Hi Eddie,

You will probably find that most suppliers have tanks which have one valve for feeding the burner and a filler valve which is very similar if not identical to lighter filler valves. Although many people use these successfully I am not very impressed with them. I find it very difficult to ensure that I have filled the tank and fuel seems to spurt from the filler nozzle before the tank is full.

Many people do use standard gas cylinders and a special connector is available to screw on to the top of these cans. The connector has a valve for control of the gas to the burner. Suppliers such as Forest_Classics and Maccsteam will supply these and they are on the internet

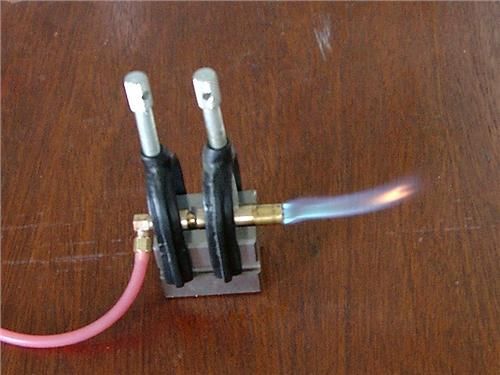

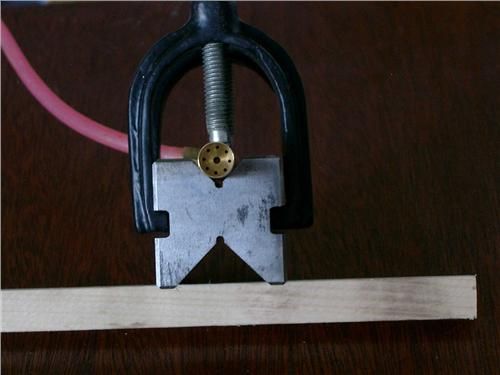

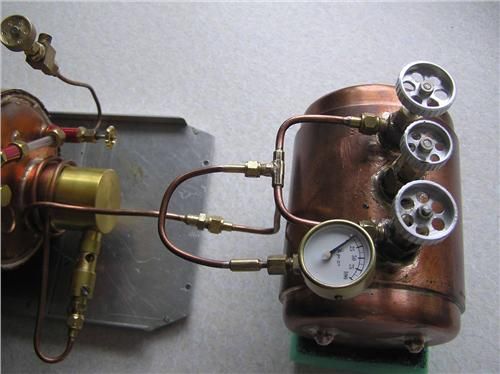

Martin Ranson has written an article which describes his method of filling which is much more reliable but he makes his own tanks. He advocates three valves on his tanks, one for filling and on for venting when filling. A third valve is used for the burner supply but this means making your own valves. I have made my own based on Martins designs and they work fine. My own tank has a supply valve which allows neat fuel to be fed to the burner by having a tube reach to the bottom of the tank. This is based on Peter Arnott’s design and also works well but requires a vaporising coil to ensure acceptable burning.

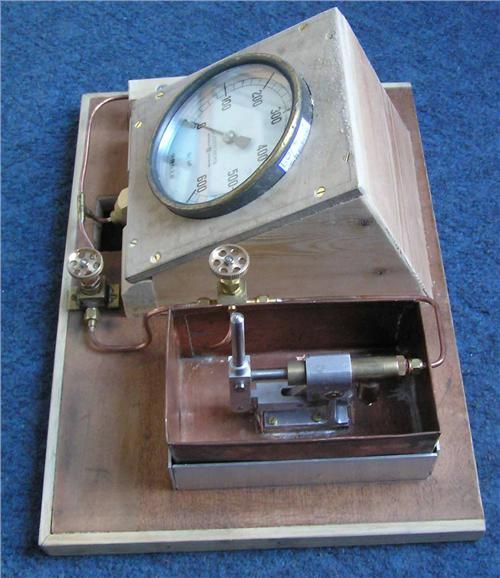

Martin also believes that a pressure gauge is desirable in the supply pipe as this can be very useful to see what is happening when the burner is working.

Martin has written an article in a recent Model Boats mag. (July 2008) so you can see his designs for your own interest. My own boiler is shown in this forum (Steam) under LPG burners where a picture of the boiler with a vaporising coil is featured.

If you are interested in using this method I can advise you further but Martin Ranson has detailed his method of the heat shunt in his article which may suit you better. You mentioned ‘cans in the sun’ and ‘over pressure’ resulting from this. The suppliers suggest that cans are kept out of very sunny places such as in cars. Tanks which are made up by amateurs should also have the filler pipe made such that a space is left into which the fluid can expand and Martins tanks embody this safety arrangement. You would be well advised to use his design to avoid excessive pressure. You may not know but the fluid expands to 250 times its liquid volume when it turns into gas!

You must realise that experimentation with LPG has its own dangers so you must work with scrupulous accuracy when making the tanks and all the fittings and tank testing should be done to regulation pressure. Since making my first tank I have had another tank made by a professional supplier called Maccsteam and you can find him on the internet. His tanks come with a test certificate and are made to stringent standards. I have no personal connection other than as a satisfied customer.

I hope I have covered the points you asked about and I must assure you that I am no expert in these matters. What I will tell you is what I have actually done myself and any experience I have had with it together with any sources of useful guidance I have found in the modelling press. I believe it is important that you make your own assessment of each new thing you do and be careful as you do it.

All the best, Fred Graham

se