Well!

As mentioned recently in another thread (see **LINK**), I have been off on a full scale woodworking tangent now for some time, and while I have no intention whatsoever of abandoning that anytime soon, I have decided that now is a good time to intersperse a moel boat project.

An important reason is that my next woodworking project will be a seven foot Roubo style workbench, made from hard maple, to get which I'd been planning to travel up to Arnhem in the Netherlands, where there's a top notch timber yard. However, under current lockdown rules the trip would certainly count as non-essential, and thus neither it nor the border crossing involved would be allowed. And, even when I will eventually be able to make the trip, I would still want to let the timber accilmatise to my workshop for a number of weeks or even months.

Oh, and just to be clear: I much prefer to have only one project going at a time; I tend to lose focus if I don't.

Anyway, another reason is that this morning I finally finished the sharpening station that I've been working on since mid-January! For the first bit of that build, see my post in the thread linked to above, where I left off at the time of chopping out the mortises …

For the shelf support mortises, that are set against the grain, I prefered to define the openings with chisel and router plane …

… and then drill and pare out the actual mortises …

… to take the shelf support stringers.

Next up was sawing all the tenon cheeks …

… and shoulders …

… until I finally had all the parts ready for clean-up and assembly, including a set of 6 mm diameter draw bore pins made from riven ash.

So, after cleaning up all the inner faces with smoothing plane and, where required, cabinet scraper, it was time to asemble first the two gables …

… and then join these together with the long rails …

… to produce a complete table undercarriage, which was then cleaned up also on the outer faces.

As sharpening is a wettish and sometimes messy business, I wanted a finish that will give good protection, and therefore opted for four coats of Le Tonkoinois – a French linseed- and tungoil-based yacht varnish.

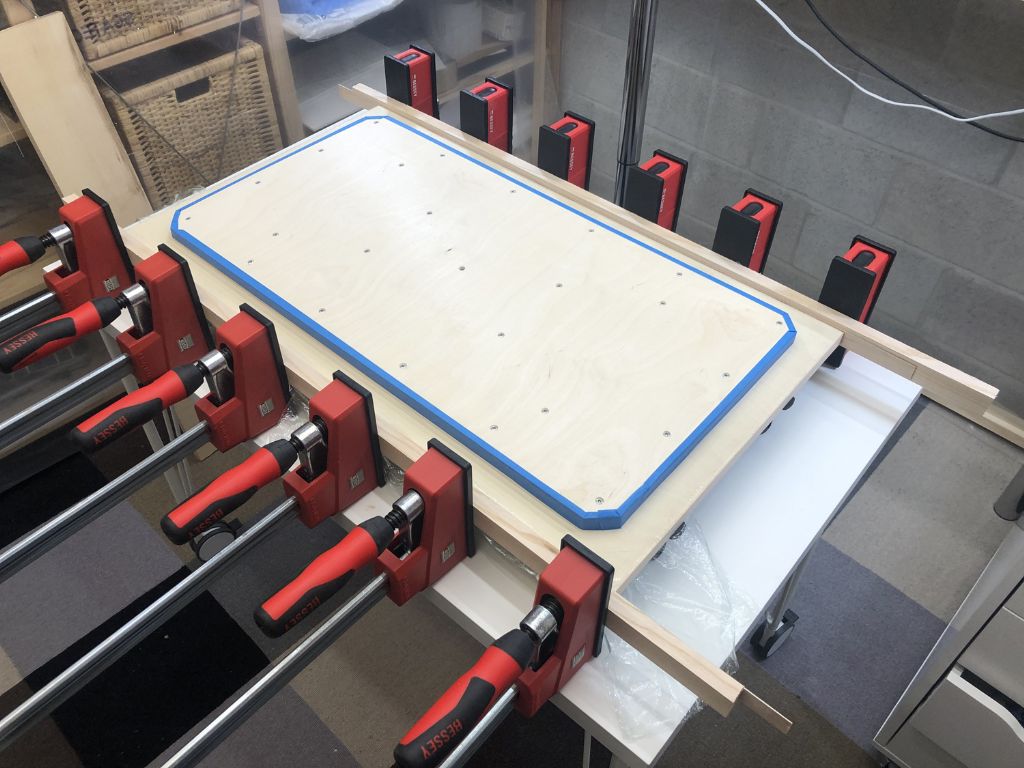

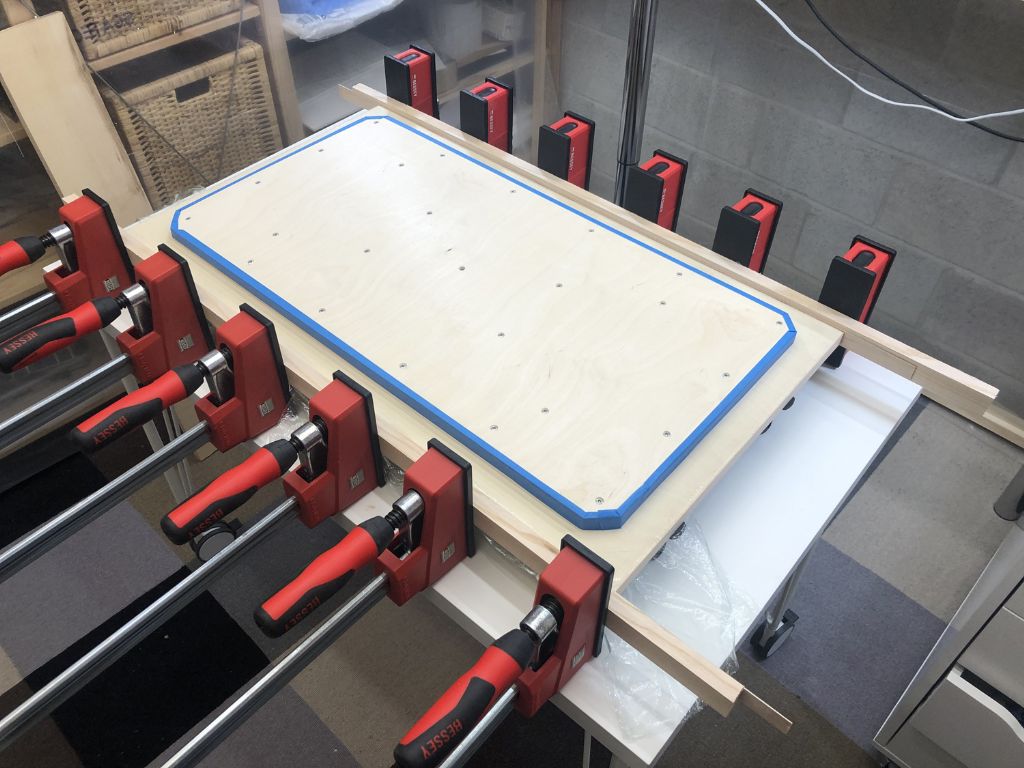

Once the varnish was fully cured, it was time to make up a sub-top from some 18 mm birch plywood, with a first piece fitted just inside the top opening …

… and then glued and screwed to an overlay piece. As the edges of the latter will be visible, and plywood edges are not the prettiest of sights, I covered these with some 1.5 mm maple veneer, produced from offcuts from the main build …

… to this effect.

To be continued …

Edited By Banjoman on 07/04/2020 10:07:47