The world's leading magazine for all model boating interests

Help required for building Billings Bluenose II “600”

Help required for building Billings Bluenose II “600”

- This topic is empty.

-

AuthorPosts

-

28 January 2018 at 20:14 #75456

Banjoman

Participant@banjomanYou're welcome, John!

For getting thread through small holes, like in deadeyes and blocks, I find it really helps to stiffen the end of the thread. To this end, I use a thin CA glue (I usually use Zap CA glues, but there are other brands too; the Zap thin one is the pink bottle: **LINK**), in which I dip the end maybe 10 mm or so. Any excess drops I wipe off with some kitchen roll before they have time to set. After 15 to 20 seconds the end will be stiff as a board, and can very easily be threaded through any hole that it'll fit through.

Once everything has been threaded through, the stiff end can simply be snipped off.

Good luck and happy building

Mattias

28 January 2018 at 20:41 #75458John Arnold 3

Participant@johnarnold3Thanks again Mattias

The use of CA glue had been mentioned some time ago I remember and I had been meaning to ask is CA glue the same as what we know as Super Glue which stick almost instantly. Now that you have sent a link I can see that it is a Cyanoacrylic glue and "bonds fingers and eye lids together in an instant" and so that is what it must be and easily obtainable everywhere here.

John

28 January 2018 at 21:17 #75459Banjoman

Participant@banjomanJohn,

Yes indeed: CA = Cyanoacrylate = Super Glue.

For model building purposes it comes in several varieties, the three most important of which are thin, medium and thick. Medium I rarely use, but thin and thick are two of my more frequent go-to glues for a number of jobs.

Thin CA is perfect when the two parts to be glued together can be held together tightly in the desired position. A small drop of thin CA applied to the edge of the joint will then be sucked into the joint by capillary forces, and join the parts more or less instantaneously. Also perfect for wicking into ends of thread as mentioned above. Because of the very short setting time involved, thin CA is difficult or even inappropriate to use where the two parts have to be brought together after the glue has been applied.

Thick CA on the other hand has a setting time of usually between 30 and 60 seconds, so although a certain deftness is required, it works for first applying glue to one side of the joint, and then bringing the two parts together.

And yes: one well-known feature of CA glues is their capacity for glueing fingers to each other or to the parts. If this happen, don't try to break the bond by force – you'll pay for that in skin!

Instead you can either get a bottle of CA debonder (usually produced and sold by the glue manufacturer) or you just get (preferably before you start glueing!) and keep handy a bottle of acetone from your local chemist's/pharmacy (I don't recall off the top of my head which word you use in Australia), as the active ingredient in the brand name debonders happens to be just that – acetone. A small quantity of debonder or acetone on the glued-together fingers or whatever, and within 10 to 20 seconds, the glue bond will be released. Also works for build mistakes, if the materials involved in any erroneously glued-together parts can take beig soaked in acetone (if in doubt, test first on some scrap material).

Mattias

Edited By Banjoman on 28/01/2018 21:18:09

Edited By Banjoman on 28/01/2018 21:19:04

Edited By Banjoman on 28/01/2018 21:19:25

28 January 2018 at 22:29 #75461John Arnold 3

Participant@johnarnold3Thanks Mattias,

I have found Zap-a-gap on Ebay and will order. I don't think I have any 'super glue' at present and although I am sure I can find some cheaper ones the Zap-a-gap says it has superior wicking action.

Now back to my complaints about Billings. On some pages of the instruction manual showing diagrams it also shows what is a tube of glue one marked SEKUNDLIM and the other PLASTLIM. I think after googling the first one (all hits in German) that it is a superglue and that Plastlim is marketed by Tamiya and is an Extra Thin Cement is widely popular glue among modellers.

IT's annoying enough that the manual has everything described in 8 languages but when some things are only in one and that is not English it is really annoying.

Any thoughts or ideas?

John

29 January 2018 at 02:24 #75465John Arnold 3

Participant@johnarnold3Sorry to ask yet another question but I thought it would be obvious and that is thin and thick CA glue.

Obviously Zap-a-gap is thin but what brand/type is thick? I searched my local hardware's (and most other things) website for 'super glue' and found a few brands and some were listed as GEL type yet they are described as "sets in seconds" yet your description is that the thick type sets in 30-60 seconds. Some listed state 'sets in 10 seconds' which I think should be enough time to realign the pieces if necessary. I am still wondering why Billings suggests PLASTIM for some parts as I have no idea what this is.

29 January 2018 at 07:00 #75467Banjoman

Participant@banjomanJohn,

No worries — if you don't ask, you get no answers!

Every brand of CA glues (at least for modelling purposes) that I know of has several different types in their range; this is true for Zap Glues, for Deluxe Materials, for Bob Smith Industries and others too.

If we stick (pun intende) to Zap Glues, they have ZAP CA (thin, pink label), ZAP-A-GAP (medium, green label) and SLO-ZAP (thick, yellow label): **LINK**. (They also do a gel, a foam safe CA and a rubber toughened, but neither of those should be of great interest to you for this build).

There is also their debonder (**LINK**), but as I said, pure acetone also works fine for the purpose.

One more thing about CA glues. The bottles in which they come have fairly large in-built nozzles, so stright from that nozzle, you are quite likely to get far too much glue on a joint, and it can be rather difficult to control the amount, especially when it comes to the thin variant, which is very liquid!

Zap also sells two different add-on nozzles that I really like, Z-Ends and Flexi-Tips: **LINK**. In particular the Flexi-Tips are extremely useful, and give neigh-on perfect flow control and precision in application. If you don't find the Zap brand flexi-tips, there are similar products available from other brands that should normally fit the Zap bottles as well.

Now, for the Billings instructions, sekundlim and plastlim is not German, but Danish (Billings is a Danish company), and do indeed mean what you think they do. While lim means glue, sekund is second (as in the measurement of time) and plast of course means plastic.

In other words, where the instructions say sekundlim, they mean use a suitable CA glue for this joint, and where it says plastlim, you should use some form or other of styrene plastic glue. I'm sure we all remember the classic Humbrol tubes, although these days my personal preference is for the Tamiya Cement liquid glues that you mention! As usual, there are other brands available, so my recommendations are simply based on what I have tried myself and liked, and I really like the Tamiya stuff.

Actually, the Tamiya Cement also comes in different thicknesses, and should in my experience be used in the same way as CA glues, i.e. the extra thin formula (**LINK**) for capillary glueing and the standard formula (**LINK**) for applying glue before joining the parts together.

In general, anything from Tamiya is usually very good, not least their masking tapes, which are just the right amount of sticky and can be pressed down to give clean and crisp lines but won't lift any previous coats of paint when removed (unless you were careless and didn't give things time to dry, or the paint hadn't at all bonded to the surface which happened once to me when painting a smokestack made from PVC tube).

Mattias

Edited By Banjoman on 29/01/2018 07:02:47

29 January 2018 at 08:20 #75471John Arnold 3

Participant@johnarnold3Thanks again Mattias for the expert descriptions.

I should have realised that being a Danish company those words would be in Danish – silly me.

I am wondering why Billings suggest using a CA glue for gluing plastic parts to timber parts (masts) and the Plastlim glue where plastic parts are glued together. I am wondering if CA glue would also work satisfactorily otherwise maybe a product they sell here in Australia. Gorilla glue is described as NOT a CA glue and taking 30-6- seconds to bond and is suitable for bonding plastic, have a look at **LINK** Yes this is that Bunnings hardware store chain I have mentioned in the past.

I am just trying to make it easy to obtain suitable supplies rather than have to order them in by post and have to wait up to a week.

Another question? The paint colour diagram suggests Mahogany stain (Bedjse/Stain/Mordant/Beize/Mordient) for the masts, timber roofs and some plastic parts. I am happy to use that on the wooden parts but I would not think that a stain would 'take' to plastic and so and thinking a brown paint on the plastic? Does plastic normally require a primer especially when using acrylic paint (I have other colours to paint on some plastic parts). I never used primer on plastic kits '100 years ago' but did use solvent based paints (all that was available).

Oh how I wished I was within a reasonable distance of a good hobby shop.

BTW that plan I sent also shows the places for eyebolts and the belaying pins which the manual doesn't. That helps a lot.

John

29 January 2018 at 08:55 #75473Banjoman

Participant@banjomanJohn,

Plastic cement like the Tamiya ones bonds styrene plastic parts together by briefly melting the plastic of the joint, or in other words welding the parts together. If such a joint is well made, the two parts literally become one.

This only works when both surfaces of the joint are made from styrene plastic. To glue a plastic part to another material, like wood, you need a glue that will bond to both materials. CA glues do this, as do epoxies.

I have never tried the Gorilla CA glue you linked to, so cannot say anything about what it will and won't do well, but if it is not too expensive, you could always get some and try it out. As I've said several times, my tuppence'orth of advice is mainly based on what I use myself, and as I've been happy with the results I get from for example Zap products, I haven't tried any others. That does not mean that other products aren't any good — for all I know they might even be better — but just that I have no experience of them.

About stains, as you rightly surmise you cannot stain plastic, but will have to paint those parts. Primer probably isn't strictly necessary, but is nevertheless often a good idea; it is also a good idea to degrease the parts before painting them. My go-to substance for degreasing is methylated spirits that I get from my local pharmacy — but whatever product you use, test it first on a piece of scrap material to make sure it doesn't aversely affect the plastic.

My preferred technique for making a paint job look like wood is to first paint it a flat medium brown using acrylic paint, and then imitate a wood grain pattern using artist's oil paints; see at the bottom of this page **LINK** and the top of the next one, and also towards the bottom of this page **LINK**. It is really quite easy to do, with the one drawback that oil paints are very slow drying (expect drying times of up to a week).

I just mention this technique; however, for your purposes, I think that a flat brown will do just as nicely …

Mattias

Edited By Banjoman on 29/01/2018 08:56:03

29 January 2018 at 10:31 #75476John Arnold 3

Participant@johnarnold3Thanks again Mattias

I am wondering if epoxy resin adhesives would be suitable for glueing plastic together (anything to try and avoid the post).

John

29 January 2018 at 10:50 #75477Banjoman

Participant@banjomanYou're welcome John!

Again, I haven't tried, so I don't know, but if I had to venture a guess I suppose they would work. Probably not quite as well, and they might be a bit trickier for getting neat joints.

Would there by any chance be a good toy shop within reasonable distance off where you are? They might carry a selection of plastic kits, and also have a stand with some sort of paints and glues. Perhaps not the Tamiya stuff, but maybe Revell (**LINK**) or the good ol' Humbrol (**LINK**)?!

Otherwise, make a test with some scrap pieces from the plastic frames and see how easy it is to glue them together with an epoxy glue easily available to you, and how strong the bond seems te be.

Mattias

29 January 2018 at 11:00 #75479John Arnold 3

Participant@johnarnold3Aha a toy shop. Why didn't I think of that as there is one in the town I am driving to tomorrow. Thanks.

John

29 January 2018 at 11:04 #75480Banjoman

Participant@banjomanNo guarantee, of course — things have changed mightily since back in the day when toy shops were a main outlet for plastic model kits, but if you're more or less passing one anyway, It is at least worth a look-see!

Mattias

30 January 2018 at 03:43 #75490John Arnold 3

Participant@johnarnold3I have just returned from a hobby shop which is about 30 minutes drive away. I had been there before but before I became interested in model boat construction. I knew that they sold aircraft and model trains. I certainly will now return there should I need more 'supplies'.

They had a large selection of paints but mainly Tamiya and Revell as well as different brands of glues including Revell 'professional' liquid glue even marked 'plastiek-ljm' which has a long thin nozzle for accurate placement of the glue. They also had a small selection of paintbrushes but not the one I want for the hull so that will come from my local art supplies.

I mentioned to the owner that I was building a Billings kit and he said he would never sell them mainly because of lack of information and instructions and bad translation from Danish to English in the instructions. He said that he built one of their kits about 20 years ago and they have not improved their instructions in all that time.

I spoke to him about some of the things I have asked here and he was aware of the answers I have received.

Lastly when I asked if the plastic parts required a primer before using acrylic paint he said not necessarily BUT to ENSURE I washed the plastic parts with soapy water in case any oils from the manufacture were still on them. Maybe you recommended that before I can't remember.

John

30 January 2018 at 07:43 #75491Banjoman

Participant@banjomanJohn,

That's very good news! It is very handy not to have to send off for absolutely everything one needs, and even more valuable to be able to discuss one's options and choices with a well-informed trader!

I had not mentioned soapy water (which does indeed work very well), but did suggest degreasing with methylated spirits. If you want to avoid putting fingerprints on any newly cleaned surfaces, you could don vinyl, latex or nitrile gloves while handling them after cleaning.

Vinyl gloves are the cheapest, and can usually be found in DIY stores and similar. Latex is more expensive, and some people's skin can be sensitive to the material. Nitrile is even more expensive than latex, say maybe $60 or so for a box of 200, but is my preferred option, as I find them much more comfortable and with a better sense of touch than latex. Latex gloves can often be found in DIY shops, too, but can also be bought from pharmacies, which is where I always order my nitrile gloves from — they are used a lot in hospitals and similar situations and are thus easily available through the pharmaceutical supply chain.

Apart from the fingerprint issue, nitrile gloves also give the best protection against chemicals, and so I always wear them when for example mixing Milliput (**LINK**) or other resins or epoxies, as repeated skin exposure to such substances won't necessarily but can cause a sensitivity to develop. Latex give almost as good protection, but vinyl apparently very little. I am currently not sensitive to any of all that, but don't want to become it either, and so take precautions.

However, if the purpose is only to protect a part against fingerprints before painting, cheap vinyl will do just fine

Mattias

30 January 2018 at 09:31 #75494John Arnold 3

Participant@johnarnold3Hi Mattias,

You did indeed mention methylated spirits I now remember.

I have vinyl gloves in my workshop which I use when gardening. I prefer them to latex gloves as I find they are easier to get on and they don't tear/rip as easily. Maybe I should try and source large size latex gloves as the ones we buy are from the supermarket and usually only come in medium size. But I will take your advice that latex are better when using epoxy resins. Thanks for that tip.

I checked out Ebay for the nitrile gloves and can get 100 for $A19 which isn't expensive. They are also listed as disposable mechanic gloves black nitrile gloves tattoo glove and some are blue in colour. Must get some even if for other uses too.

John

Edited By John Arnold 3 on 30/01/2018 09:36:52

30 January 2018 at 11:14 #75495John Arnold 3

Participant@johnarnold3Oops another question.

I must confess I haven't yet painted the hull but was going to tomorrow.

I have yet to attach the 'chain plates' to the side of the hull. The instructions don't mention when to do this (before or after painting) yet the video put out by Billings shows the hull being painted BEFORE they are attached.

I want your opinion as to when it is best to do this. Obviously they will need to be GLUED to the hull as there are no holes for small pins to attach them. I thought perhaps that the bond might be stronger glueing them to bare timber rather than a painted surface. You opinion please. Maybe it really doesn't matter.

John

30 January 2018 at 11:25 #75496Banjoman

Participant@banjomanJohn,

On a static model, it matters much less than on a working one, where strains and forces have to be absorbable; however, the general rule is too avoid as far as possible glueing anything to a painted surface.

The thing is, if you glue it to paint, the strength of the joint will only be as strong as the adherence of the paint to the wood (i.e. probably not very strong).

Are the chain plates supposed to be painted too? If so, in the same colour as the hull or a contrasting one?

(a) If they're to be painted the same as the hull, it's simple: glue them on before painting!

(b) If to be left unpainted or painted in a contrast colour, it becomes a tad trickier. There are various approaches possible, but I'm afraid I haven't time just now to write them up in detail. If you need this advice, please let me know, and I'll get on to it ASAP.

If you don't, because (a) applies, no worries, I'll still write them up but a bit later …

Mattias

30 January 2018 at 16:41 #75499Banjoman

Participant@banjomanJohn,

To be more precise, I don't think one needs to protect the hands against the odd small smear from normal epoxy glue; Milliput, which is an epoxy based, two-component filler and sculpting paste, must be mixed by kneading the two components together for several minutes, and that sort of exposure, where you would be rubbing it into the skin for a fairly long time, can potentially trigger a latent sensitivity.

That said, I like to wear disposable gloves for most messy jobs, including working with epoxy glue, just simply to keep my fingers clean …

I don't much like latex gloves either, for a number of reasons, and find the nitrile ones much more comfortable and useful, for all sorts of jobs around the house.

Now, as I wrote in my previous, if the chain plates are going to be painted the same colour as the hull, I for one would definitely glue them in place first. That way, you'll glue them to the base material, plus if there are any glue stains, they will disappear under the paint.

If they are going to be painted a different colour, you are (not least at scale 1:100) likely to get a much crisper and neater result if you paint hull and chain plates separately before glueing on the latter. What you then do is (a) don't paint the backs (i.e. the surface that'll be glued to the hull) of the chain plates, and (b) mask off the hull were they are going on.

By the latter I mean, before painting the hull, carefully mark onto it exactly where each chain plate will sit. Then add a small strip of masking tape to the central part of the area that will be covered by each chain plate. Don't try to mask to the exact borders, but keep inside them; it is sufficient that there is a small slit in the hull paintwork in the middle under each chain plate where the glue can bind to the wood rather than the surrounding paint.

Mattias

30 January 2018 at 20:41 #75502John Arnold 3

Participant@johnarnold3Mattias

You have answered my question when you asked if the plates are to be painted the same colour as the hull – yes they are so problem resolved.

And if I'm not too careful (at 1:100 most parts are very small and fiddly and already I am using tweezers to position small parts) with the epoxy and some finds its way onto the hull no problem as the paint will cover it.

Thanks

John

31 January 2018 at 04:47 #75503John Arnold 3

Participant@johnarnold3Hi Mattias,

What is your preference to glue metal (chain plates) to timber (hull). CA glue or "5 minute epoxy resin" (comes in a self mixing plunger where equal parts are dispensed together). Can you paint over either after cured (in case I get clumsy)?

John

31 January 2018 at 06:55 #75504Banjoman

Participant@banjomanJohn,

On a static model like yours, where the chain plates have to be well stuck on but don't need to withstand for example wind force when out sailing like a r/c model would, I'd use either thin CA applied by capillary action with the parts already held together, or a five minute epoxy applied with the parts still apart.

I would not use thick CA, as it has to be applied with the parts apart but gives only a very short time to adjust them in their places, and for a neat look you want the chain plates to sit just so, each one at precisely the right angle and height.

Which technique to go for depends on circumstances.

If it is possible for you to hold each chain plate in place with some form of clamp (clothes pegs come to mind if you've nowt fancier to hand), well pressed down, CA will work best. You clamp the plate in place, and then apply a very small amount of thin CA to the edge of the joint, and hey presto: by capillary action, the glue is pulled in under the chain plate, and the glue goes off almost immediately.

With thin CA, don't try to hold the chain plates down with a finger tip; you will almost certainly glue your finger to the model! If you cannot clamp, you might make some sort of pressing-down tool from some spare strip wood or similar, and use that to hold down the part, It'll work fine as long as it applies even pressure on as much as possible of the surface without quite reaching the edge of the chain plate metal (again you don't want to glue it to the model).

(Within brackets, I should perhaps say that CA glue cures by absorbing moisture from the air. This means that in a humid environment, it will go off very quickly, while if the air is very dry, it might take much longer than what the manufacturer suggests. CA glue also has a limited shelf life, once the bottle has been opened; I usually throw opened bottles away when I begin to notice a serious deterioration in performance.)

If it is difficult to clamp or hold down the chain plates, you might be better off using 5 minute epoxy. Apply it sparingly (only a very thin bead is needed) with the help of for example a cocktail stick or a tooth pick dipped in a small blob of the glue (don't try to apply straight from the tip of the syringe — you'll get far too much glue on such small parts) and hold the part in place until the glue has grabbed. With 5 minute epoxy you will have several minutes at least to adjust the part until satisfied. However, if you cannot clamp each chain plate as you go, you will probably need a fresh small blob of glue from the syringe for each chain plate, as the previous blob will of course have cured while you were adjusting and pressing down the previous chain plate!

Both types of glue are eminently paintable, so small amounts of excess glue won't be a problem. That said, excess thin CA outside of the joint can easily be removed before it has had time to cure by holding a corner of a piece of kitchen roll up to it — it'll very neatly wick up into the paper. Don't try to wipe it off, as it might cure while you're at it and glue some kitchen roll to the model. Just wick it away.

As long as epoxy glue has not cured, any excess is easily wiped off with for example a cotton bud, dipped in methylated spirits.

Fresh epoxy on your hands will simply wash off with soap and water. If you get CA on your hands, first use debonder or acetone, and then wash with soap and water. Or use disposable gloves!

Good glueing

Mattias

Edited By Banjoman on 31/01/2018 06:56:11

31 January 2018 at 07:26 #75505John Arnold 3

Participant@johnarnold3Thanks Mattias.

I remember many years ago I stuck two fingers together and either debonder wasn't then available or I didn't have it. Luckily it was a very small 'joint' and I carefully got my fingers apart using a thin very sharp razor blade.

2 February 2018 at 02:45 #75521

2 February 2018 at 02:45 #75521John Arnold 3

Participant@johnarnold3I am glad you suggested gluing the chain plates to the hull before painting as the parts are so small (about 25mm x 1.5mm x 1mm) I found it impossible not to get some glue on the hull itself (and my fingers) which will be covered by paint (not my fingers

) but not a good look on the top of paint. I used 5 minute epoxy resin as I didn't trust myself using CA glue.

) but not a good look on the top of paint. I used 5 minute epoxy resin as I didn't trust myself using CA glue.Also the many small wooden pieces which make up the deck structures (those with sky.lights) which needed to be glued together (pva paint) very fiddly especially to keep them square. I would hate to build a model smaller than this one.

2 February 2018 at 06:33 #75522Banjoman

Participant@banjomanI does sound as though you managed to stick them on, though!

Yes, 1:100 is a pretty fiddly scale!

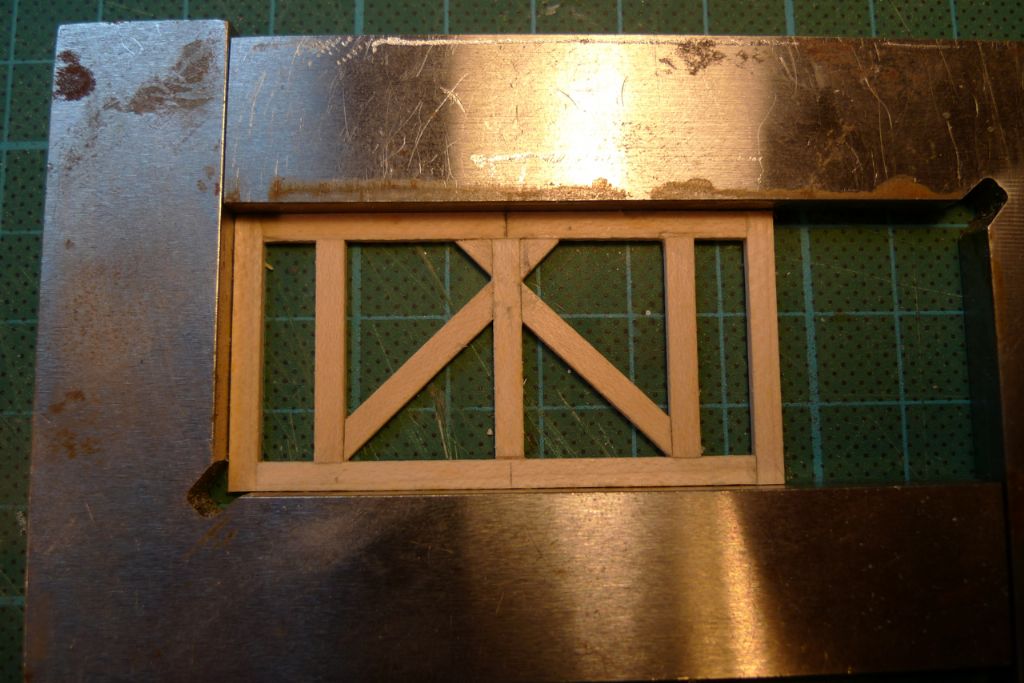

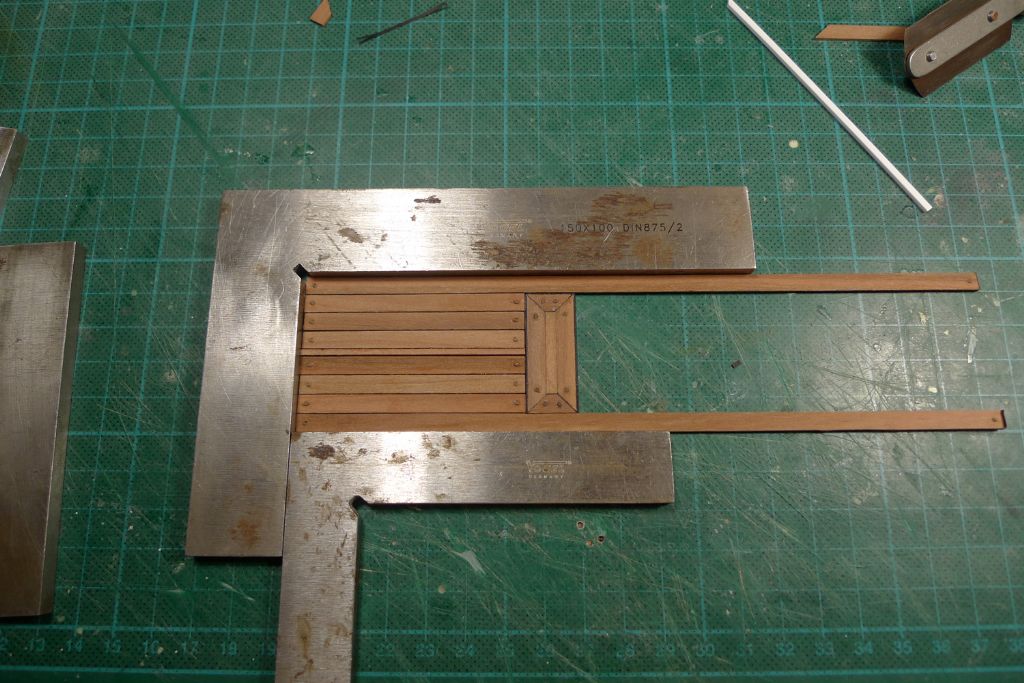

For keeping small stuff square when glueing it together, I almost invariably use some engineer's precision squares, like here for instance:

Or here:

For starters, being steel they have a bit of weight to them, so will not move about quite as easily as lighter materials. Because they're flat (i.e. have no edged handle like some other types of try square that are meant to use the edge of the workpiece as datum) they can be used on any flat surface, and moved around any way that suits a specific situation. They have enough of edge depth (+/- 6 mm or so) to give good purchase against the materials that are being squared up, but are at the same time flat enough that one can get at the materials from above for keeping them pressed down if needed. They can also be slid against one another, as shown above, to allow one to apply strong and even pressure in perfect square — something that it is much, much more difficult to achieve with just the fingers.

All in all, I find them absolutely the bee's knees, and use them a great deal for all sorts of jobs where squareing up or aligning or pressing together is involved.

I have four of the smaller size shown above (70×100 mm, I think) and two of the larger (100×150 mm). The only negative aspect is that they're not exactly given away for free …

Mattias

2 February 2018 at 08:48 #75523John Arnold 3

Participant@johnarnold3Hi Mattias,

I have seen on hobby shops web sites very small squares but as you point out not cheap. Actually I improvised and used a piece of the ply timber which originally contained laser cut parts as a small square.

Some of the deck structures I had to get reasonable square when gluing 4 small pieces together were only about 13mm x 4mm x 3mm each. Would have been easier if I had a 3D printer – do you have one of those?

I am almost ready to mount the 'deck structures and fittings' then comes the rigging which is going to be a real challenge not only to do it in the correct order but and to get the 'ropes' (lines,sheets) in the correct places and either knots or wrapping the ends with another thread and glueing.

BTW how long do you suggest I leave the "5 minute epoxy resin' to fully cure before painting and should it be lightly sanded? Small amounts aren't where they were intended

John

Edited By John Arnold 3 on 02/02/2018 08:50:43

-

AuthorPosts

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Code of conduct | Forum Help/FAQs

Latest Replies

-

- Topic

- Voices

- Posts

- Last Post

-

-

Vic Smeed’s Legacy

Started by:

Colin Bishop

in: All things floating

Colin Bishop

in: All things floating

- 5

- 7

-

1 hour, 40 minutes ago

Colin Bishop

Colin Bishop

-

Vic Smeed’s Silver Mist

1

2

…

32

33

Started by:

Bob Abell 2 in: Scratch build

- 4

- 823

-

2 hours, 43 minutes ago

Colin Bishop

Colin Bishop

-

Eezebilt RAF Fire Boat

Started by:

Tim Cooper in: Build Blogs

- 2

- 4

-

3 hours, 16 minutes ago

Tim Cooper

-

Feathered Friends

Started by:

Chris Fellows

in: Soapbox

Chris Fellows

in: Soapbox

- 3

- 8

-

8 hours, 36 minutes ago

Chris Fellows

Chris Fellows

-

4D Modelshop

Started by:

Keith Long in: Scratch build

- 6

- 9

-

1 day, 5 hours ago

Colin Bishop

Colin Bishop

-

Fairey Huntsman 31

1

2

…

5

6

Started by:

Chris Fellows

in: Build Blogs

Chris Fellows

in: Build Blogs

- 14

- 139

-

2 days, 2 hours ago

Chris Fellows

Chris Fellows

-

Fairey Faun

1

2

3

Started by:

Chris Fellows

in: Build Blogs

Chris Fellows

in: Build Blogs

- 7

- 58

-

2 days, 2 hours ago

Chris Fellows

Chris Fellows

-

Fairey Huntsman 28

1

2

…

7

8

Started by:

Chris Fellows

in: Build Blogs

Chris Fellows

in: Build Blogs

- 1

- 195

-

2 days, 4 hours ago

Chris Fellows

Chris Fellows

-

John Cobb’s Crusader

1

2

…

7

8

Started by:

Paul T

in: Scratch build

Paul T

in: Scratch build

- 1

- 192

-

3 days, 4 hours ago

John W E

John W E

-

Complex Automata

Started by:

Colin Bishop

in: Soapbox

Colin Bishop

in: Soapbox

- 1

- 1

-

4 days, 7 hours ago

Colin Bishop

Colin Bishop

-

RAF Fireboat ID

Started by:

Dave Reed

in: Collectors’ corner

Dave Reed

in: Collectors’ corner

- 8

- 24

-

5 days, 8 hours ago

Tim Cooper

-

TID steam tug 42″ – PN Thomas drawing enlarged

1

2

Started by:

Ray Wood 3

in: Scratch build

Ray Wood 3

in: Scratch build

- 8

- 33

-

6 days, 2 hours ago

Richard Simpson

Richard Simpson

-

Lady of Skye (puffer)

1

2

Started by:

mick east

in: Build Blogs

mick east

in: Build Blogs

- 9

- 43

-

6 days, 12 hours ago

Richard Simpson

Richard Simpson

-

Building a hull.

Started by:

mick east

in: Scratch build

mick east

in: Scratch build

- 7

- 10

-

1 week, 1 day ago

Ray Wood 3

Ray Wood 3

-

Todays Boating

1

2

…

210

211

Started by:

ashley needham

in: All things floating

ashley needham

in: All things floating

- 84

- 5,252

-

1 week, 2 days ago

Colin Bishop

Colin Bishop

-

Sea Rover Restoration

Started by:

harry smith 1 in: Collectors’ corner

- 4

- 10

-

1 week, 2 days ago

Richard Simpson

Richard Simpson

-

WORKSHOP LIGHTING

Started by:

John W E

in: All things floating

John W E

in: All things floating

- 9

- 18

-

1 week, 3 days ago

Colin Bishop

Colin Bishop

-

Mayhem Website Down

Started by:

Colin Bishop

in: All things floating

Colin Bishop

in: All things floating

- 4

- 10

-

1 week, 6 days ago

Colin Bishop

Colin Bishop

-

MAGGIE M trawler

Started by:

sammyk

in: Buy/Sell or Trade

sammyk

in: Buy/Sell or Trade

- 2

- 3

-

1 week, 6 days ago

sammyk

sammyk

-

meter

Started by:

Alasdair Allan

in: All things floating

Alasdair Allan

in: All things floating

- 5

- 16

-

2 weeks, 1 day ago

Chris Fellows

Chris Fellows

-

River Queen 2”- 1’.

Started by:

Richard B in: Steam powered models

- 5

- 7

-

2 weeks, 1 day ago

Richard B

-

Deluxe Superphatic Glue.

Started by:

Colin Bishop

in: All things floating

Colin Bishop

in: All things floating

- 4

- 12

-

2 weeks, 2 days ago

Chris Fellows

Chris Fellows

-

How to add photos to your posts

Started by:

Colin Bishop

in: Adding Images to Forum Posts

Colin Bishop

in: Adding Images to Forum Posts

- 3

- 16

-

2 weeks, 2 days ago

Len Morris 2

-

Cataract

Started by:

Bob Wilson in: Soapbox

- 2

- 4

-

2 weeks, 3 days ago

Colin Bishop

Colin Bishop

-

The mighty tug Wattle

1

2

3

Started by:

mick east

in: Build Blogs

mick east

in: Build Blogs

- 10

- 61

-

2 weeks, 3 days ago

Richard Simpson

Richard Simpson

-

Vic Smeed’s Legacy

-