I will be re-reading that section of your thread Bob, when the time comes! However one other possibility, given that this is a much smaller boat is temporarily fixing it to the bench and using a curved length of wood to sit the entire length of the strip of veneer, held down with long screws, carefully tightened to exert the necessary pressure.

Looking at that kit review I’m struggling to see how he secured both hatches, and water proofed them, especially the servo hatch, as I’m guessing that area may well suffer a little more than the odd splash!

I wonder how much speed he got from the 600 speed brushed motor he fitted? The running pics show it on the plane, so I guess it was quick enough. However whats the chance it got to 14.9mph? 1/12th of the record of 170+ that’s the full size set in 1950! Pretty good I’d say.

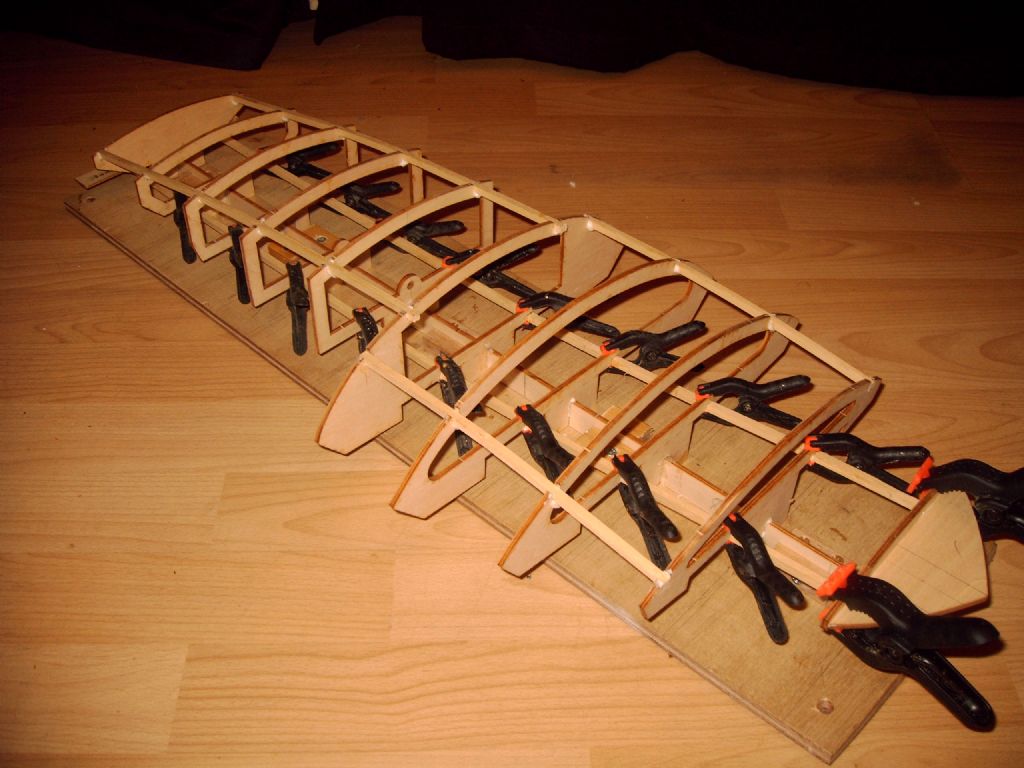

A further point from that review, is there is no mention of paint/resin being applied to the inner hull surface. leaving it, in my view, susceptible over time, to damp ingress damaging the structure and finish from within. As the construction process leaves huge areas inaccessible to do this after hull construction is complete, some thought will have to be given to the subject prior to starting.

Phil (head hurting from all this thinking

)

.jpg)

.jpg)

I hadn’t ticked the public box should be visible now mate. pencil marks were expected so no problem. Jumping in with both feet is not on the agenda. do you know which issue of the mag the article was in? if you look at the pic of the open box you’ll see some A3 paper that I’ve traced all the sheet parts onto. The issue of the hatch is under consideration, probably extend it rearwards under the fin much the same as that guy on that other forum did with the join on the edge of the red stripe. it’ll be needed just to fit the rudder servo.

I hadn’t ticked the public box should be visible now mate. pencil marks were expected so no problem. Jumping in with both feet is not on the agenda. do you know which issue of the mag the article was in? if you look at the pic of the open box you’ll see some A3 paper that I’ve traced all the sheet parts onto. The issue of the hatch is under consideration, probably extend it rearwards under the fin much the same as that guy on that other forum did with the join on the edge of the red stripe. it’ll be needed just to fit the rudder servo. )

).jpg)

.jpg)