Dhow Construction Project

My Hobbies for many years have been computing, sailing and model airplane construction. Sailing to escape from a high-pressure job, model airplanes were with my grandchildren and science students, and computing was a passion. Now retirement has arrived and I have the time to do the things I always wanted, but did not have the time. But what? A long-term project, yes, and something that would both indulge interests and stretch imagination, knowledge and skills. Yes: design and build a… sailing boat! But, where lay challenge, as many such designs were available, and I had for years sailed a 14ft catamaran so knew about conventional sails and how to use them. I needed to shift out of my comfort zone.

A glance around the nautical world took me to the “Dhow”, from India, Arabia and East Africa, beautiful and with a sail configuration foreign to me. Decision made: I would design, build and sail a dhow, with radio control and an electric motor to safely bring the model home when all else failed.

And so the following questions arose:

1. Were there any existing dhow design plans out there that I could use? None found. Why? It appeared the craftsman skills of dhow design and construction were handed down from father to son over countless generations. Priding themselves on not requiring plans, they follow dhow-construction tradition and meet the capacity, produce and trading route requirements of each sponsoring merchant.

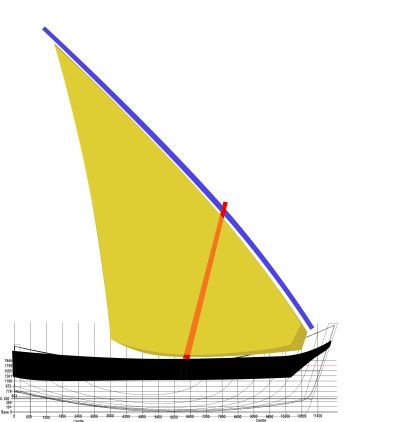

2. Were there any photos of dhows? Yes, plenty, so I collected over 100 and studied them closely for hull shape: side-view, plan-view and cross-section. Rigging was explored, mast/s (size and angle), yards (like booms but at the top), sail shape and sheet arrangements, and standing rig to support mast etc.

3. How does one control a dhow’s sailing direction, trim for running and tacking, and go about? I foresaw a problem here, as the way the mainsail hung beneath the yard on the port side, for example, free of the mast, would have it bearing against the mast on the opposite tack – not a good look as the sail-shape would be compromised. Many days of searching the web brought scant results, asking at the local sailing club drew a blank, then I located a reference to the out-of-print book “The Dhow – An Illustrated History of the Dhow and its World”, by Clifford W. Hawkins. Eureka! Solid gold. Answers found, and much more.

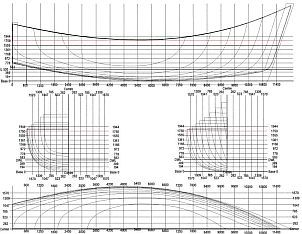

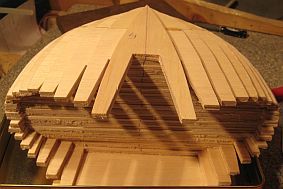

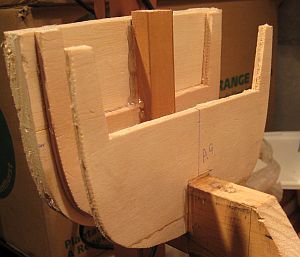

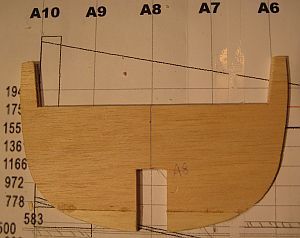

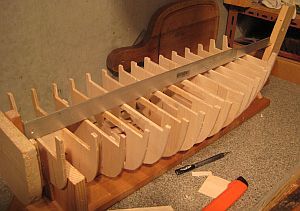

4. How to create a set of plans from which to scratch-build? First I explored available 3D boat design software, finally selecting FreeShip2.6 from sourceforge.net for its availability, strong support base of users, low price (free), and relative ease-of-use. (With previous experience with 3D programs I felt confident, and this proved to be the case.) I chose non-chine (chines seemed to be absent in dhows), then adjusted to 20 stations, a healthy beam size, and significantly raised bulwarks forward and starboard (as many dhows displayed). Mast position, size and slope was approximated from many photographs, as was yard length and position of tilt-attachment point.

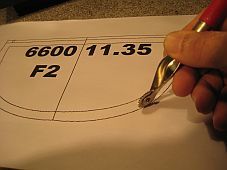

One problem I encountered was how to enlarge the printed product from 20 cms to 100 cms long retaining a high degree of accuracy. Using Photoshop, I created a sequence of vector pathways following each of the lines on the plan, particularly the bulkhead shapes and the side-view. Each pathway was then precisely enlarged by the same factor. And from them 1 pixel wide lines were drawn, each on its own separate layer. Thus sharp, accurate plans were produced. To ensure exact symmetry of the bulkheads, I worked initially with only the port side half, and once enlargement was completed, copied the half-pathway, flipped horizontally the new bit, moved it and aligned to the centerline of the first.

5. How to control the dhow via RC? I drew up a list of changes I would need to be able to make (motor speed/direction), rudder changes, mainsheet setting, forward-sheet setting, yard-foot control via back-sheet, yard elevation adjustment up and down mast. These I then translated to the number of channels required, and put it to one side for later consideration. Not an area of expertise, I trust that the space available will be plenty, and the hull construction sufficiently strong to cope with a variety of servo locations.

6. How to build-in propeller and driveshaft, and electric motor of what suitable size? Allowance made based on rough sizes located on Internet, and final decisions left till later. This is not a strong area for me, so I will try to work generically here and refine details later during installation phase.

There seems to be a length limit for each posting, so I will work further on creating this thread. Keith.

Edited By Keith Richardson on 21/03/2009 04:49:32