another Barrel back launch

another Barrel back launch

Code of conduct | Forum Help/FAQs

Latest Replies

Viewing 25 topics - 1 through 25 (of 25 total)

-

- Topic

- Voices

- Last Post

-

- Puffer advice 1 2 … 4 5

- 10

- 2 weeks ago

- Todays Boating 1 2 … 210 211

- 84

- 4 weeks ago

- Fairey Huntsman 28 1 2 … 7 8

- 2

- 1 month ago

Viewing 25 topics - 1 through 25 (of 25 total)

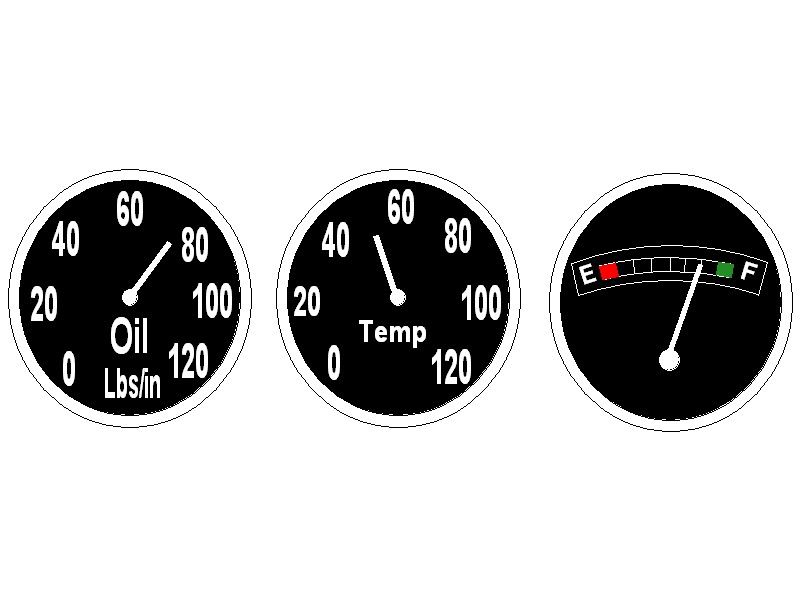

especially one that costs Zero £’s. A thought that occoured to me in the wee small hrs was would this style of launch have had nav lights I really can’t remember from my childhood. also who sells deck fittings for this scale of boat or am I going to have to fashion my own. I’m thinking fairleads and cleats etc also maybe a flagstaff at the stern oh and I’ll need a convincing stearing wheel and control panel etc.

especially one that costs Zero £’s. A thought that occoured to me in the wee small hrs was would this style of launch have had nav lights I really can’t remember from my childhood. also who sells deck fittings for this scale of boat or am I going to have to fashion my own. I’m thinking fairleads and cleats etc also maybe a flagstaff at the stern oh and I’ll need a convincing stearing wheel and control panel etc.

how do I undo that one

how do I undo that one