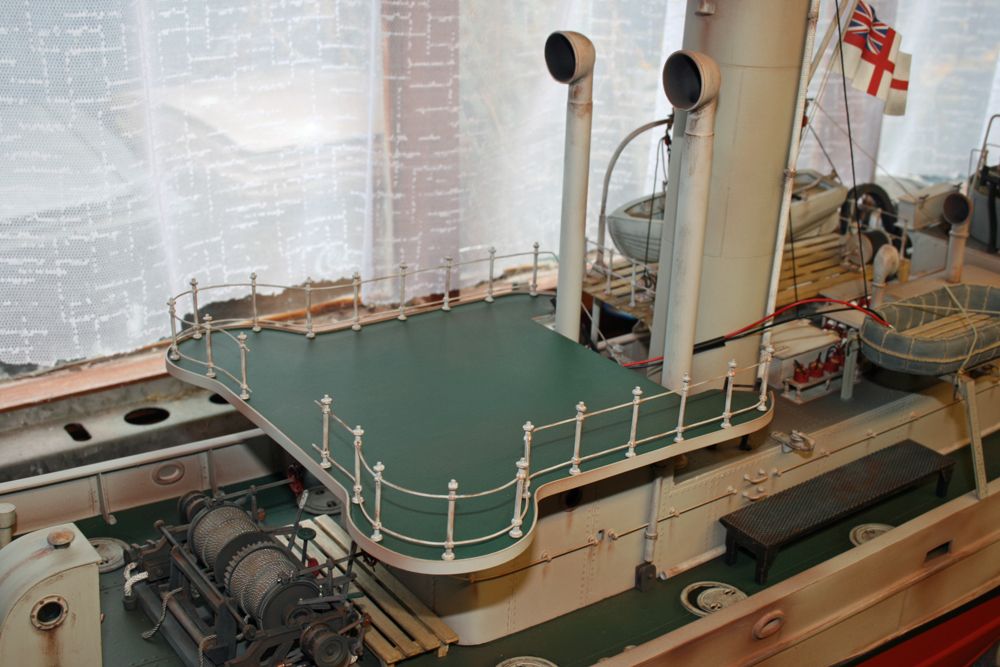

So, to the wheelhouse deck handrails.

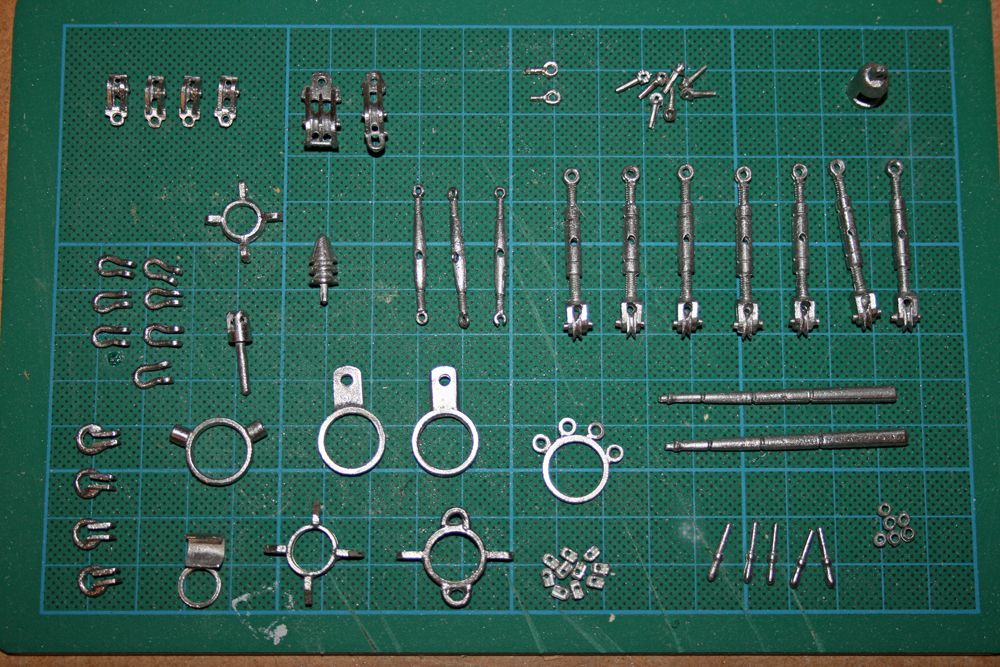

The stanchions for these differ to previous ones seen, as the holes for the wires are just below the top and just above the bottom of the stanchion. Also, they have a ‘spike’ on top onto which the white metal capping pieces fit.

The first task was to lay the four white metal capping pieces onto the deck, up against the vertical strip which fits around the deck perimeter. The holes in the capping pieces, into which the tops of the stanchions will eventually fit, can then be used as a guide to drill into the deck, ensuring that the stanchions when fitted will be correctly spaced, and parallel to each other (as each hole was drilled, I put a small length of wire through it to prevent the capping piece from moving).

Next, the brass wire lengths (once again, purchased seperately as the wire within the kit was too thin & easily damaged) were bent to shape – each railing on each side was made from two lengths, the curved front section and the straighter rear section, top and bottom, making four lengths each side, eight in total. The stanchions were slipped over the wires, and superglued into the holes a few at a time, using the white metal capping pieces temporarily dry-fitted to ensure correct alignment.

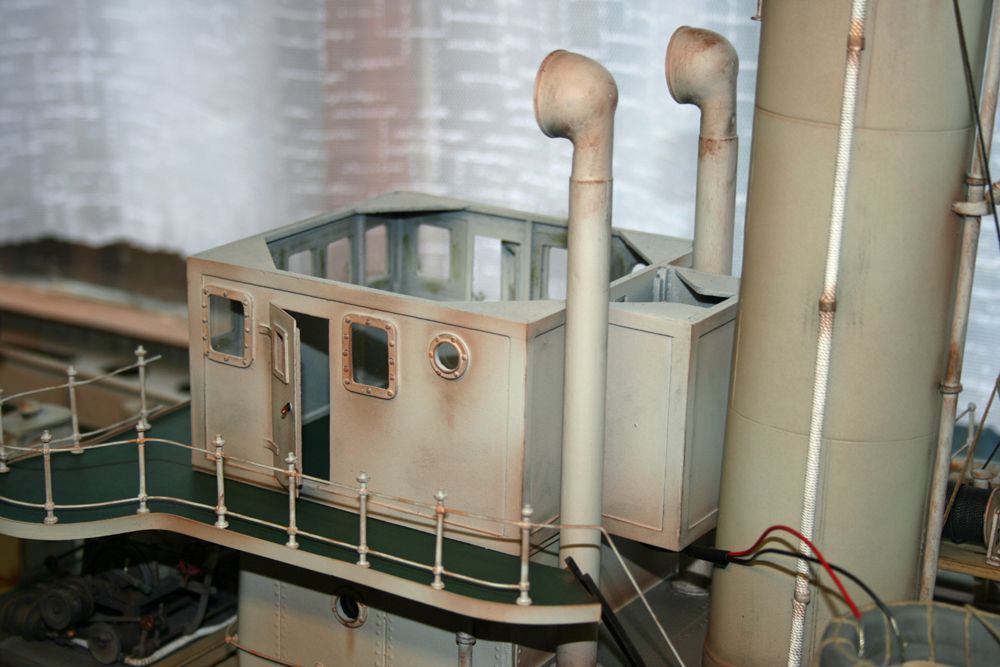

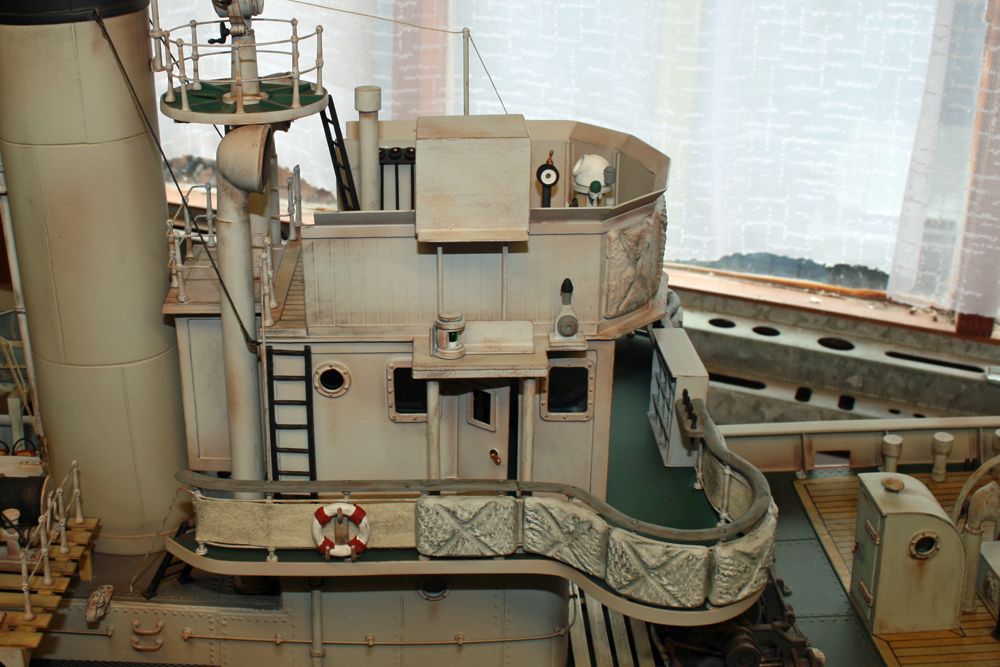

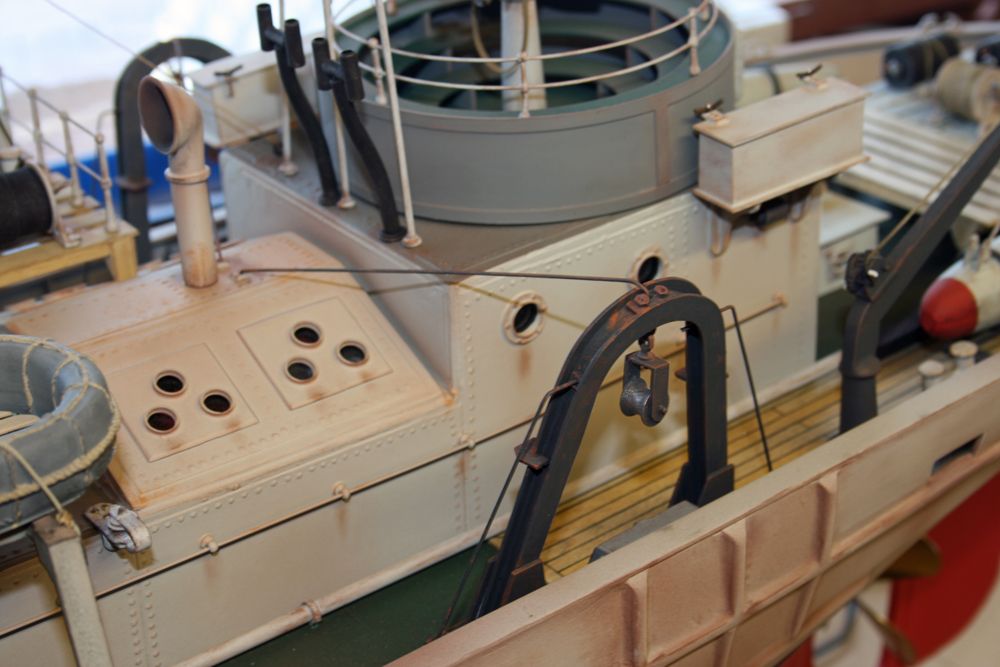

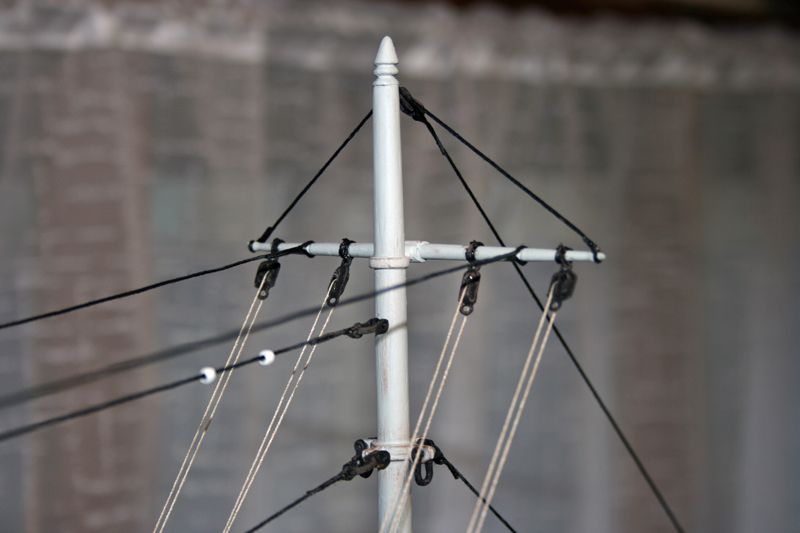

The following photos show the railings in place, painted and weathered:

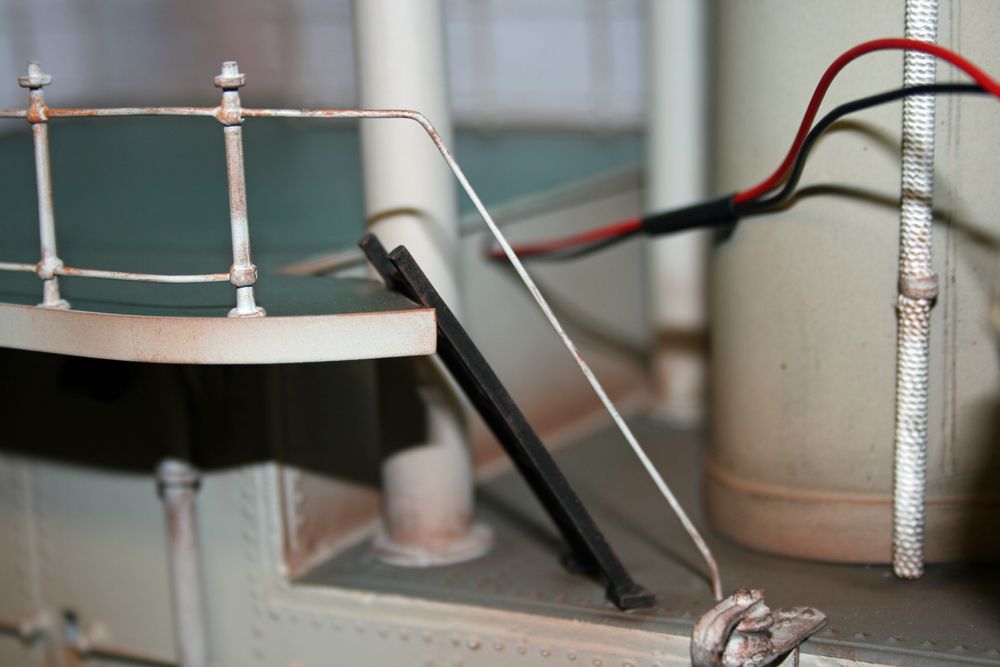

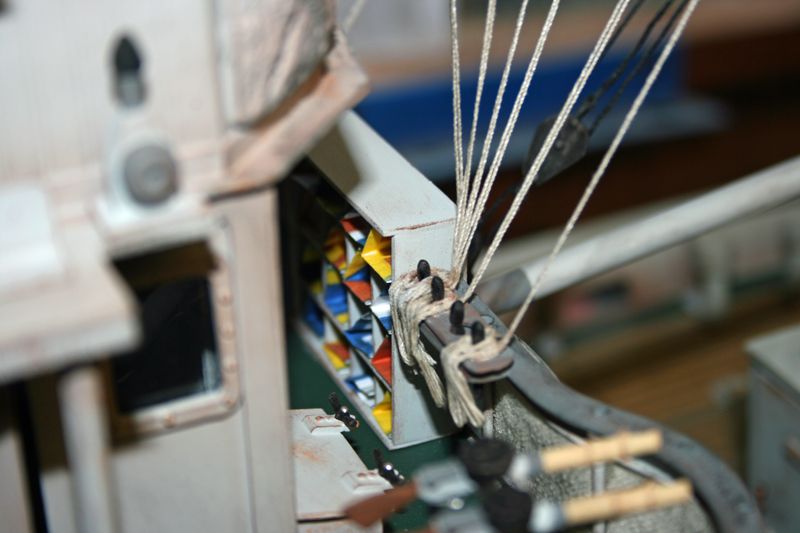

The above photo of the stair handrail also shows the aforementioned wiring that will pass up into the rear ‘extension’ and through the hole into the wheelhouse for the interior lighting and navigation lights.

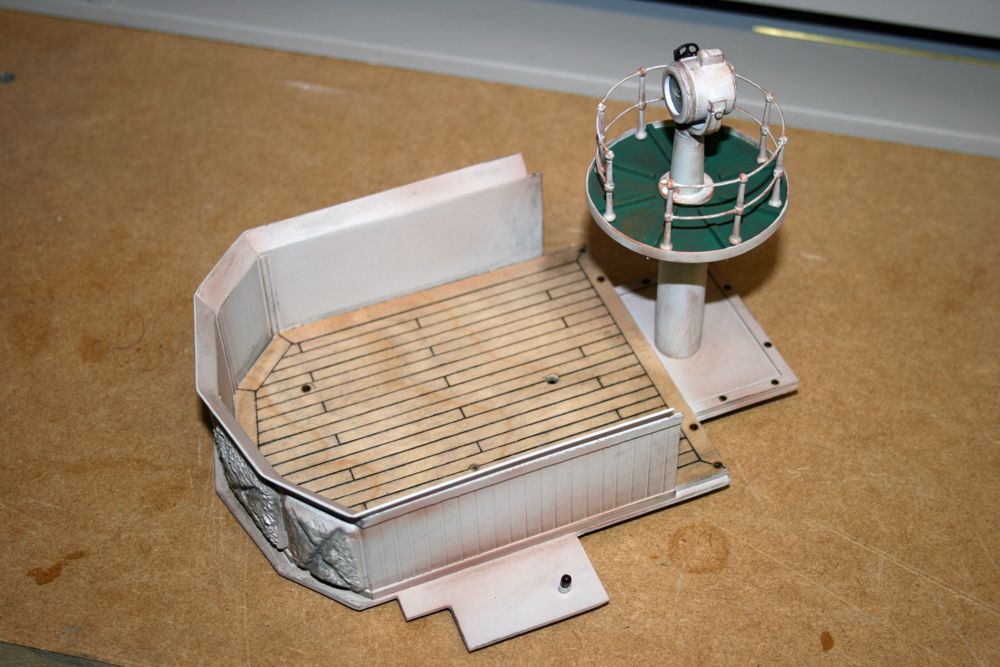

Finally for now, some pics of the wheelhouse placed in position (but not yet glued):

Next will be the fitting of the material strip that runs around the wheelhouse deck railings, between the upper and lower rails. Although some Solartex (a heat-shrink plastic film which is attached using a modellers iron) is included, I will use something more realistic, and will probably tether (by stitching) this to the railings as per other various ships I’ve seen photos of. There will also be the internal wheelhouse detail to fit, before moving on to the roof (compass platform deck) and lighting which will be attached to the underside of the roof.

Paul.