My Clyde Puffer

My Clyde Puffer

- This topic has 287 replies, 19 voices, and was last updated 4 months, 1 week ago by

James Hill 5.

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Code of conduct | Forum Help/FAQs

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

-

- Todays Boating 1 2 … 210 211

- 84

- 1 week, 2 days ago

Viewing 25 topics - 1 through 25 (of 25 total)

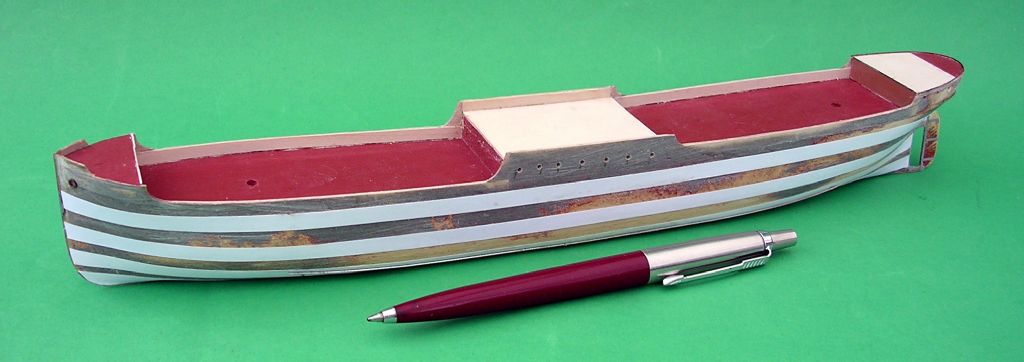

![006 [800x600].jpg 006 [800x600].jpg](/wp-content/uploads/sites/5/images/member_albums/2391/922913.jpg)

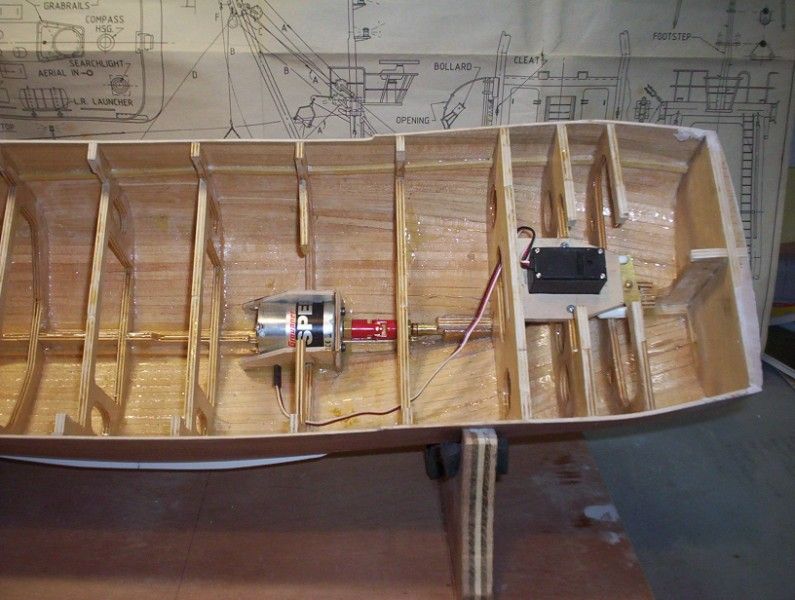

I'm sure the ply planking will be strong enough to just resin inside as John has said, my Cullamix tug is balsa planked so I used some proper woven glass cloth , as she weighs in at 35 lbs she also needed the strength, I think you maybe surprised how much ballast and battery weight she will require.

I'm sure the ply planking will be strong enough to just resin inside as John has said, my Cullamix tug is balsa planked so I used some proper woven glass cloth , as she weighs in at 35 lbs she also needed the strength, I think you maybe surprised how much ballast and battery weight she will require.