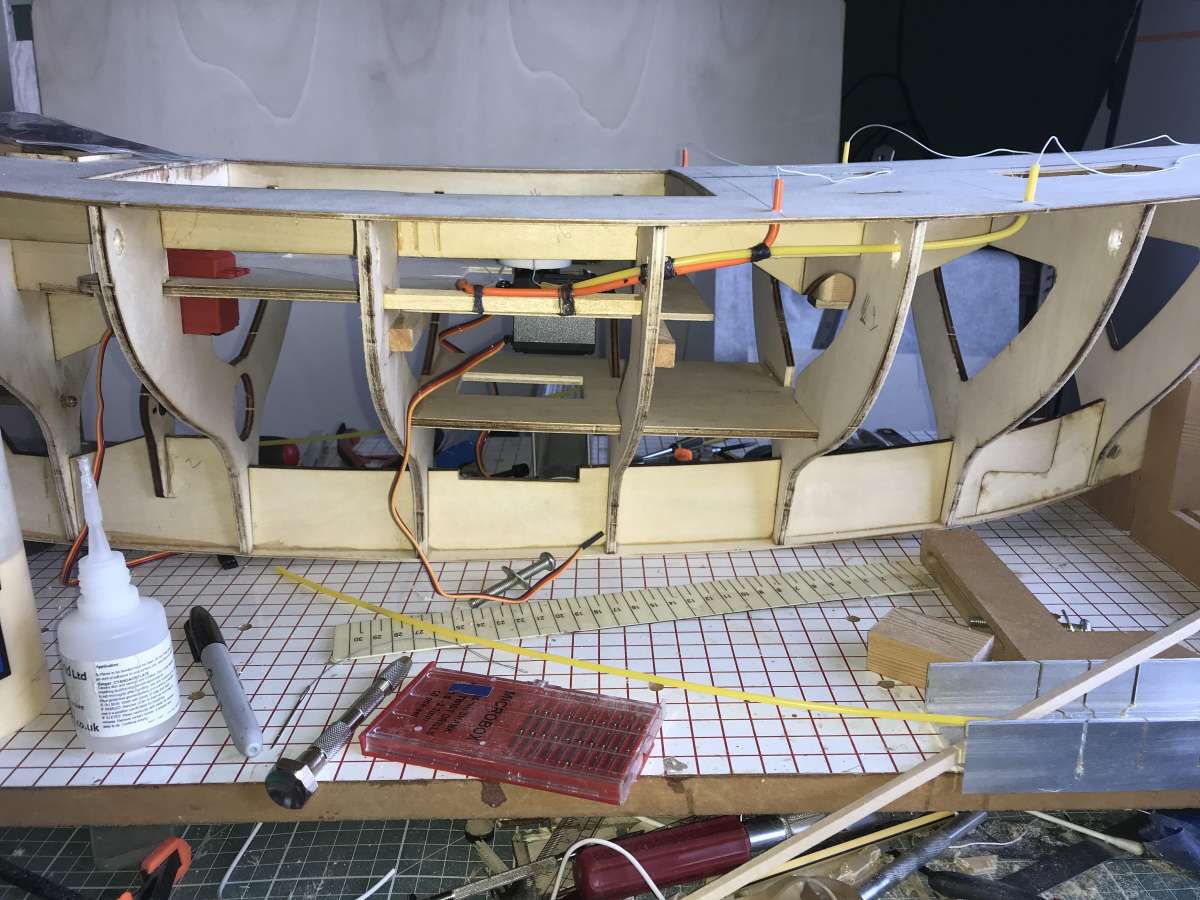

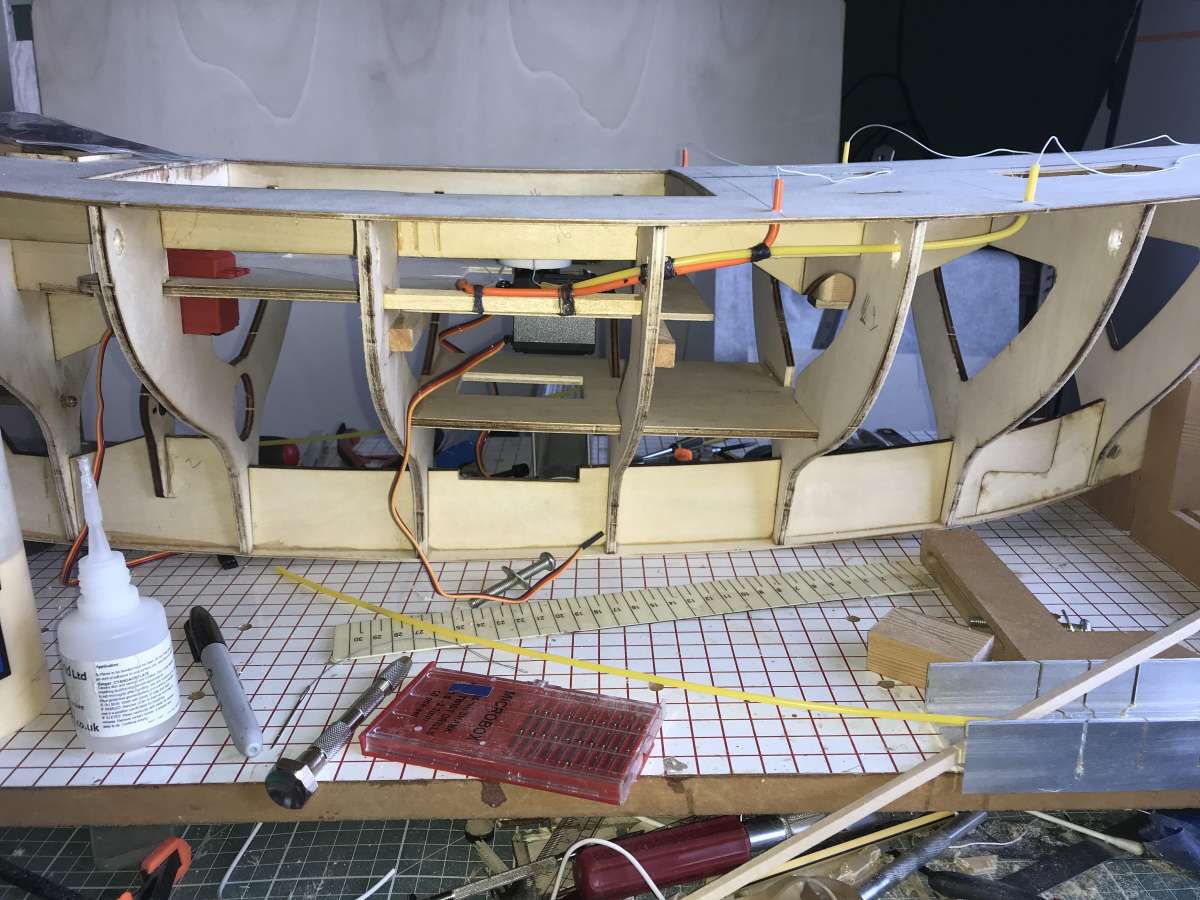

Finally, just for your interest, a photo of how I used the plastic tubing to get the sheets from sail to servo with the minimum hassle. I used orange and yellow because that’s what I had, but for simplicity, the orange tubes go to one servo and yellow servos to the other. The bindings are just polyester thread soaked in CA (after binding).

Sorry if I’ve gone on a bit; it’s a failing of mine. BTW, if you’re wondering what the 10mm holes in the bulkheads are for, I used miniature G cramps to hold the deck down while gluing it and the holes are for somewhere to put the lower jaw.

Cheers,

John

Johannes Jones.

This is how the Dragen came out. Not bad for a first attempt, I thought. And I didn’t do any of that tapering until it became necessary to close tapered gaps. Just kept planking until the planks didn’t want to curve anymore, then started up from the keel. I found it much easier than I’d anticipated.

This is how the Dragen came out. Not bad for a first attempt, I thought. And I didn’t do any of that tapering until it became necessary to close tapered gaps. Just kept planking until the planks didn’t want to curve anymore, then started up from the keel. I found it much easier than I’d anticipated.