The world's leading magazine for all model boating interests

Sir Lancelot

Sir Lancelot

Home › Forums › Building Kits › Sir Lancelot

- This topic is empty.

-

AuthorPosts

-

10 November 2010 at 13:46 #28836

Robin Lee

Participant@robinlee31938Err .. I think you meant Paul, Bob.Robin10 November 2010 at 15:36 #28839Bob Abell 2

Participant@bobabell2Er……..Sorry about that, RobinI mean Paul of course!………….Very nice model!Bob10 November 2010 at 17:54 #28841Paul Godfrey

Participant@paulgodfrey14946Thanks for your comments Bob (I knew who you meant!!).I started this boat in June last year, and I’m guessing another six months or so before it’s finished – so a total build time of around two years.I was expecting it to take a bit longer than this, perhaps three years, as I only spend around half an hour each weekday evening (it’s a real pain having to go to work!), and on average around six hours during the weekend. But then, I’m not in any rush to finish it, as I get most pleasure from building rather than sailing.Regards, Paul.12 November 2010 at 09:43 #28863Wallace Manning

Participant@wallacemanning93491Paul I agree with you I get more pleasure from the building than the sailing although i do enjoy going to the lake to have a sail when the weather is ok due to my health these days and I just love to show of my boats because I have built them and not brought them already done keep the great work going ,Im 2 years at the build in two weeks time time .Time flys when you are having fun. wallace28 November 2010 at 15:46 #29013Paul Godfrey

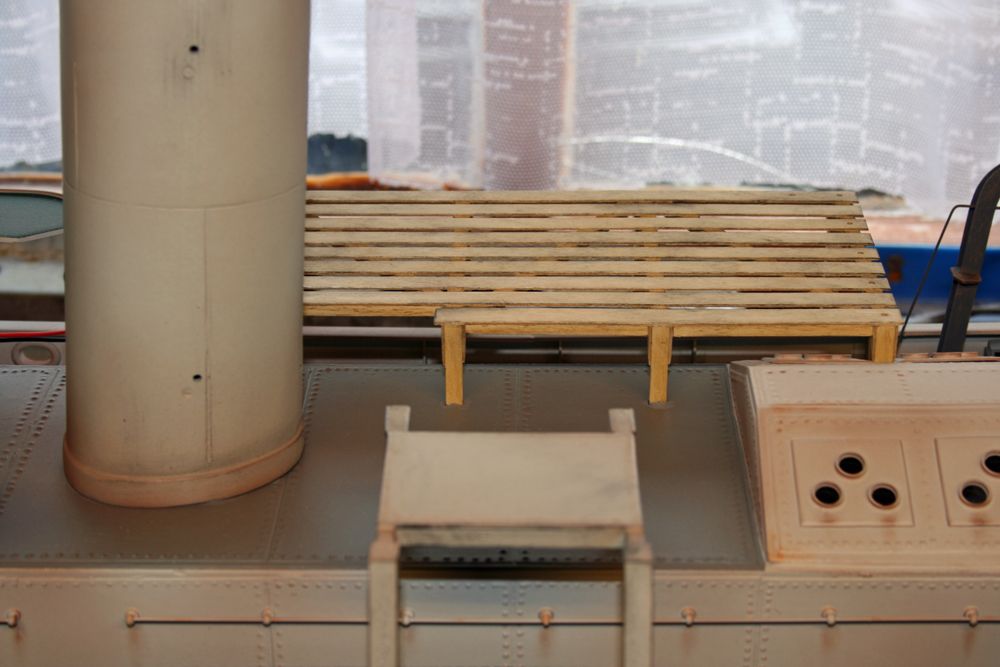

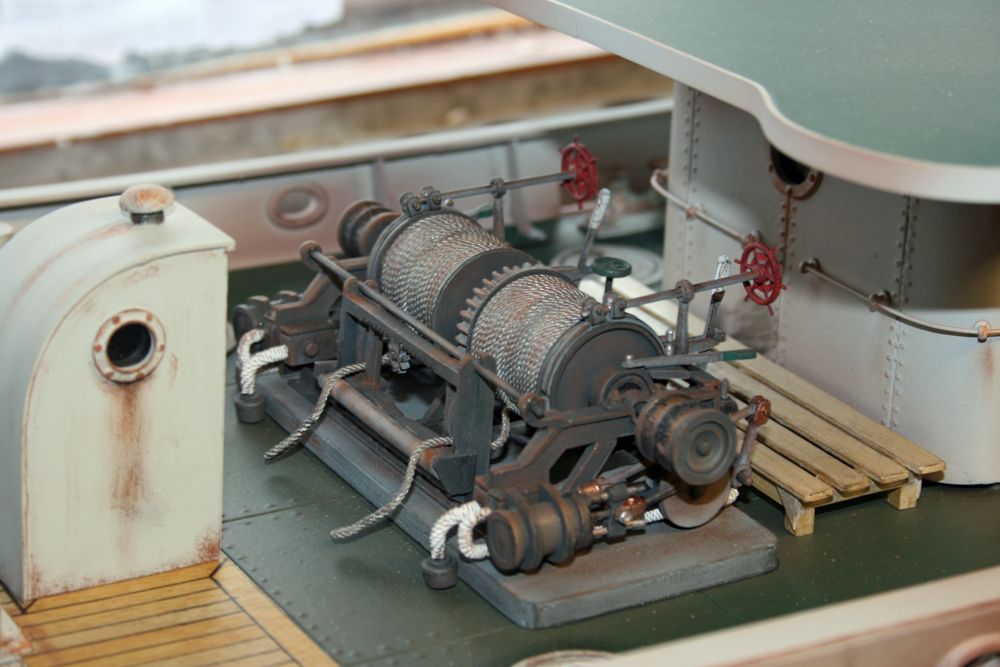

Participant@paulgodfrey14946Some more progress on the superstructure to report.The lights have been fitted to the lower superstructure, and the funnel, boat deck, and carly float mounting have been attached:The carly float mounting has two legs resting on the bulwark capping, and two legs which attach to the superstructure. As mentioned in a recent posting, I was a little nervous about fitting this, and the boat deck, as holes have to be accurately marked and cut into the superstructure, through which the inboard legs protrude. I started by ensuring the superstructure was level across the boat by using a small spirit level, and sat another level on top of the carly float mounting. I lowered the mounting so that the inboard legs (cut longer of course, as they will pass through the holes to be cut) rested on the superstructure, ensuring that the outer legs were directly above the bulwark capping, when looking straight down from above. The spirit level sat on the mounting ensured that this was level whilst being positioned. Once in place, I marked the position of the inboard legs, and cut the holes by firstly drilling a small hole, and then filing to the final shape with a small square-section file.Once the holes were cut, the mounting could be dry-fitted, and again ensuring that the top surface was level, the inboard legs could be marked where they entered the superstructure. With the mounting removed, the inboard legs could be trimmed down a little, making sure there was sufficient left for strengthening with some P38 on the inside. To initially attach the mounting though, a little thick superglue was dabbed on each leg, just below the previously added marks, and the mounting pushed down into place.Once set (left overnight), the aforementioned P38 was applied to the ends of the legs protruding into the superstructure. The same process was applied to the boat deck, which has four inboard legs requiring holes in the superstructure.The funnel was attached by firstly glueing with epoxy the piece of ply fitted flush into the bottom of the funnel, to the similarly shaped ply base fitted to the superstructure – see previous posts for details. Once set, three screws were used to strengthen the join between the plywood pieces, and finished off with some P38 around the inside of the join between the funnels front edge, and the superstructure.The next photo shows the access to the switches and charging jacks, beneath where the rear gun tub will be positioned.And here’s a photo of the main winch in position in front of the superstructure:The lower superstructure still has numerous other items to be fitted to it, one of them being the rear gun tub. The next pic shows the base, previously cut out to help with the positioning of the access hole for the switches, and some of the other styrene components.The boat and carly float will be made up once the lower superstructure has been completed.And finally, an overall photo of the boat as she is at present:I will be continuing with the rear gun tub and the rest of the lower superstructure. I will then add the wiring for the lights to be fitted into the companionways and escape scuttles, and will then move onto the funnel detailing, boat deck and carly float. This will just leave the upper superstructure, the mast, and the rigging.Paul.29 November 2010 at 10:51 #29021Wallace Manning

Participant@wallacemanning93491Hi Paul once again I must say Sir Lancelot is coming on fab its really looking great so glad you do not have any probs with fitting the boatdeck and carley float ,did you varnish the boat deck like i did.I love the way you have done the opening under the rear gun mounting you are so cleaver I will be bringing my leads for the lights on my Sir Lancelot to the rear it does save lifing off and putting back on the superstructure how do you do the lead from the battery to a place for charging so as not to take the battery out all the time.Anyway Paul will have to get onto doing abit on mine soon just doing the small bits will post some more photos very soon I hope,so untill keep the great build going it really is a fab job. wallace29 November 2010 at 15:59 #29023Robin Lee

Participant@robinlee31938Hi Paul,Really coming to life now. Will it be ready for the MPBA Nats next year? See you at the BWMY&PBC Xmas bash.Robin29 November 2010 at 19:59 #29025

See you at the BWMY&PBC Xmas bash.Robin29 November 2010 at 19:59 #29025Paul Godfrey

Participant@paulgodfrey14946Hi Wallace & Robin,Many thanks as always for your commentsWallace – I would like to take the credit for the wiring, but can’t! Dave Milbourn of ACTion Electronics kindly produced both a main wiring diagram, and a separate battery charging diagram, for me. The main diagram is on ACTion’s web site:The battery charging diagram uses a component called a ‘Schottky Diode’, allowing the batteries to be charged without disconnecting them first. I can’t see this on the web site, but I’m sure Dave will e-mail you a copy if required.All I had to do was work out the best place for the switches – being at the rear of the electronics tray, with the batteries in front of it, does mean however that the wiring goes back and forth somewhat! Take a look at some earlier photos showing the battery wiring looms and the electronics tray.With regards to the boat deck, I first gave it a coat of sanding sealer, followed by a light sanding with 600 grade wet & dry. After ‘dirtying’ it with some dry-brushing using matt black enamel, I sprayed a couple of coats of matt polyurethane varnish, mixed 50/50 with enamel thinners, before fitting it to the superstructure.Robin – I expect it will be finished around April/May, so yes, before the Nats, but not sure if I’ll take it there – I’m sure however that you’ll try to talk me into it!!Regards,Paul29 January 2011 at 21:47 #29662Paul Godfrey

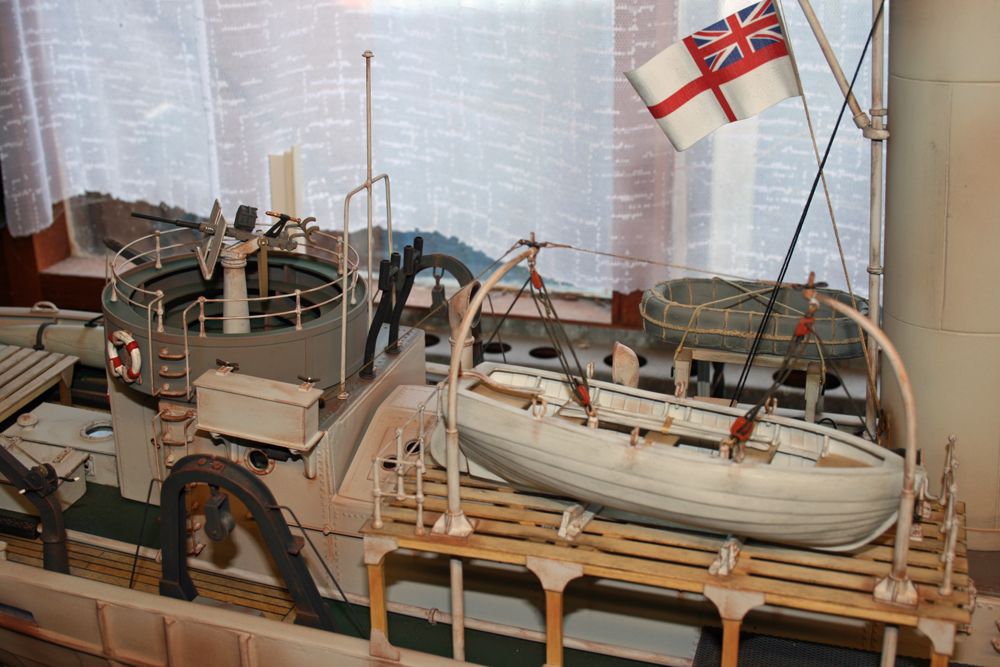

Participant@paulgodfrey14946As it’s been a couple of months since my last posting (thanks to Christmas, the flu…), I suppose an update is due!The lower superstructure is finished in terms of the detailing that is directly fitted to it – the funnel, boat & carly float decks, and the rear gun are all separate assemblies with their own bags of white metal components. Although I’ve had to fit the basic funnel & decks to the superstructure, they’ll all be finished off in due course.Here is a photo of the superstructure to date:At the front,the vertical stering chain tubes have been fitted, along with the ladders up to the wheel house deck. The chequer plate platforms have also been attached to the main deck – you can see in this photo and a later one that the long steering chain tubes that run along the bottom of the superstructure have been attached via their brackets to the deck, not the lower sides of the superstructure as shown in the plans. I had planned to do this a while ago, and had therefore not attached the chequer plate platforms until the tubes were in place. The reason for this? – if the tubes were attached to the lower sides of the superstructure, they could easily be damaged when lifting this off, and it would also mean that the platforms would need to be attached to the deck further out, or directly to the sides of the superstructure – again more vulnerable to damage.Just behind the funnel there is a locker, sand buckets in a rack, and two lifebelt racks:The bucket handles were a real challenge for me, taking several attempts to get right! The lifebelt racks were similarly fiddly to make – each one has a white metal top & bottom piece with ten holes in each, into which the wire uprights fit, then a capping piece of ply is attached on top. I made the four corner uprights from wire, and built the basic structure with these. I the made up eight slightly narrower uprights from plastic rod, and slid them through the holes into place, before adding the ply top. It also took a while to hand paint the lifebelts (there’s twelve in total).The next photo shows the vents, stove pipes, lockers and other fittings, along with the steering chain tubes, and the gun turret:And here’s some more pics of the turret (minus gun, of course!):You will see in the above photo that I’ve had to change the handrails next to the steps – they should run from the turret straight down to just above deck level, but as I’ve made the turret removable for access to the switches, they have been altered accordingly (modellers licence yet again!).The last photo shows the boat as she is now:Next will be finishing the lighting to the escape hatches/companionways, followed by the completion of the funnel detailing & rear gun.Paul.

29 January 2011 at 22:17 #29664neil hp

Participant@neilhplooking absolutely superb paul.it is a masterpeice.neil.30 January 2011 at 15:51 #29673Robin Lee

Participant@robinlee31938Hi Paul,The degree of realism you are achieving is truly outstanding . Can’t wait to see it on the water.RegardsRobin30 January 2011 at 17:26 #29676Paul Godfrey

Participant@paulgodfrey14946Thanks very much Neil & Robin for your kind comments once again.I can’t quite believe just how much more there is still to do, and how much detail is still to be added! Think I’ll be quite nervous when I eventually take it to the lake for the first time!Best wishes,Paul.30 January 2011 at 19:22 #29679Wallace Manning

Participant@wallacemanning93491Happy New Year Paul lovely job its looking goodwallace30 January 2011 at 20:51 #29680Paul Godfrey

Participant@paulgodfrey14946Thanks Wallace, and happy new year to you also.Regards,Paul.23 February 2011 at 17:49 #29917Paul Godfrey

Participant@paulgodfrey14946The lighting for the lower superstructure & main deck escape scuttles / companionways has now been completed. The 12v grain of wheat bulbs attached to the underside of the lower superstructure were seen in previous photos, and were fairly straightforward. However, I had made things difficult for myself with regards to the main deck lighting by not installing the wiring at an earlier stage!I made a wiring loom consisting of 1) a connector to join to the electronics tray, 2) a single bulb for the rear deck, and 3) three bulbs for the front section of the main deck. The bulb and its wiring at the rear was easy to fit due to its proximity to the main opening in the deck, but the front three needed some head scratching!. I ended up using a strip of 1/4 inch square section hardwood to which I attached the front part of the wiring loom (with black electrical tape), with the three separate bulbs correctly spaced to line up with the three holes I had drilled through the deck at an earlier stage. I then slid the wood strip / wiring through the deck opening into the gap between the top of the batteries and the underside of the deck, and ‘fished’ the bulbs through the holes using a piece of thin brass rod with the end bent into a hook.It would have been better if I’d remembered to take a photo of all this before fitting it – but I did take one of a bulb poking through its hole, and secured with a small piece of plywood which had a central hole drilled into it, then slotted from the hole to one side, allowing the wires to be fed through:Although fiddly, at least the bulbs can be prized from their holes, and the wood strip / wiring removed if needed.The companionways etc were then attached with a little superglue, and job done! The next pics taken in dusky conditions show some of the lights (which are turned on / off from the transmitter):I’ve also finished the funnel detailling, consisting of a small mast at the front, a vent pipe at the rear, a lagged pipe up the port side for the steam whistle, and the flag:I haven’t taken a separate photo of the white metal components for the funnel as there weren’t that many – four mounting brackets for the mast, three for the lagged pipe, three for the rear vent, plus the flag mast mount and the steam whistle. There’s also several small rope-attachment rings for the funnel support guides.The next photo is a section of the lagged pipe, with the steam whistle on top:I started by dry-fitting the three mounts into holes I had drilled at a previous stage, and inserting the core of the pipe which is made from 2.2mm brass rod. Thick superglue was then applied to the rod where it passed through the mounts, and was left to dry.The rod / mounts assembly was then pulled off the funnel so that I could wrap around the lagging (made from the same 1.5mm ‘rope’ used for the winches on the fore and rear decks) inbetween the mounts and the whistle I had glued to the top. Thick superglue was applied down the length of the brass rod prior to wrapping around the lagging. When dry, I sprayed the whole assembly with grey primer, and then painted the lagging by hand with matt white Humbrol enamel, and the other components in their various colours. Weathering was finally added to complete the assembly, which was then glued to the funnel.The next pic shows the flag, its mast, and other attachments:The rear vent is 4mm alloy tube, the flag mast base is a white metal item (as is the pulley), the mast itself I used plastic tube, and the mast capping was cut from 0.5mm thick plasticard using a hole-punch. The flag mast support at the top is made from 1mm brass rod.The flag is from BECC, and was prepared as follows:1) Instead of applying a bead of glue around the edge as per the accompanying instructions (to stop the edge of the flag from fraying when trimmed to size), I sprayed the flag with some matt varnish mixed 50/50 with enamel thinners.2) When virtually dry, I trimmed it to size with a sharp knife and steel rule.3) I loosley ‘concertinered’ it up, and placed it on the bench with a lightish weight resting on it to hold it in this position (not heavy enough to squash the folds of the flag together)4) When fully dry (next day), the weight was removed, and the flag could then be ‘teased’ out into the shape you see in the above photo.Continued in next post . . . . . . .23 February 2011 at 17:55 #29918Paul Godfrey

Participant@paulgodfrey14946. . . . . Continued from last posting:5) The flag rope was glued in place, and the end of the flag folded over this, and glued down.6) A liitle grubiness was added by dry-brushing, and the job was done!The final photo for now is of the flag rope attached to the cleat on the funnel:That’s it for now. Next will be the rear gun, and the Carly Float.Paul.

9 March 2011 at 17:11 #30041Paul Godfrey

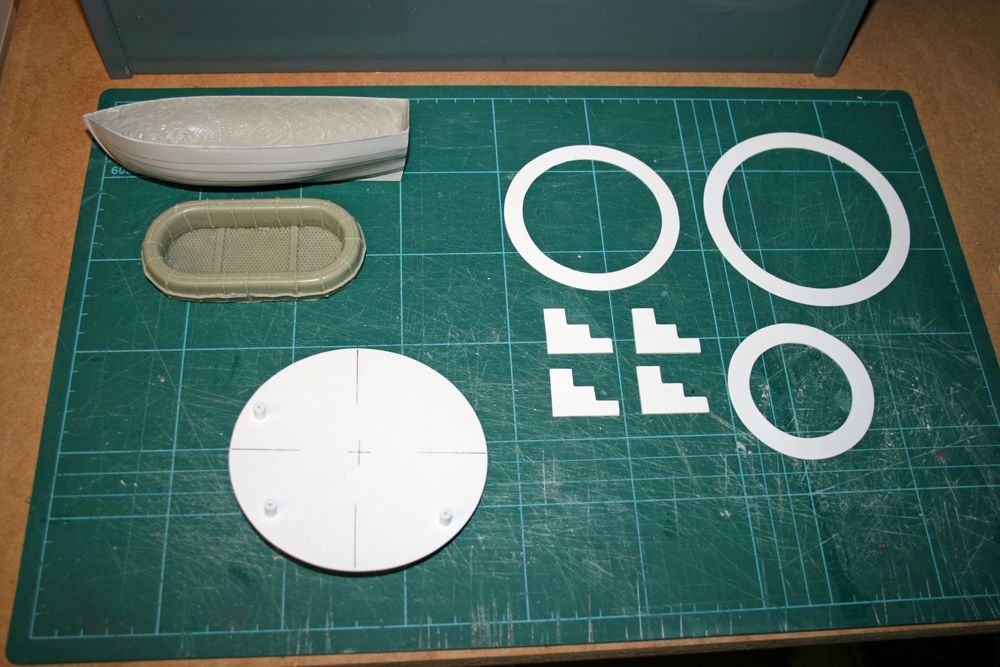

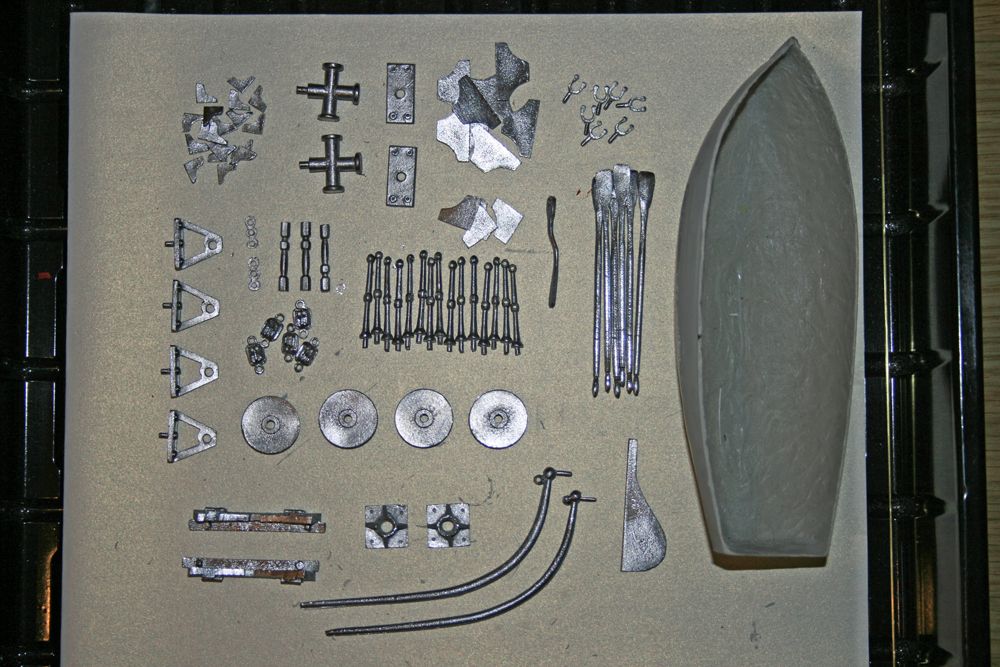

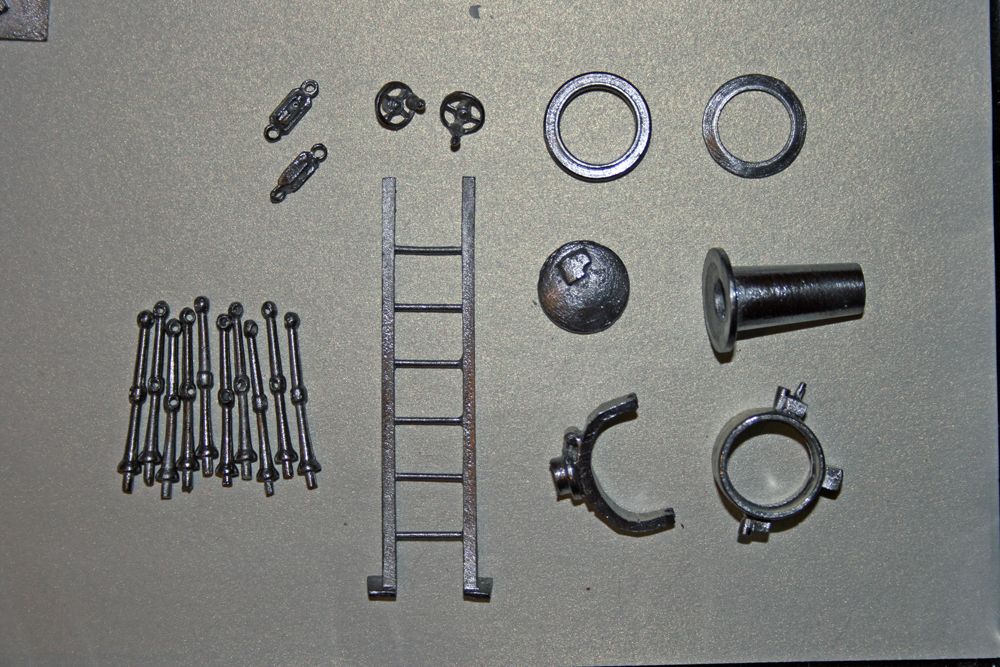

Participant@paulgodfrey14946A brief update on what I’ll be doing next, with some photos of the white metal components to be used.As mentioned in the previous posting, The Carly Float & rear (20mm Oerlikon) Gun are next on the agenda, but I’ve decided to also build the Searchlight (as the components for this were in the same bag as the funnel fittings) and complete the boat deck at the same time.Here’s the cleaned-up metal items for the boat / boat deck, together with the fibreglass boat itself:Next is the searchlight. This will have working lights fitted, so consideration needs to be given to incorporating the bulbs and wiring when it comes to building it up:Here’s the cleaned-up rear gun components:And finally the resin moulding for the Carly float:Plywood is used for the flooring planks in the Carly float, the thwarts and top capping for the boat, and the searchlight base (constructed with triangular support ribs underneath and a plywood edging as per the forward gun platform).As I’m building the above assemblies simultaneously, progress should hopefully be fairly quick – more updates to follow over the next few weeks.Paul.31 March 2011 at 19:29 #30242Paul Godfrey

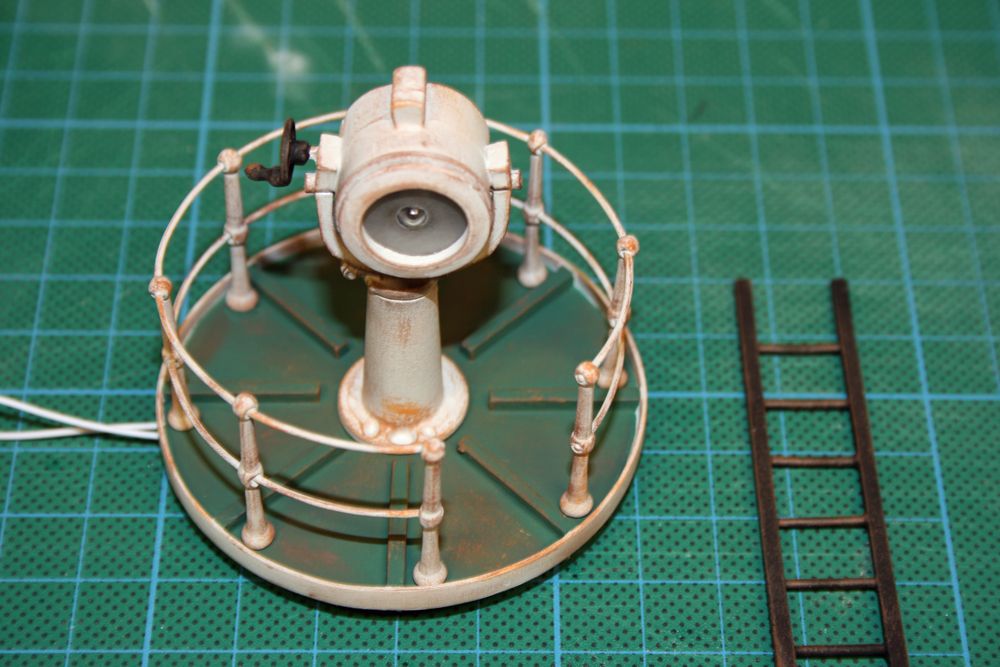

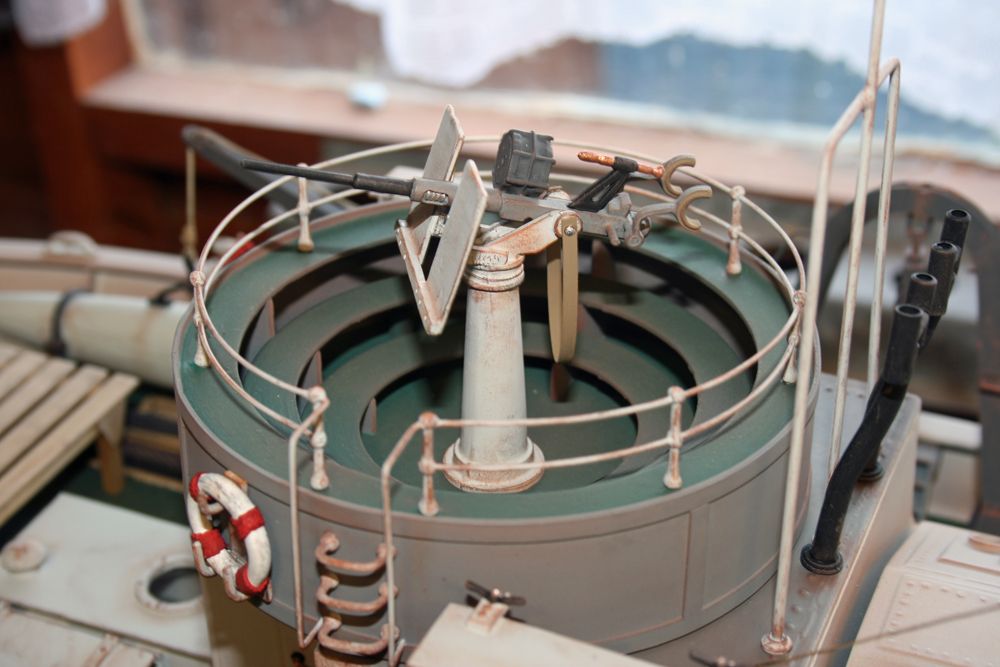

Participant@paulgodfrey14946The first of two updates this evening on recent progress (can’t seem to fit everything into a single posting due to the amount of info/photos I usually include!).The searchlight, Carly Float, boat & boat deck, and rear gun have all now been completed. This post will concentrate on the searchlight & rear gun.The first photo shows the searchlight mounted on its platform:Construction of the platform follows the same method as used for the front gun platform, ie plywood disc with a thin plywood strip around the edge, with supports underneath, and wooden ‘treads’ on the upper surface. The white metal components seen in the previous posting fitted together nicely, but prior to construction, holes were drilled in the light housing and the ‘U’ shaped mounting bracket to facilitate the fitting of a working light (12v). The wires pass through these parts, down the lower main mount, and can be seen in the above photo exiting beneath the platform.The searchlight & its platform will eventually be mounted above the wheelhouse/compass deck, on a thick wooden dowel, approximately level with the tall vents in front of the funnel.The following photos show the completed rear gun in position:This is of white metal construction, except for the strap hanging down which was made from very thin plasticard, and the front section of the barrel which is brass wire rod.To finish off this first update today, a photo of the bow which hasn’t been photographed that much, as the boat is usually facing the other way!!31 March 2011 at 21:15 #30243Paul Godfrey

Participant@paulgodfrey14946Now for the boat deck & Carly Float.The Carly Float is made from resin, and has the rope detailing moulded in, so this needs painting by hand after the float itself has been painted. The next photo shows the float on its mount, secured by ropes:As you would have seen, the boat deck wooden structure was built previously, and the boat and other detail has now been added. This consists of the railings, winches, bollards, davits, and plating to the outer faces of the deck & supports:The boat is very well detailed, and was built as follows:1) The fibreglass moulding (as seen in the posting earlier this month) needed the inside smoothed out, and this was done using a couple of applications of P38, sanded after each layer.2) A length of 2mm square section wood was glued along the inside of the boat, along the line of the keel.3) Strips of thin card were glued end-on to the wood strip, up to the top edges of the boat. They were evenly spaced from bow to stern, taking into account the positions of the seats and rowlocks, which all needed to line up.4) further strips of the 2mm square section wood were glued on top of the card strips, from bow to stern, one each side of the boat around 10mm from the top edges – these are the supports for the seats etc.5) At this stage, the entire inside of the boat was painted light grey.6) The wooden floorboards, seats, bow and stern pieces were cut to size and fitted, followed by the ‘knees’ which were painted grey.7) The capping around the top edge was made up (by drawing around the upside-down boat onto the thin ply), and was blended in using model filler. This, and the outside of the boat, was then painted grey.8) Holes were drilled into the capping piece for the rowlocks, to line up with the seats.9) The rudder, tiller arm, and oars were the fitted, followed by some weathering.The following photo shows this in more detail:This also shows the davits, blocks and associated rope.The final photo is the boat as she is to date:The next stage is the wheelhouse and compass deck, which will then only leave the mast, some odds and ends including the supports to the four gallows, and of course the crew! (I won’t use the five white metal crew included, but will instead buy some of the ‘Wee Friends’ resin figures, as these are of course lighter, and the detail is superb.Thats it for now,Paul.1 April 2011 at 09:48 #30245Wallace Manning

Participant@wallacemanning93491Hello Paul once again what can I say it is really coming together now and looking fab how time flys as you know I have been at mine now for 28 mths.Oh nearly forgot had it in my fish pond over the w/e to try and ballast it up wow it takes alot have had to go and buy some lead pettets online put the photos on line and she weights a ton.Just keep the good work going.wallace1 April 2011 at 17:31 #30247Robin Lee

Participant@robinlee31938Really looking like the real thing now Paul. I bet you can hardly wait to finish it and get it into the lake. I only hope it does not weigh “a ton” as Wallace states above. 1 April 2011 at 19:06 #30248

1 April 2011 at 19:06 #30248Wallace Manning

Participant@wallacemanning93491Robin its around 56lb in weight I thinkwallace1 April 2011 at 21:15 #30249Paul Godfrey

Participant@paulgodfrey14946Thanks Wallace & Robin,Thank god it doesn’t weigh a ton, otherwise my workbench would be a pile of matchwood!! Even at 50+ lbs, I’m getting nervous at the thought of transporting it, especially when it’s very easy to damage! (Robin, I may well ask you for some guidance on building a box to keep/transport it in ).I am very pleased with recent progress except the angle of the ropes between the davits and the small boat – I had fixed the brackets to which the ropes attach inside the boat too near the centre, creating the angle when instead they should be roughly vertical. I knew that I would not be happy until rectified, so with much fiddling about and some modification, the brackets were not only moved towards the ends of the boat, but were also strengthened at the base as well (they would have been easily broken off).The ropes/blocks are now vertical, and I’m much happier. No more photos taken as yet, but future postings will show what I know is a vast improvement.Wallace – I’ve now seen your boat in the fishpond, and it’s looking great. Hope there wasn’t any leaks!Robin, hope to see you Sunday week for the competition, maybe this Sunday as well. Oh, and by the way, my next boat is on order. Remember the Warwick show . . . . . .Regards,Paul.2 April 2011 at 12:52 #30252

).I am very pleased with recent progress except the angle of the ropes between the davits and the small boat – I had fixed the brackets to which the ropes attach inside the boat too near the centre, creating the angle when instead they should be roughly vertical. I knew that I would not be happy until rectified, so with much fiddling about and some modification, the brackets were not only moved towards the ends of the boat, but were also strengthened at the base as well (they would have been easily broken off).The ropes/blocks are now vertical, and I’m much happier. No more photos taken as yet, but future postings will show what I know is a vast improvement.Wallace – I’ve now seen your boat in the fishpond, and it’s looking great. Hope there wasn’t any leaks!Robin, hope to see you Sunday week for the competition, maybe this Sunday as well. Oh, and by the way, my next boat is on order. Remember the Warwick show . . . . . .Regards,Paul.2 April 2011 at 12:52 #30252Robin Lee

Participant@robinlee31938Wallace and Paul – 56 lb! – you will have to start working out at the Gym before tackling that. Problem is not so much the vertical lift but the leaning into the back of a car in order to extract it. Box – this will add to the weight of course. I wonder if anybody else has ideas about how to handle large models! Paul – ah yes, PF’s number one rule – if you have made a mistake or something has not turned out right, do not bodge it, start again.Yes also looking forward to the first regatta having not sailed since October (Ok a short sail after the work party last weekend).Regardsrobin2 April 2011 at 19:55 #30253

Box – this will add to the weight of course. I wonder if anybody else has ideas about how to handle large models! Paul – ah yes, PF’s number one rule – if you have made a mistake or something has not turned out right, do not bodge it, start again.Yes also looking forward to the first regatta having not sailed since October (Ok a short sail after the work party last weekend).Regardsrobin2 April 2011 at 19:55 #30253Wallace Manning

Participant@wallacemanning93491Paul and Robin — yea its a very heavy ship got told off last week by my girls for lifing it into my pond I use cambelts to lift in/out of the water and it was heavy and that was without thesuperstrut on ,Its just about fits into the car with all the seats down.Paul you are like myself if you dont like it re-do it I have done that alot during my build its nearly done around 95% will take it to club show next week but not sailing.Keep the good work going. wallaceAuthorPosts- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Code of conduct | Forum Help/FAQs

Latest Replies

Home › Forums › Building Kits › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Vic Smeed’s Legacy

Started by:

Colin Bishop

in: All things floating

Colin Bishop

in: All things floating

- 2

- 2

-

6 hours, 31 minutes ago

Tony Hadley

Tony Hadley

-

4D Modelshop

Started by:

Keith Long in: Scratch build

- 6

- 9

-

13 hours, 8 minutes ago

Colin Bishop

Colin Bishop

-

Fairey Huntsman 31

1

2

…

5

6

Started by:

Chris Fellows

in: Build Blogs

Chris Fellows

in: Build Blogs

- 14

- 139

-

1 day, 10 hours ago

Chris Fellows

Chris Fellows

-

Fairey Faun

1

2

3

Started by:

Chris Fellows

in: Build Blogs

Chris Fellows

in: Build Blogs

- 7

- 58

-

1 day, 10 hours ago

Chris Fellows

Chris Fellows

-

Vic Smeed’s Silver Mist

1

2

…

32

33

Started by:

Bob Abell 2 in: Scratch build

- 4

- 822

-

1 day, 11 hours ago

Tony Hadley

Tony Hadley

-

Fairey Huntsman 28

1

2

…

7

8

Started by:

Chris Fellows

in: Build Blogs

Chris Fellows

in: Build Blogs

- 1

- 195

-

1 day, 12 hours ago

Chris Fellows

Chris Fellows

-

Eezebilt RAF Fire Boat

Started by:

Tim Cooper in: Build Blogs

- 2

- 3

-

1 day, 13 hours ago

Dave Reed

Dave Reed

-

Feathered Friends

Started by:

Chris Fellows

in: Soapbox

Chris Fellows

in: Soapbox

- 3

- 7

-

1 day, 16 hours ago

Chris Fellows

Chris Fellows

-

John Cobb’s Crusader

1

2

…

7

8

Started by:

Paul T

in: Scratch build

Paul T

in: Scratch build

- 1

- 192

-

2 days, 12 hours ago

John W E

John W E

-

Complex Automata

Started by:

Colin Bishop

in: Soapbox

Colin Bishop

in: Soapbox

- 1

- 1

-

3 days, 15 hours ago

Colin Bishop

Colin Bishop

-

RAF Fireboat ID

Started by:

Dave Reed

in: Collectors’ corner

Dave Reed

in: Collectors’ corner

- 8

- 24

-

4 days, 16 hours ago

Tim Cooper

-

TID steam tug 42″ – PN Thomas drawing enlarged

1

2

Started by:

Ray Wood 3

in: Scratch build

Ray Wood 3

in: Scratch build

- 8

- 33

-

5 days, 10 hours ago

Richard Simpson

Richard Simpson

-

Lady of Skye (puffer)

1

2

Started by:

mick east

in: Build Blogs

mick east

in: Build Blogs

- 9

- 43

-

5 days, 20 hours ago

Richard Simpson

Richard Simpson

-

Building a hull.

Started by:

mick east

in: Scratch build

mick east

in: Scratch build

- 7

- 10

-

1 week ago

Ray Wood 3

Ray Wood 3

-

Todays Boating

1

2

…

210

211

Started by:

ashley needham

in: All things floating

ashley needham

in: All things floating

- 84

- 5,252

-

1 week, 1 day ago

Colin Bishop

Colin Bishop

-

Sea Rover Restoration

Started by:

harry smith 1 in: Collectors’ corner

- 4

- 10

-

1 week, 1 day ago

Richard Simpson

Richard Simpson

-

WORKSHOP LIGHTING

Started by:

John W E

in: All things floating

John W E

in: All things floating

- 9

- 18

-

1 week, 2 days ago

Colin Bishop

Colin Bishop

-

Mayhem Website Down

Started by:

Colin Bishop

in: All things floating

Colin Bishop

in: All things floating

- 4

- 10

-

1 week, 5 days ago

Colin Bishop

Colin Bishop

-

MAGGIE M trawler

Started by:

sammyk

in: Buy/Sell or Trade

sammyk

in: Buy/Sell or Trade

- 2

- 3

-

1 week, 5 days ago

sammyk

sammyk

-

meter

Started by:

Alasdair Allan

in: All things floating

Alasdair Allan

in: All things floating

- 5

- 16

-

2 weeks ago

Chris Fellows

Chris Fellows

-

River Queen 2”- 1’.

Started by:

Richard B in: Steam powered models

- 5

- 7

-

2 weeks, 1 day ago

Richard B

-

Deluxe Superphatic Glue.

Started by:

Colin Bishop

in: All things floating

Colin Bishop

in: All things floating

- 4

- 12

-

2 weeks, 1 day ago

Chris Fellows

Chris Fellows

-

How to add photos to your posts

Started by:

Colin Bishop

in: Adding Images to Forum Posts

Colin Bishop

in: Adding Images to Forum Posts

- 3

- 16

-

2 weeks, 1 day ago

Len Morris 2

-

Cataract

Started by:

Bob Wilson in: Soapbox

- 2

- 4

-

2 weeks, 2 days ago

Colin Bishop

Colin Bishop

-

The mighty tug Wattle

1

2

3

Started by:

mick east

in: Build Blogs

mick east

in: Build Blogs

- 10

- 61

-

2 weeks, 2 days ago

Richard Simpson

Richard Simpson

-

Vic Smeed’s Legacy

-

Latest Issue

Newsletter Sign-up