Sovereign of the Seas

Sovereign of the Seas

Code of conduct | Forum Help/FAQs

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

-

- Todays Boating 1 2 … 210 211

- 84

- 1 week, 1 day ago

Viewing 25 topics - 1 through 25 (of 25 total)

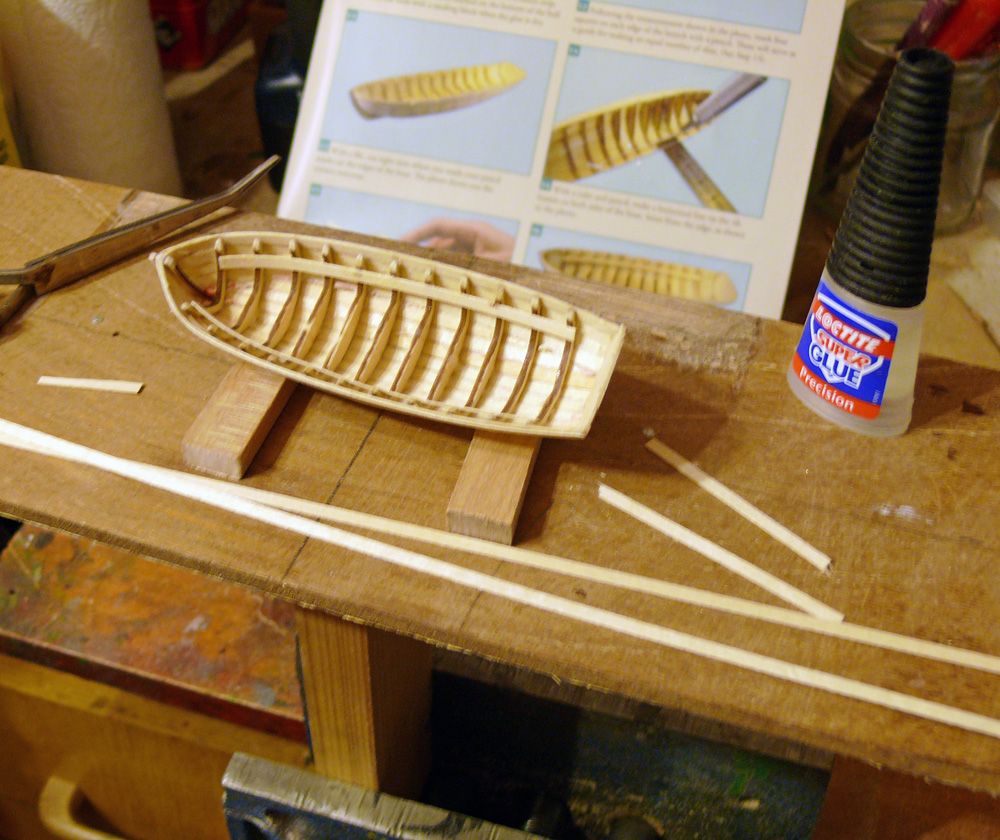

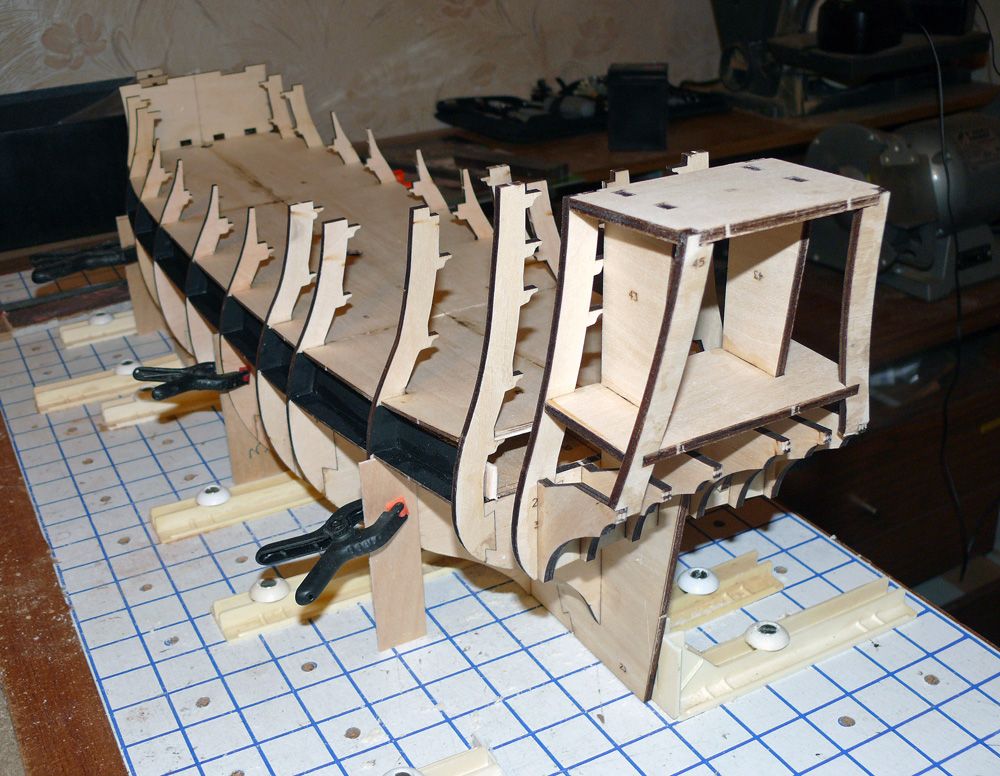

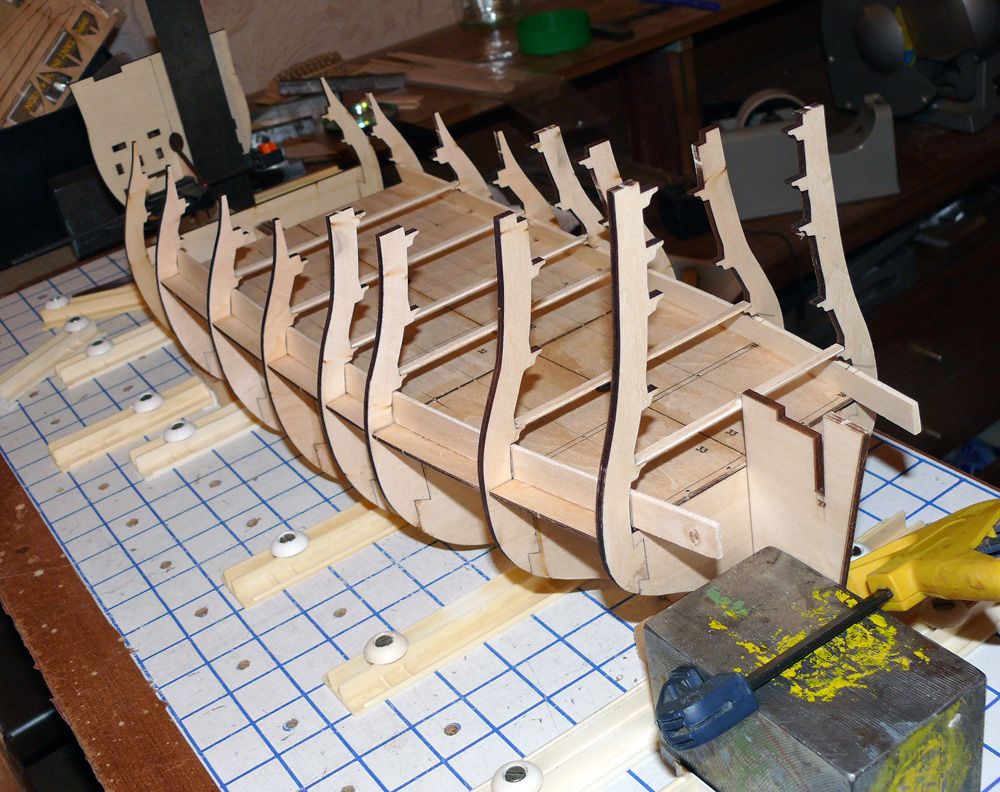

Of course it was a rib that was held in place by the deck I had fittted, so I couldn't remove it and fettle it to fit.

Of course it was a rib that was held in place by the deck I had fittted, so I couldn't remove it and fettle it to fit.