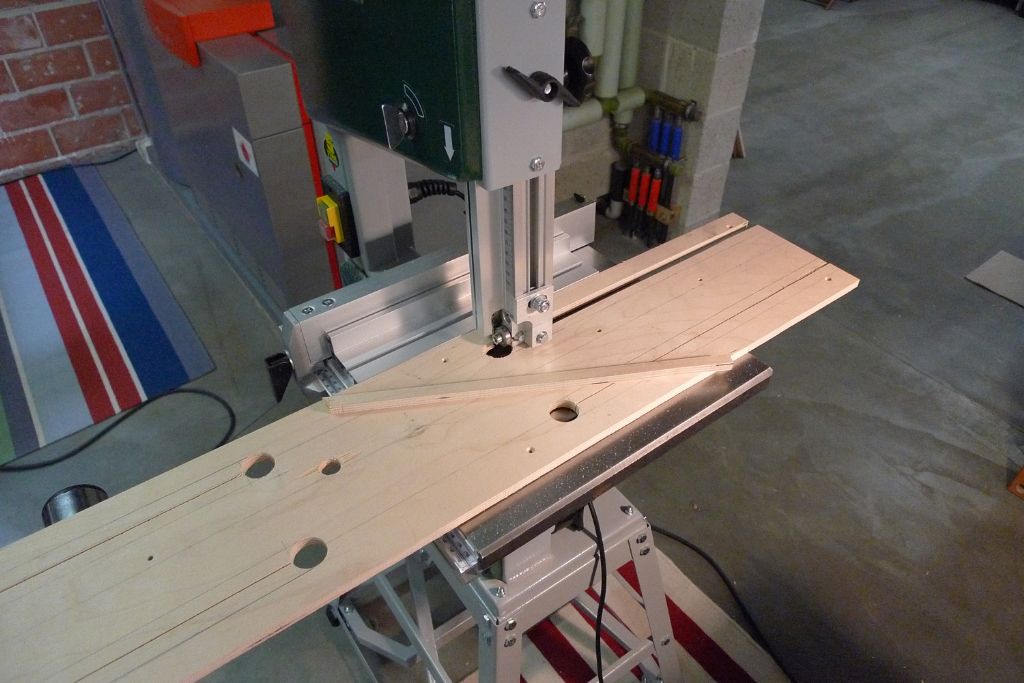

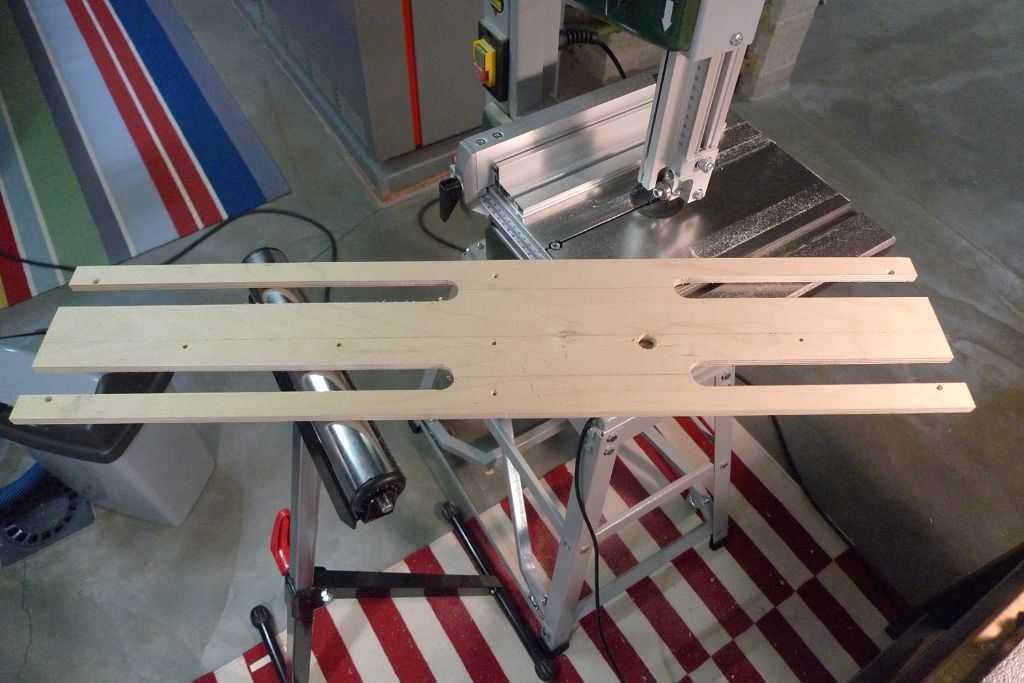

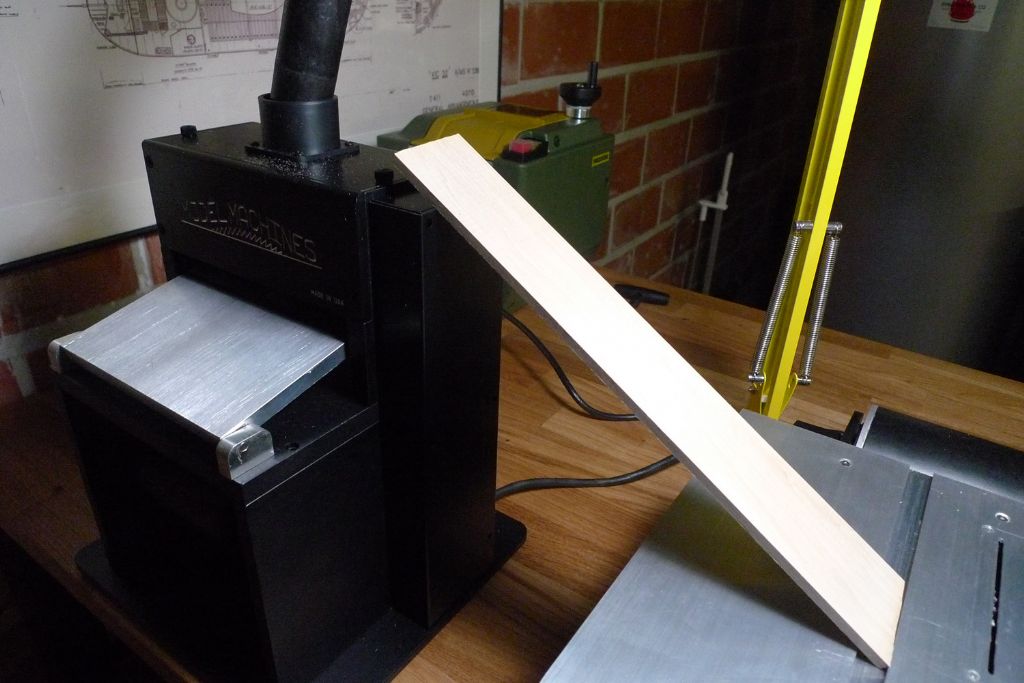

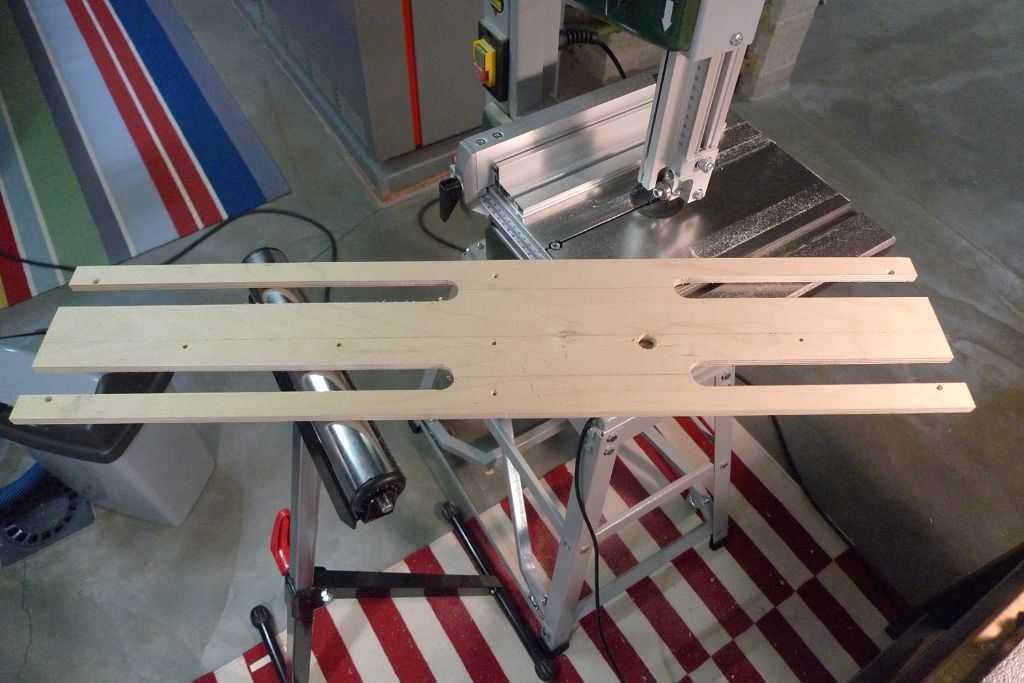

The main eason why I made up this sledge base from both plywood and pine panel was that I (as yet) have no router, and figured that the easiest way to create the necessary stepped grooves would be to work with two pieces.

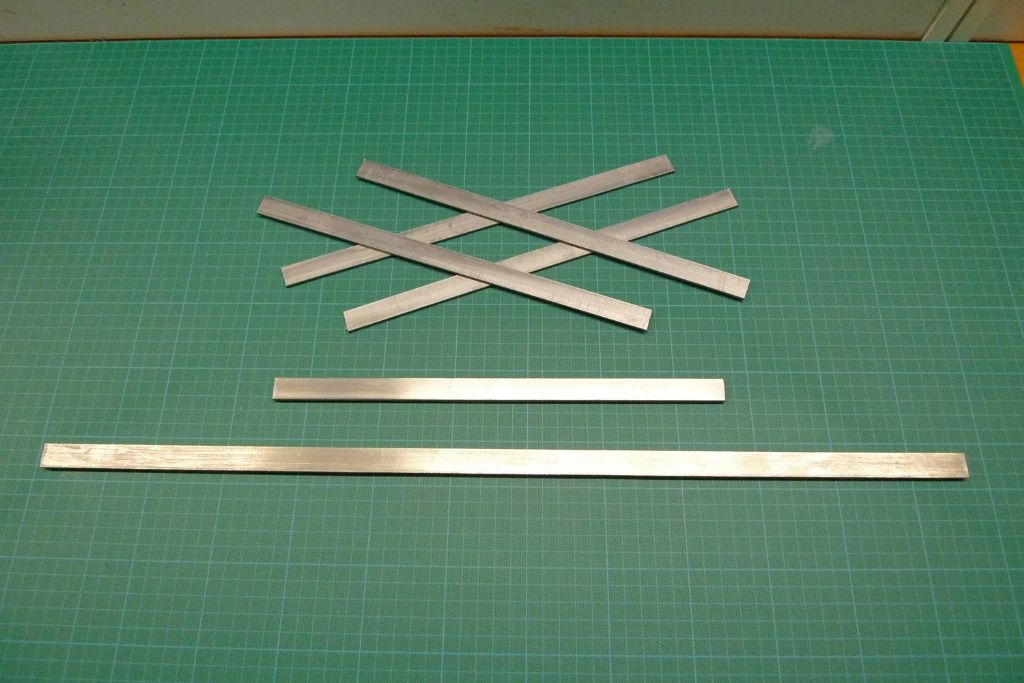

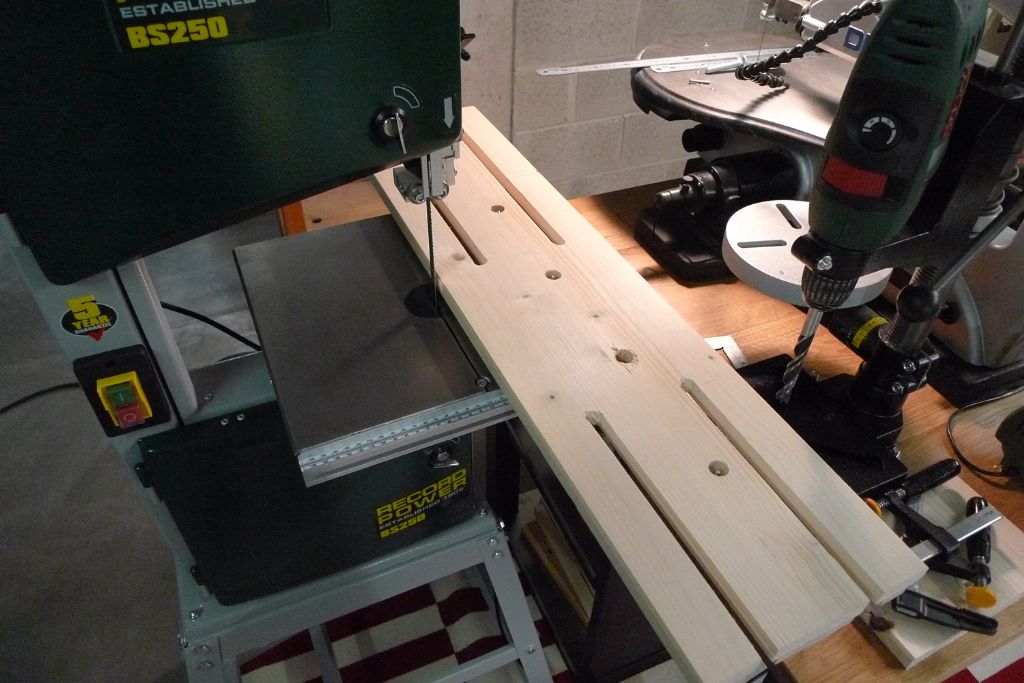

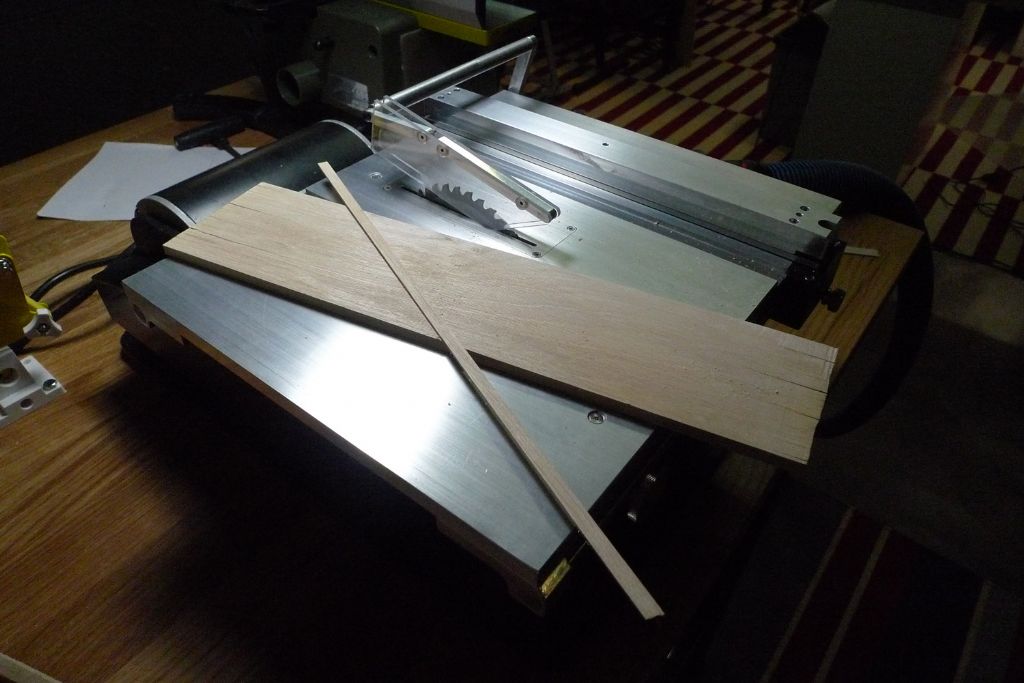

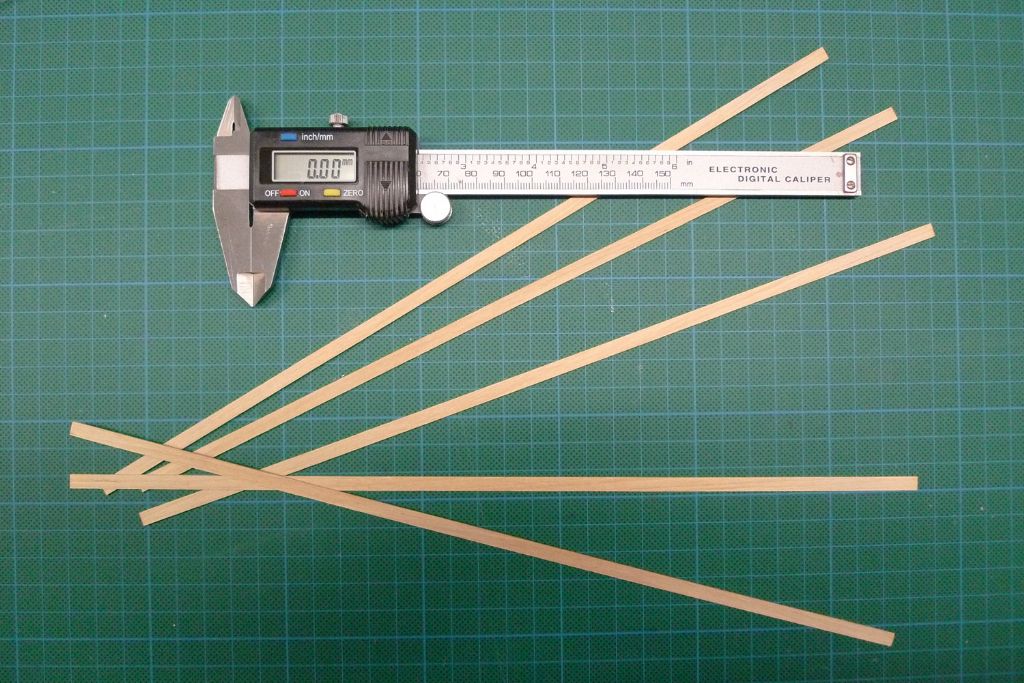

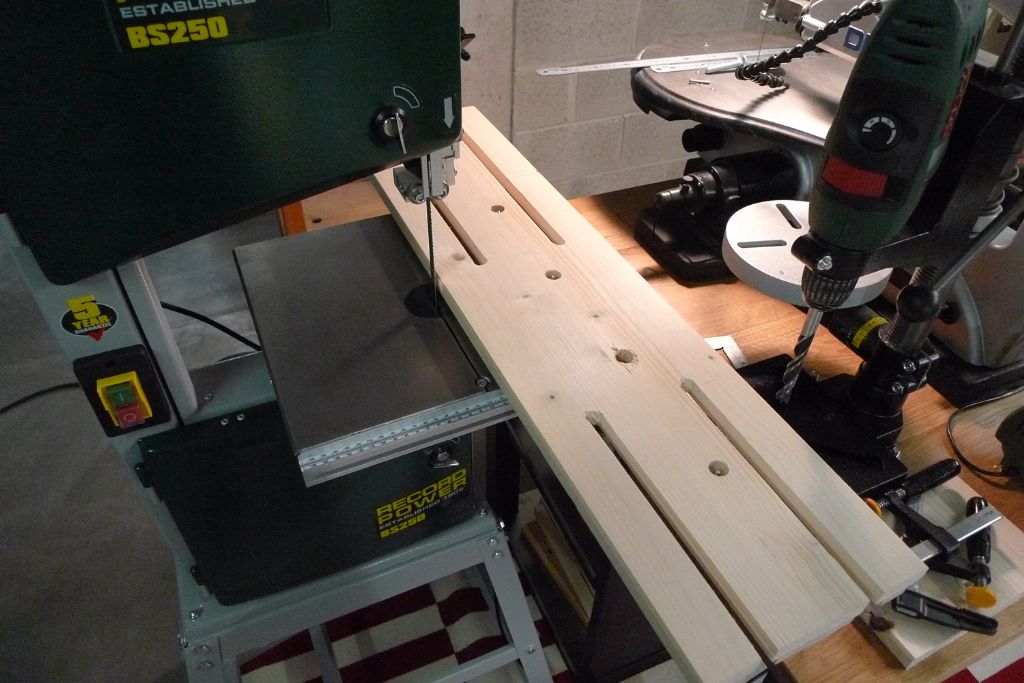

To mark both those pieces with exactly the same lines, I next made four lengthwise saw cuts into them, 50 mm from each outer edge, and 250 and 350 mm from the respective ends.

The two pieces were the separated again by unboilting the steel flat and rmovinbg the six screws, after which the plywood was given 25 mm diameter holes at the ends of the four saw cuts …

… and the correspnding strips of wood sawn away too …

to produce four slots, 25×250 and 25×350 mm respectively.

The pine panel was similarly treated, but with slots only 12 mm wide.

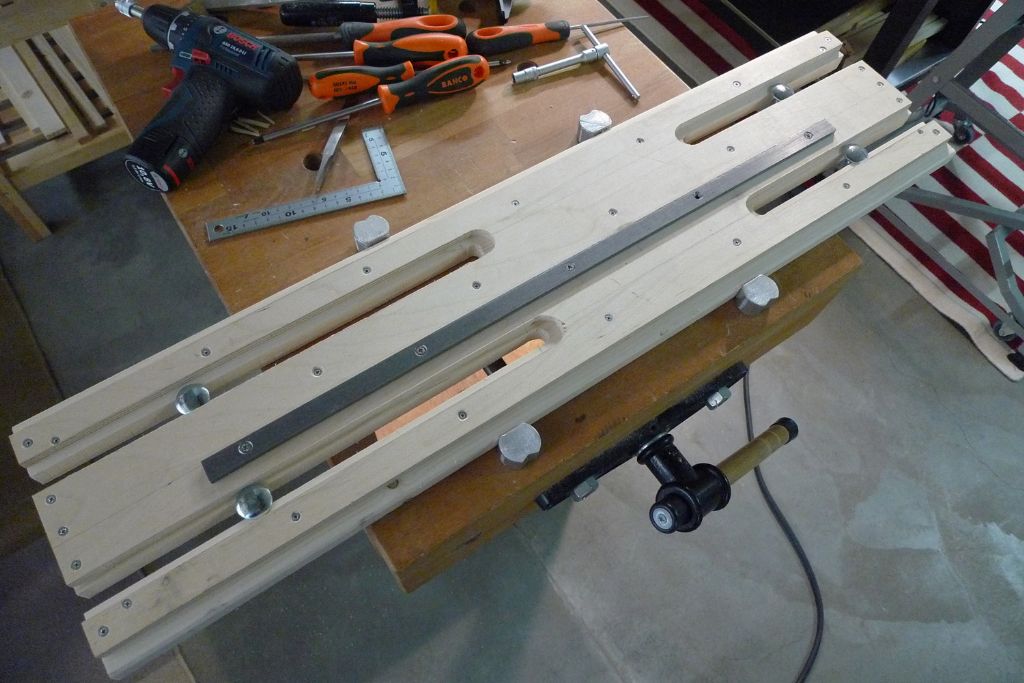

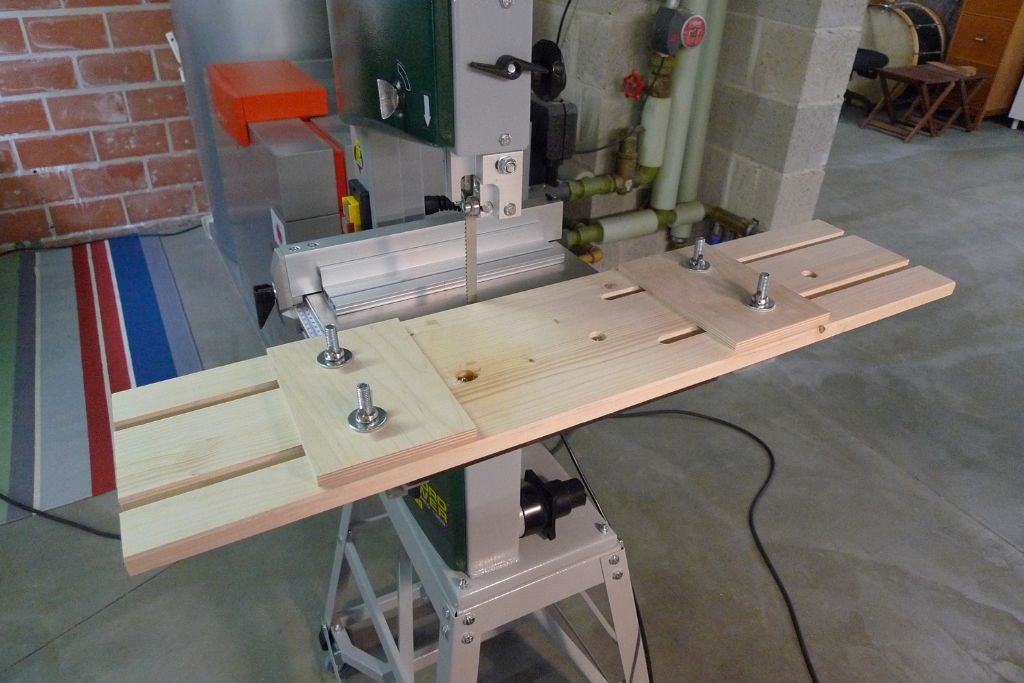

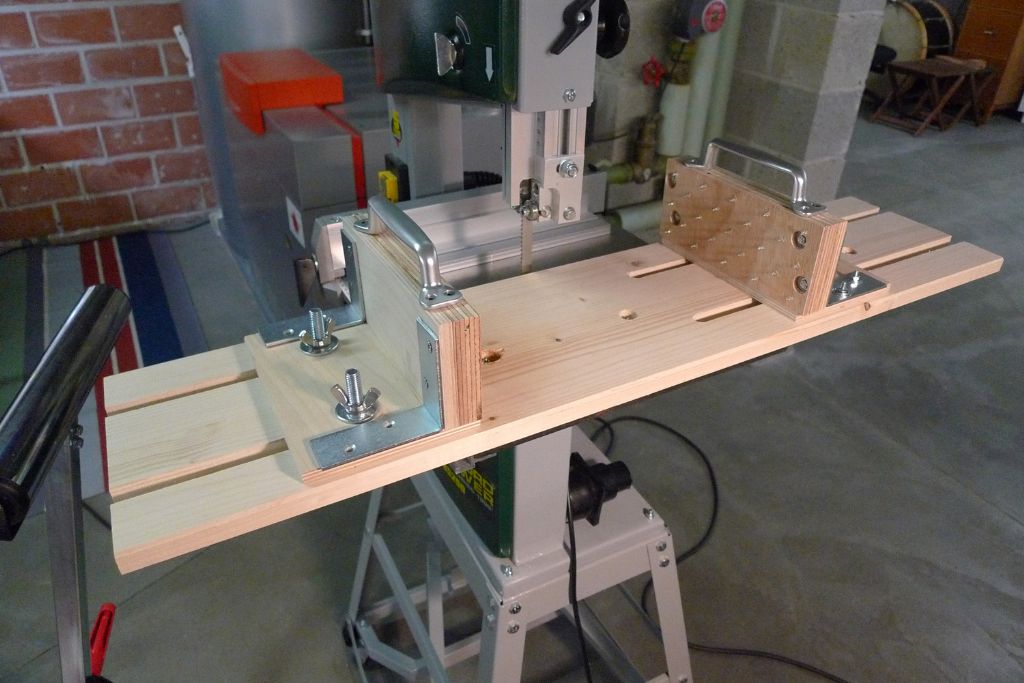

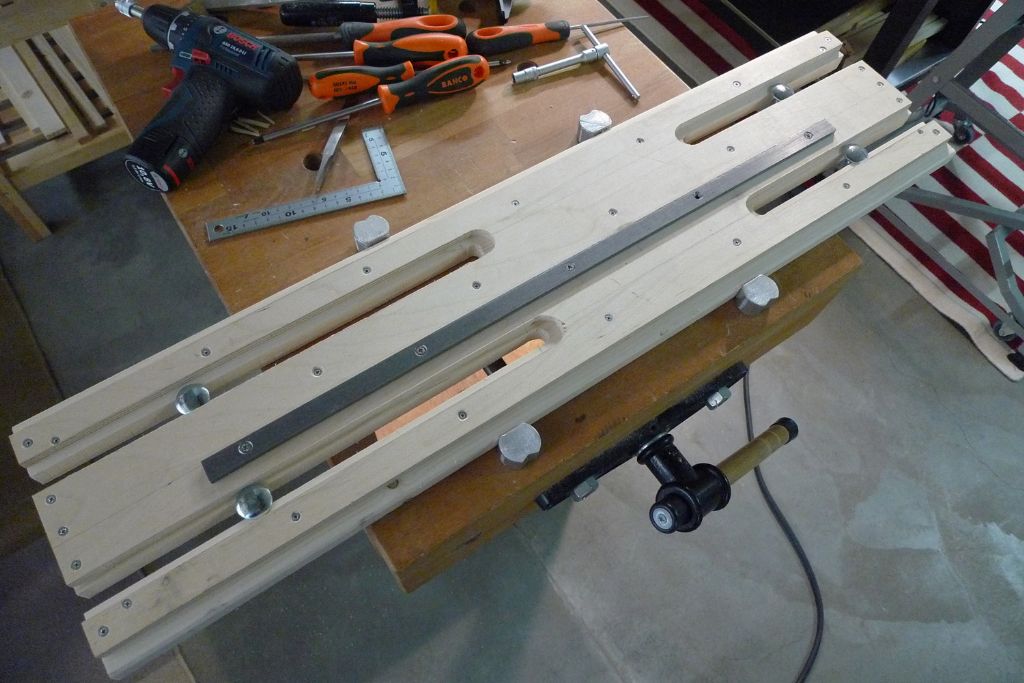

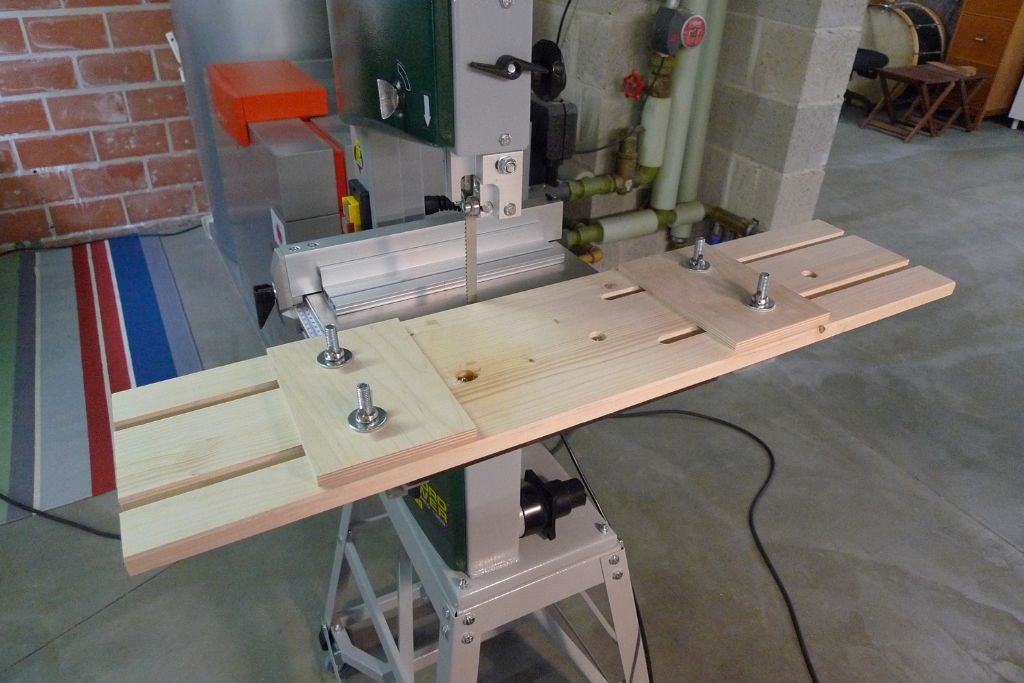

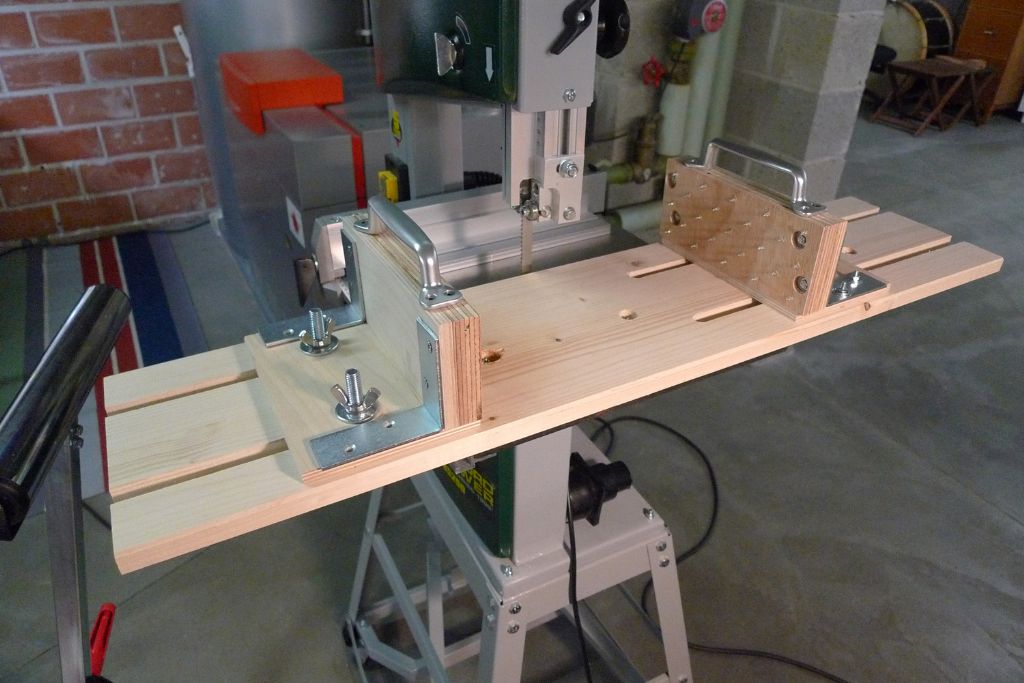

Once the plywood and the pine were screwed back together (this time with considerably more than just six screws), 4 stepped slots were created into which the wide ends of four M10 bolts fitted nicely.

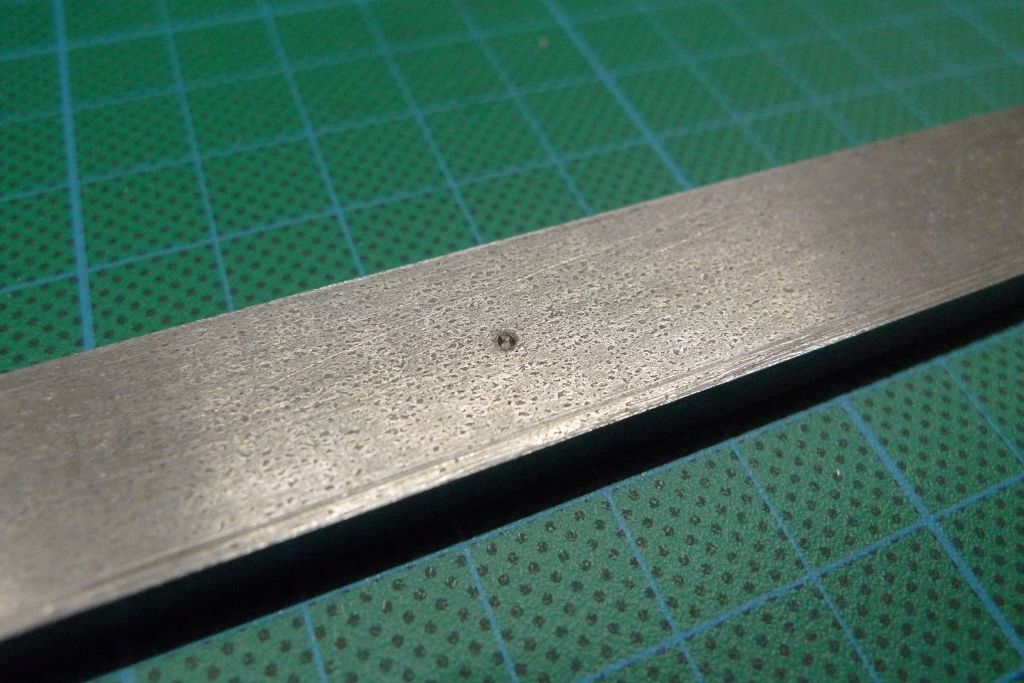

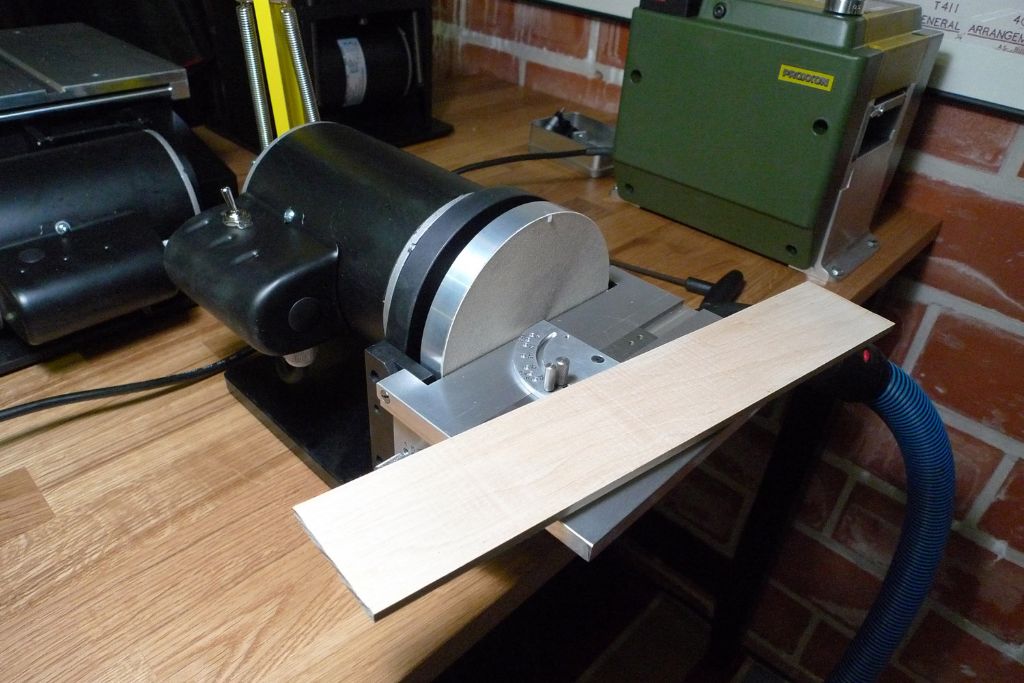

An intermediate drilling accident had led to a large drill bit going all the way through the wood where one of the five steel flat fastening bolts were meant to go, so the micro lathe was called into service …

… to make up a suitable plug …

… which was then epoxied in place.

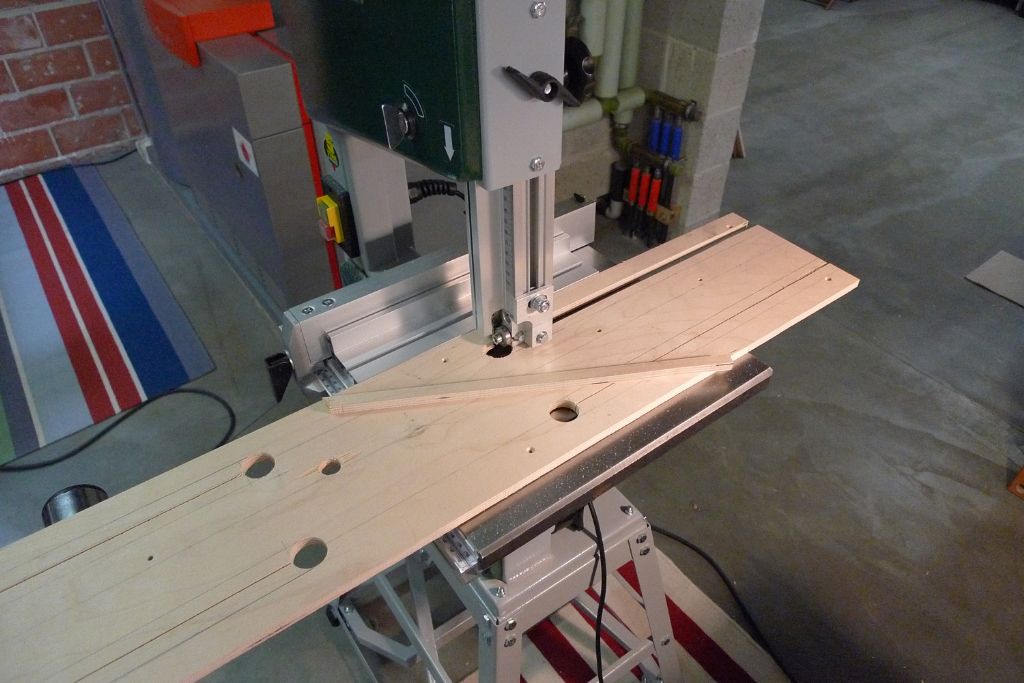

A first holding piece was the made up in the form of a 45×18 mm lattice through which a series of 10 mm holes were drilled. With this, flat pieces, such as plywood, can be held down to have straight edge sawn on to them.

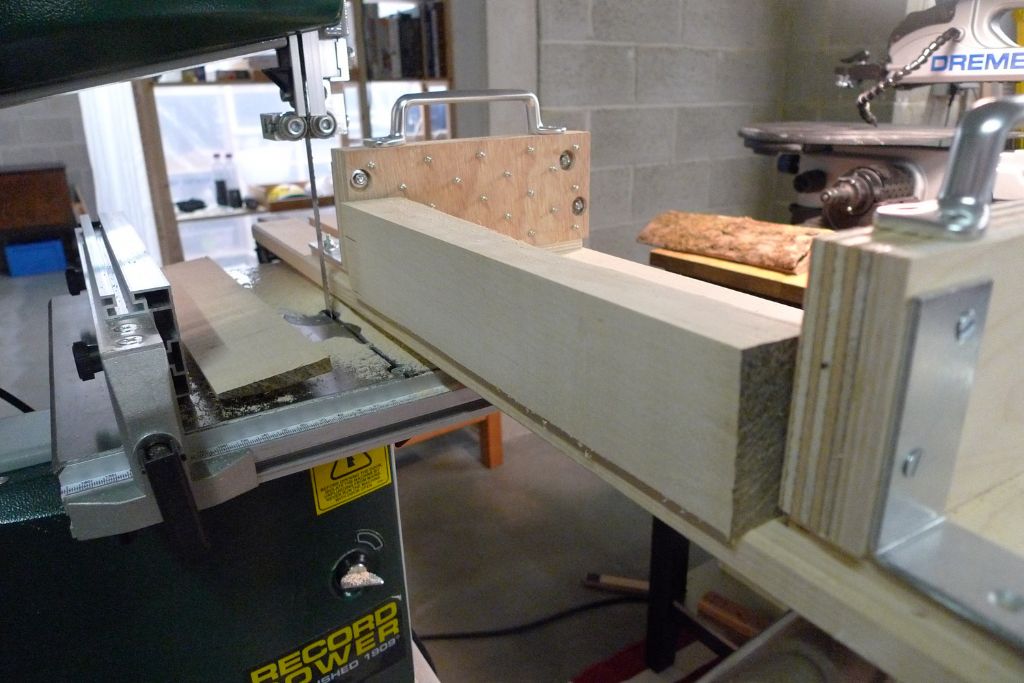

For lumpier or more uneven pieces, a different system will be needed though, so next I made up two 9 mm plywood sliders, some 180×120 mm in size, and drilled 10 mm holes through these, too, so that they can be fixed by M10 bolts and wingnuts in any position from +/- 95 to 660 mm apart.

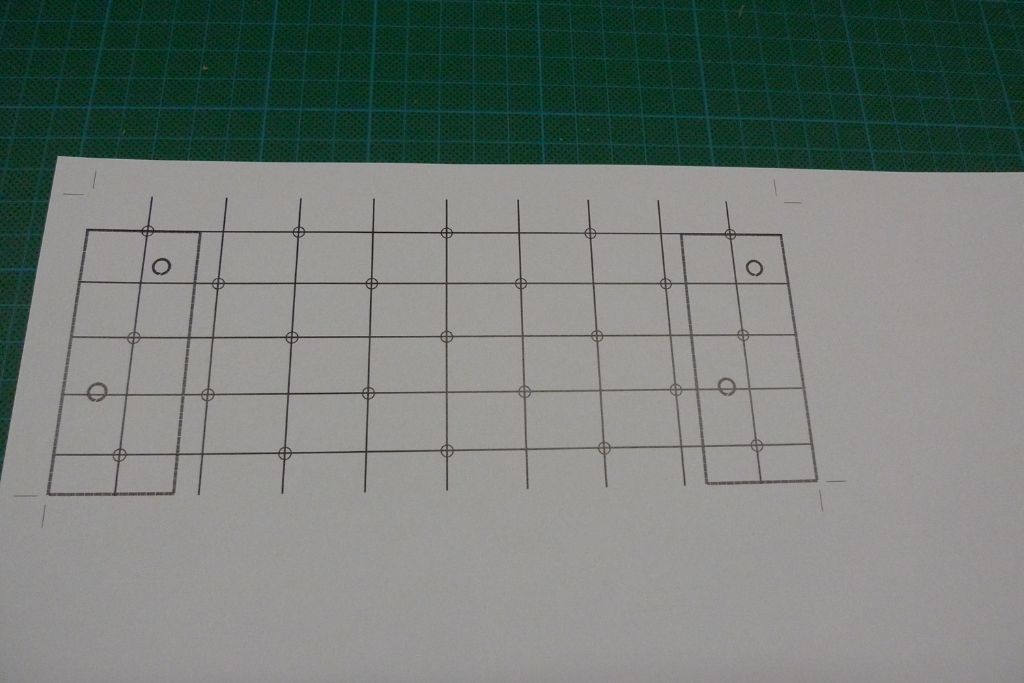

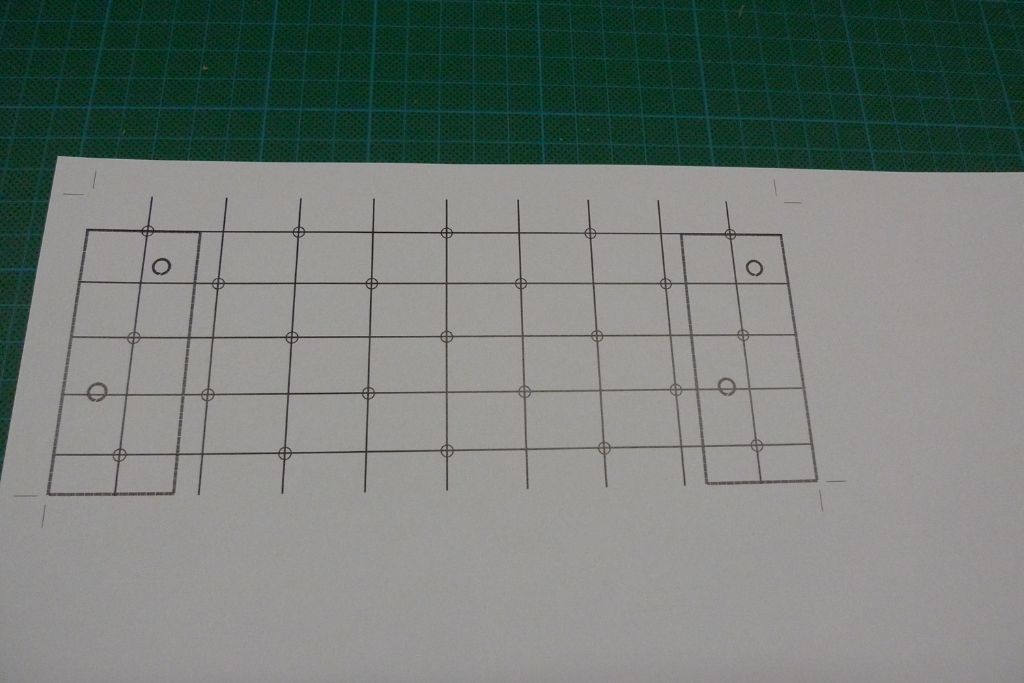

After cutting out two further pieces of plywood, these 20 mm thick, I plotted out and printed a pattern on paper …

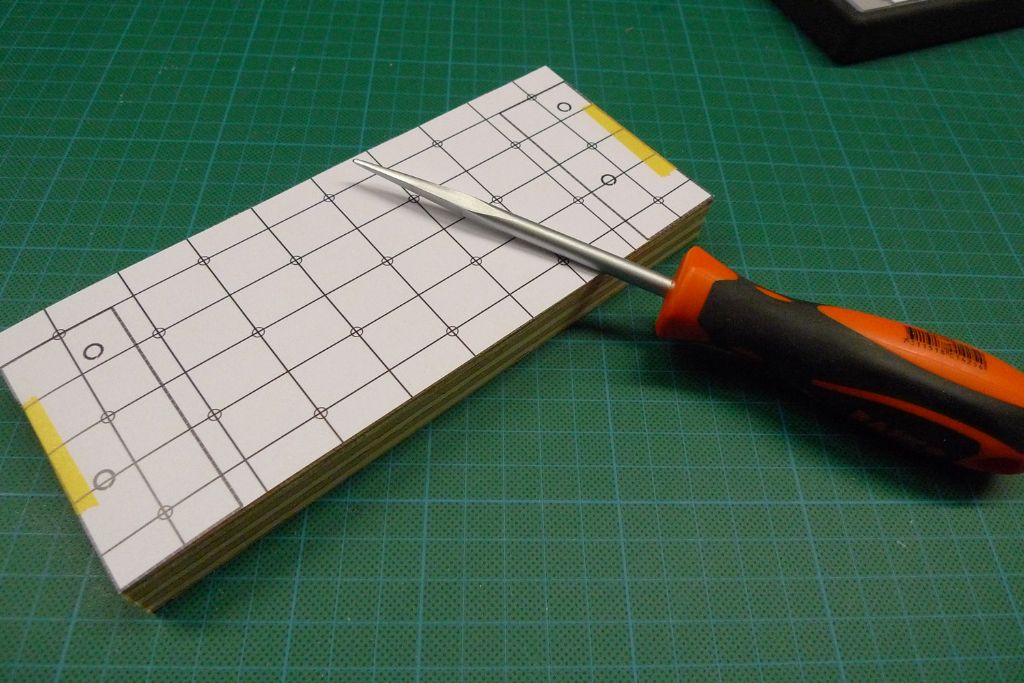

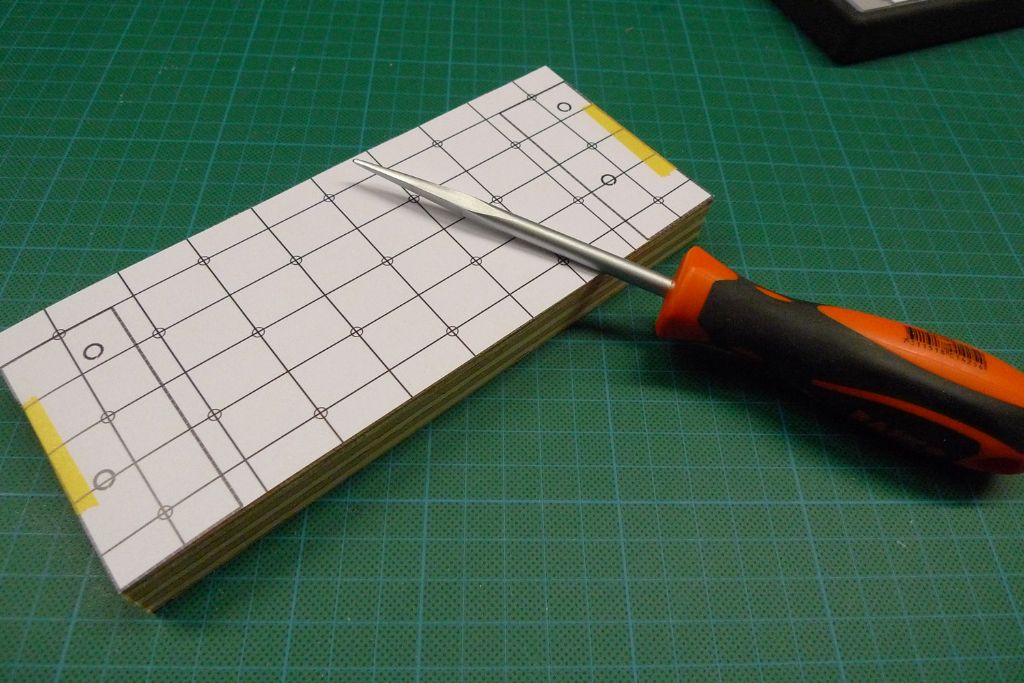

… that was taped onto the plywood blocks …

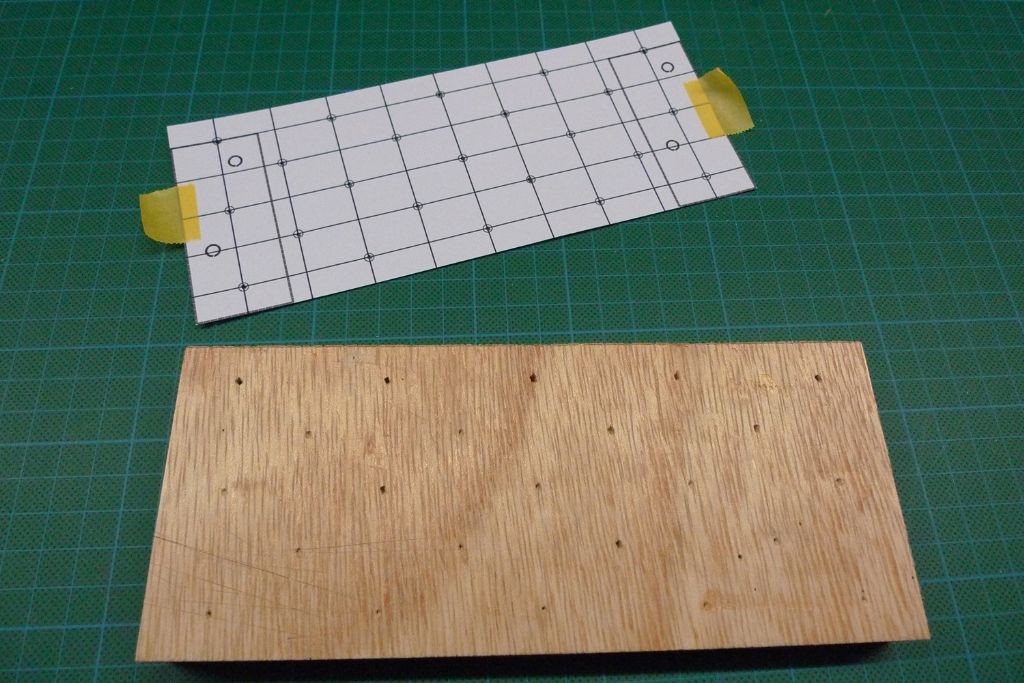

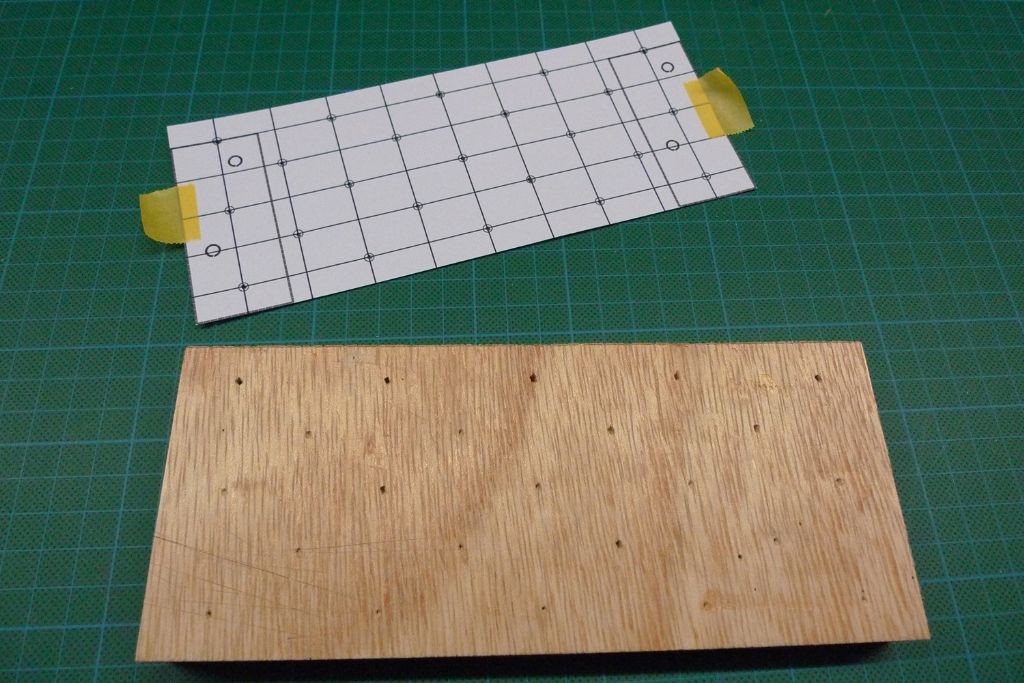

… the pattern transferred with an awl …

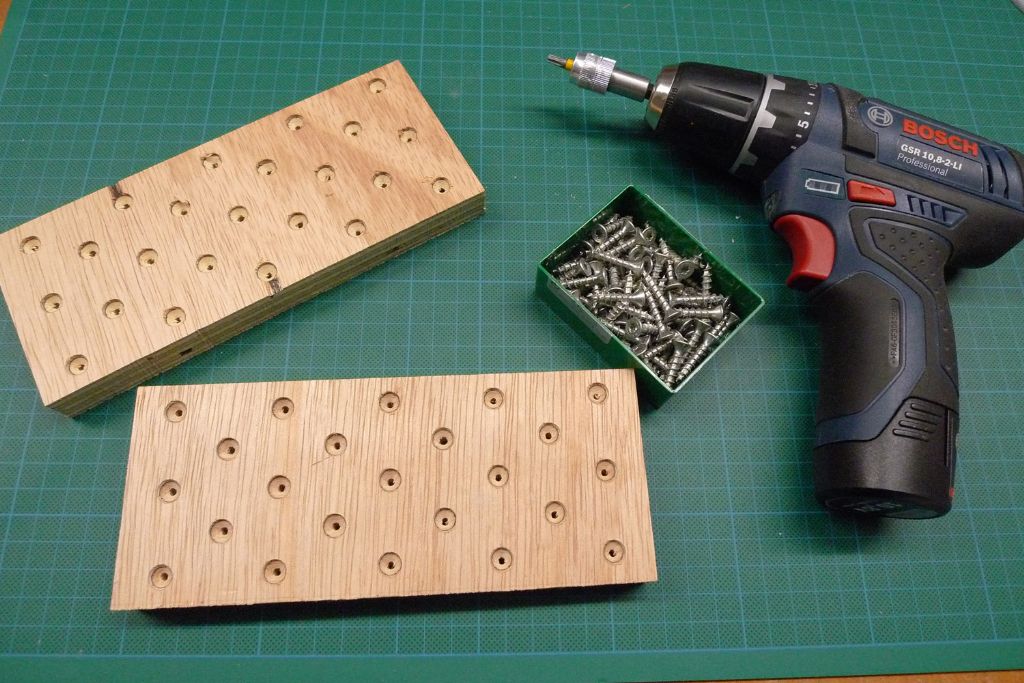

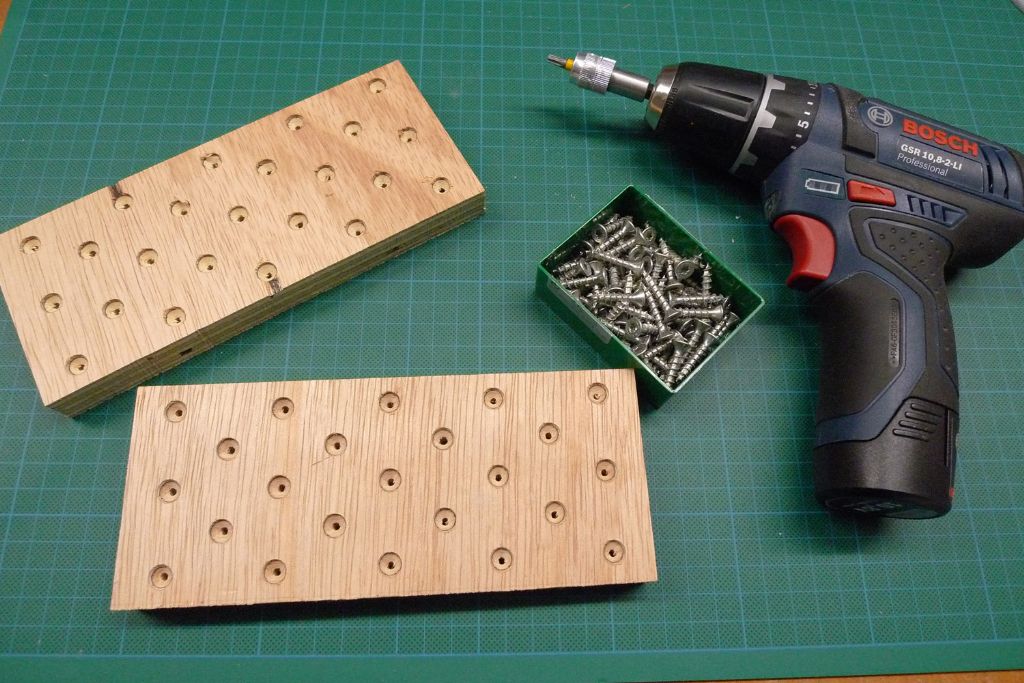

… drilled and countersunk …

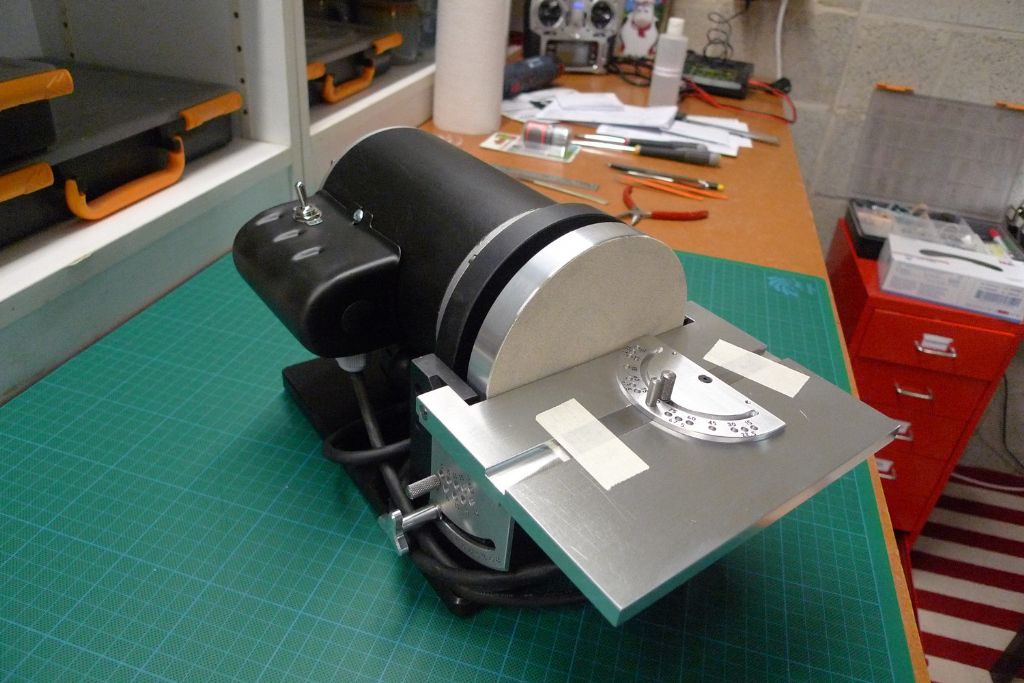

… so that a serties of woodscrews could be fixed through the plywood, to make up two studded pads.

The pads were further reinforced with back plates from 9 mm plywood glued onto their backs …

… and then secured to the plywood sliders, with a couple of handles added on top of each pad.

To be continued …

Mattias

Edited By Banjoman on 01/04/2018 21:49:11