The world's leading magazine for all model boating interests

Sir Lancelot

Sir Lancelot

Home › Forums › Building Kits › Sir Lancelot

- This topic is empty.

-

AuthorPosts

-

31 March 2010 at 18:20 #26207

Paul Godfrey

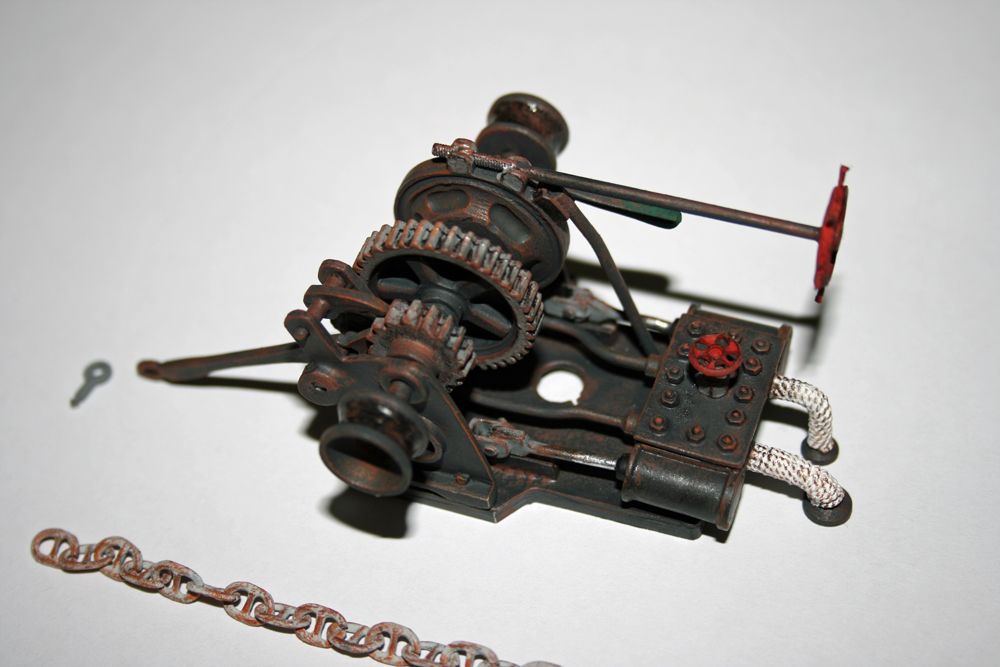

Participant@paulgodfrey14946Hi all,A brief update this time, with a few photos of the completed anchor windlass. I’m pleased with how it’s turned out, and very much look forward in the future to building the main winch, which contains probably 4 or 5 times the number of parts.Once the windlass has been attached to the foredeck, the small eye bolt seen in the first two photos will be fixed into the deck, and the barring lever can then be bound to it. Finally, the anchor chain can be fitted.That’s the foredeck completed, and I’ll post some photos in due course which will also show the forward gun deck, once this area has been finished off. My next job, however, will be to wire-up the electronics (I just need to buy a receiver), as I think that on a long build such as this, it’s a good idea to vary the tasks rather than just do all the building in one go, all the painting in one go, etc.Paul.Edited By Paul Godfrey on 31/03/2010 18:28:00

31 March 2010 at 18:59 #26208Robin Lee

Participant@robinlee31938Hi Paul. The windlass looks very good and the weathering has certainly brought it to life. The kit parts look high quality – did they require much work on them before painting? Some kit suppliers who will remain un-named provide white metal parts of dubious quality requiring much filing and filling and sanding or even replacement with a scratch made substitute.Robin31 March 2010 at 21:07 #26211Paul Godfrey

Participant@paulgodfrey14946Hi Robin,I’ve been very happy indeed with the overall quality of the white metal parts – with the odd exception, the parts are very detailed and crisp, and go together well. Yes, some parts do need some extra work to get them looking good, but when building a well-weathered boat such as this, a bit of surface-texture can actually look better, especially when a ‘rusty’ finish is needed.I do wish that manufacturers would cast gear wheels in such a way that the join-line doesn’t run through the teeth, as this is almost impossible to clean up properly!!Thanks for your comments Robin, see you soon.Regards, Paul.14 April 2010 at 21:08 #26419Paul Godfrey

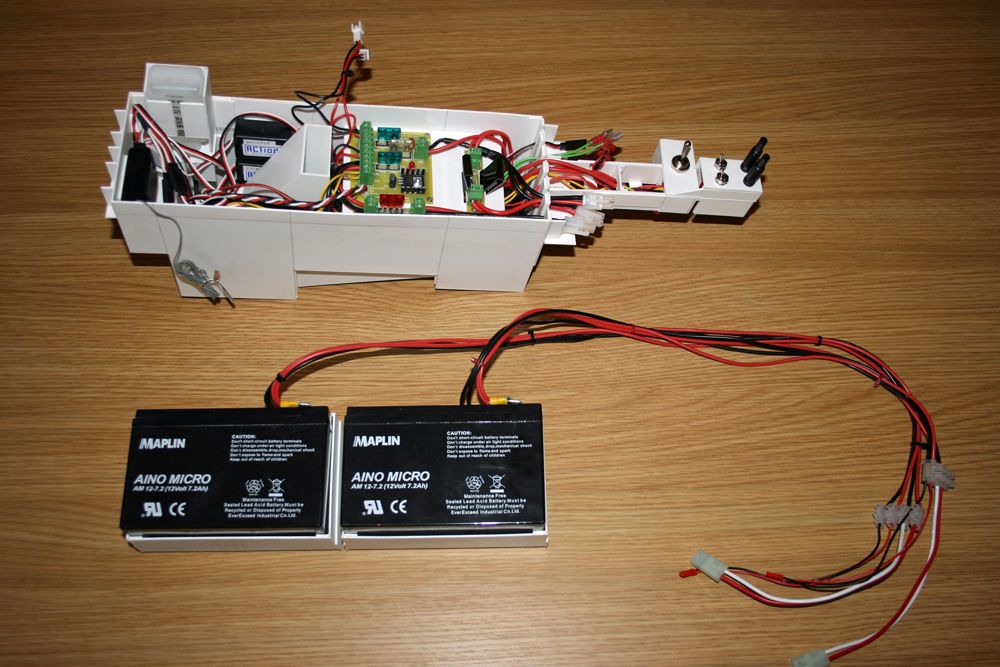

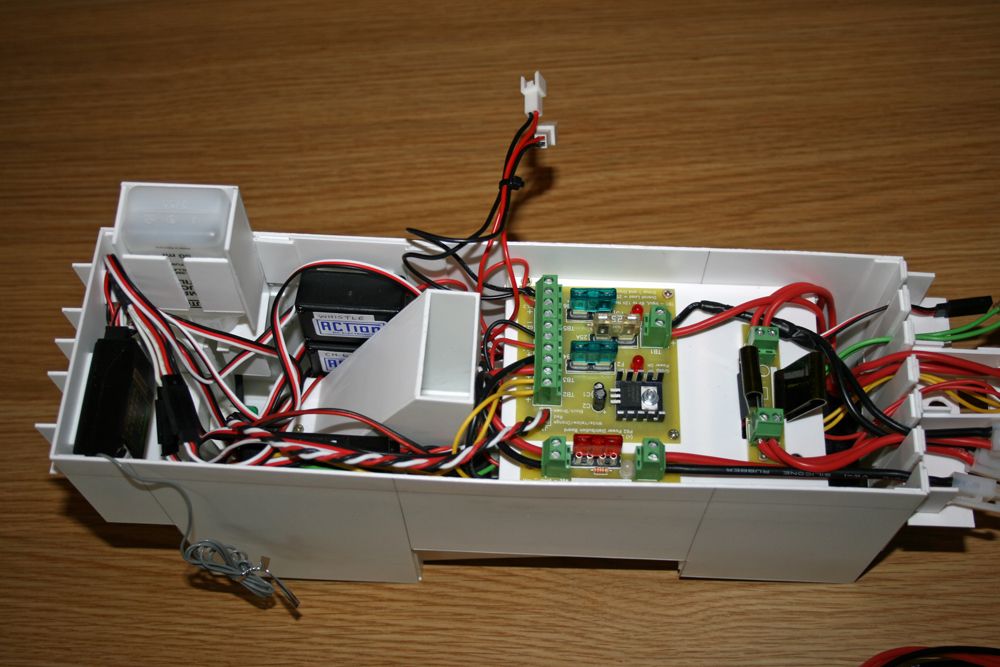

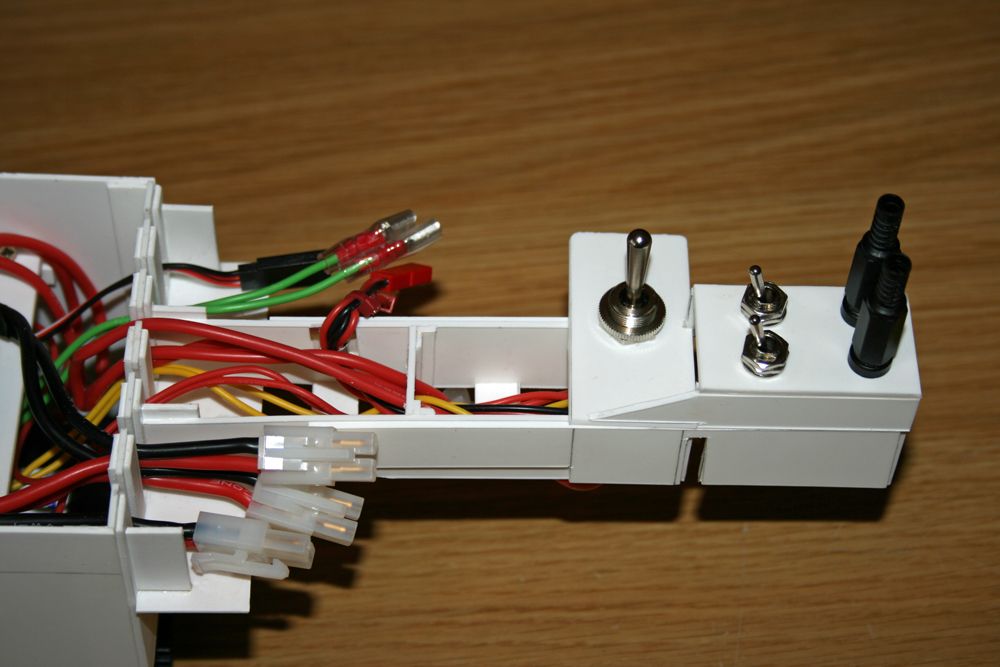

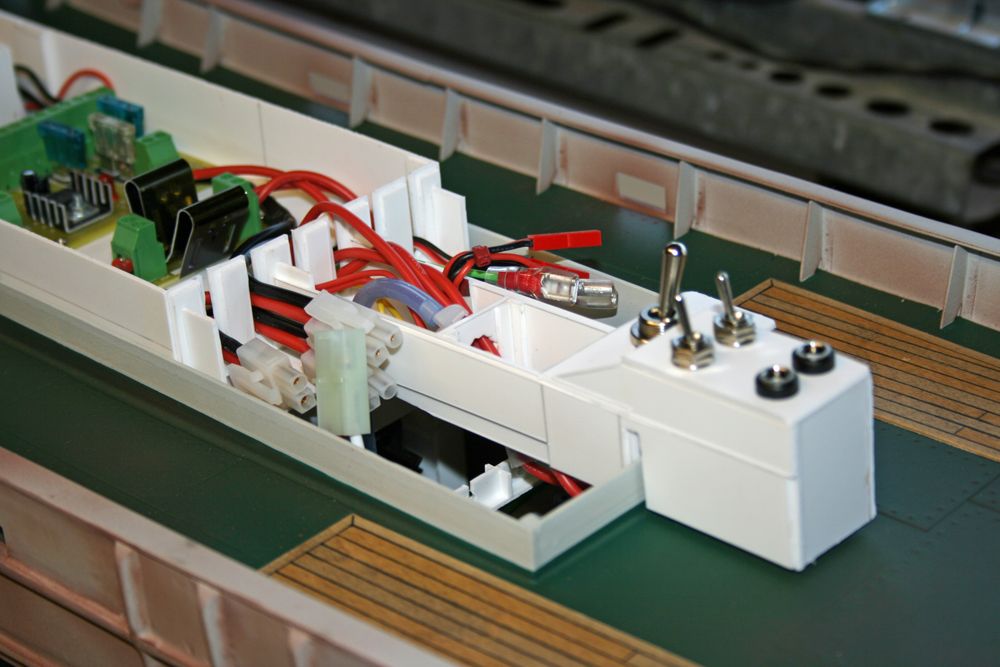

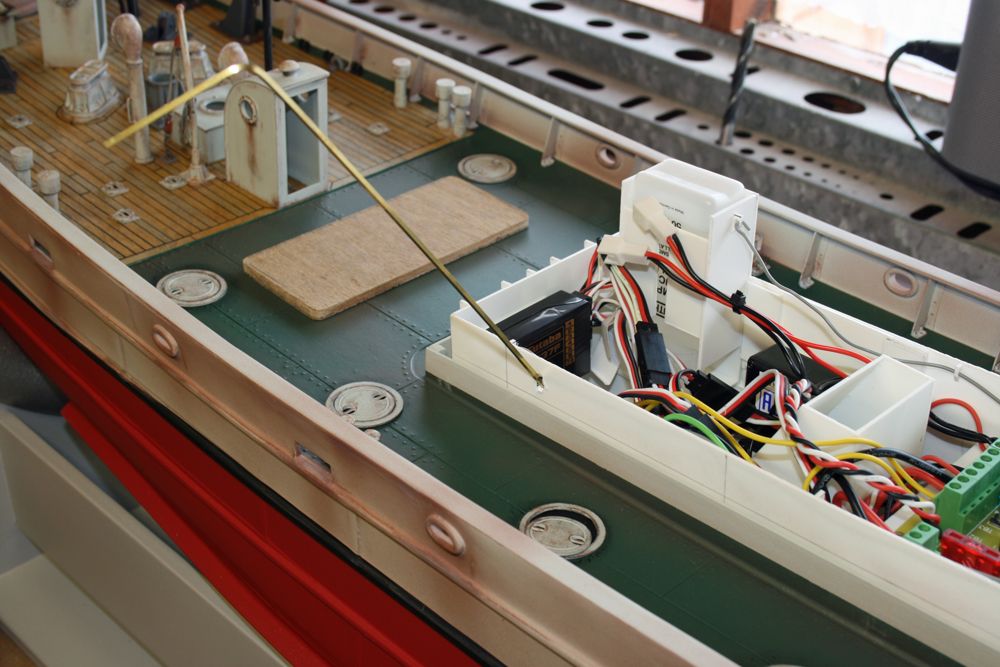

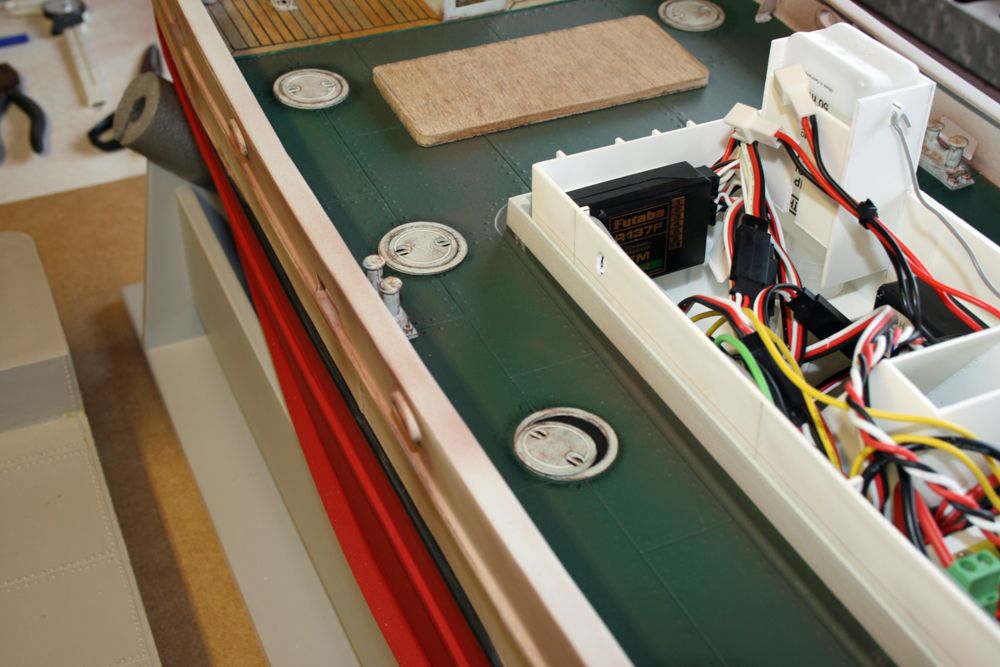

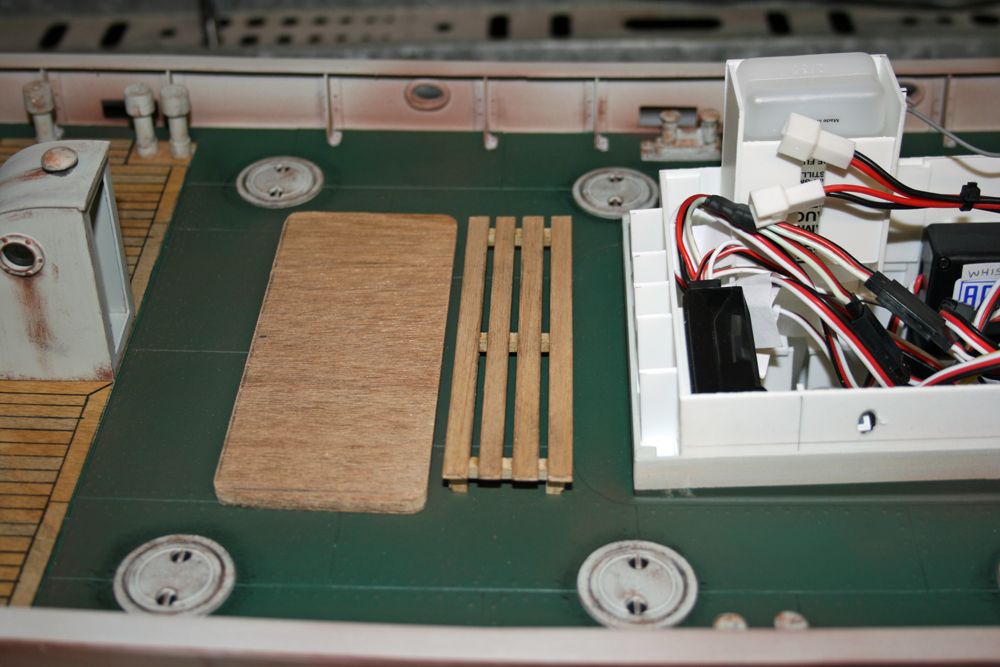

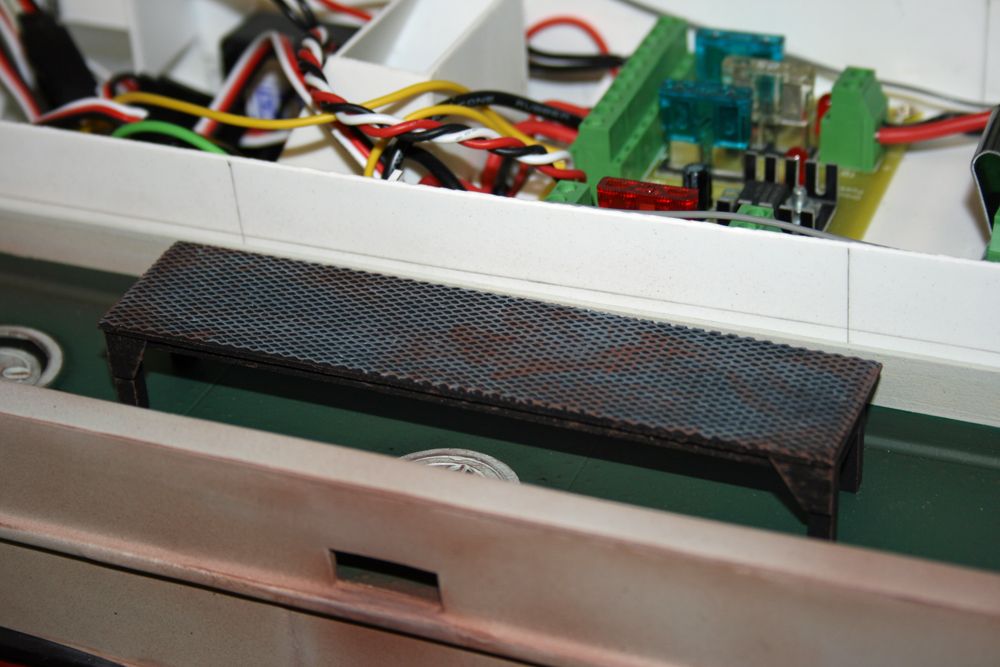

Participant@paulgodfrey14946I’ve just about finished the wiring-up of the electrical goodies, and the following photos shows both the electrics tray, and the two batteries with their own looms attached:As previously described, the batteries can be slid into place on ‘rails’, and each one having it’s own wiring loom makes removal, if needed, easier. The looms will be clipped to the inside of the hull, and routed to where they will connect to the wires exiting the rear of the tray.The individual components have been listed and described previously, as has the construction of the tray. You will note however, that an ‘extension’ has been added to the rear of the tray, and this houses the three switches (main power, smoke, and sounds), together with the charging jacks for the two batteries.One of my aims is to be able to switch everything on & off easily when at the lake (this includes the smoke oil valve which I have briefly touched upon in a previous posting, but yet to complete), without having to remove the superstructure and all the rigging which attaches to it. With the removable tray idea, the switches & jacks either had to be attached to the boat and have connections which could be seperated to allow removal of the tray, or alternatively be attached to the tray itself. After much head scratching, I decided to position them within the raised rear superstructure area, and make the rear gun turret which sits on top, removable. A hole will be cut into the superstructure top, allowing access to the switches and jacks, once the turret has been lifted off. The following pics show the tray in position, with the extension resting at deck level, and how the (as yet untouched) superstructure will cover it:The last two photos show the position where the wires exit the rear of the tray, together with the extension:In the last photo but one, the three connectors exiting this side of the extension are for the motor and the two battery looms, the black and red wires (with small red cable tie) are attached to the charging jacks at one end, and will connect to wires with the battery looms, the two green wires on the other side of the extension are for the speaker (see previous posts for installation of this), and finally the servo wire for the rudder servo.Lastly, in the above phote, you can just make out the blue silicon tube which is attached to the propshaft oiling pipe, and which passes through a hole made in the rear horizontal platform of the tray. This allows oiling of the propshaft without removal of the electrics tray.Thats all for now. Next will be the completion of the front gun and platform.Paul.16 April 2010 at 14:16 #26438Robin Lee

Participant@robinlee31938Hi Paul, the concept of all the electrics being installed in a modular form has worked out very well. Once again your descriptions coupled with excellent photography is setting new standards for this forum. As I know you personally from us both being members of Brentwood MY&PBC I am aware you work for a bank but surely you must be an engineer in disguise!RegardsRobin16 April 2010 at 18:18 #26444Paul Godfrey

Participant@paulgodfrey14946Hi RobinThanks again for your comments.I think it’s because I work for a bank that I enjoy hobbies such as model making, photography (ie using my hands more than my brain), and also being outdoors, so this particular hobby is great for many reasons!!I’ll be bringing the boat along to tonights meeting, so you can judge it properly! (be kind!).Regards, Paul.27 May 2010 at 20:26 #26959Paul Godfrey

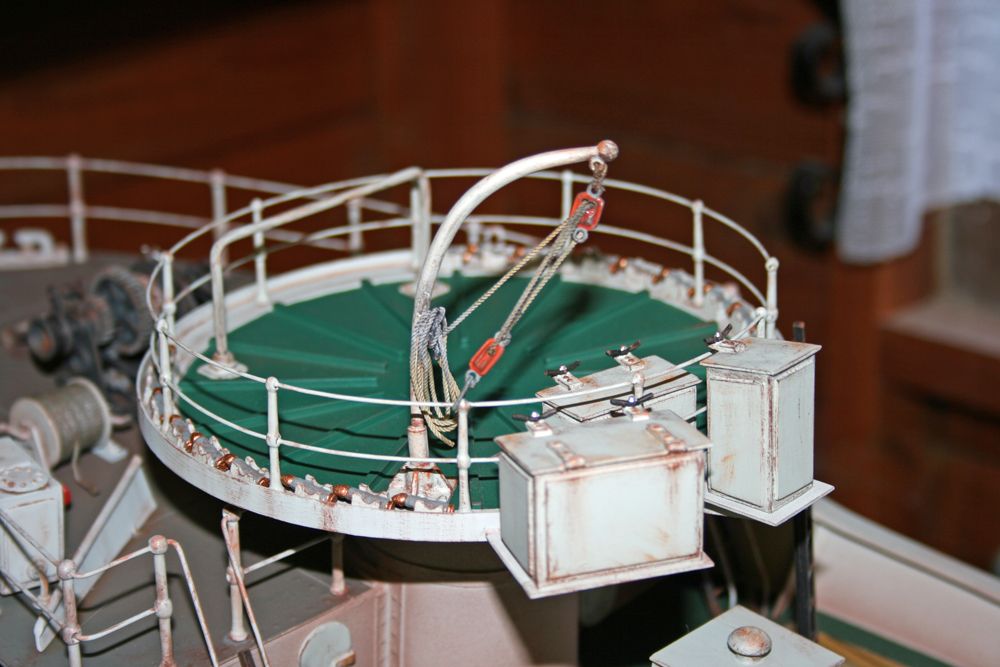

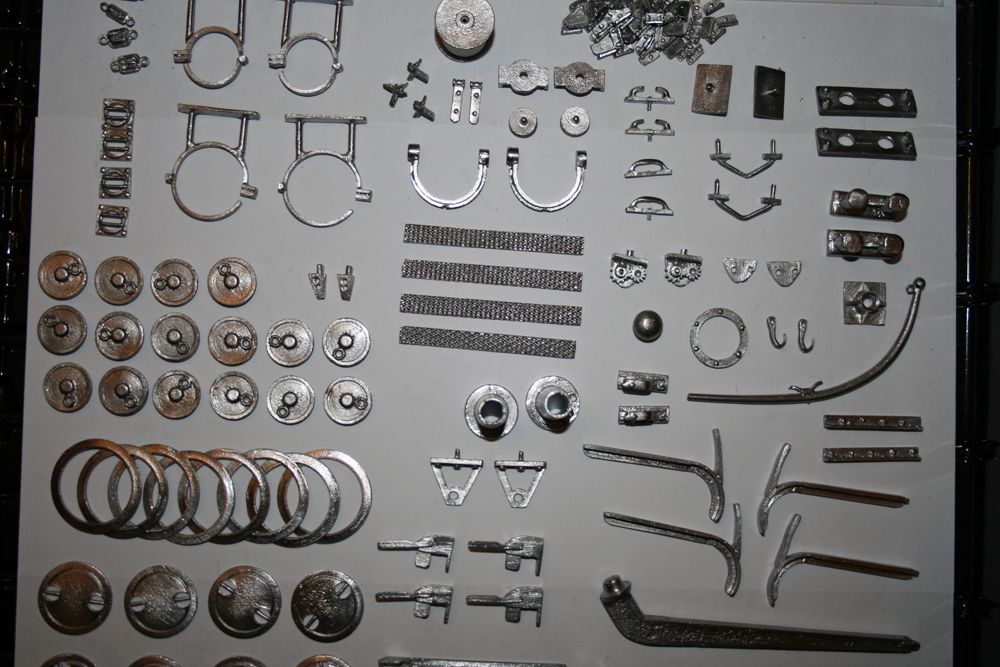

Participant@paulgodfrey14946I’ve been concentrating on the front section of the main deck since my last post, with the next bag of white-metal components, bag 3, covering this area. Here’s a photo of the contents of bag 3:The next photos show close-ups of some of the items:The nuts and bolts in the one-but-last photo are used to hold down the mast base and the gallows, by passing through holes that need to be drilled into the deck.Bag 3 also includes the parts needed to complete the front gun platform (the gun itself is bag 4, and will therefore be next on the agenda), and the following pic shows this completed:The lockers were constructed in the same way as the water tanks on the foredeck, and was described in an earlier posting.The rope seen above was purchased on e-bay, comes in several thicknesses, and looks super. It does need a little drop of superglue applied before cutting, to prevent it unravelling.The brass railings were also an aftermarket purchase, for the same reason as the foredeck railings, ie the supplied wire is a little thin, and can be accidentally bent very easily. I have never bent wire into a perfect circle before, and it made me think about ways of doing this accurately. I firstly tried to bend the wire around a large tube, more or less the same diameter as the railings, but of course, this sprung open to a much larger size when released from the tube. It therefore occurred to me to wrap the wire around a much smaller object, and after a little experimentation, I found the ideal diameter size to be around 2 inches or so. This meant wrapping a suitable length of wire around a vitamin bottle (!) several times, and when released, was virtually the correct size for the platform.I first glued 3 stanchions in 3 of the adjacent pre-drilled holes in the gun platform, and left them overnight to fully dry. I then fed both the upper and lower pre-bent railings through these stanchions, and glued them to the first stanchion only. I then slid a couple more stanchions onto the other end of both wires, and glued them into the next 2 holes in the platform. Once dry, another 2 stanchions were slid on & glued, and so on until all were fitted. When fully dry, the excess lengths of wire were cut off at the final stanchion, leaving the gap where the ladder to the main deck fits.On the subject of the ladder, Mountfleet supply 2 ladders (the same as the ones which link the main deck to the foredeck), which need joining and cutting to produce one longer ladder of a sufficient size to stretch between platform and main deck. Once I had measured for the length required, I cut and glued the 2 supplied ladders together, ensuring that the gap between the rungs either side of the join were equal to the others. Once dry, I decided to fit a length of thin steel wire down the full length of both uprights to add further strength, and this was done using thick superglue, with the ladder laid face-down on my building board. With the completed ladder painted, these wires just appear to be part of it, and indeed are barely noticeable.The final 3 photos are of the almost completed front main deck area – just the gallows to be added, which are currently being built. The crews & officers companion ways, and the escape scuttle, are just laying on the deck at the moment as wires for the lighting in these items will be fed through first. Once the LEDs are fitted, these items will be glued into place, and the doors fitted.Thats all for now. As mentioned, the gallows are being built, and the gun will follow after this.Paul.27 May 2010 at 22:04 #26965neil hp

Participant@neilhpfantastic work , paul……i’m glad i sold mine now………i could never have reached that beautiful build standard. superb.neil29 May 2010 at 10:41 #26992Paul Godfrey

Participant@paulgodfrey14946Hi Neil,Thanks very much for your comments (but I’m sure you could have built yours even better!!).Regards, Paul.29 May 2010 at 12:13 #26993neil hp

Participant@neilhpnot a chance matey….i’m a bally awful painter for a start, lol.when are we going ta see ya on here.come and have a dabble..we don’t bite, lol29 May 2010 at 15:55 #26995Robin Lee

Participant@robinlee31938Hi Paul,I do like your logical approach to building and your taking the time and effort to producing this build log. Your method of constructing the railings around the gun platform is interesting. I think some other builders might have approached this by bonding all stanchions to the paltform then feeding the circular railings through all the stanchions. Your method of progressively threading the stanchions onto the railing then bonding the stanchion avoids any possibilty of the railings binding in the stanchions. Keep up the good work.RegardsRobin31 May 2010 at 15:51 #27019

Keep up the good work.RegardsRobin31 May 2010 at 15:51 #27019Paul Godfrey

Participant@paulgodfrey14946Hi Guys,Yes, I had thought about bonding all the stanchions to the platform first, but chose my way for two reasons:1) Binding, as you’ve mentioned. I found that even passing the wires through a few stanchions was a bit fiddly, and could be quite difficult if the holes in the stanchions are not exactly in the correct position.2) Damage. The little ‘stub’ at the bottom of each stanchion, which fits into a hole for added strength, is actually quite fragile, and doesn’t take much to snap it off (glad there were several spares in the kit!!). I am sure I would have damaged a few of these when trying to pass a wire through the dozen or so stanchions in one go, and again especially if the holes in the stanchions for the wires were not correctly alligned.Regards, Paul.31 May 2010 at 19:30 #27023Wallace Manning

Participant@wallacemanning93491Hi Paul I must say you are still doing a great job, I had alot of touble with the white metal stanchions before so on my build of the Sir Lancelot I used brass stanchions and passed the wire through the holes I had to drill holes abit bigger to take the wire I used as I found the wire in the kit always kinks.I think I put photo up on mayhem about it.I have loved building the boat and into month 18 just started to build up now that a friend from another model club has done the lights for me as Im no good at it.Paul I have done the main mast with a pin up the middle also with 4 bolts so I can remove it if I want to.Back to yours Paul what a great job on the build you are doing I wish I could do the write up like you keep up the good build.wallace31 May 2010 at 20:30 #27024Paul Godfrey

Participant@paulgodfrey14946Hi Wallace,Thanks for your kind words about my build so far. I’ve kept up with your own build Wallace, and I’m very much enjoying it – you are doing a super job, and it’s long overdue that I add a posting to your build log, so I’ll do this now!!Best Wishes, Paul.17 June 2010 at 21:47 #27332Paul Godfrey

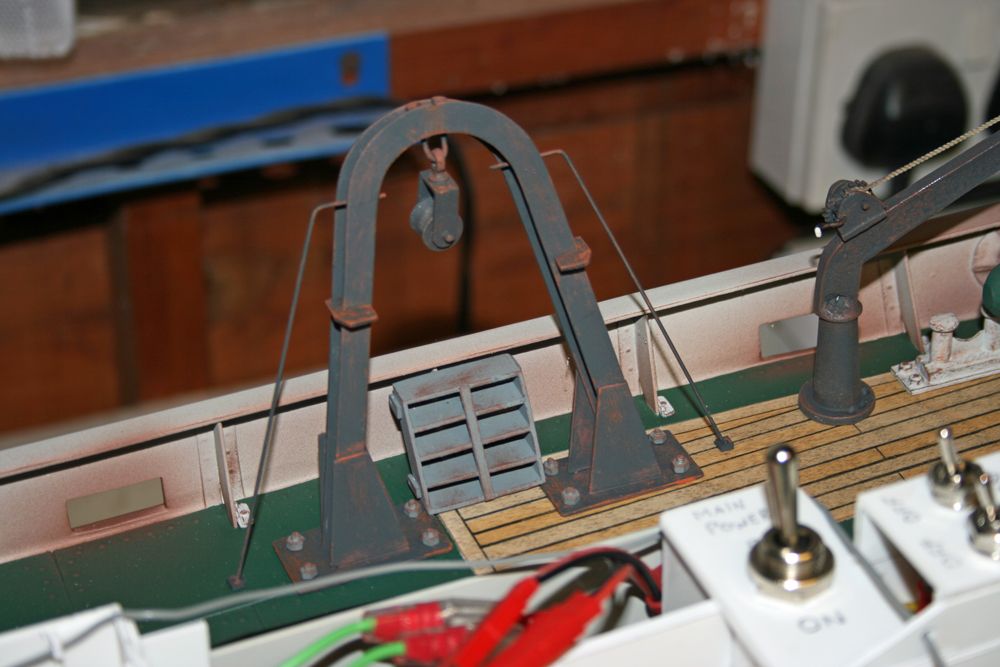

Participant@paulgodfrey14946I’ve now finished the 12 pdr gun that is located on the platform above the front bulkhead. The first photo shows the white metal components, and the following two are of the completed gun:The gun went together well, but there were no ‘sight rings’ which fit onto the rods which protrude through the shield. The odd thing is that these sight rings are mentioned in the written instructions, and shown in the photos at the back of the manual, but are not listed in the gun parts, nor are they shown on the construction diagram!! I did go onto Mountfleets new web-site, and send them a message via the ‘contact’ section, but that was several days ago, and no response has been received. Now I know that I could just give them a call, but thats not the point, is it?The gallows have also been built, and these are of plasticard construction (not much of that in this kit), apart from the pulleys, steps, and some small fixings which are white metal. The support rods are from 1mm brass wire, and the following photo shows two of the completed items:The next photos show the gun and front gallows fitted:You may remember a photo in a previous posting showing a heap of white metal nuts and bolts, and you can see from the above photo that eight of these are used to attach each gallows. Holes are marked and drilled through the deck, and the gallows can then be glued in place along with the nuts & bolts. Finally, the support rods and their fixing brackets can be attached – the rods passing through the deck at the bottom, and the gallows at the top.Finally, a photo of the virtually completed front third of the boat – only the mast (which has supports going from it to the top of the front gallows) to be done, and that will be much later in the build. Oh – and the companionway doors, which have been made, but which will not be attached until the lighting in these areas has been installed.A little break from building, as next will be a few tweaks to the electronics, namely:1) Remove the Steam Whistle unit, and use instead the ACTion P100 digital sound unit for this,2) Wire up the charging jacks to the charger, and test all is well,3) devise & fit the remote on/off control for the smoker oil,4) Drill ventilation holes in the ‘electronics tray’ lower supports, which fit either side of the motor.Thats it for now.Paul.11 August 2010 at 18:23 #28052Paul Godfrey

Participant@paulgodfrey14946I’ve now completed the 4 outstanding jobs to the electronics / electronics tray as mentioned in my last post, and have added more items to the main deck and stern area (I’ve also been on holiday, hence the time it’s taken to reach this stage & add the posting!)

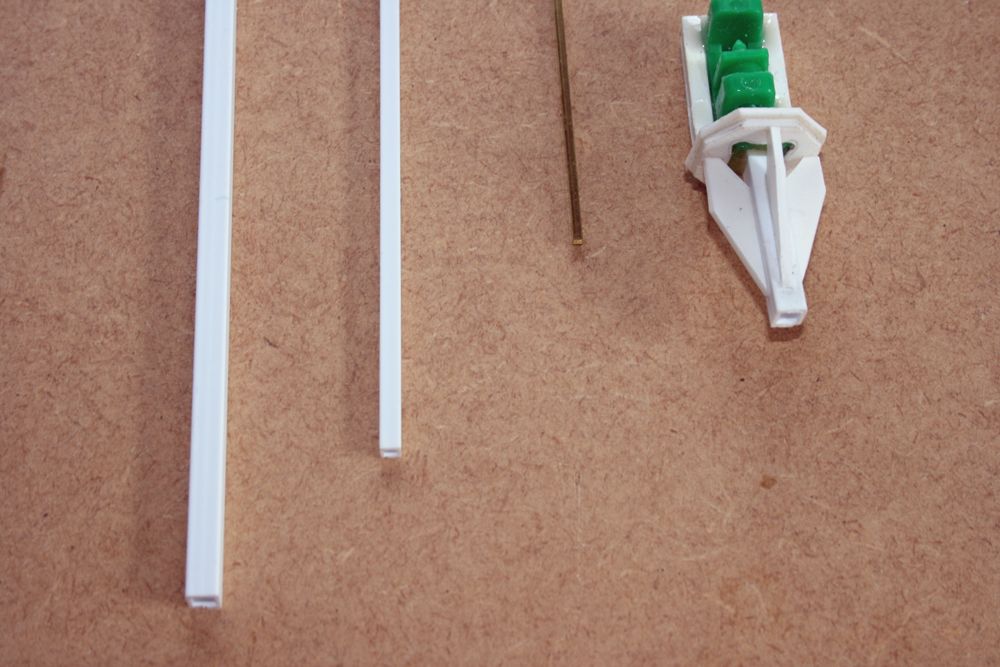

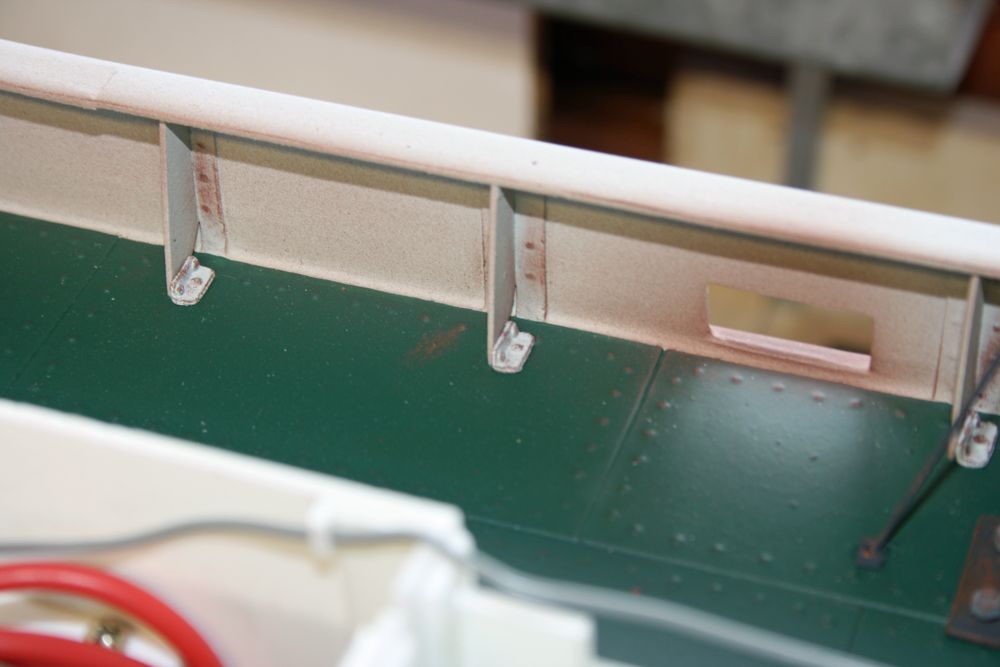

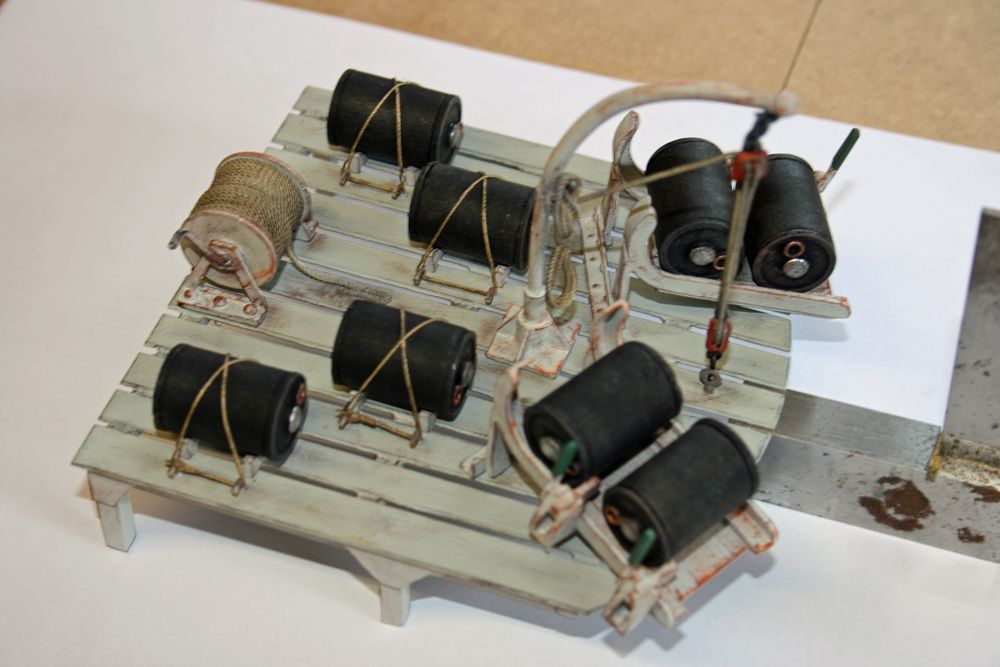

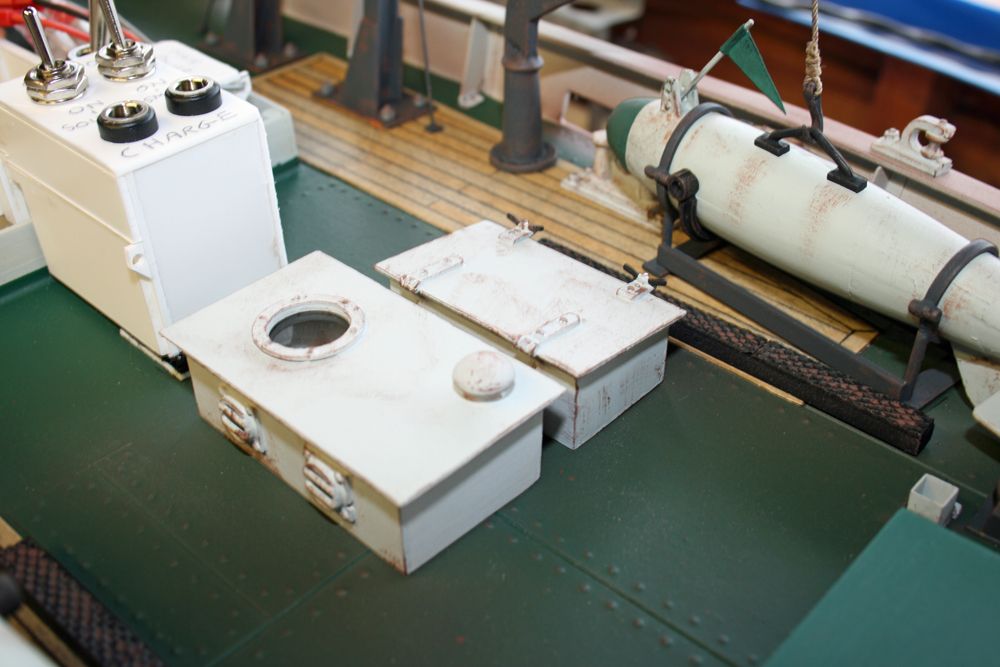

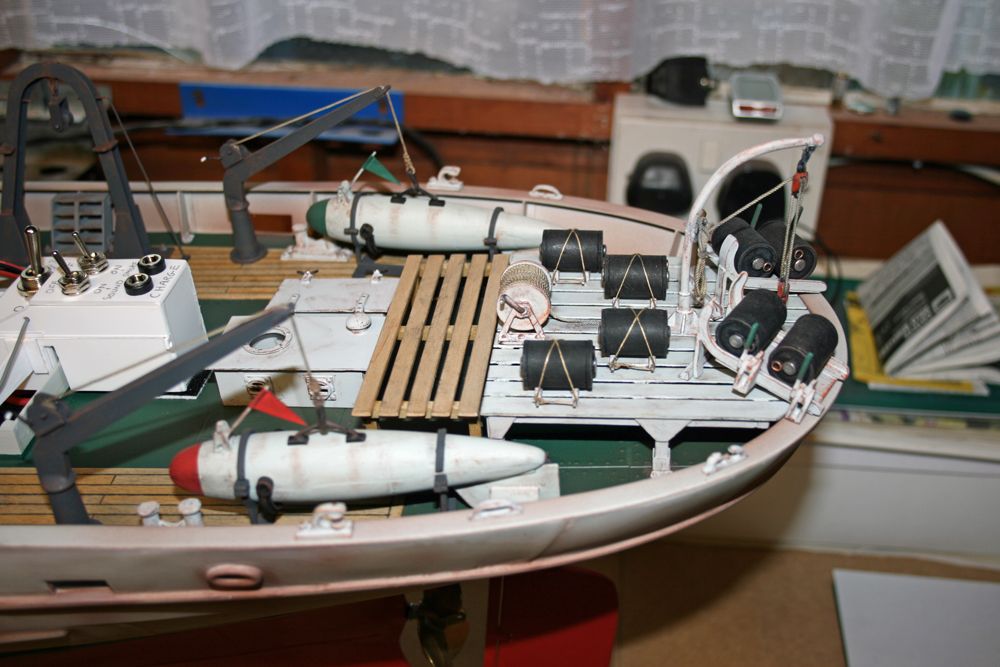

The first photo shows the items used to complete the remote smoker oil shut-off valve:The green valve has been fitted into a ‘box’ made from plasticard & plastic strip, and was shown in a previous posting. Now, a length of the larger plastic tube on the left of the photo has been bonded to the valve ‘handle’ with support pieces, as can be seen. A length of the thinner plastic tube will be inserted into this, and the square-section brass rod with one end bent at 90 degrees will slide into this, to be used to turn the valve. The next pic shows the valve in position:So, the box in which the green valve is fitted, is bonded to the inside of the electronics tray, beneath the smoker oil container, and has the oil tube passing through it as can be seen. Leading up to the port side of the electronics tray, near the top, is a section of the larger plastic square-section tube, with the smaller plastic tube glued inside. The brass square-section rod can then be passed through a hole which has been made at the top of the electronics tray, into the tube. The brass rod is a snug fit in the smaller plastic tube, and the outer plastic tube adds strength. The following photo shows the brass rod slid in place, ready to open/close the valve,Eventually, a small hole will be made in the superstructure to allow the rod to be inserted, and this will be covered when not in use by some sort of flap, or something similar. You can also just about see above that the aerial lead has been routed around the perimeter of the tray, passing through little brackets made for the purpose.The following photos show the white metal components for the main deck & stern area, and the moulded plastic oropesa floats:Next job on the deck was to paint, weather, and fit the 46 bulwark support brackets:Followed by the 8 coal scuttles, each of which comprise of the hatch and surround. The hatches have openings in them where the lifting handles are fitted, so it was neccessary to paint the deck beneath them in matt black. I decided to leave one of the hatches in a semi-open position, so the whole area within the surround was painted matt black. (I have read that to produce the effect of coal beneath the scuttle, some people have used the plastic cartridge that 35mm films are supplied in, painted matt black inside, and inserted into a hole cut in the deck. This is then partially filled with real ground coal, and the hatch left open – wish I’d known about this sooner!).By the way, the wooden slab between the front two scuttles will eventually be the base for the winch, and at this stage has only been cut to size.I then built the stern grating, which I’m very pleased with. This is a removable structure to allow access to the hatch over the rudder linkage, and consists of a winch, depth charges, discharge rails, and davit:I made up two chocks for each of the four spare depth charges, each one from 3 pieces of 2mm square hardwood – 2 smaller angled pieces glued to the ends of a longer bottom piece, and used small angled lengths of 1mm brass wire for the 16 tie-down points. Call me over-cautious, but I was worried that the 4 depth charges on the discharge rails looked a bit precarious, so I drilled a 1mm central hole in the bottom of each one, and glued in a small length of wire which fits into holes drilled into the ply supports for the rails – much more secure!Here is the potato locker and skylight – the latter is not attached at the moment as, like the one at the front of the main deck, it will have lighting fitted inside.11 August 2010 at 18:46 #28054Robin Lee

Participant@robinlee31938Really coming on well Paul, looking forward to seeing it at the lake. Would you care to elaborate on the function of your oil cut-off valve. If you did not have the valve what would be the consequences?Robin 11 August 2010 at 19:03 #28056

11 August 2010 at 19:03 #28056Paul Godfrey

Participant@paulgodfrey14946. . . . . . . . Continued from earlier posting today, as this next chunk vanished!!

You can also see above, and in the following photo, the oropesa floats. These are now moulded plastic items in the kit as seen in the earlier photo, whereas they used to be vac-formed halves which needed to be joined together. You can also just about see one of the 4 mounts for the stern grating, made from a small length of square-section brass tube into which the legs of the grating fit.The oropesa float davits are, apart from the bases, solid white metal, and because of their weight, some people make their own from wood or plastic – I’ve retained the originals. Talking of the bases, these were missing in the kit, and indeed, are not listed in the parts for bag 8. On the plan, they are shown as part number ’35’, which is the same part used for the base of the searchlight. I phoned Mountfleet to advise them of this – they were very helpful, and sent me the missing parts very quickly (twice in fact, as the first went missing in the post – excellent service!).The final two pics are views of the stern area:As far as the deck is concerned, the remaining items to complete are: the mast (as previously mentioned, will leave this until later in the build), the winch, the gratings for the winch & at the rear between the stern grating and skylight, and the kites/otters.Thats all for this installment.Regards, Paul.

11 August 2010 at 19:13 #28057Paul Godfrey

Participant@paulgodfrey14946Hi Robin,The green valve is supplied with the smoker unit, and I’m guessing that if the oil supply is not cut-off when not in use, the ‘wick / element ‘ that absorbs the oil will saturate, and oil may drip from it. The element is positioned below the oil bottle, and is gravity-fed, so it seems sensible to be able to shut the supply off.A large part of my earlier post had vanished for some reason, and I’m so glad I copied it!Cheers, Paul.11 August 2010 at 19:28 #28059Wallace Manning

Participant@wallacemanning93491 Hi paul what you have done is first class keep up the good work im just waiting to get my own boat back as a friend is putting lights on it for me will have to have lessons to do it myself.

Anyway Paul your build is just great.wallace11 August 2010 at 20:49 #28062

Hi paul what you have done is first class keep up the good work im just waiting to get my own boat back as a friend is putting lights on it for me will have to have lessons to do it myself.

Anyway Paul your build is just great.wallace11 August 2010 at 20:49 #28062Paul Godfrey

Participant@paulgodfrey14946Hi Wallace,Thank you for your kind comments once again. I’ve been keeping an eye on your build, and look forward to seeing all the lights fitted, as this is something I’ll be tackling in the future.All the best,Paul.26 August 2010 at 19:30 #28192Paul Godfrey

Participant@paulgodfrey14946A (relatively) short update this time.With the exception of the mast & winch, the remaining items to be fitted to the main deck have now been completed. The first photo shows the wooden grating which fits between the rear ‘depth charge’ grating, and the skylight:And the next is of the grating for the winch, fitted between this and the front of the superstructure:The winch base, which can be seen above, has at this stage only been cut to size, and has been laid on the deck to help with the positioning of the grating. The next pic shows one of the two kites/otters, which as can be seen are stored between the rear gallows:The kites are made from plasticard, and the individual parts build into the shape as above. However, photos of these items on some of the articles/builds of Sir Lancelot on the internet, and indeed the plans, show the left and right sides of each kite sloping in towards the front (as you look at it in the above photo), so I’m not sure – in any case, I’m happy with the way they are.The next photo shows one of the two chequer plate platforms, built from a rectangle of 1.5mm plywood, with stripwood for the legs, and thin ply for the leg supports. The top is then covered with a piece of fine mesh, cut to shape with a sharp knife, and I decided to attach this by painting over the plywood with a layer of thin superglue, onto which the mesh can be laid. The whole assembly is then pained matt black, and the idea is that some silver paint is used to highlight the mesh – applied using a piece of cloth with a small amount of paint on it. The silver looked awful, as it was impossible to achieve a uniform surface – some areas had a little paint, whilst others had too much, causing the mesh to appear ‘thicker’ in those areas. The reflective nature of silver also exagerated the differences. So, I re-painted the platforms, and once dry, tried lightly sanding the surface of the mesh. This also looked poor. So, after re-painting the platforms AGAIN with matt black, I used a little light grey applied by cloth, followed by some rusting effects, and this is much better.These platforms will be either attached to the superstructure sides, or the deck, at a later stage.Finally for now, an overall pic of the boat as she is now.27 August 2010 at 15:22 #28197Robin Lee

Participant@robinlee31938Hi Paul, I like your idea of a short update! Seriously the Sir Lancelot is looking very good. You have become a master of the weathering . I particularly like the gallows.. I had to do a “Google” of “kite otter” before realising what you were referring too as I had assumed at first glance they were steps for gaining access over the bulwarks! Keep up the good work.RegardsRobin 27 August 2010 at 21:21 #28198

27 August 2010 at 21:21 #28198Paul Godfrey

Participant@paulgodfrey14946Hi Robin,The posting ended up being somewhat longer than first anticipated!Thanks for your comments re the weathering – I’m a long way off from being a master, but I’m happy with the results, especially as it’s my first attempt.My next posting will be short(!), as it will only show the components, and the construction diagram, for the winch. This will be added in the next few days.Regards, Paul.1 September 2010 at 16:16 #28226Paul Godfrey

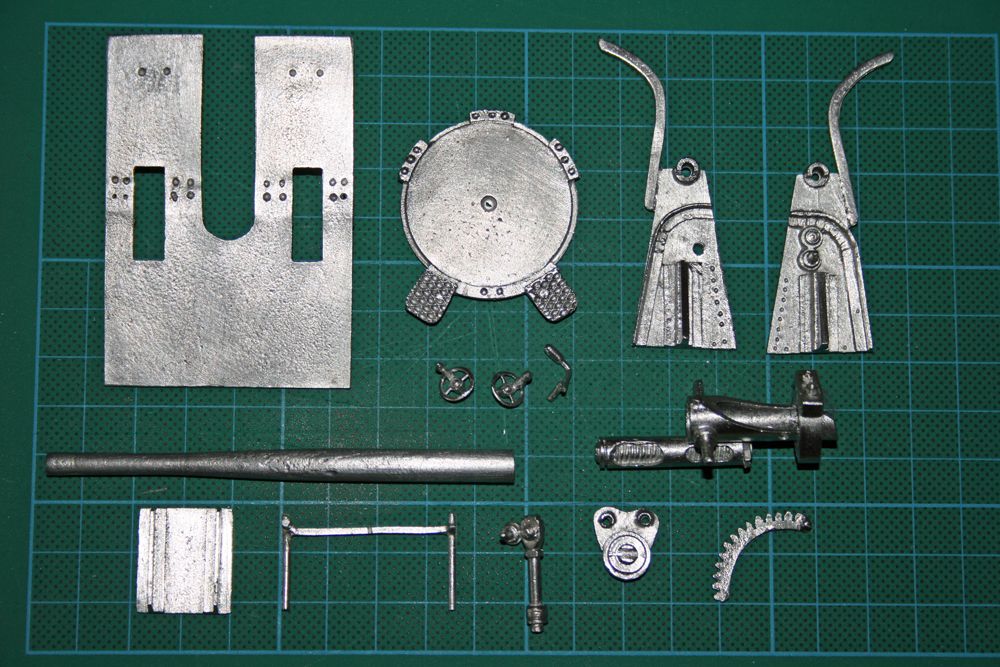

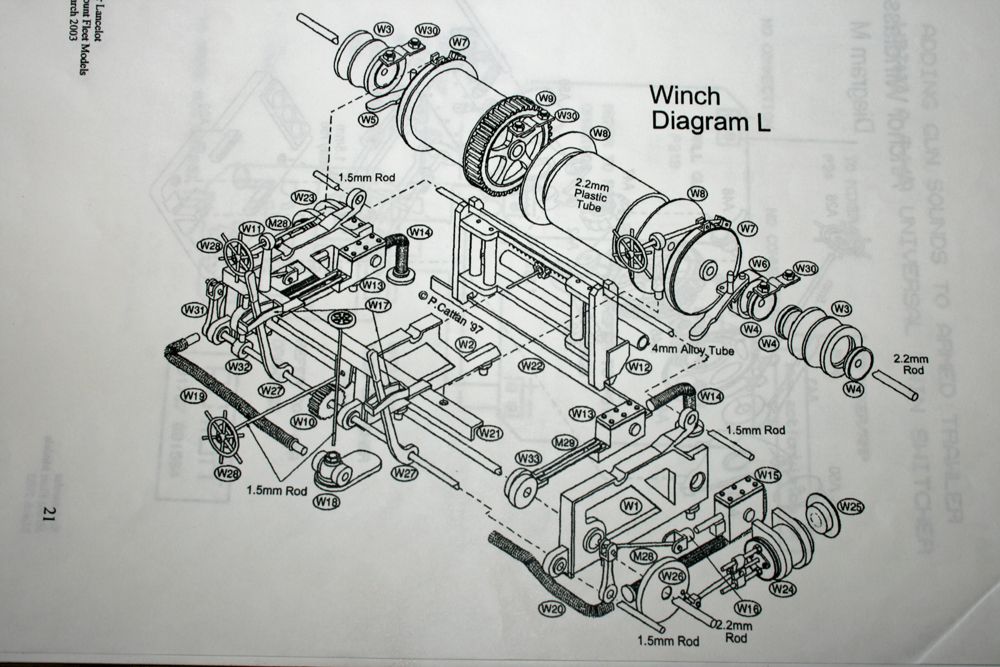

Participant@paulgodfrey14946WINCH CONSTRUCTION Part 1I’ll start off with the construction diagram of the winch from the instruction manual (there’s also about a page and a half of step-by-step instructions on the manual’s A4 sized pages, which will be a great help):And here are the white metal components, together with the wooden base plate & plastic tubes for the drums:The ‘rope’ was purchased from e-bay, and is a slightly thicker version of that used on the smaller winches on the foredeck & stern grating. The other parts required for the build are various thicknesses of wire, and 4mm alloy tube, all of which are of course included in the kit.Part 2 to follow soon!Paul.Edited By Paul Godfrey on 01/09/2010 16:17:00

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Code of conduct | Forum Help/FAQs

Latest Replies

Home › Forums › Building Kits › Topics

-

- Topic

- Voices

- Posts

- Last Post

-

-

Vic Smeed’s Legacy

Started by:

Colin Bishop

in: All things floating

Colin Bishop

in: All things floating

- 2

- 2

-

6 hours, 30 minutes ago

Tony Hadley

Tony Hadley

-

4D Modelshop

Started by:

Keith Long in: Scratch build

- 6

- 9

-

13 hours, 7 minutes ago

Colin Bishop

Colin Bishop

-

Fairey Huntsman 31

1

2

…

5

6

Started by:

Chris Fellows

in: Build Blogs

Chris Fellows

in: Build Blogs

- 14

- 139

-

1 day, 10 hours ago

Chris Fellows

Chris Fellows

-

Fairey Faun

1

2

3

Started by:

Chris Fellows

in: Build Blogs

Chris Fellows

in: Build Blogs

- 7

- 58

-

1 day, 10 hours ago

Chris Fellows

Chris Fellows

-

Vic Smeed’s Silver Mist

1

2

…

32

33

Started by:

Bob Abell 2 in: Scratch build

- 4

- 822

-

1 day, 11 hours ago

Tony Hadley

Tony Hadley

-

Fairey Huntsman 28

1

2

…

7

8

Started by:

Chris Fellows

in: Build Blogs

Chris Fellows

in: Build Blogs

- 1

- 195

-

1 day, 12 hours ago

Chris Fellows

Chris Fellows

-

Eezebilt RAF Fire Boat

Started by:

Tim Cooper in: Build Blogs

- 2

- 3

-

1 day, 13 hours ago

Dave Reed

Dave Reed

-

Feathered Friends

Started by:

Chris Fellows

in: Soapbox

Chris Fellows

in: Soapbox

- 3

- 7

-

1 day, 16 hours ago

Chris Fellows

Chris Fellows

-

John Cobb’s Crusader

1

2

…

7

8

Started by:

Paul T

in: Scratch build

Paul T

in: Scratch build

- 1

- 192

-

2 days, 12 hours ago

John W E

John W E

-

Complex Automata

Started by:

Colin Bishop

in: Soapbox

Colin Bishop

in: Soapbox

- 1

- 1

-

3 days, 15 hours ago

Colin Bishop

Colin Bishop

-

RAF Fireboat ID

Started by:

Dave Reed

in: Collectors’ corner

Dave Reed

in: Collectors’ corner

- 8

- 24

-

4 days, 16 hours ago

Tim Cooper

-

TID steam tug 42″ – PN Thomas drawing enlarged

1

2

Started by:

Ray Wood 3

in: Scratch build

Ray Wood 3

in: Scratch build

- 8

- 33

-

5 days, 10 hours ago

Richard Simpson

Richard Simpson

-

Lady of Skye (puffer)

1

2

Started by:

mick east

in: Build Blogs

mick east

in: Build Blogs

- 9

- 43

-

5 days, 20 hours ago

Richard Simpson

Richard Simpson

-

Building a hull.

Started by:

mick east

in: Scratch build

mick east

in: Scratch build

- 7

- 10

-

1 week ago

Ray Wood 3

Ray Wood 3

-

Todays Boating

1

2

…

210

211

Started by:

ashley needham

in: All things floating

ashley needham

in: All things floating

- 84

- 5,252

-

1 week, 1 day ago

Colin Bishop

Colin Bishop

-

Sea Rover Restoration

Started by:

harry smith 1 in: Collectors’ corner

- 4

- 10

-

1 week, 1 day ago

Richard Simpson

Richard Simpson

-

WORKSHOP LIGHTING

Started by:

John W E

in: All things floating

John W E

in: All things floating

- 9

- 18

-

1 week, 2 days ago

Colin Bishop

Colin Bishop

-

Mayhem Website Down

Started by:

Colin Bishop

in: All things floating

Colin Bishop

in: All things floating

- 4

- 10

-

1 week, 5 days ago

Colin Bishop

Colin Bishop

-

MAGGIE M trawler

Started by:

sammyk

in: Buy/Sell or Trade

sammyk

in: Buy/Sell or Trade

- 2

- 3

-

1 week, 5 days ago

sammyk

sammyk

-

meter

Started by:

Alasdair Allan

in: All things floating

Alasdair Allan

in: All things floating

- 5

- 16

-

2 weeks ago

Chris Fellows

Chris Fellows

-

River Queen 2”- 1’.

Started by:

Richard B in: Steam powered models

- 5

- 7

-

2 weeks, 1 day ago

Richard B

-

Deluxe Superphatic Glue.

Started by:

Colin Bishop

in: All things floating

Colin Bishop

in: All things floating

- 4

- 12

-

2 weeks, 1 day ago

Chris Fellows

Chris Fellows

-

How to add photos to your posts

Started by:

Colin Bishop

in: Adding Images to Forum Posts

Colin Bishop

in: Adding Images to Forum Posts

- 3

- 16

-

2 weeks, 1 day ago

Len Morris 2

-

Cataract

Started by:

Bob Wilson in: Soapbox

- 2

- 4

-

2 weeks, 2 days ago

Colin Bishop

Colin Bishop

-

The mighty tug Wattle

1

2

3

Started by:

mick east

in: Build Blogs

mick east

in: Build Blogs

- 10

- 61

-

2 weeks, 2 days ago

Richard Simpson

Richard Simpson

-

Vic Smeed’s Legacy

-