Hello Bob

So many questions

Lets start at the beginning:

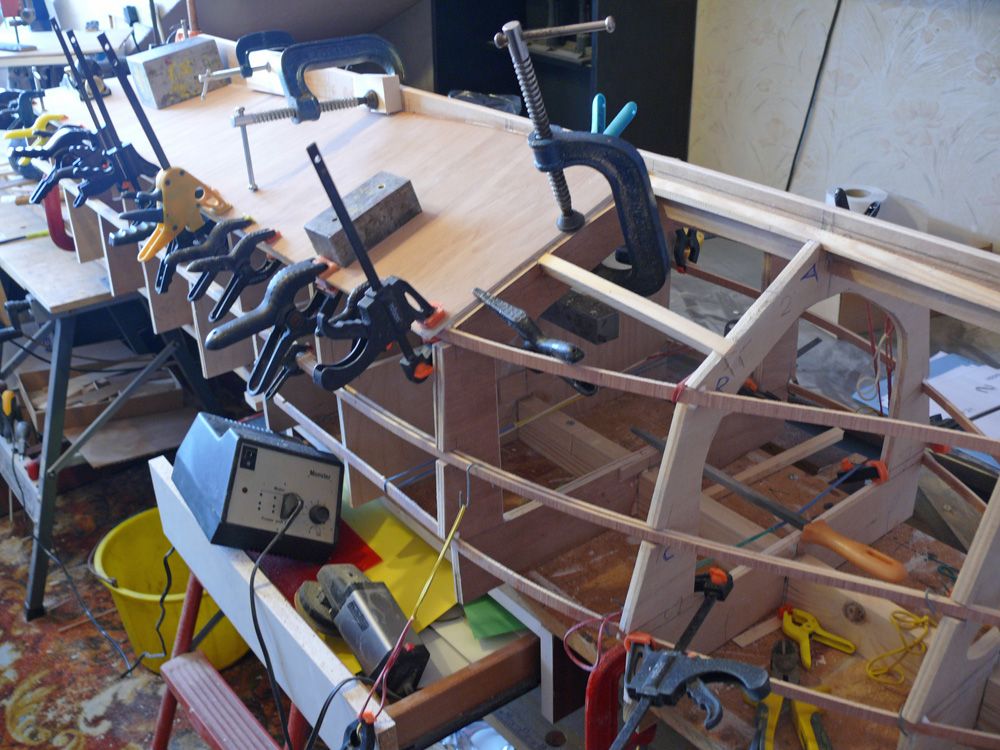

The model can be sheeted or planked (or a combination of both) as both systems have the same level of difficulty (or ease) providing that the major joint of bilge chine is carried forward to the point between the Bow post & F1 where the joint melts into the hull.

If planking I would adopt a board layout from vertical to 30deg from the vertical (tight double diagonal) using, as Colin suggested, a lamination made from 1.5mm thick planks.

If sheeting I would use 2 layers of 1.5mm ply.

Bob: the laminate stringers will be superb and will introduce a great deal of strength to the bows, strength that previously would have come from those bulky breasthooks.

Bob, Dave & Colin: F1 & F2 are the correct shape as the intention is to produce a rapid change in hull direction at this point, as Colin says it will produce the 'pinched' look that was synonymous with boat from the Edwardian era.

Bob: The ABELL drives should fit quite nicely next to each other in the bay between F3 and F4 but as I can only guesstimate the weight of these units we might have to do some clever ballasting to offset the mass of these motors.

Bob: Your boats shouldn't leak but you could use a car washer pump to evacuate any 'liquid problems'

Bob: Internal fitting with dolls house equipment would look great and a 'real' horn could be a nice feature.

Paul