Hello Brian,

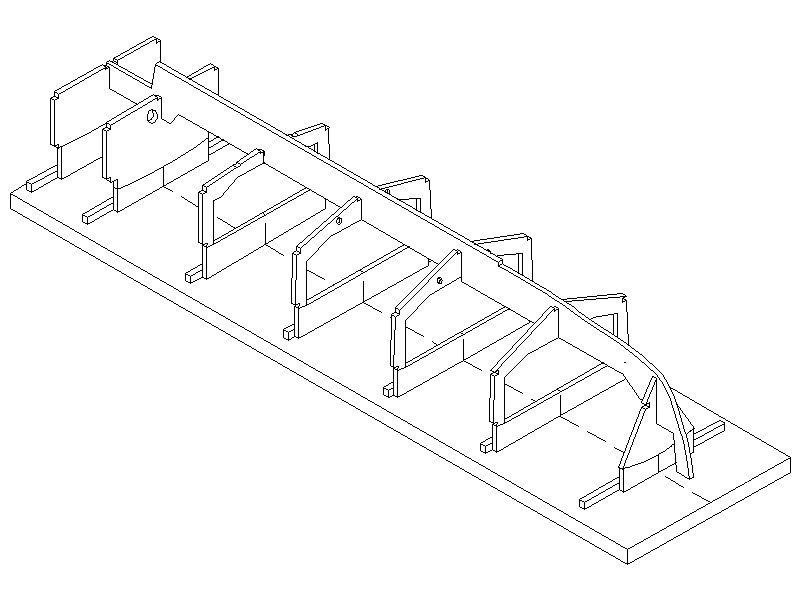

There are two obvious ways to set up the frames for a build, either upright or up side down. Which ever way chosen, they must be arranged about a chosen datum – that is a reference that will be common to ALL frames of the build. I usually find that the waterline is a good choice to make, as all frames will either have this line through them, or can be related to it by a measured distance on your plan.

For yachts build up side down! This allows the keel to be above the work, and enables access to almost all the hull for planking/sheeting etc.

When Gareth says extend the frames, he means that you allow for an extension of material (ply?) on each frame at the deck line such that this can be screwd to a cross beam. This beam is screwed to a building board which is level and flat. The cross beam length is longer than the boat is wide so that the screws can be withdrawn once the frames are covered! The length of the extension to the frame is such that when all the frames are mounted the waterline (marked on each frame) is parallel to the building board and all the waterline marks are in a straight line to each other.

When viewed from either end along the length, the frames if set up correctly should replicate the plan view you started with on paper, if not, move the offending frame till it's in the right place.

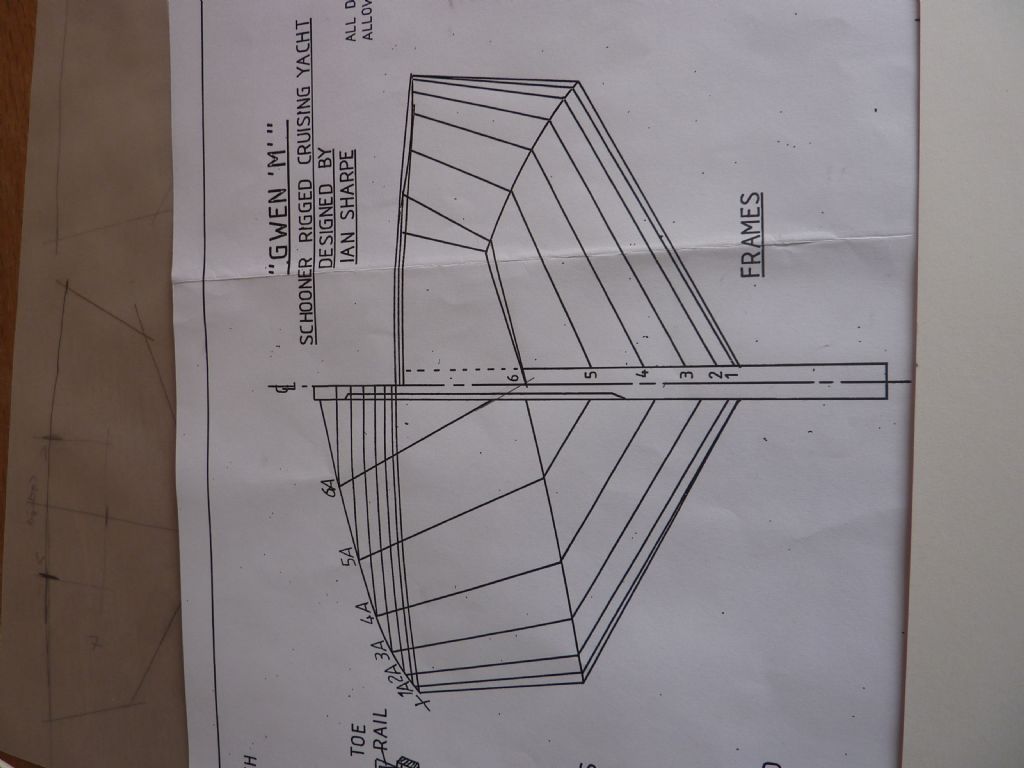

On your indicated plan of the frames above, draw a line perpendicular to the keel centre line about 2 inches above the deck. As you take off each frame, include this excess as it is the extension discussed above. We would normally either phtocopy the plan enough times to give a separate sheet for each frame, or better still, scan to a computer and use the crop/cut/flip capabilities therein to create a full frame for each frame required and then print out ensuring they are to the correct scale. NOTE you must allow for the plank thickness on each frame that is subtract the thickness as it is usual for the plans to show the final outside dimensions. [The builder can use whatever thickness material desired.]

With this yacht hull, it is possible to build the hull over the frames without incorporating any of the rames into the hull. When the hull is covered it can be lifted off and then cross beams inserted to hold the shape. I've made several IOM hulls this way using 0.8mm ply and 2mm joining batterns along the chine edges. They are still going strong, as Gareth saw last weekend! The deck, once fitted gives good strength the the final build, fitted after any other internal bits have been added.

Kim.