Dear All

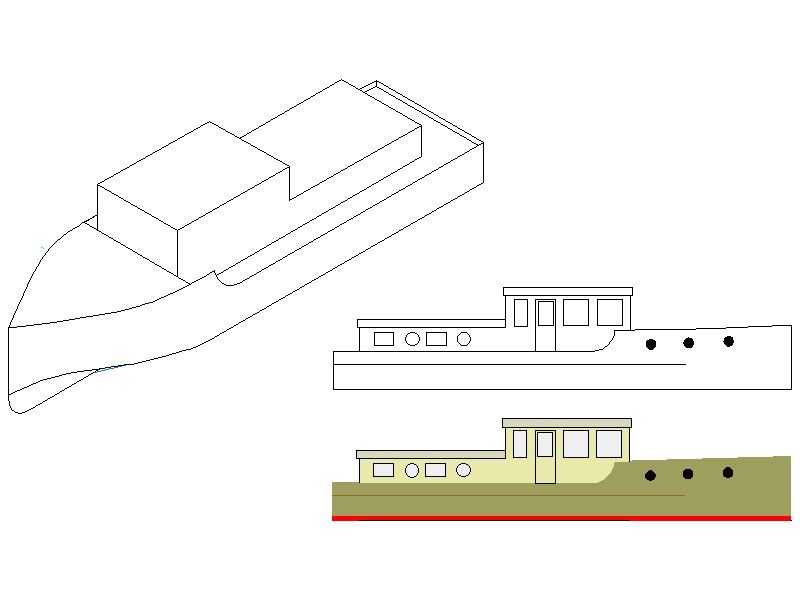

The drawings for the vintage cruiser 'Lady Jane' have reached the point where construction can begin.

So in the true tradition of all 'Blue Peter' builds we will start at the beginning and explain the process in easy to understand step by step sections (just so the hard of thinking hover van builder can keep up)

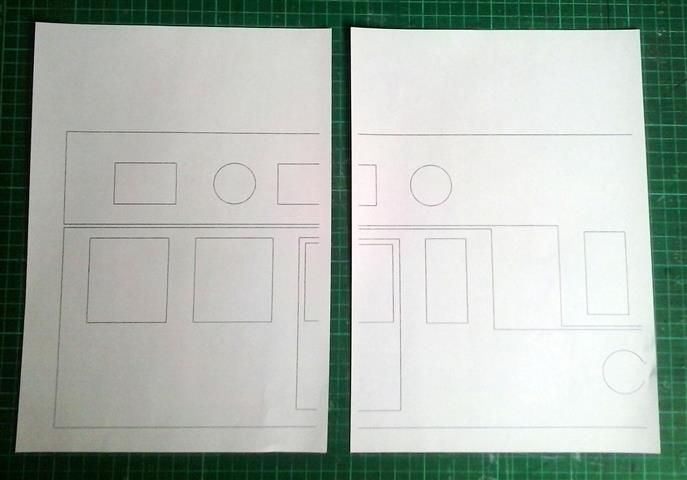

The drawings and instructions are sent by email in easily printed PDF format……this means that the recipient doesn't have to do anything fancy or open the files with any specialist software ….in fact all you need is an email address, a computer with Adobe Reader and a standard A4 printer.

The drawings are also 1:1 scale templates and all that the reciepiant need do is print them.

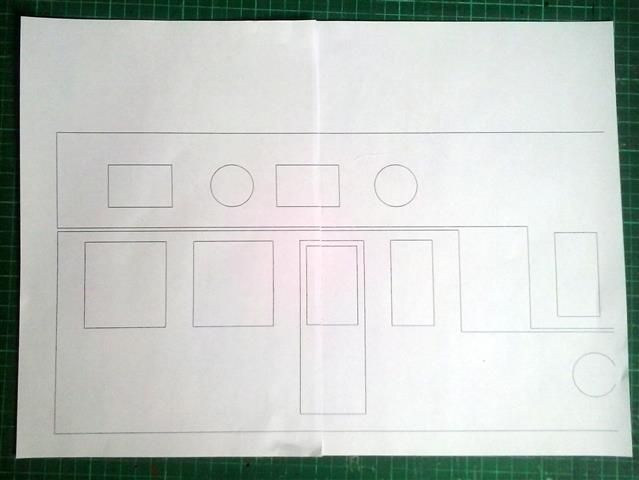

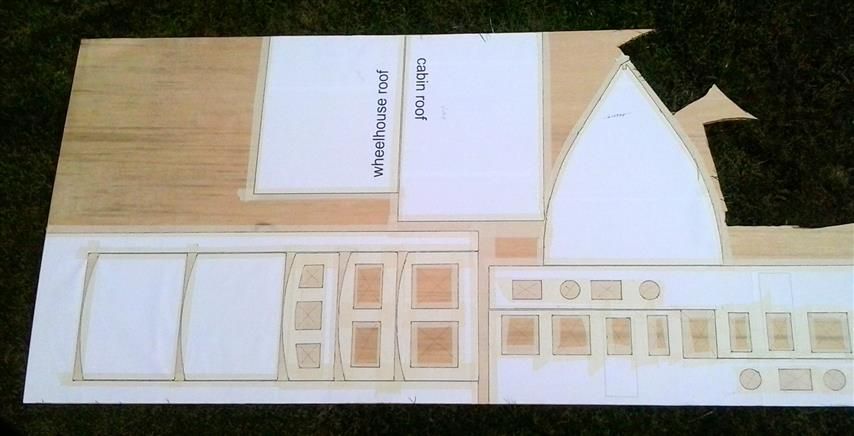

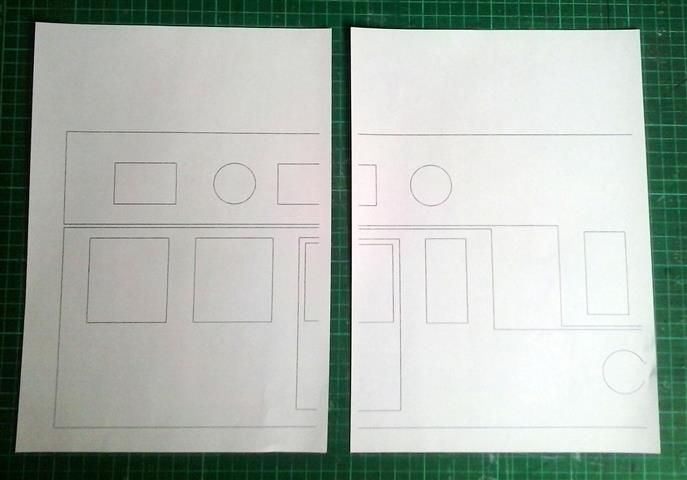

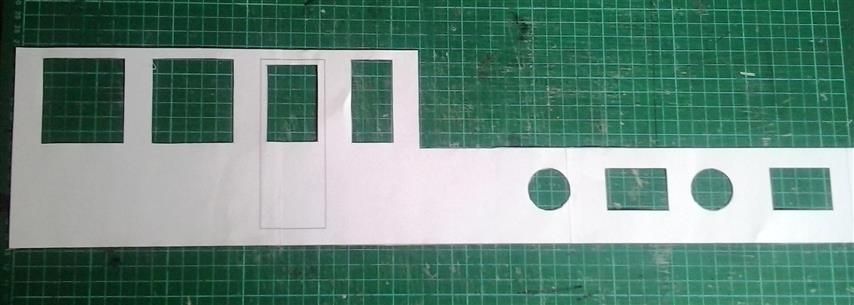

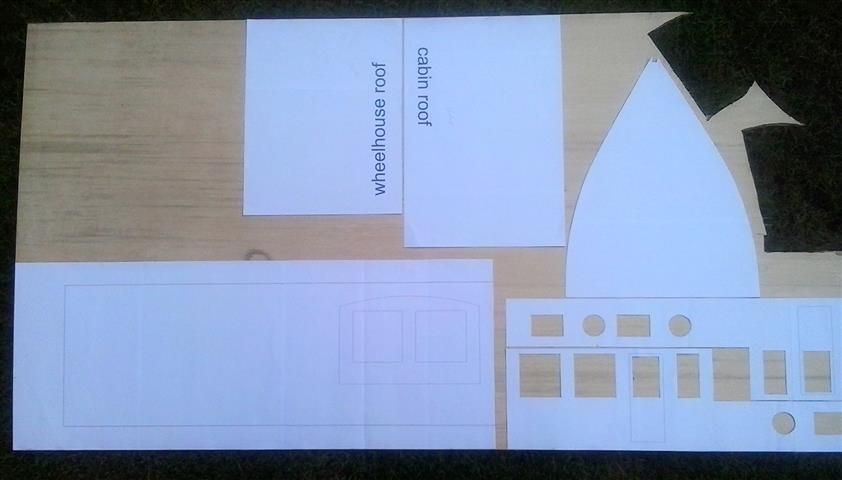

The larger sections of the model are spread across a few pages and when printed they look like these below.

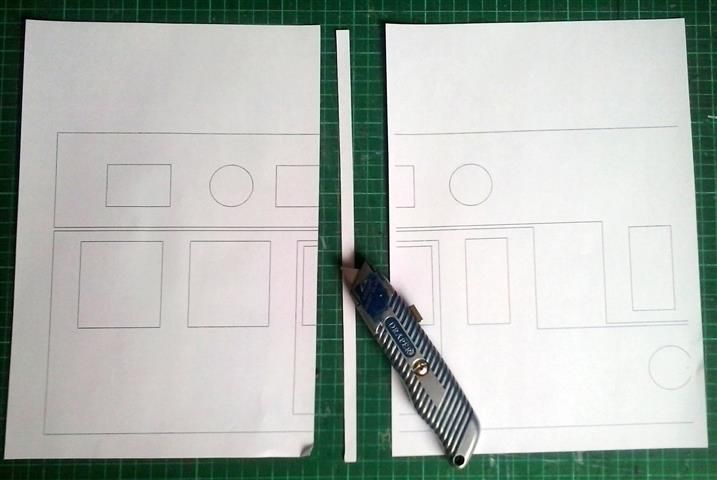

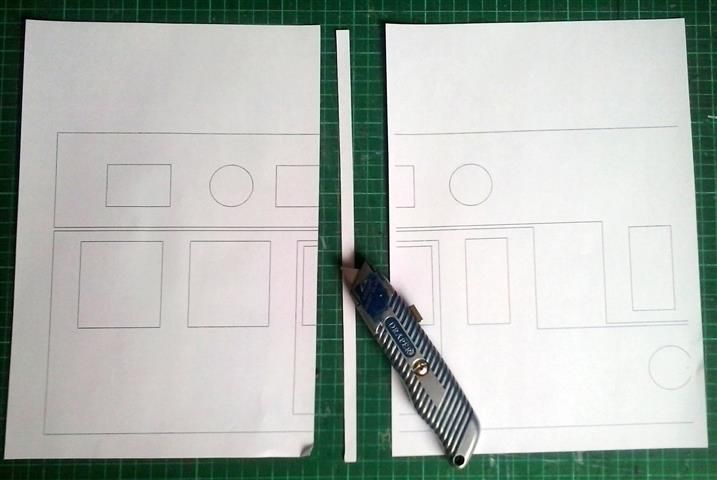

The printed sheets have margins and location marks so the trimming of the sheets is easy.

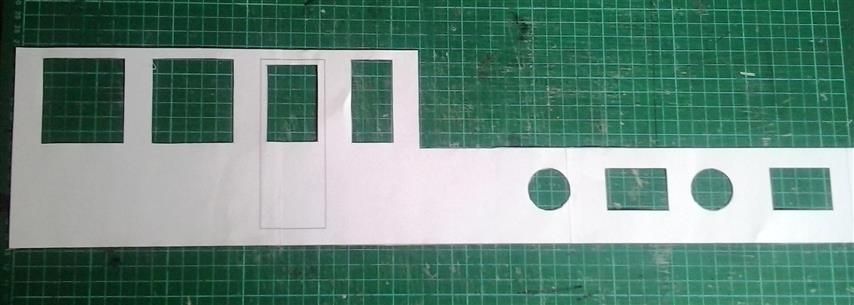

Simply cut along the margin line on one side of each sheet.

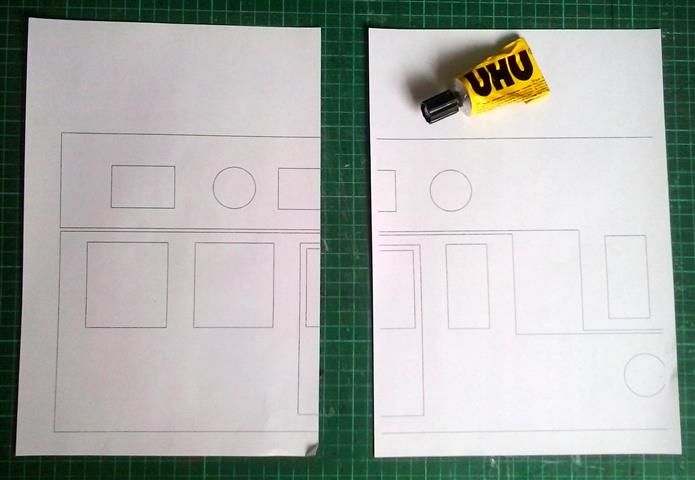

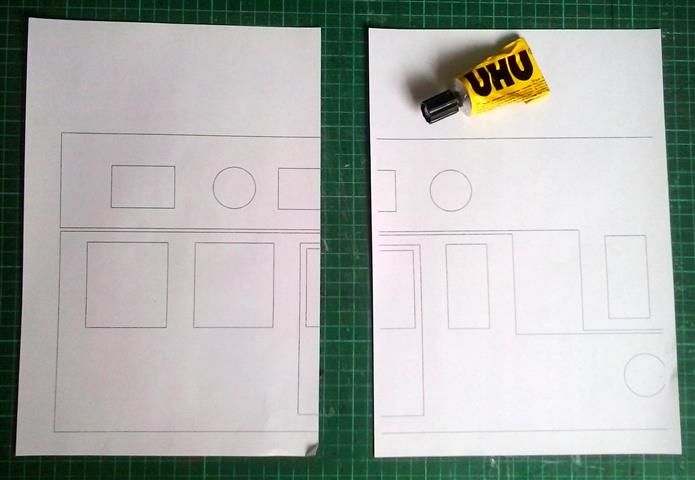

And glue the sections together

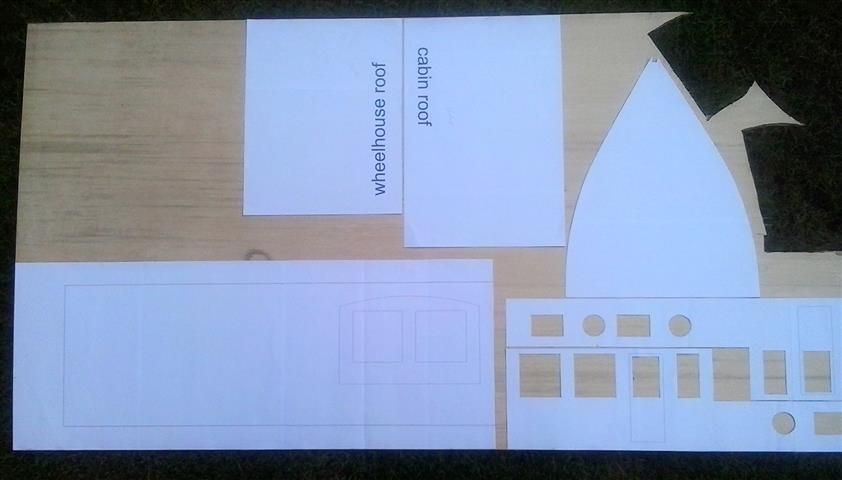

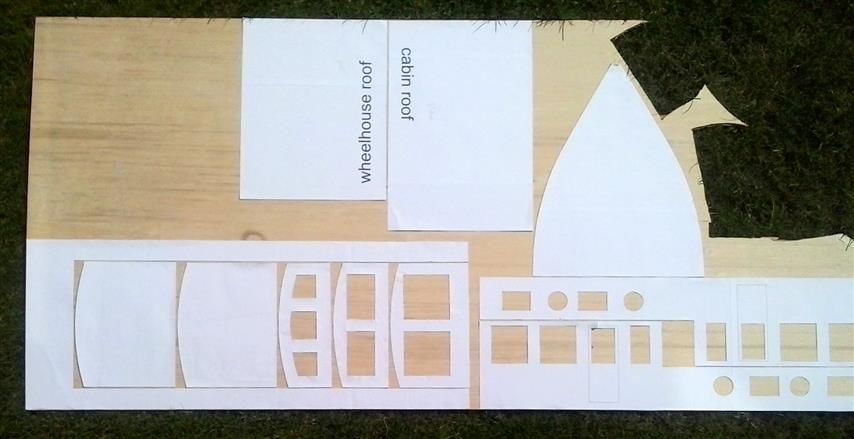

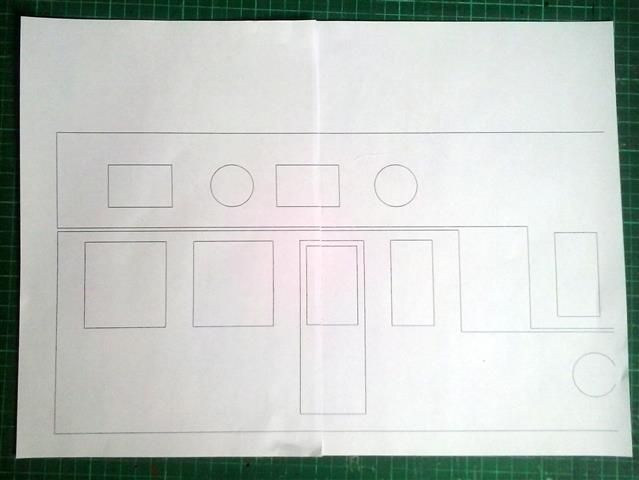

In this way large sections of the drawing can easily be printed and assembled.

Then the full size templates can be cut out ready for transferring to timber ready for cutting out.

Paul

Edited By Paul T on 30/06/2014 15:40:09