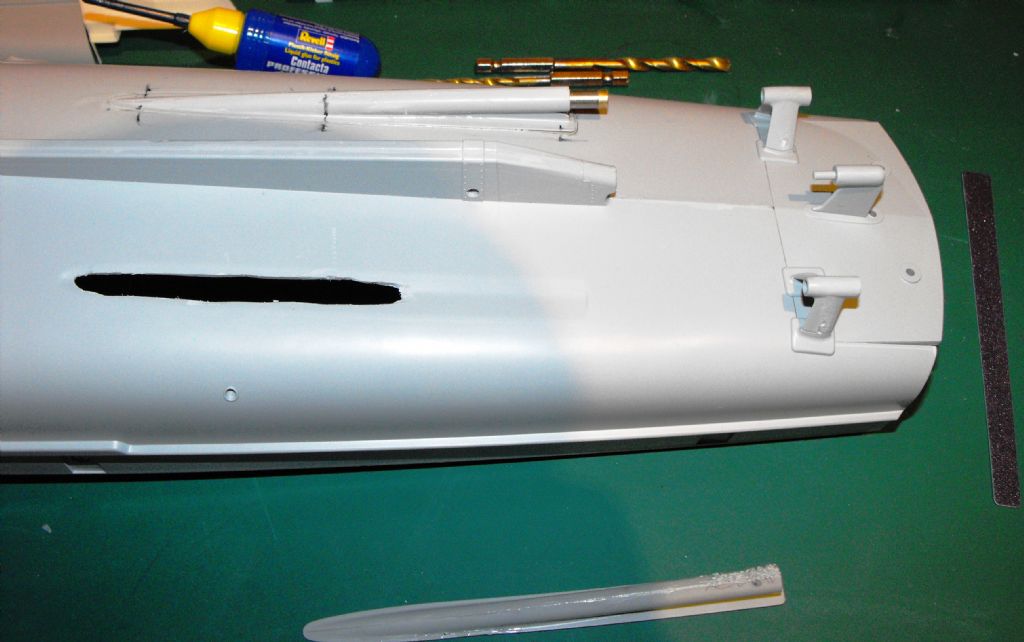

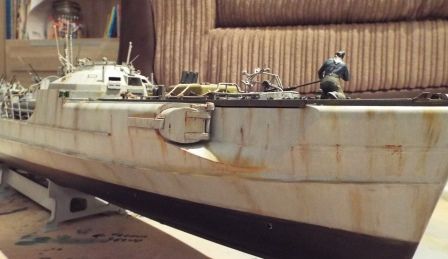

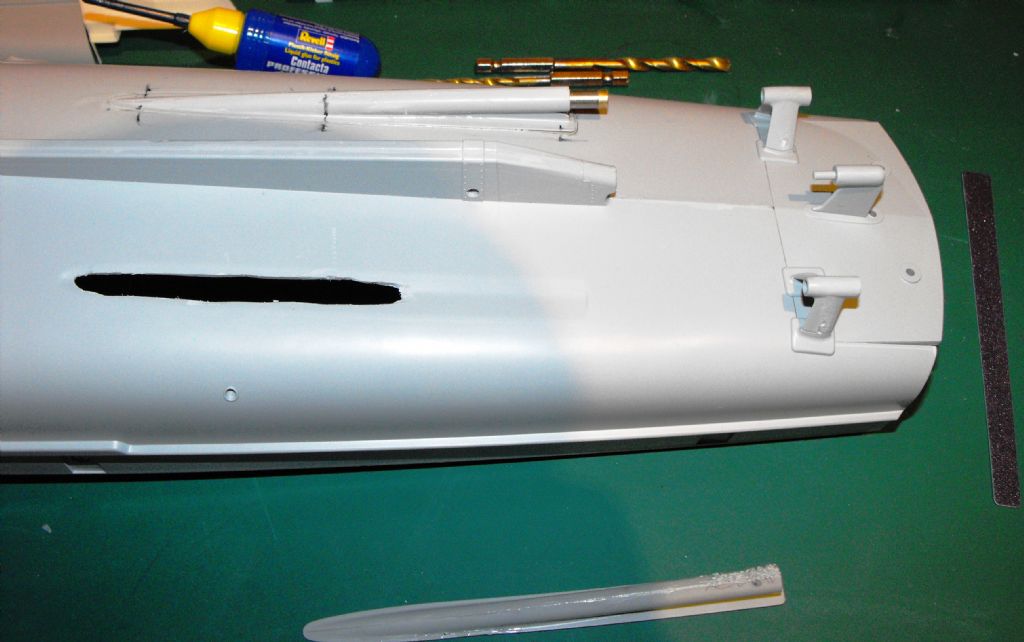

Go back to the beginning of my build thread, and there are a number of photo's of cutting out of the gull bottom.

Go back to the beginning of my build thread, and there are a number of photo's of cutting out of the gull bottom.

This was done with a combination of modelling knife/dremmel multi tool.

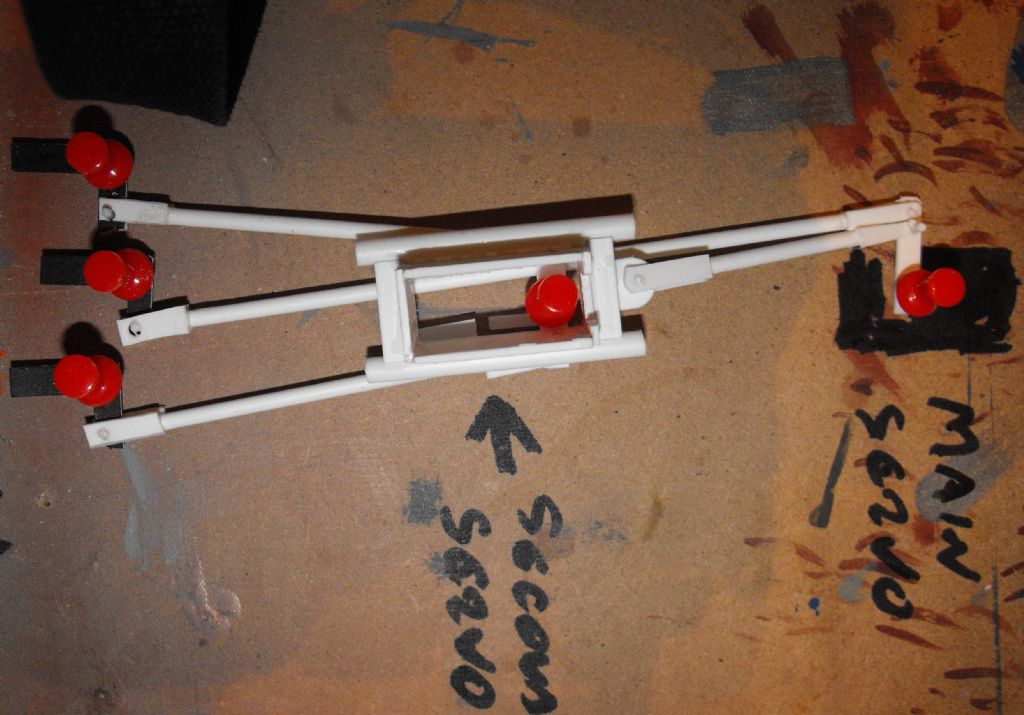

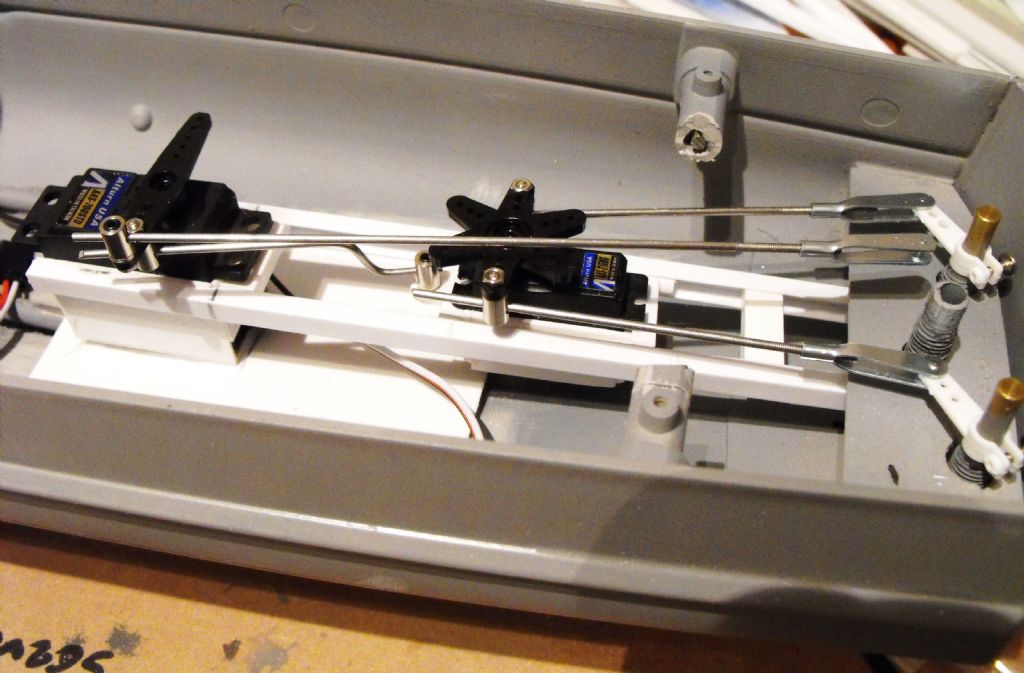

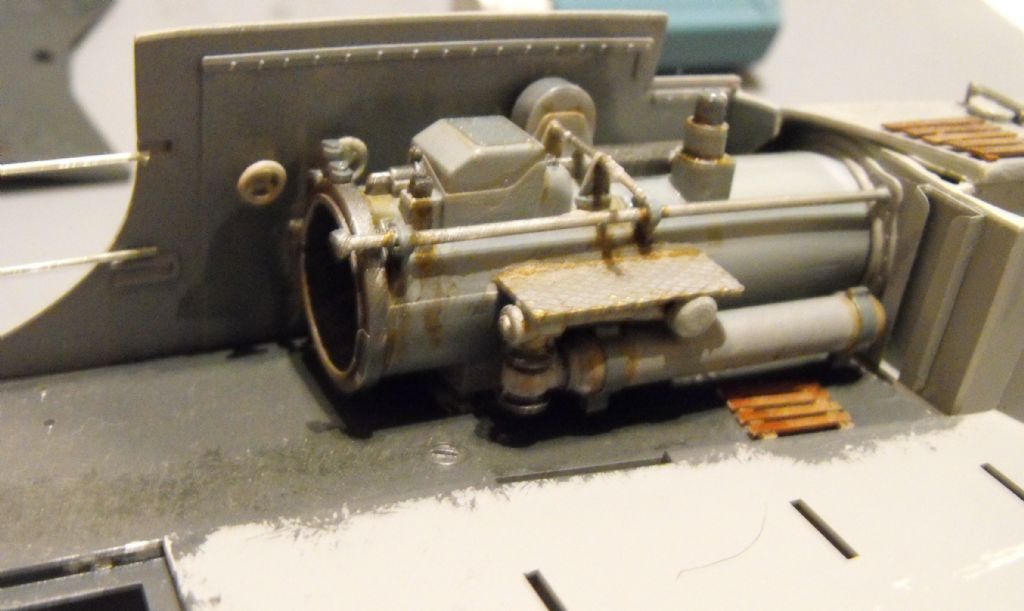

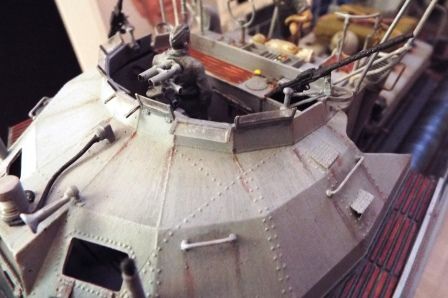

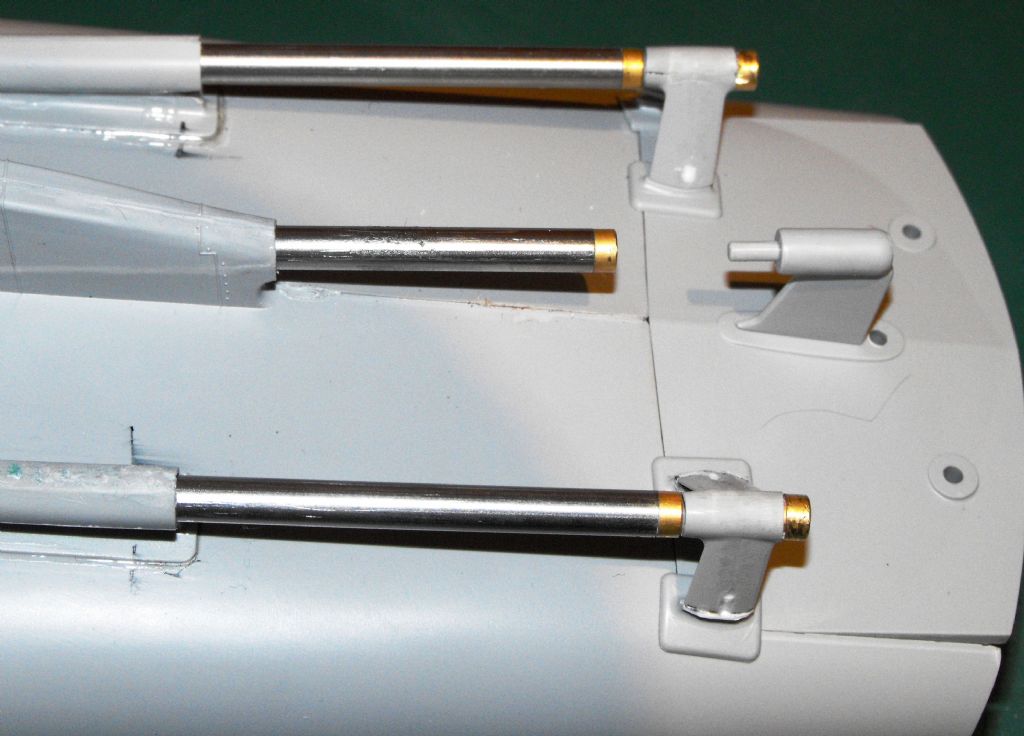

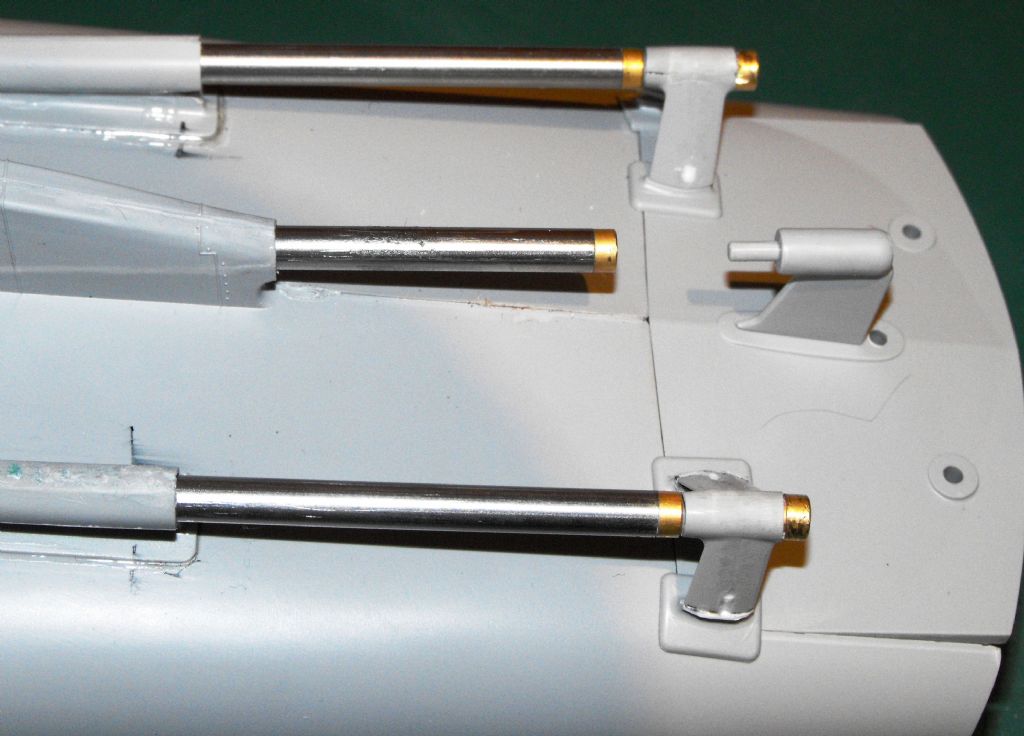

I hollowed out the prop tunnels with my dremmel, and then Inserted brass bushes in the Kits 'A' frames to support the aft end of the prop shaft.

The hollowing out and alignment is a trial and error prodedure, grind, try it, grind try it. Dont rush, just take your time.

The tunnels end up being very fragile with very thin walls.

I inserted the prop shafts into the 'A' frames then the tunnels around the propshaft.

Then I offered the tunnels up to the hull to get the correct alignment. The inner end of the prop shafts are secured through a bulkhead made from plasticard, to stop the shafts from flexing.

I made a mixture of cyano & cyano filling powder and poured it into the joint of the tunnel/hole from inside the hull to provide rigidity and waterproofing.

A cheaper alternative to cyano filler, is talcum powder, I only used the filler as I had it in my stash.

I hope this is of some help. don't forget to post shots of your build!