I recently bought a new bandsaw in the form of a Record Power BS250, a fairly small 10" table top machine, to complement my old Proxxon micro bandsaw. The latter will still be very much used, as it is perfect for cutting really small and/or thin stock; however, one very quickly hits its limitations in the form of cutting height and throat depth. Also, the Proxxon cannot take blades wider than 5 mm or so.

After some fairly extensive research, my primary reason for choosing the BS250 was that it came across as one that would give a fair amount of bang for a fairly limited buck. It is not that I could not have afforded a somewhat more expensive machine, but my tool wish list is much, much longer than my pockets are deep, so in order to continue saving up for further aquisitions later on, I decided to go for a more modest option that will sufficiently well meet my immediate bandsaw needs for my projects over the next few years, until I can hopefully get the one that I really want: **LINK**

Anyway, after getting some top notch after market blades from Tuff Saws in Wales, and generally setting up, running in and getting to know the machine, I am happy to report that it fully lives up to my expectations. That is to say that it is not perfection on a plate, but that it does what it said in the manufacturers description that it would do, does it well enough and, in my view, is of better than average quality and precision for a PRC-built bandsaw in the price range in question (UK list price is £269.99; I got it from a German dealer for +/- £255).

So much for background. Now to my question. One of the uses to which I intend to put the machine is to resaw not-too-large wooden stock. To this end, I wish to put together a cradle to run with the mitre fence groove (on the right-hand side of the saw table in the photo above) as a guide, so that the initial cuts can be made in a piece of rough stock to establish the necessary datum surfaces against which subsequent cuts can be squared off using the parallel fence.

This is where the 10 thou come in. One of the few things that came with the machine that clearly is not up to snuff is the mitre fence: it is very cheaply made, but as they say in one of my favourite cartoons: "What do you want for 10 cents? Gasoline?"

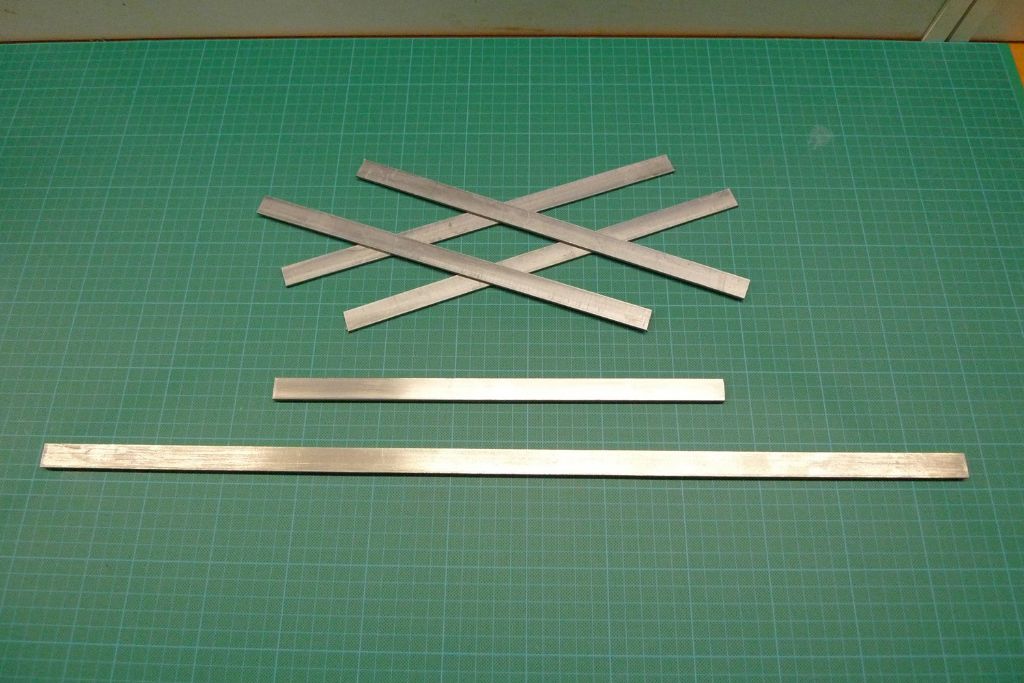

I knew beforehand from various reviews that this was a weak point, and it doesn't really matter. What in particular makes this mitre fence pretty useless is that there is too much play between the fence guide and the walls of the groove. The fence guide is made from aluminium, and while not of perfectly even dimensions, in most places it is from 15.86 to 15.88 mm wide, i.e. close enough to the 15.875 mm that equals 5/8" for me to conclude that it is made from what is meant to be a piece of 5/8" alu stock.

As already mentioned, the groove, however, is that much wider that there is sufficient play for the mitre fence to not necessarily run true. I've checked the difference in as many ways as I've been able to, visually …

… with a feeler gauge …

… and with the slide calliper …

… and have found that within a tolerance of one or two thousandths of an inch, the groove is 0.635" wide, i.e approximatly 16.129 mm. This makes the difference with the mitre guide pretty much exactly 10 thousandths of an inch, or approximately 0.25 of a mm.

This difference may not sound like much, but the amount of play between the mitre fence and the groove is really quite noticeable.

My question is thus: does anyone hear know of a good source for non-standard metal stock? I would like to get my hand on, say, two feet or so of (preferably steel) flat metal, about 3/16" thick and 0.630" wide. Given that 0.630" is within a gnats whisker of 16 mm, I might have more luck looking in Germany, but I thought it worth asking the question here, too. My ususal source of metal stock, Macc Models, carries ground gauge plates, but has nothing in the measurements I'm looking for. I could easily get 5/8" wide mild steel from them, but as already suggested I then fear there would be too much play.

Any advice or suggestion would be warmly welcomed

Mattias

Edited By Banjoman on 04/01/2018 12:05:33

Edited By Banjoman on 04/01/2018 12:07:15