Hello Ray,

I see what you mean, and that should indeed both work and look more than good enough. A small caveat perhaps, although I'm sure you have already thought about it: those working brass bottlescrews tend to unscrew themselves quite easily, and are likely to need to be secured at the right level of tension. One way might be to get a few miniature nuts to fit whatever thread (M2? M2.5?) they have, unscrew the bottles, put on a nut either end and then screw the bottle back on. As long as you don't need to close the bottlescrews all the way in, once you're happy with the tension you just tighten the added nuts against the bottle ends, and it should all be stable enough. If adjustment is needed afterwards it will be easy enough to ease off on the securing nuts …

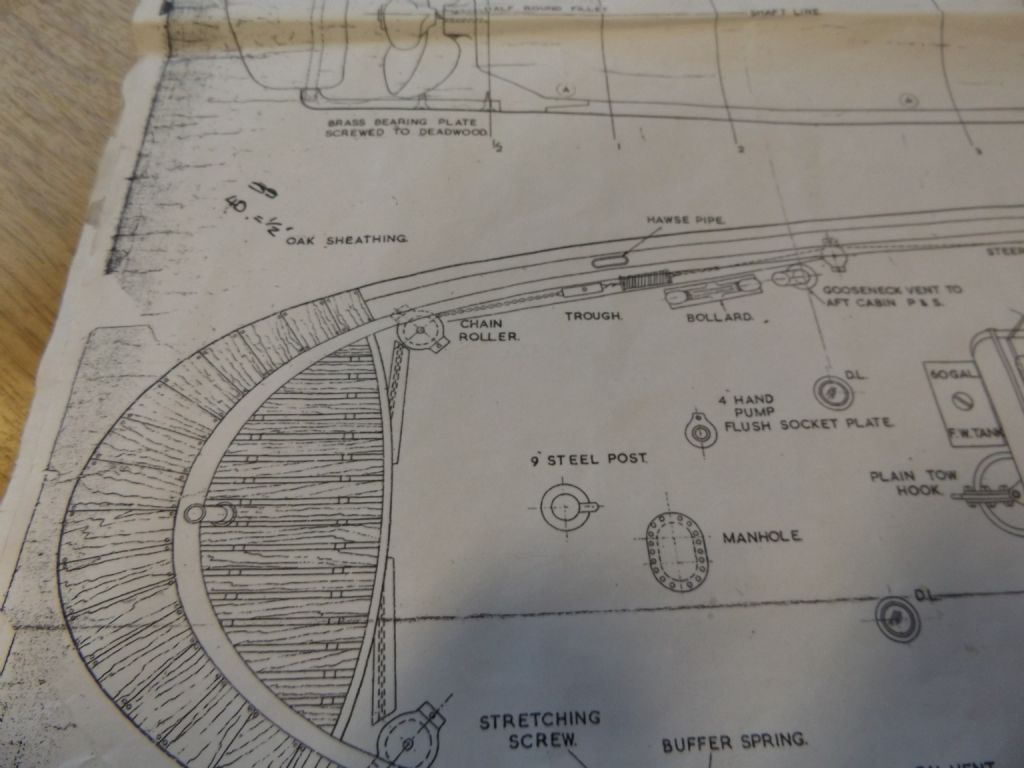

As for making the steering wheel move, I'm sure it must be feasible, although it should be remembered that in real life such a wheel would, I think, be quite heavilly geared down (or up, depending on perspective), so that for a rudder movement of maybe 30 degrees, the wheel would need to be turned quite a number of full revolutions.

As I think I've already mentioned here on the forum, my wife and I spent five days on the VIC 32 up in Scotland for my 50th birthday back in 2015 (which, by the way, is when and where my avatar picture was taken), and the VIC 32 had one of those chain-and-roller steering set-ups.

Perhaps a slightly more primitive version, in that I don't think there was much in the way of shock-absorbing springs. As a matter of fact, there was quite an amount of slack in that chain, which the skipper expained was for reasons of both comfort and security for the helm — any pressure or shocks against the rudder could be quite plainly felt through the wheel, and we were all told in no uncertain terms that whenever we felt a wave hit the rudder out in open water, we must immediately take both hands well away off the spokes, as a strong enough wave could easily set the wheel spinning with a force well beyond human strength to control and that could give one a very nasty rap or even break one's hand or arm.

After having had a few waves knock the wheel spinning while I was at the helm, I quite saw what he meant, and the slack in the chain gave us amateurs just enough warning to have time to let go off the wheel.

I dare say, though, that any tug operated by professionals in the (comparatively) narrow and congested waters of the Thames would have had a tighter set up rudder operation, and thus also put those shock absorbers to good use …

Thank you very much, too, for your kind compliments about my Moonbeam build! And yes, I shall most certainly have a go at making the sails myself …

Mattias

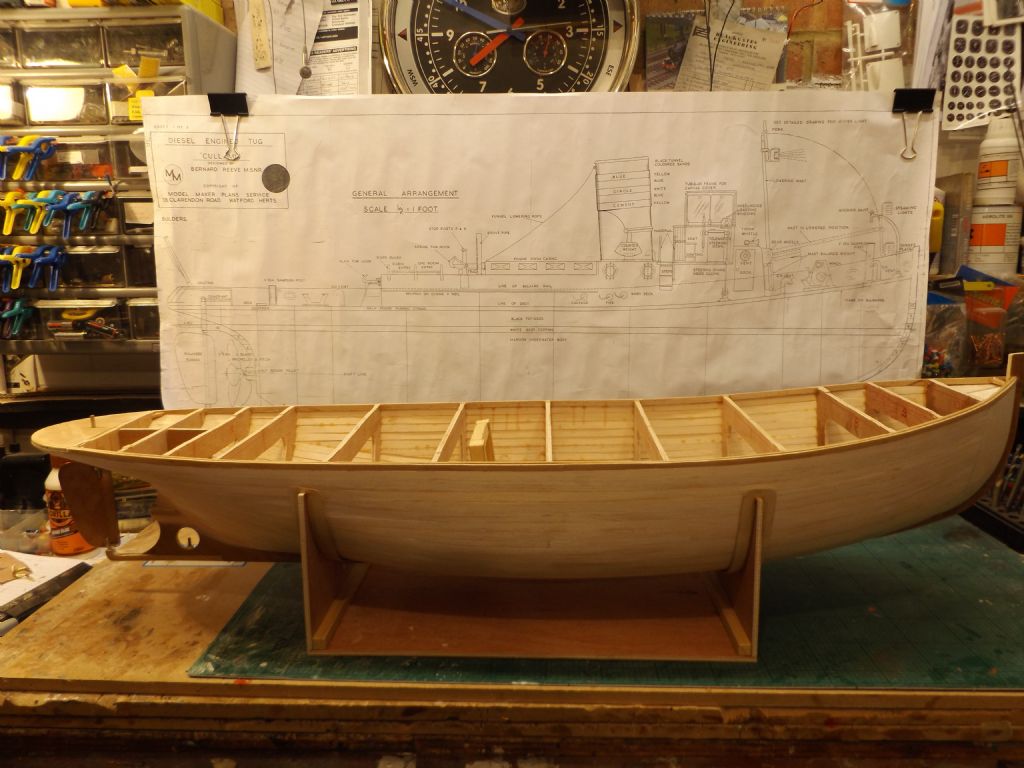

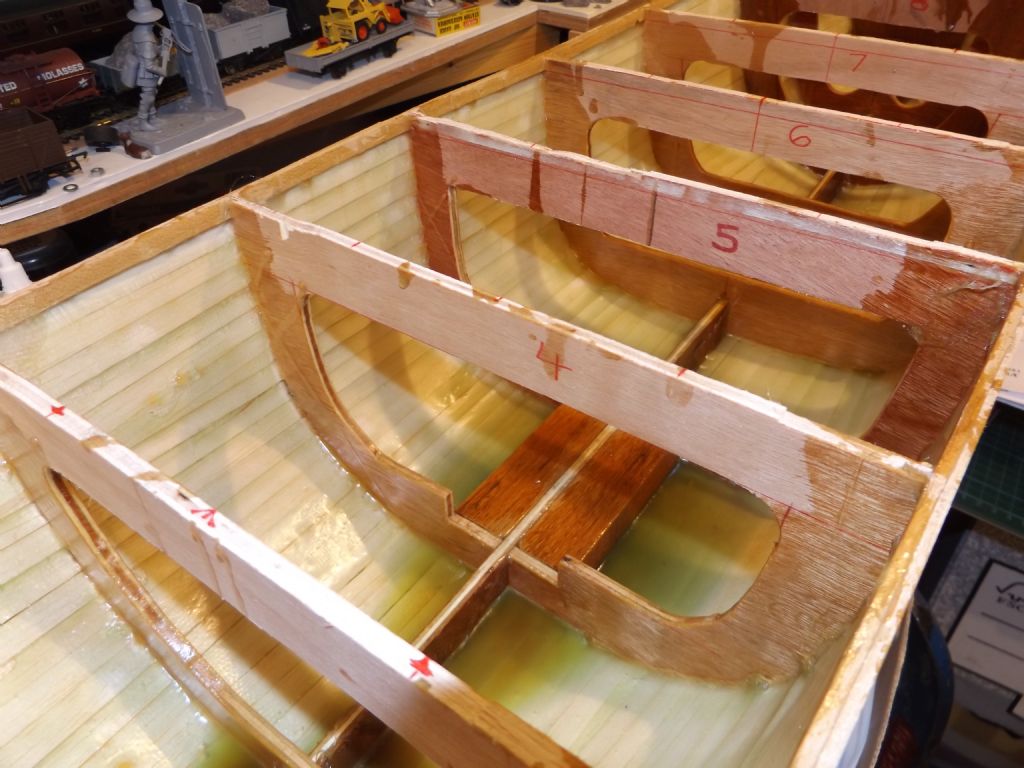

Can't seem to get the photos in the right order ! more in my album.

Can't seem to get the photos in the right order ! more in my album.