Beginners luck

Beginners luck

- This topic is empty.

Viewing 17 posts - 1 through 17 (of 17 total)

Viewing 17 posts - 1 through 17 (of 17 total)

- Please log in to reply to this topic. Registering is free and easy using the links on the menu at the top of this page.

Code of conduct | Forum Help/FAQs

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

-

- Todays Boating 1 2 … 210 211

- 84

- 1 week, 2 days ago

Viewing 25 topics - 1 through 25 (of 25 total)

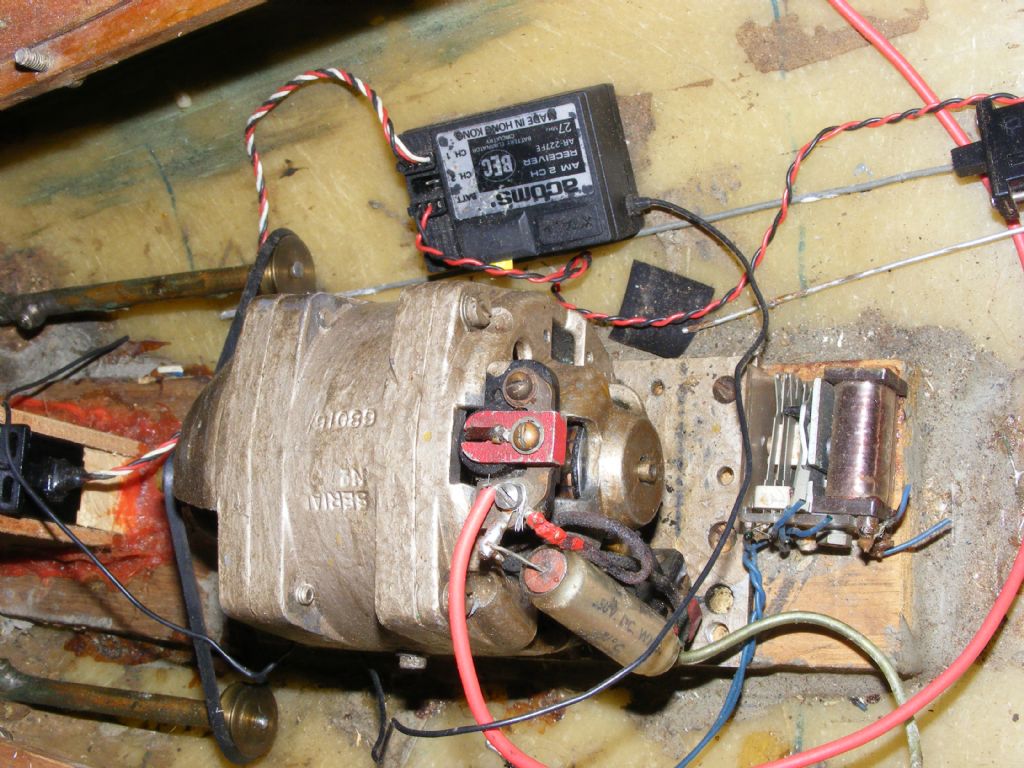

we used to buy a magazine called Exchange and Mart – can anyone remember it? You could get 100s and 1000s of goodies to be bought a sold and in among them were surplus electric gear from the Armed Forces and one of the favourites were bomb site motors – we modellers used to look for them – they were small and compact – the only drawback was they were between 18 and 24 volts; very low amps and this motor reminds me of that.

we used to buy a magazine called Exchange and Mart – can anyone remember it? You could get 100s and 1000s of goodies to be bought a sold and in among them were surplus electric gear from the Armed Forces and one of the favourites were bomb site motors – we modellers used to look for them – they were small and compact – the only drawback was they were between 18 and 24 volts; very low amps and this motor reminds me of that.