Neil,

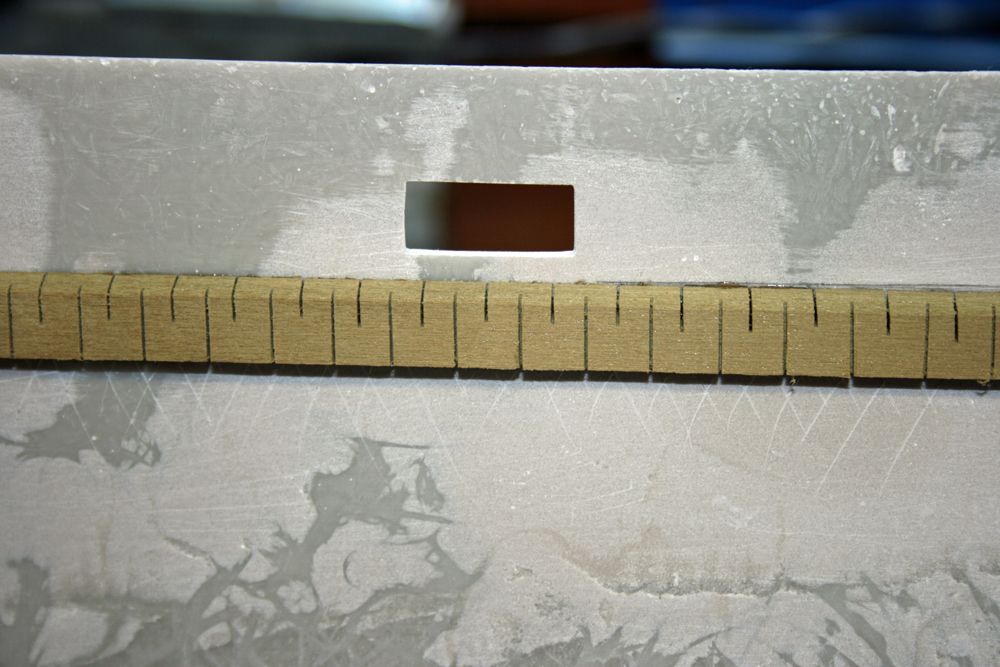

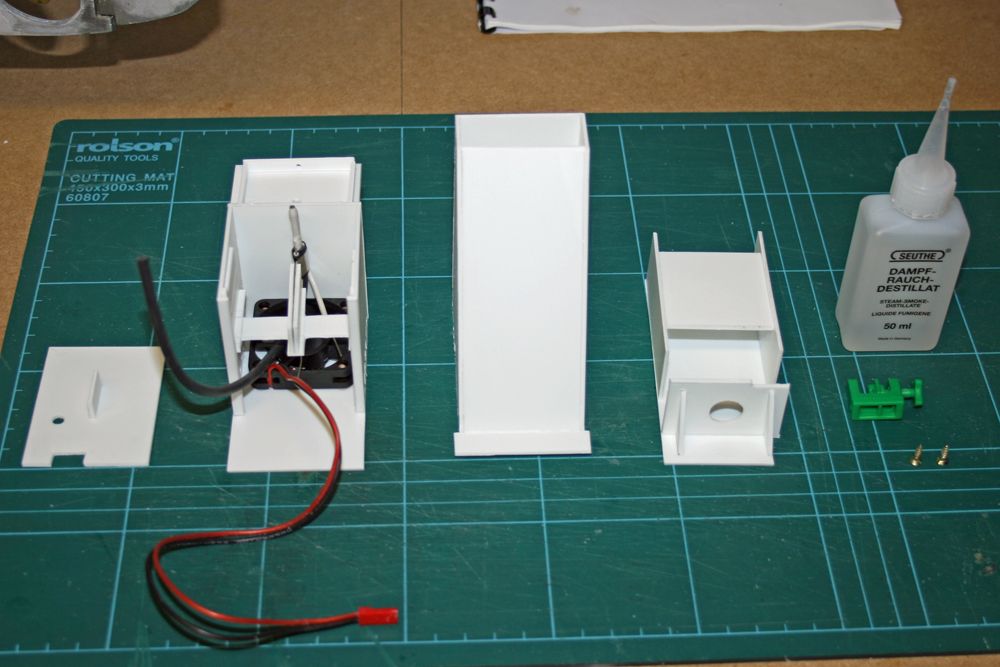

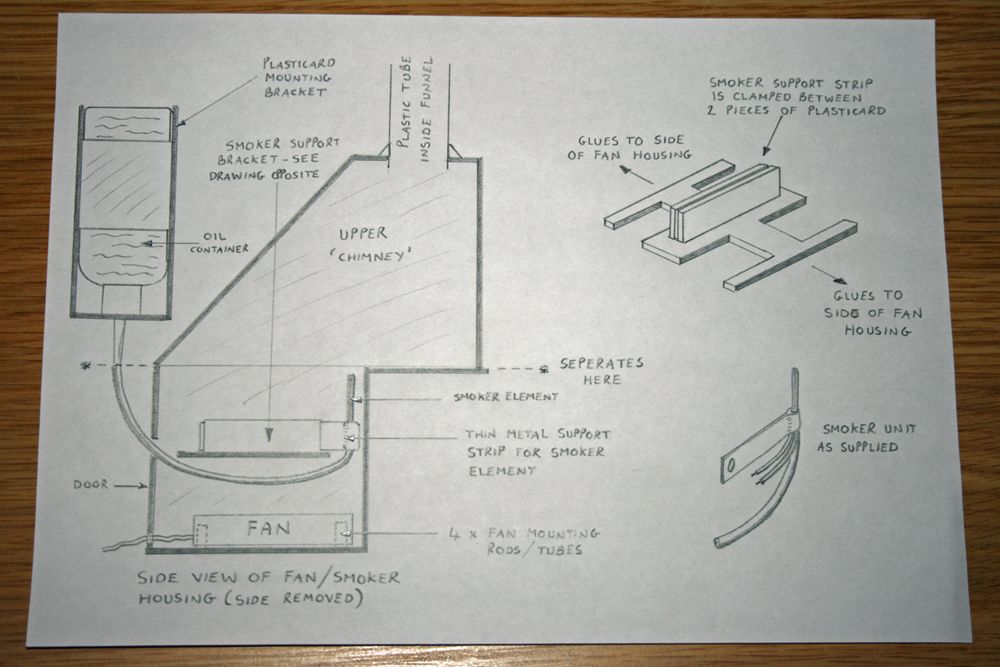

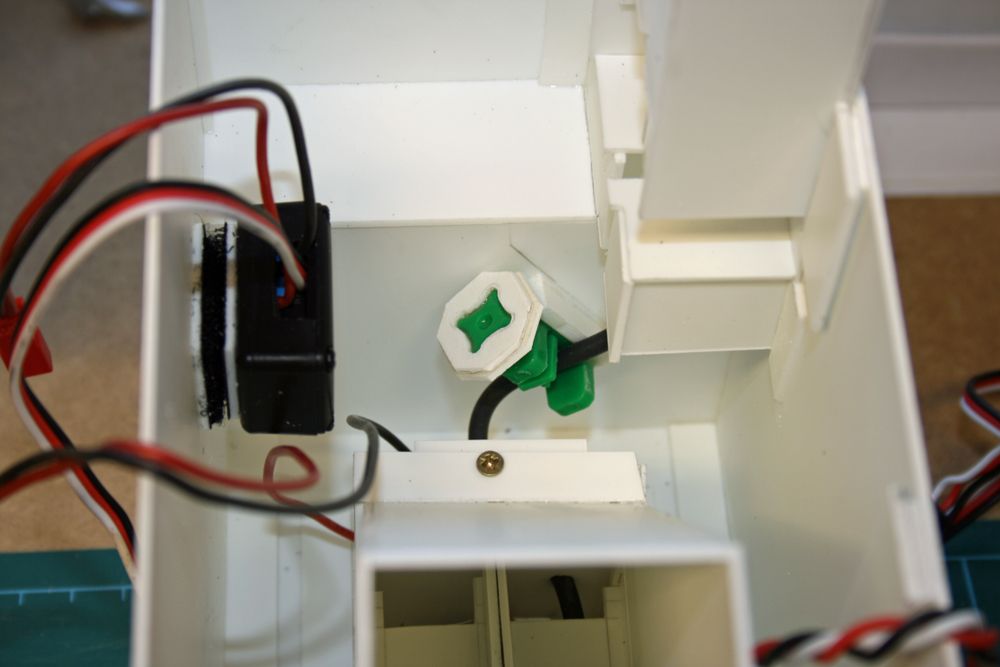

You’re very welcome. I forgot you have a Sir Lancelot to build (it’s an age thing), so if you want measurements for anything I have done, you only have to ask. I have made a slight improvement to the oil bottle holder. In the photo of the individual smoker housing components, and the drawing, the oil bottle is slotted in to a plasticard ‘cage’ made up of a back, sides, and a smaller front piece, together with a bottom piece with a hole in it, into which the nozzle fits. Previously, this unit then slotted into another bracket attached to the side of the tray. Now though, the bracket has been removed, and the cage has been itself glued to the side of the tray. To allow the bottle to be lifted out with the feed tube still attached, I have cut a vertical slot in the front of the cage, and a slot in the bottom where the nozzle fits into the hole. Here’s a photo:

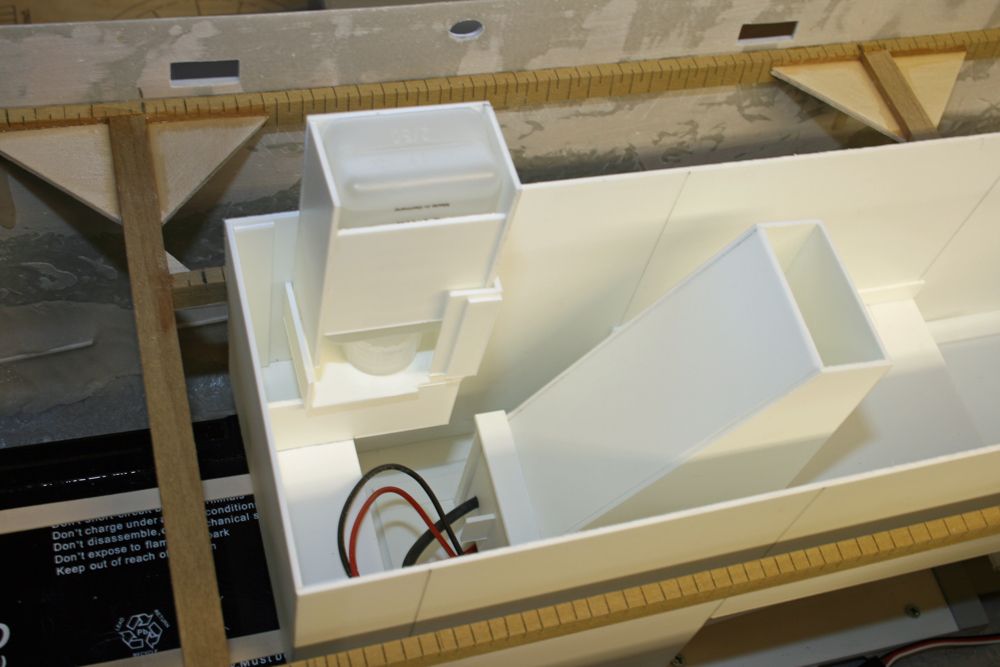

So, to remove the oil bottle and the smoker housing, I remove the chimney, then lift the smoker housing up at the same time as the oil bottle, directing the feed tube through the slots I’ve now cut.

Dave,

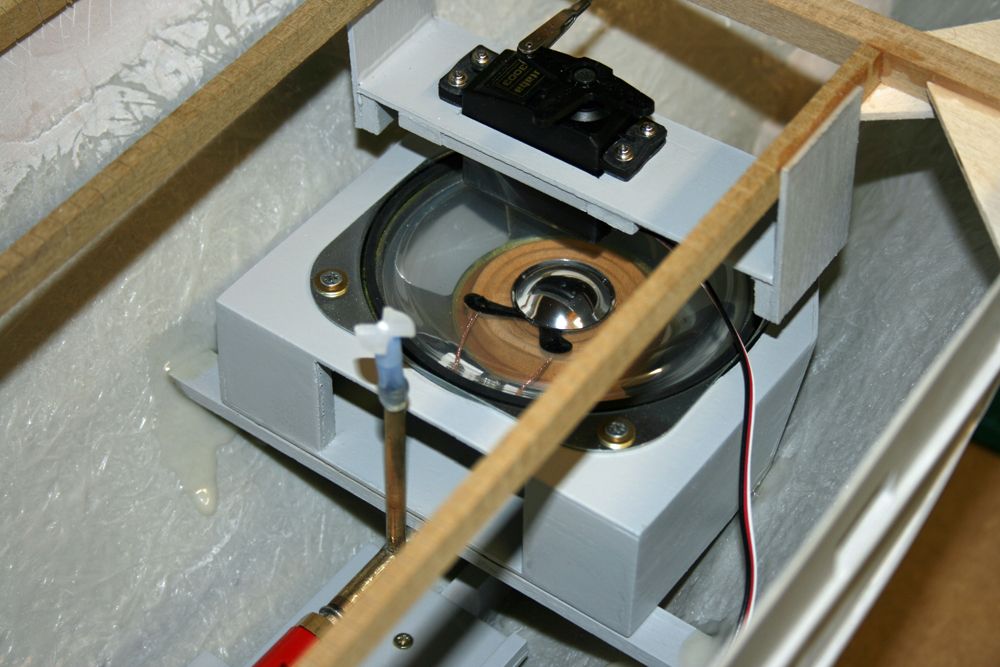

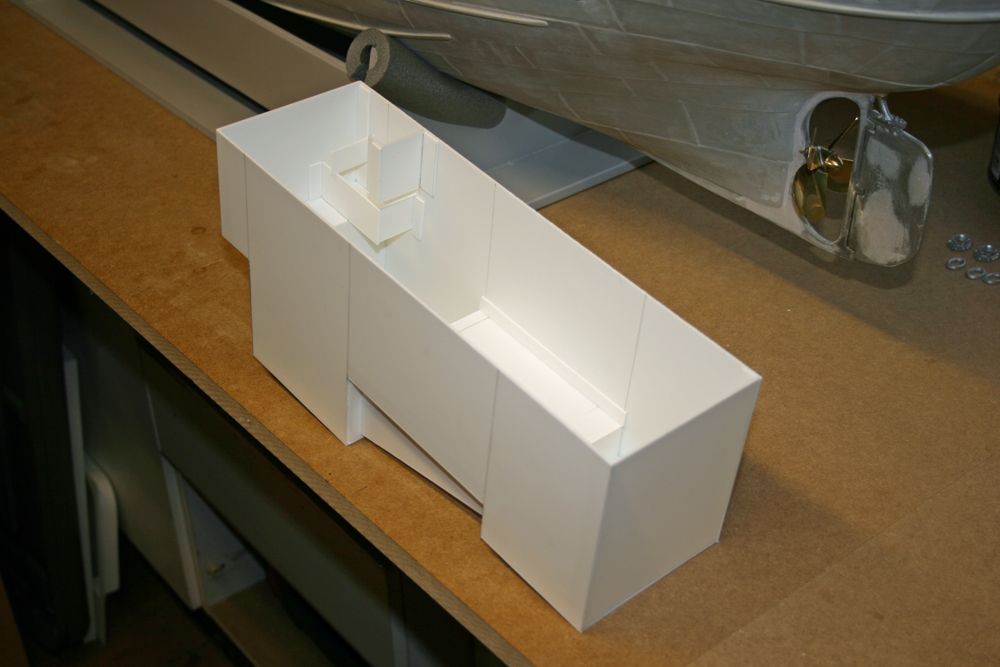

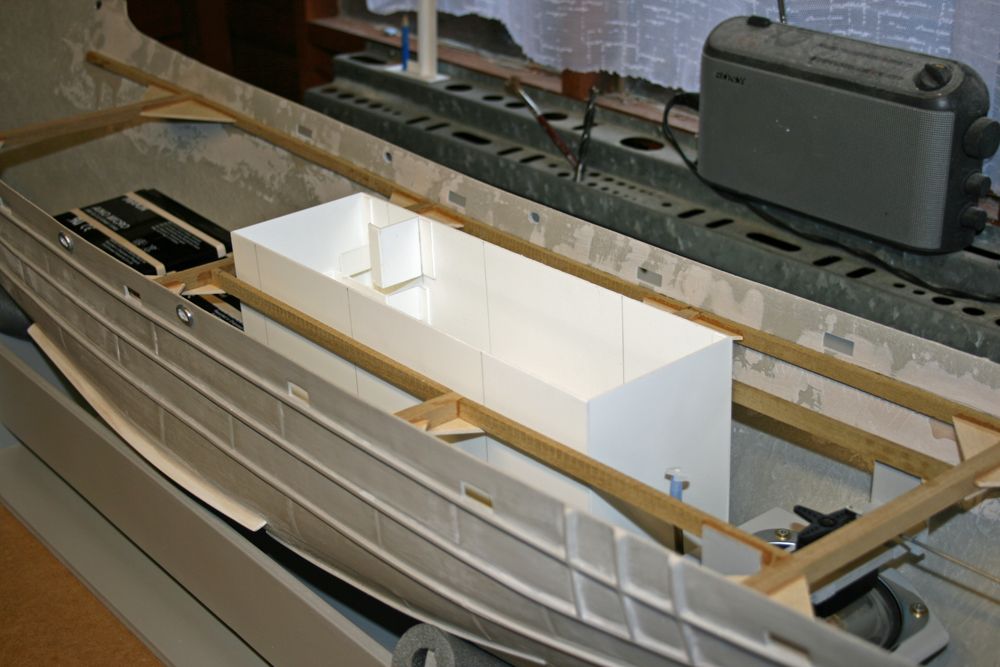

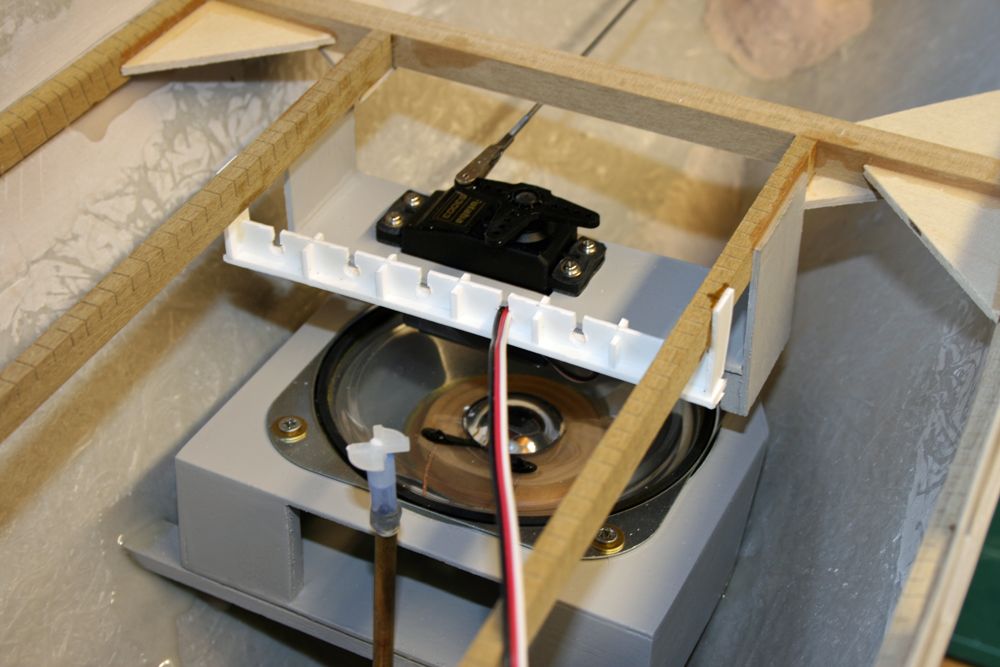

The speaker box I’ve made does have a back – the photo’s flash has caused a shadow and perhaps given the impression it doesn’t. The only opening is at the front end for the wires. The box is now well and truly glued into place, but there will be some more photos of hull interior once I’ve put in the electronics, prior to the deck being fitted. Thanks for the tip regarding the ducting tube – I’ll make this addition in due course.

Cheers, Paul