Hi Phil The lack of technical info for motor/prop combinations is one of my pet rants,

that is why I build a test rig (dynamometer) to look at motor performance. Some of the results opened my eyes, (eg at max power out some motors are less the 50% efficient, and lose 100watt of battery power Heating up the model).

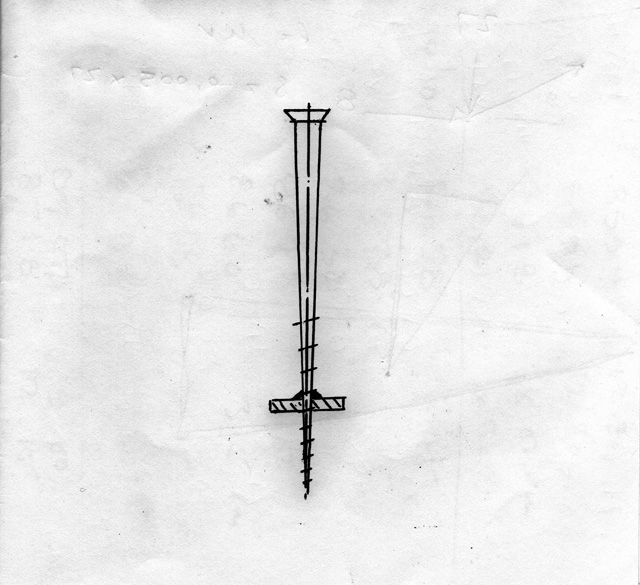

Following on from those tests I have been trying to run a test rig for prop output/performance. It needs to be adaptable for different props, controlable and give measurable readings.

My latest is a low pressure pump in which the prop under test is the impeller, the motor is one that I have all the info from previous tests. The proposal is to measure the amount of water moved per minute, at various speeds under controlled conditions. This may enable me to find the most efficient rpm for a given prop, how big a motor is needed to achieve this etc.

In full size engineering, the first parameter when selecting a motor was Horsepower(watts in metric) then max speed required, after which came motor size, type etc.

With model motors the case size seems to be paramount, and motors with the same number eg 540, from different suppliers give different performances.

Sorry about the rant, you mentioned something I do find exasperating

Breathless Tom

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)