Hi Ron and Ian,

I only really tried the iron transfer method on ply and there it works sort-of okay (I used it to label my transport cases), I can see where it doesn't work on balsa and especially on thin balsa. My guess would be that it is too soft for this method anyways, and the heat being applied on one side doesn't help either.

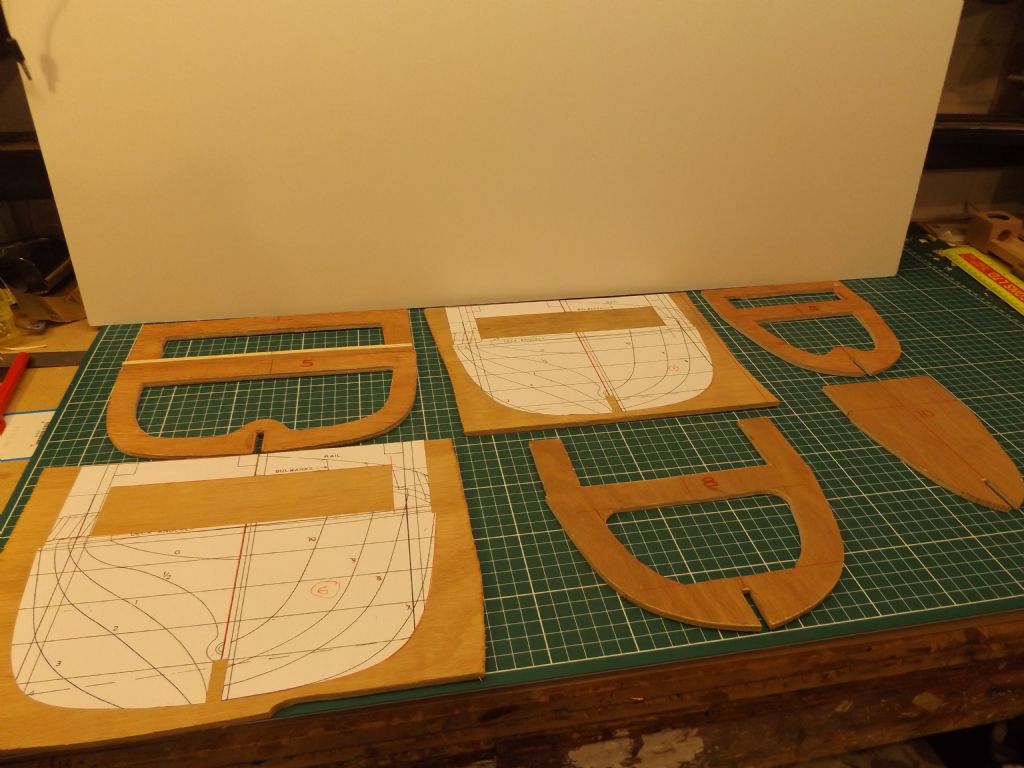

Truth be told, my method to date for build plans, has been to print out the plans (or copy them) and use spray adhesive to stick it to the balsa. Then cut out with a knife, and remove the paper ASAP again. (if you wait too long, the paper sticks too badly to the wood and you end up having to sand which is a pain with the glue and all). Most spray adhesives have two ways of applying: spray both sides, wait 10 minutes for a pernanent bond, or only spray one side (the paper!), wait 20 minutes and then stick, which gives you a sticky notes-like bond – if you remove it within a couple of days…

That, or stick the (copies of…) plans to a thick piece of cardboard and use that as a cutting template.

P.S. to create nice labels/texts/pictures on transport cases I found a way that works somewhat better than the heat transfer method: Use water-based Polyurethane clear coat to stick the image (printed side down) to the case, let it dry and then gently rub the paper away with plenty water and a sponge and discarded toothbrush. Then apply second coat to seal.

Edited By Diede van Abs on 03/10/2018 15:18:20

it works for me.

it works for me.