hi everyone

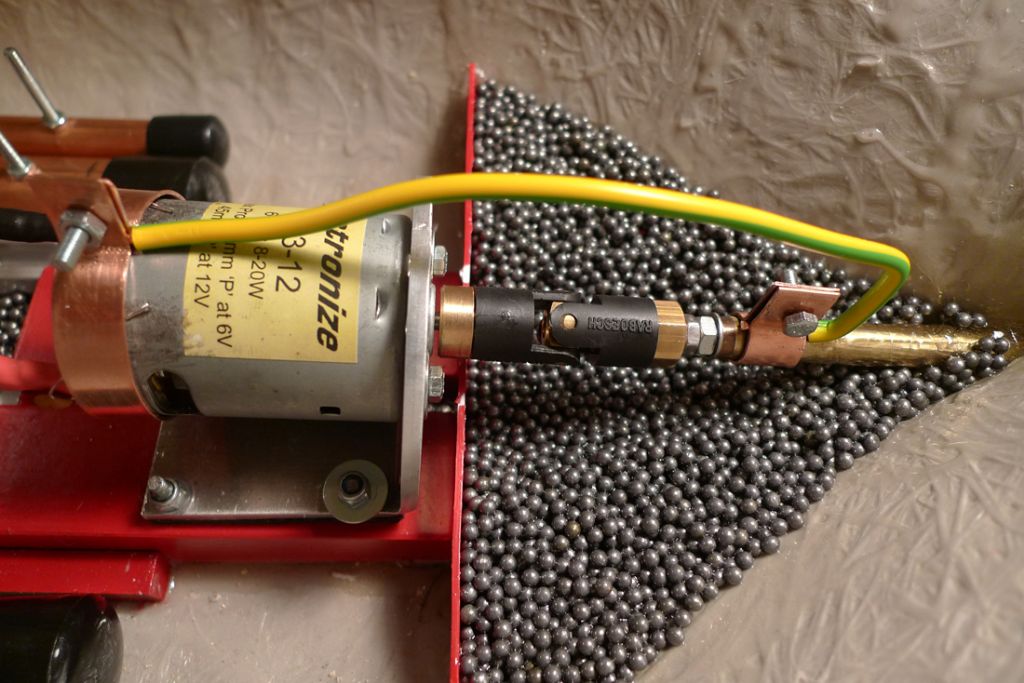

I have recently bought a new little brushed motor and a set of suppressors. Easy I thought, even read the instructions that came with them and did a search here for any other useful information. Found an interesting discussion started a long time ago about whether they are needed or not. Not opening that can of worms again. Just going to fit them.

Armed with some sandpaper to roughen the surface, some solder and my trusty iron, off I went on a journey to not working and back again.

So, not to be deterred I grabbed a great big rasp from the tool box and roughened it a bit more. Hotel not working for an overnight stay. After a big breakfast of "I am not going to give up" I grabbed some different solder, fired up the gas torch and tried again. This trip is seriously bugging my melon man.

So what the heck is going wrong? Wrong solder, still not rough enough or something else entirely?

To save on trips to "this is still not working" I submit myself to your thoughts.

Cheers

Andy