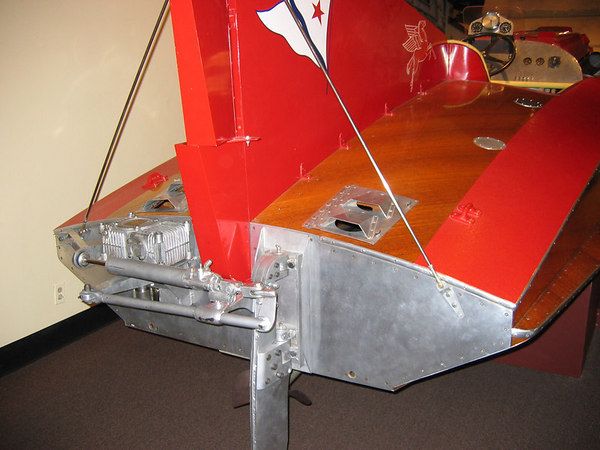

Hi Bob currently 552g and that’s including the fin, rudder, that water inlet, and the cowl,

Still about ten planks, (5g) a tiny amount of 1.5mm ply, the seat. (Which has been trimmed down from 49g to 20g) most of that veneer (about 70g) and the paint. To go on.

So she will be a lot over my optimistic 500g empty target.

prob more like 750g!!! However on the plus side those who know, and are running similar sized hydro’s, on very similar power set ups, are running at 1.5+kg rtr weight.

So as my power/rx set up should weigh (according to mnf fig’s) 500g. I feel optimistic that a recreation of the 1952 water speed record attempt should be on the cards.

The seat by the way is currently waiting on a second coat of paint, and in its trimmed down state looks 100% more like the real one. Photo to follow soon.

I do feel that 20 or so grams of epf is worth it for the safety factor in the event of a blow over! Which I believe is still possible on this power setup. Also the rx is going in a balloon (I hope) and all electrical cons will get some form of waterproofing

So what do you think of the scoop? it’s the best I can think of at the min but still not sure there isn’t a better way without silly lengths of silicone running to a wedge rudder/pickup!

Phil

Edited By Phil Winks 1 on 11/04/2010 15:36:30

now where have they got too.

now where have they got too..jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

)

).jpg)