Well, there is a lot of food for thought in the various posts. Particularly when this recipient knows so little about boats.

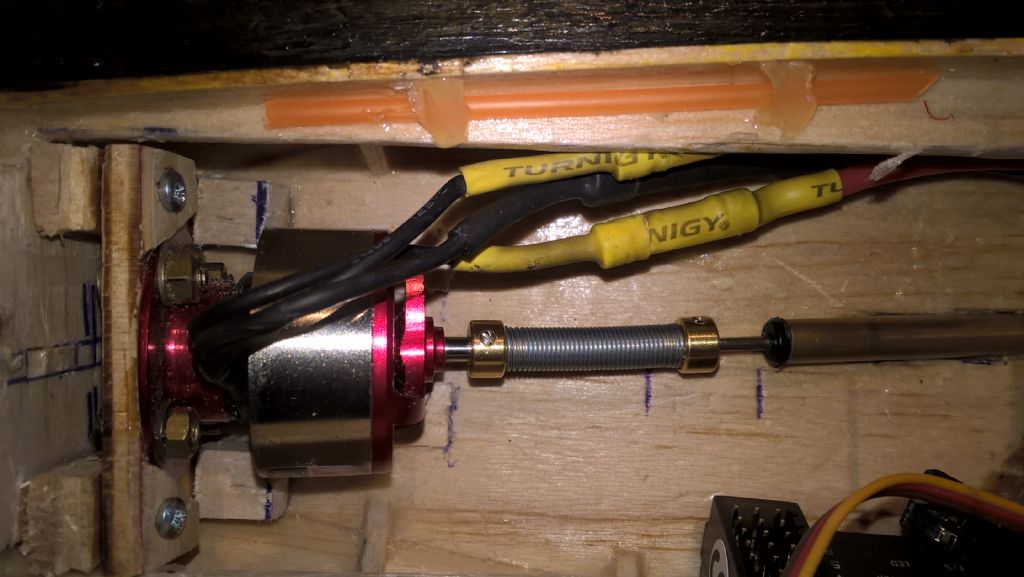

I Have been looking at the Feilun, initially principally for spares. Doing a rough (W=Av) calc on running time, Lipo size and volts I have come to the conclusion that it pulls circa 200w. Even if optimistic I expect that my circa 80w in, is pretty low.

I have re-read the Eze-Bilt site, and am not sure what is thought to be relevant that I should look at?

I can see that some fitted a 400 sized brushed motor. My experience suggests that 480 (which I have and had a few) are good for only 80w and then not for long, as brush/commutator limitations soon contribute to a short useful life.

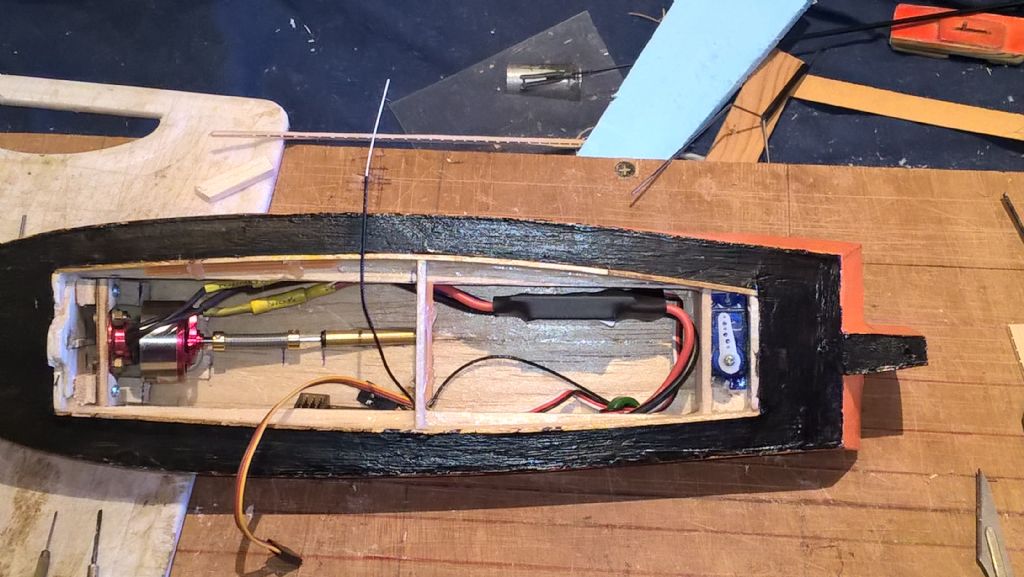

Any way, onto what I have got at present.

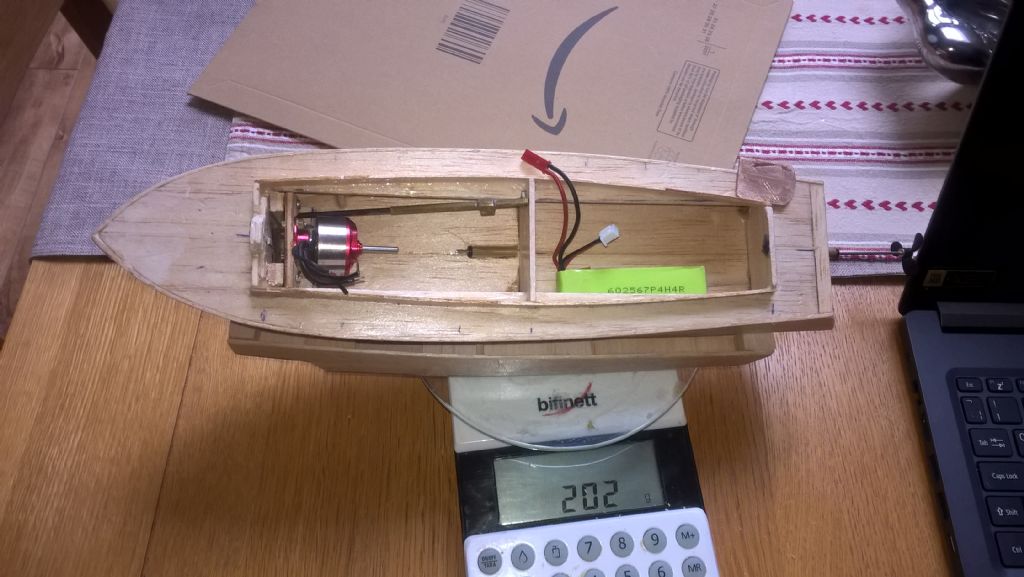

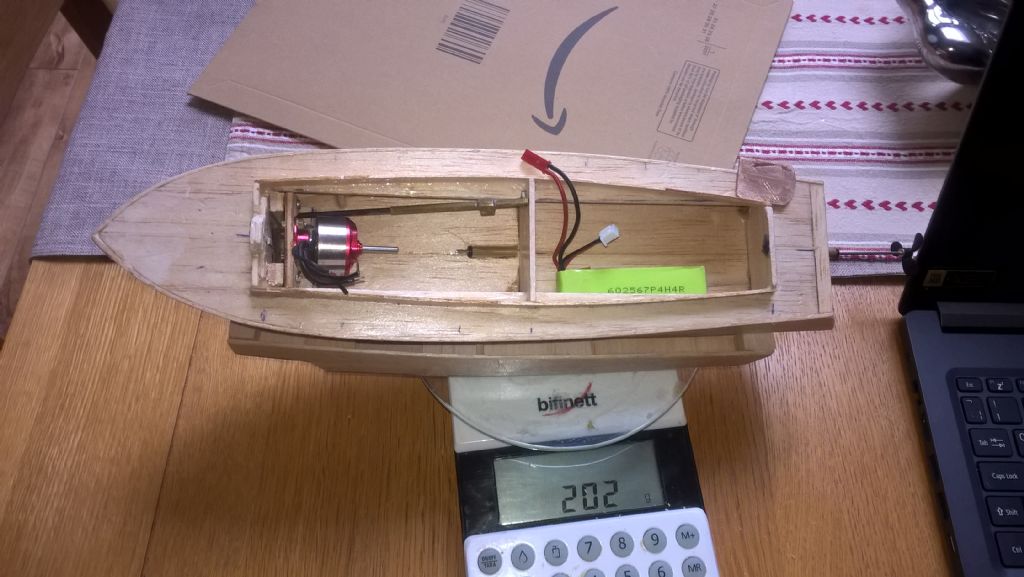

With all the major bits, stuck in at present it weighs in at 202g. There will be an extra 9g servo -Rx a bit of paint slapped on say circa 250g finished. Is that heavy?

I have now started on my own rudder.

It weighs a bit more than I would like for the size. I know it is not balanced, but it is made from copper (a old 1d). I am thinking of narrowing the chord (width) by say a third. Does that seem a good thing to do. I also intend to continue filling it down in thickness, to loose a few grams more. It is tedious, as it took some time to get rid of all of the raised bits.

I have bought a Feilun UJ, which is a good piece of kit (IMO) although not immediately suitable for the kit I have. Dam cheap as well at £2.50 (delivered). Unfortunately, being a dork I do not know what some bits are for. I get the two shaft couplings, plus the bomb bell, but what are all the other bits for?

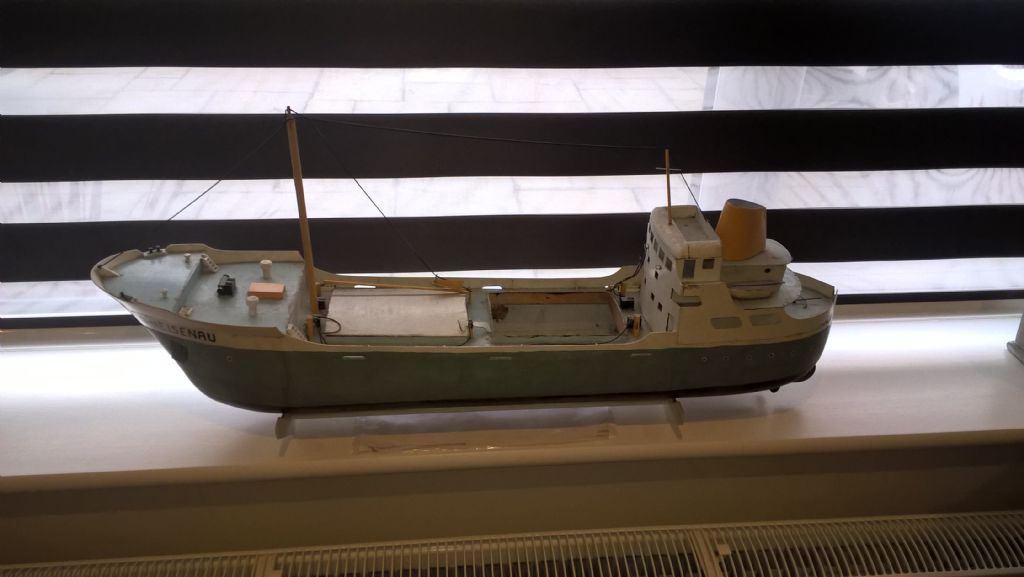

I can imagine that I am already upsetting the KK purists, as I can see that I am drifting away from the purity of the original model. There is a major plus side, I am learning a lot, I am starting to think again, plus a degree of experimenting is what makes hobbies fascinating.

Something one of you guys had me waking up thing about "Dimensionless Relationships". I thought of Froude Numbers and how it relates to boats. Thinking why is the Mermaid long and narrow, when I am intuitively thinking mush wider at the stern would be better. Then the penny dropped, ger clunk, it would go a little faster in a straight line, than my wider boat, which would perhaps be more stable turning.

Now what is relevant, that you could and hopefully will help me with. I have been considering a little skeg/keel/bagger board, forward of the propeller, with a view in keeping it running straighter. Rather than just relying on the rudder and prop thrust interaction.

All of which reminds me of trying to establish where the longitudinal CG is. Hopefully again your knowledge and experience will educate me to how it works, or if it is relevant.

I know I have slowed up, partly because I am uncertain what to do for the best.